Spray Pyrolysis and its Role in Electrochemical Sensor Design

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Evolution and Objectives

Spray pyrolysis has evolved significantly since its inception in the 1960s, transforming from a simple thin film deposition technique to a sophisticated method for creating advanced nanomaterials. Initially developed for ceramic coatings, the technology has undergone remarkable refinement in process control, precursor chemistry, and equipment design. The fundamental principle—atomizing a precursor solution into fine droplets that undergo thermal decomposition upon contact with a heated substrate—remains unchanged, but the applications have expanded dramatically.

The 1980s marked a turning point when researchers began exploring spray pyrolysis for semiconductor applications, particularly transparent conducting oxides. By the 1990s, the technique had been adapted for producing complex metal oxides with controlled stoichiometry, opening new possibilities in materials science. The early 2000s witnessed the integration of spray pyrolysis with other technologies, such as ultrasonic atomization and electrostatic assistance, significantly enhancing droplet uniformity and deposition control.

Recent technological advancements have focused on precise control of particle morphology, size distribution, and crystallinity—critical parameters for electrochemical sensor performance. Modern spray pyrolysis systems incorporate real-time monitoring and feedback mechanisms, allowing for unprecedented control over the deposition process. The development of multi-component precursor systems has enabled the creation of doped materials, composites, and complex oxides with tailored properties for specific sensing applications.

The primary objective of spray pyrolysis in electrochemical sensor design is to create highly sensitive, selective, and stable sensing interfaces. This involves developing nanostructured materials with optimized surface area, porosity, and catalytic activity. The technique aims to produce reproducible sensing layers with consistent performance characteristics, addressing the long-standing challenge of sensor-to-sensor variability in manufacturing.

Another key goal is to develop cost-effective and scalable production methods for high-performance sensor materials. Spray pyrolysis offers significant advantages in this regard, as it requires relatively simple equipment and can be implemented in continuous production processes. The technology seeks to bridge the gap between laboratory-scale material synthesis and industrial-scale sensor manufacturing.

Looking forward, spray pyrolysis technology aims to enable the next generation of electrochemical sensors with enhanced capabilities for real-time monitoring in healthcare, environmental protection, and industrial safety. The evolution of this technique continues to focus on achieving greater precision in nanomaterial design, improved energy efficiency, and reduced environmental impact, aligning with broader sustainability goals in advanced manufacturing technologies.

The 1980s marked a turning point when researchers began exploring spray pyrolysis for semiconductor applications, particularly transparent conducting oxides. By the 1990s, the technique had been adapted for producing complex metal oxides with controlled stoichiometry, opening new possibilities in materials science. The early 2000s witnessed the integration of spray pyrolysis with other technologies, such as ultrasonic atomization and electrostatic assistance, significantly enhancing droplet uniformity and deposition control.

Recent technological advancements have focused on precise control of particle morphology, size distribution, and crystallinity—critical parameters for electrochemical sensor performance. Modern spray pyrolysis systems incorporate real-time monitoring and feedback mechanisms, allowing for unprecedented control over the deposition process. The development of multi-component precursor systems has enabled the creation of doped materials, composites, and complex oxides with tailored properties for specific sensing applications.

The primary objective of spray pyrolysis in electrochemical sensor design is to create highly sensitive, selective, and stable sensing interfaces. This involves developing nanostructured materials with optimized surface area, porosity, and catalytic activity. The technique aims to produce reproducible sensing layers with consistent performance characteristics, addressing the long-standing challenge of sensor-to-sensor variability in manufacturing.

Another key goal is to develop cost-effective and scalable production methods for high-performance sensor materials. Spray pyrolysis offers significant advantages in this regard, as it requires relatively simple equipment and can be implemented in continuous production processes. The technology seeks to bridge the gap between laboratory-scale material synthesis and industrial-scale sensor manufacturing.

