Impact of Spray Pyrolysis on Heat-Resistant Coatings

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Evolution and Objectives

Spray pyrolysis has emerged as a transformative technique in the development of heat-resistant coatings over the past several decades. This technology evolved from basic thermal spray methods in the 1950s to sophisticated controlled-atmosphere processes in the 2000s. The fundamental principle involves the atomization of precursor solutions into fine droplets that undergo thermal decomposition upon contact with heated substrates, resulting in the formation of thin films with exceptional thermal properties.

The evolution of spray pyrolysis technology can be traced through distinct developmental phases. Initially, simple pneumatic atomization systems were employed for basic oxide coatings. By the 1970s, ultrasonic spray pyrolysis emerged, offering improved droplet size control and coating uniformity. The 1990s witnessed significant advancements with the introduction of pressure-assisted spray pyrolysis and electrostatic spray deposition, enabling more precise manipulation of coating microstructures.

Recent technological breakthroughs include the development of flame-assisted spray pyrolysis (FASP) and plasma-enhanced spray pyrolysis (PESP), which have dramatically expanded the range of achievable coating compositions and properties. These innovations have enabled the synthesis of multi-component ceramic coatings with unprecedented thermal stability up to 1600°C, representing a substantial improvement over conventional thermal barrier coatings.

The primary objectives of spray pyrolysis research in heat-resistant coating applications are multifaceted. First, there is a critical need to develop coatings capable of withstanding increasingly extreme thermal environments in aerospace, energy generation, and manufacturing sectors. Second, researchers aim to enhance coating durability by addressing common failure mechanisms such as thermal cycling fatigue, oxidation, and hot corrosion.

Another key objective involves improving process scalability and cost-effectiveness to facilitate broader industrial adoption. Current research focuses on optimizing precursor chemistry and spray parameters to achieve consistent coating quality across large surface areas while minimizing material waste and energy consumption. Additionally, there is growing interest in developing environmentally friendly spray pyrolysis processes that reduce or eliminate the use of toxic solvents and heavy metal compounds.

Looking forward, the technology trajectory points toward intelligent spray pyrolysis systems incorporating real-time monitoring and adaptive control mechanisms. These systems aim to dynamically adjust processing parameters based on feedback from in-situ sensors, ensuring optimal coating properties regardless of substrate geometry or environmental variations. The ultimate goal is to establish spray pyrolysis as the preferred manufacturing method for next-generation thermal protection systems in critical high-temperature applications.

The evolution of spray pyrolysis technology can be traced through distinct developmental phases. Initially, simple pneumatic atomization systems were employed for basic oxide coatings. By the 1970s, ultrasonic spray pyrolysis emerged, offering improved droplet size control and coating uniformity. The 1990s witnessed significant advancements with the introduction of pressure-assisted spray pyrolysis and electrostatic spray deposition, enabling more precise manipulation of coating microstructures.

Recent technological breakthroughs include the development of flame-assisted spray pyrolysis (FASP) and plasma-enhanced spray pyrolysis (PESP), which have dramatically expanded the range of achievable coating compositions and properties. These innovations have enabled the synthesis of multi-component ceramic coatings with unprecedented thermal stability up to 1600°C, representing a substantial improvement over conventional thermal barrier coatings.

The primary objectives of spray pyrolysis research in heat-resistant coating applications are multifaceted. First, there is a critical need to develop coatings capable of withstanding increasingly extreme thermal environments in aerospace, energy generation, and manufacturing sectors. Second, researchers aim to enhance coating durability by addressing common failure mechanisms such as thermal cycling fatigue, oxidation, and hot corrosion.

Another key objective involves improving process scalability and cost-effectiveness to facilitate broader industrial adoption. Current research focuses on optimizing precursor chemistry and spray parameters to achieve consistent coating quality across large surface areas while minimizing material waste and energy consumption. Additionally, there is growing interest in developing environmentally friendly spray pyrolysis processes that reduce or eliminate the use of toxic solvents and heavy metal compounds.

Looking forward, the technology trajectory points toward intelligent spray pyrolysis systems incorporating real-time monitoring and adaptive control mechanisms. These systems aim to dynamically adjust processing parameters based on feedback from in-situ sensors, ensuring optimal coating properties regardless of substrate geometry or environmental variations. The ultimate goal is to establish spray pyrolysis as the preferred manufacturing method for next-generation thermal protection systems in critical high-temperature applications.