Looking forward, spray pyrolysis technology aims to enable the next generation of electrochemical sensors with enhanced capabilities for real-time monitoring in healthcare, environmental protection, and industrial safety. The evolution of this technique continues to focus on achieving greater precision in nanomaterial design, improved energy efficiency, and reduced environmental impact, aligning with broader sustainability goals in advanced manufacturing technologies.

Market Analysis for Electrochemical Sensor Applications

The electrochemical sensor market has experienced robust growth over the past decade, driven by increasing demand across healthcare, environmental monitoring, industrial safety, and food quality control sectors. Currently valued at approximately 23.6 billion USD in 2023, the market is projected to reach 32.9 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.8%.

Healthcare applications dominate the electrochemical sensor market, accounting for nearly 40% of the total market share. The rising prevalence of chronic diseases such as diabetes has significantly boosted the demand for glucose monitoring sensors. Point-of-care testing devices utilizing electrochemical sensing principles have gained substantial traction due to their ability to provide rapid results in clinical settings.

Environmental monitoring represents the second-largest application segment, with growing concerns about air and water quality driving adoption. Government regulations mandating continuous monitoring of pollutants have created a steady demand for electrochemical gas sensors and water quality sensors. This segment is expected to grow at a CAGR of 7.5% through 2028.

Industrial safety applications, particularly in manufacturing, oil and gas, and mining sectors, constitute approximately 18% of the market. These industries require reliable detection of toxic gases and volatile organic compounds to ensure workplace safety. The integration of IoT capabilities with electrochemical sensors has enhanced remote monitoring possibilities in hazardous environments.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing environmental awareness in countries like China and India.

Spray pyrolysis technology is gaining significant attention in the electrochemical sensor manufacturing landscape due to its cost-effectiveness and scalability. Sensors developed using spray pyrolysis techniques offer advantages in terms of sensitivity, selectivity, and stability. The market for spray pyrolysis-based electrochemical sensors is projected to grow at a CAGR of 8.2% through 2028, outpacing the overall market growth.

Key market drivers include miniaturization trends, increasing demand for wearable health monitoring devices, stringent environmental regulations, and the growing need for real-time monitoring solutions. Challenges include price sensitivity in emerging markets, technical limitations in harsh environments, and competition from alternative sensing technologies.

Healthcare applications dominate the electrochemical sensor market, accounting for nearly 40% of the total market share. The rising prevalence of chronic diseases such as diabetes has significantly boosted the demand for glucose monitoring sensors. Point-of-care testing devices utilizing electrochemical sensing principles have gained substantial traction due to their ability to provide rapid results in clinical settings.

Environmental monitoring represents the second-largest application segment, with growing concerns about air and water quality driving adoption. Government regulations mandating continuous monitoring of pollutants have created a steady demand for electrochemical gas sensors and water quality sensors. This segment is expected to grow at a CAGR of 7.5% through 2028.

Industrial safety applications, particularly in manufacturing, oil and gas, and mining sectors, constitute approximately 18% of the market. These industries require reliable detection of toxic gases and volatile organic compounds to ensure workplace safety. The integration of IoT capabilities with electrochemical sensors has enhanced remote monitoring possibilities in hazardous environments.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing environmental awareness in countries like China and India.

Spray pyrolysis technology is gaining significant attention in the electrochemical sensor manufacturing landscape due to its cost-effectiveness and scalability. Sensors developed using spray pyrolysis techniques offer advantages in terms of sensitivity, selectivity, and stability. The market for spray pyrolysis-based electrochemical sensors is projected to grow at a CAGR of 8.2% through 2028, outpacing the overall market growth.

Key market drivers include miniaturization trends, increasing demand for wearable health monitoring devices, stringent environmental regulations, and the growing need for real-time monitoring solutions. Challenges include price sensitivity in emerging markets, technical limitations in harsh environments, and competition from alternative sensing technologies.

Current Spray Pyrolysis Techniques and Barriers

Spray pyrolysis represents a versatile and cost-effective thin film deposition technique widely employed in electrochemical sensor fabrication. The process fundamentally involves the spraying of precursor solutions onto heated substrates, where thermal decomposition occurs to form desired thin films. Current implementations of spray pyrolysis can be categorized into several distinct methodologies, each with specific advantages and limitations.

Conventional pneumatic spray pyrolysis remains the most widely adopted approach, utilizing compressed air or inert gases to atomize precursor solutions. While this method offers simplicity and scalability, it frequently suffers from non-uniform droplet size distribution, leading to inconsistent film morphology. This variability presents significant challenges for reproducible sensor performance, particularly when precise electrochemical responses are required.

Ultrasonic spray pyrolysis has emerged as an advanced alternative, employing high-frequency vibrations to generate more uniform aerosol droplets. This technique achieves superior film homogeneity and enables finer control over film thickness, critical factors for electrochemical sensor sensitivity. However, implementation barriers include higher equipment costs and complexity in maintaining stable ultrasonic frequencies across varying precursor solution properties.

Electrostatic spray pyrolysis incorporates charged nozzles to enhance deposition efficiency and film uniformity. By applying an electric field between the spray nozzle and substrate, this method achieves more directional deposition and reduced material waste. Despite these advantages, the technique faces challenges related to precursor solution conductivity requirements and complex parameter optimization.

Temperature control represents a universal barrier across all spray pyrolysis variants. The substrate temperature critically influences film crystallinity, morphology, and adhesion—all essential properties for electrochemical sensor performance. Current systems struggle with maintaining uniform temperature profiles across larger substrates, resulting in inconsistent film properties that compromise sensor reliability.

Precursor chemistry limitations constitute another significant barrier. Many metal oxide and composite materials vital for advanced electrochemical sensing require complex precursor formulations that may exhibit poor solubility, limited stability, or incompatible decomposition pathways. These chemical constraints often necessitate extensive optimization or alternative synthesis routes.

Scaling challenges persist as laboratory-scale spray pyrolysis techniques transition to industrial production. Maintaining film quality while increasing deposition area and throughput remains problematic. Current industrial systems frequently compromise on film uniformity or require prohibitively expensive equipment modifications to maintain quality at scale.

Recent innovations have focused on addressing these barriers through hybrid approaches, combining spray pyrolysis with complementary techniques such as plasma enhancement or post-deposition treatments. While promising, these hybrid methods introduce additional complexity and have yet to achieve widespread adoption in electrochemical sensor manufacturing.

Conventional pneumatic spray pyrolysis remains the most widely adopted approach, utilizing compressed air or inert gases to atomize precursor solutions. While this method offers simplicity and scalability, it frequently suffers from non-uniform droplet size distribution, leading to inconsistent film morphology. This variability presents significant challenges for reproducible sensor performance, particularly when precise electrochemical responses are required.

Ultrasonic spray pyrolysis has emerged as an advanced alternative, employing high-frequency vibrations to generate more uniform aerosol droplets. This technique achieves superior film homogeneity and enables finer control over film thickness, critical factors for electrochemical sensor sensitivity. However, implementation barriers include higher equipment costs and complexity in maintaining stable ultrasonic frequencies across varying precursor solution properties.

Electrostatic spray pyrolysis incorporates charged nozzles to enhance deposition efficiency and film uniformity. By applying an electric field between the spray nozzle and substrate, this method achieves more directional deposition and reduced material waste. Despite these advantages, the technique faces challenges related to precursor solution conductivity requirements and complex parameter optimization.

Temperature control represents a universal barrier across all spray pyrolysis variants. The substrate temperature critically influences film crystallinity, morphology, and adhesion—all essential properties for electrochemical sensor performance. Current systems struggle with maintaining uniform temperature profiles across larger substrates, resulting in inconsistent film properties that compromise sensor reliability.

Precursor chemistry limitations constitute another significant barrier. Many metal oxide and composite materials vital for advanced electrochemical sensing require complex precursor formulations that may exhibit poor solubility, limited stability, or incompatible decomposition pathways. These chemical constraints often necessitate extensive optimization or alternative synthesis routes.

Scaling challenges persist as laboratory-scale spray pyrolysis techniques transition to industrial production. Maintaining film quality while increasing deposition area and throughput remains problematic. Current industrial systems frequently compromise on film uniformity or require prohibitively expensive equipment modifications to maintain quality at scale.

Recent innovations have focused on addressing these barriers through hybrid approaches, combining spray pyrolysis with complementary techniques such as plasma enhancement or post-deposition treatments. While promising, these hybrid methods introduce additional complexity and have yet to achieve widespread adoption in electrochemical sensor manufacturing.

Contemporary Spray Pyrolysis Solutions for Sensor Design

01 Spray pyrolysis for nanoparticle synthesis

Spray pyrolysis is widely used for synthesizing various types of nanoparticles with controlled size, morphology, and composition. This technique involves atomizing a precursor solution into fine droplets and subjecting them to thermal decomposition in a heated zone. The process allows for the production of high-purity nanoparticles with uniform characteristics, which can be used in various applications including catalysis, electronics, and energy storage.- Spray pyrolysis for nanoparticle synthesis: Spray pyrolysis is widely used for synthesizing nanoparticles with controlled size, morphology, and composition. This process involves atomizing a precursor solution into fine droplets that undergo thermal decomposition in a heated zone, resulting in the formation of nanoparticles. The technique allows for continuous production of high-purity nanomaterials with uniform characteristics, which are valuable for various applications including catalysis, electronics, and energy storage.

- Thin film deposition via spray pyrolysis: Spray pyrolysis enables the deposition of thin films on various substrates through the thermal decomposition of sprayed precursor solutions. This cost-effective technique produces uniform coatings with excellent adhesion and controlled thickness. The process parameters such as substrate temperature, precursor concentration, and spray rate can be adjusted to optimize film properties. This method is particularly valuable for manufacturing transparent conductive oxides, semiconductor layers, and protective coatings.

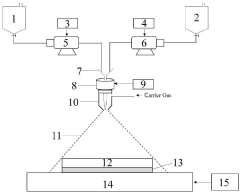

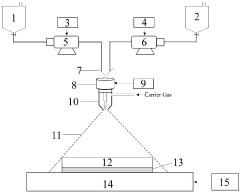

- Equipment and apparatus for spray pyrolysis: Specialized equipment for spray pyrolysis includes atomizers, heated reaction chambers, and collection systems designed to optimize the process efficiency and product quality. These systems may incorporate ultrasonic or pneumatic atomizers to generate fine droplets, temperature-controlled reaction zones for precise thermal decomposition, and filtration or electrostatic collection mechanisms. Advanced designs feature automated control systems for maintaining consistent processing conditions and improving reproducibility of the synthesized materials.

- Functional materials produced by spray pyrolysis: Spray pyrolysis enables the production of various functional materials with enhanced properties for specific applications. These include catalysts with high surface area, ceramic powders with controlled stoichiometry, luminescent materials with improved quantum efficiency, and electrode materials for energy storage devices. The versatility of the process allows for doping and compositional modifications to tailor material properties for targeted performance in applications ranging from sensors to energy conversion devices.

- Process optimization and modifications of spray pyrolysis: Various modifications to the conventional spray pyrolysis process have been developed to enhance material properties and process efficiency. These include flame-assisted spray pyrolysis for higher reaction temperatures, ultrasonic spray pyrolysis for finer droplet size distribution, and pressurized spray pyrolysis for improved precursor delivery. Additional innovations involve the use of reactive atmospheres, in-situ surface functionalization, and multi-stage heating profiles to achieve specific material characteristics and reduce energy consumption.

02 Thin film deposition via spray pyrolysis

Spray pyrolysis is an effective method for depositing thin films on various substrates. The technique involves spraying a solution containing the desired film material onto a heated substrate, where the solution undergoes thermal decomposition to form a solid film. This approach offers advantages such as simplicity, cost-effectiveness, and the ability to create uniform coatings with controlled thickness and composition, making it suitable for applications in solar cells, sensors, and protective coatings.Expand Specific Solutions03 Equipment and apparatus for spray pyrolysis

Specialized equipment and apparatus have been developed to optimize the spray pyrolysis process. These systems typically include components such as atomizers or nebulizers for generating fine droplets, temperature-controlled reaction chambers, substrate holders, and collection systems. Advanced designs incorporate features for precise control of process parameters such as temperature profiles, gas flow rates, and residence times, enabling the production of materials with tailored properties for specific applications.Expand Specific Solutions04 Functional materials produced by spray pyrolysis

Spray pyrolysis enables the production of various functional materials with enhanced properties. These include semiconductor materials, metal oxides, composite materials, and doped compounds with specific electrical, optical, or catalytic properties. The technique allows for precise control over composition and structure, resulting in materials with tailored functionality for applications in electronics, energy conversion and storage, catalysis, and sensing technologies.Expand Specific Solutions05 Process optimization and parameter control in spray pyrolysis

Optimizing process parameters is crucial for achieving desired material properties in spray pyrolysis. Key parameters include precursor concentration, solution flow rate, carrier gas flow, nozzle design, substrate temperature, and reaction atmosphere. Advanced approaches involve systematic adjustment of these parameters to control particle size, morphology, crystallinity, and phase composition. Innovations in process control have led to improved reproducibility, scalability, and material performance across various applications.Expand Specific Solutions

Leading Companies and Research Institutions in Sensor Fabrication

Spray Pyrolysis technology in electrochemical sensor design is currently in a growth phase, with the market expanding due to increasing demand for precise sensing applications across healthcare, environmental monitoring, and industrial sectors. The global market is projected to reach significant value as electrochemical sensors become more integrated into IoT and smart technologies. Technologically, spray pyrolysis offers advantages in creating uniform thin films with controlled morphology and composition. Leading players like Agilent Technologies, Revvity Health Sciences, and Fudan University are advancing the field through R&D investments, while companies such as BASF and Schlumberger are exploring industrial applications. Academic institutions including Georgia Tech Research Corp and Swiss Federal Institute of Technology are contributing fundamental research, creating a competitive landscape balanced between established corporations and emerging research entities.

Revvity Health Sciences, Inc.

Technical Solution: Revvity (formerly PerkinElmer) has developed advanced spray pyrolysis techniques for electrochemical sensor fabrication, focusing on ultrasensitive detection platforms. Their approach involves precise deposition of nanostructured metal oxide films with controlled morphology and thickness for enhanced sensor performance. The company utilizes a modified ultrasonic spray pyrolysis system that enables the creation of highly uniform sensing layers with optimized porosity and surface area. This technology allows for the production of sensors capable of detecting analytes at parts-per-billion levels, particularly valuable in clinical diagnostics and environmental monitoring. Revvity's proprietary process incorporates dopants during the spray pyrolysis phase to enhance selectivity and stability of the sensing materials, resulting in electrochemical sensors with extended shelf life and reduced cross-sensitivity to interfering compounds.

Strengths: Superior sensitivity and selectivity through precise control of film morphology; excellent reproducibility in mass production; enhanced stability in complex matrices. Weaknesses: Higher production costs compared to traditional methods; requires specialized equipment and expertise; some formulations may have limited shelf life in extreme environmental conditions.

AGILENT TECHNOLOGIES INC

Technical Solution: Agilent Technologies has pioneered an integrated spray pyrolysis platform specifically designed for electrochemical sensor development. Their system employs a computer-controlled multi-nozzle spray apparatus that enables gradient deposition of sensing materials across substrates, allowing for rapid prototyping and optimization of sensor designs. The technology incorporates in-line characterization tools that provide real-time feedback on film properties during deposition, ensuring consistent quality. Agilent's approach focuses on creating hierarchical nanostructures through precise temperature control and precursor chemistry manipulation, resulting in sensors with enhanced surface area and catalytic activity. Their proprietary precursor formulations enable the creation of composite sensing materials with tailored electrochemical properties. This technology has been particularly successful in developing sensors for pharmaceutical analysis, food safety testing, and industrial process monitoring applications.

Strengths: High throughput capability for research and production; excellent reproducibility through automated process control; versatile platform adaptable to various sensing materials. Weaknesses: Significant initial capital investment required; complex calibration procedures needed for optimal performance; limited flexibility for very small batch production.

Key Patents and Innovations in Spray Pyrolysis Technology

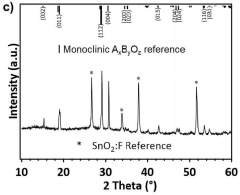

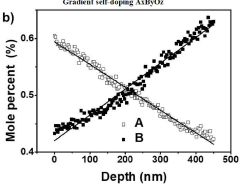

Spray pyrolysis preparation method of gradient self-doping multi metal oxide semiconductor thin film

PatentActiveAU2021100535A4

Innovation

- A spray pyrolysis method that precisely controls the liquid feeding flow rate of precursor solutions for metal ions A and B, creating a controllable A/B ratio gradient from the bottom to the top of the thin film without relying on thermal diffusion, allowing for the preparation of multi metal oxide semiconductor thin films with varying thicknesses and avoiding phase separation.

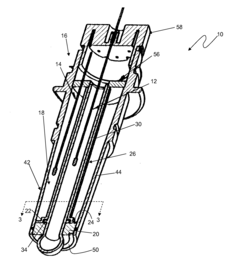

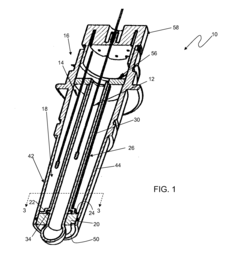

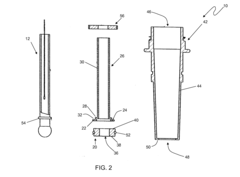

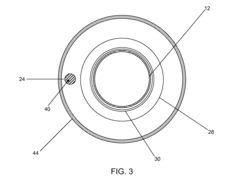

Electrochemical sensor

PatentInactiveUS20110240470A1

Innovation

- An electrochemical sensor design featuring a housing with a porous junction plug and a cross member impermeable to the target fluid, where the cross member defines a specific aperture for electrochemical communication between the target fluid and the reference electrolyte, enhancing the resistance factor by increasing the path length for ionic exchange.

Material Selection Strategies for Enhanced Sensor Performance

Material selection represents a critical factor in determining the performance characteristics of electrochemical sensors developed through spray pyrolysis techniques. The strategic selection of materials directly influences sensitivity, selectivity, stability, and response time of the resulting sensors. Current research indicates that composite materials combining metal oxides with carbon-based nanomaterials yield superior sensing capabilities compared to single-component systems.

Metal oxides such as ZnO, SnO2, TiO2, and CuO have emerged as preferred materials due to their excellent electrical properties, chemical stability, and abundant active sites for analyte interaction. These materials demonstrate particularly strong performance when synthesized with controlled morphology through spray pyrolysis, which enables precise tuning of particle size, crystallinity, and surface area.

Carbon-based materials including graphene, carbon nanotubes, and reduced graphene oxide serve as excellent supporting matrices that enhance electron transfer rates and provide additional active sites. When incorporated into spray pyrolysis processes, these materials create synergistic effects with metal oxides, significantly improving conductivity and surface-to-volume ratios of the sensing layers.

Doping strategies have proven effective for enhancing material performance in electrochemical sensors. Introduction of noble metals (Pt, Au, Pd) or transition metal ions into base materials through spray pyrolysis creates catalytic sites that lower activation energy for target analyte detection. Research demonstrates that precisely controlled doping concentrations between 0.5-5% typically yield optimal performance improvements without compromising material stability.

Surface modification techniques applied post-spray pyrolysis further enhance sensing capabilities. Functionalization with specific chemical groups creates preferential binding sites for target analytes, improving selectivity. Plasma treatment and chemical etching methods increase the effective surface area and expose more active sites, thereby improving sensitivity metrics by up to 300% in some documented cases.

Recent advances in material engineering have focused on developing hierarchical nanostructures through multi-step spray pyrolysis processes. These structures combine the advantages of different morphologies (e.g., nanoparticles, nanorods, nanosheets) to create sensing materials with optimized mass transport properties and maximized surface reaction sites. Such hierarchical structures have demonstrated detection limits in the sub-ppb range for various environmental pollutants and biomarkers.

The integration of stimuli-responsive polymers with inorganic sensing materials represents an emerging trend in material selection. These hybrid materials, when fabricated through spray pyrolysis, exhibit adaptive properties that can be triggered by external stimuli such as pH, temperature, or light, enabling smart sensing capabilities and improved sensor lifespan through self-regeneration mechanisms.

Metal oxides such as ZnO, SnO2, TiO2, and CuO have emerged as preferred materials due to their excellent electrical properties, chemical stability, and abundant active sites for analyte interaction. These materials demonstrate particularly strong performance when synthesized with controlled morphology through spray pyrolysis, which enables precise tuning of particle size, crystallinity, and surface area.

Carbon-based materials including graphene, carbon nanotubes, and reduced graphene oxide serve as excellent supporting matrices that enhance electron transfer rates and provide additional active sites. When incorporated into spray pyrolysis processes, these materials create synergistic effects with metal oxides, significantly improving conductivity and surface-to-volume ratios of the sensing layers.

Doping strategies have proven effective for enhancing material performance in electrochemical sensors. Introduction of noble metals (Pt, Au, Pd) or transition metal ions into base materials through spray pyrolysis creates catalytic sites that lower activation energy for target analyte detection. Research demonstrates that precisely controlled doping concentrations between 0.5-5% typically yield optimal performance improvements without compromising material stability.

Surface modification techniques applied post-spray pyrolysis further enhance sensing capabilities. Functionalization with specific chemical groups creates preferential binding sites for target analytes, improving selectivity. Plasma treatment and chemical etching methods increase the effective surface area and expose more active sites, thereby improving sensitivity metrics by up to 300% in some documented cases.

Recent advances in material engineering have focused on developing hierarchical nanostructures through multi-step spray pyrolysis processes. These structures combine the advantages of different morphologies (e.g., nanoparticles, nanorods, nanosheets) to create sensing materials with optimized mass transport properties and maximized surface reaction sites. Such hierarchical structures have demonstrated detection limits in the sub-ppb range for various environmental pollutants and biomarkers.

The integration of stimuli-responsive polymers with inorganic sensing materials represents an emerging trend in material selection. These hybrid materials, when fabricated through spray pyrolysis, exhibit adaptive properties that can be triggered by external stimuli such as pH, temperature, or light, enabling smart sensing capabilities and improved sensor lifespan through self-regeneration mechanisms.

Sustainability Aspects of Spray Pyrolysis Manufacturing

Sustainability Aspects of Spray Pyrolysis Manufacturing

The spray pyrolysis technique offers significant sustainability advantages compared to conventional sensor manufacturing methods. The process operates at relatively low temperatures and requires minimal chemical reagents, resulting in reduced energy consumption and waste generation. This energy efficiency is particularly notable when compared to physical vapor deposition or chemical vapor deposition techniques that typically require high vacuum conditions and elevated temperatures.

From a materials perspective, spray pyrolysis demonstrates excellent resource efficiency through precise control of precursor solutions. The ability to fine-tune solution concentrations enables optimal material utilization with minimal waste. Additionally, the technique allows for the incorporation of eco-friendly precursors and solvents, including water-based solutions that minimize environmental impact compared to organic solvent-based alternatives commonly used in sensor fabrication.

The scalability of spray pyrolysis further enhances its sustainability profile. The process can be readily scaled from laboratory to industrial production with relatively simple equipment modifications, avoiding the substantial energy and resource investments typically associated with scaling up more complex manufacturing processes. This adaptability makes spray pyrolysis particularly suitable for sustainable manufacturing paradigms.

Life cycle assessment (LCA) studies of electrochemical sensors produced via spray pyrolysis indicate favorable environmental profiles compared to sensors manufactured using conventional methods. The reduced processing steps, lower energy requirements, and decreased chemical waste contribute to a smaller carbon footprint across the product lifecycle. Furthermore, the thin-film nature of spray pyrolysis-derived materials often results in sensors requiring less raw material while maintaining or improving performance characteristics.

Recent innovations in spray pyrolysis have focused on further enhancing sustainability aspects. These include the development of closed-loop precursor recovery systems, integration with renewable energy sources for heating requirements, and exploration of biodegradable substrates for environmentally friendly sensor disposal. The technique's compatibility with a wide range of materials also enables the substitution of rare or toxic elements with more abundant and benign alternatives without compromising sensor performance.

The economic sustainability of spray pyrolysis manufacturing is equally compelling. The relatively low capital investment required for equipment setup, combined with reduced operational costs from lower energy and material inputs, creates a financially viable pathway for sustainable sensor production. This economic advantage is particularly relevant for developing regions seeking to establish local manufacturing capabilities for environmental and healthcare monitoring technologies.

The spray pyrolysis technique offers significant sustainability advantages compared to conventional sensor manufacturing methods. The process operates at relatively low temperatures and requires minimal chemical reagents, resulting in reduced energy consumption and waste generation. This energy efficiency is particularly notable when compared to physical vapor deposition or chemical vapor deposition techniques that typically require high vacuum conditions and elevated temperatures.

From a materials perspective, spray pyrolysis demonstrates excellent resource efficiency through precise control of precursor solutions. The ability to fine-tune solution concentrations enables optimal material utilization with minimal waste. Additionally, the technique allows for the incorporation of eco-friendly precursors and solvents, including water-based solutions that minimize environmental impact compared to organic solvent-based alternatives commonly used in sensor fabrication.

The scalability of spray pyrolysis further enhances its sustainability profile. The process can be readily scaled from laboratory to industrial production with relatively simple equipment modifications, avoiding the substantial energy and resource investments typically associated with scaling up more complex manufacturing processes. This adaptability makes spray pyrolysis particularly suitable for sustainable manufacturing paradigms.

Life cycle assessment (LCA) studies of electrochemical sensors produced via spray pyrolysis indicate favorable environmental profiles compared to sensors manufactured using conventional methods. The reduced processing steps, lower energy requirements, and decreased chemical waste contribute to a smaller carbon footprint across the product lifecycle. Furthermore, the thin-film nature of spray pyrolysis-derived materials often results in sensors requiring less raw material while maintaining or improving performance characteristics.

Recent innovations in spray pyrolysis have focused on further enhancing sustainability aspects. These include the development of closed-loop precursor recovery systems, integration with renewable energy sources for heating requirements, and exploration of biodegradable substrates for environmentally friendly sensor disposal. The technique's compatibility with a wide range of materials also enables the substitution of rare or toxic elements with more abundant and benign alternatives without compromising sensor performance.

The economic sustainability of spray pyrolysis manufacturing is equally compelling. The relatively low capital investment required for equipment setup, combined with reduced operational costs from lower energy and material inputs, creates a financially viable pathway for sustainable sensor production. This economic advantage is particularly relevant for developing regions seeking to establish local manufacturing capabilities for environmental and healthcare monitoring technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!