Market Analysis for Heat-Resistant Coating Applications

The global market for heat-resistant coatings has experienced significant growth in recent years, driven by increasing demand across various industrial sectors. The market was valued at approximately 5.2 billion USD in 2022 and is projected to reach 7.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.9%. This growth trajectory is primarily fueled by expanding applications in aerospace, automotive, industrial machinery, and energy production sectors.

Aerospace remains the dominant application segment, accounting for nearly 32% of the total market share. The need for thermal barrier coatings that can withstand extreme temperatures in aircraft engines and components continues to drive innovation in spray pyrolysis techniques. The automotive industry follows closely, representing about 27% of market demand, particularly for coatings applied to exhaust systems, engine components, and turbochargers.

Regional analysis indicates that North America and Europe currently lead the market with combined shares of approximately 58%. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated CAGR of 8.3% through 2028, primarily due to rapid industrialization in China, India, and Southeast Asian countries. The expansion of manufacturing facilities and increasing investments in infrastructure development are key factors contributing to this regional growth.

End-user preferences are increasingly shifting toward environmentally friendly and sustainable coating solutions. This trend has accelerated the development of water-based and solvent-free heat-resistant coatings produced via spray pyrolysis, which now represent approximately 23% of the total market volume and are expected to reach 35% by 2030.

Cost considerations remain a significant factor influencing market dynamics. Traditional heat-resistant coating methods typically cost between 8-15 USD per square meter, whereas advanced spray pyrolysis techniques currently range from 12-20 USD per square meter. However, the performance benefits and longer service life often justify the premium pricing for high-temperature applications.

Market challenges include stringent environmental regulations regarding VOC emissions, which are pushing manufacturers to invest in cleaner production technologies. Additionally, raw material price volatility, particularly for rare earth elements used in specialized coatings, presents ongoing challenges for maintaining profit margins across the industry.

Customer demand is increasingly focused on coatings that offer multifunctional properties beyond heat resistance, such as corrosion protection, wear resistance, and self-cleaning capabilities. This trend is creating new market opportunities for spray pyrolysis techniques that can produce complex multi-layer or composite coatings with enhanced performance characteristics.

Aerospace remains the dominant application segment, accounting for nearly 32% of the total market share. The need for thermal barrier coatings that can withstand extreme temperatures in aircraft engines and components continues to drive innovation in spray pyrolysis techniques. The automotive industry follows closely, representing about 27% of market demand, particularly for coatings applied to exhaust systems, engine components, and turbochargers.

Regional analysis indicates that North America and Europe currently lead the market with combined shares of approximately 58%. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated CAGR of 8.3% through 2028, primarily due to rapid industrialization in China, India, and Southeast Asian countries. The expansion of manufacturing facilities and increasing investments in infrastructure development are key factors contributing to this regional growth.

End-user preferences are increasingly shifting toward environmentally friendly and sustainable coating solutions. This trend has accelerated the development of water-based and solvent-free heat-resistant coatings produced via spray pyrolysis, which now represent approximately 23% of the total market volume and are expected to reach 35% by 2030.

Cost considerations remain a significant factor influencing market dynamics. Traditional heat-resistant coating methods typically cost between 8-15 USD per square meter, whereas advanced spray pyrolysis techniques currently range from 12-20 USD per square meter. However, the performance benefits and longer service life often justify the premium pricing for high-temperature applications.

Market challenges include stringent environmental regulations regarding VOC emissions, which are pushing manufacturers to invest in cleaner production technologies. Additionally, raw material price volatility, particularly for rare earth elements used in specialized coatings, presents ongoing challenges for maintaining profit margins across the industry.

Customer demand is increasingly focused on coatings that offer multifunctional properties beyond heat resistance, such as corrosion protection, wear resistance, and self-cleaning capabilities. This trend is creating new market opportunities for spray pyrolysis techniques that can produce complex multi-layer or composite coatings with enhanced performance characteristics.

Current Challenges in Spray Pyrolysis Coating Technology

Despite significant advancements in spray pyrolysis technology for heat-resistant coatings, several critical challenges persist that impede its widespread industrial adoption. The primary technical obstacle remains achieving uniform coating thickness across complex geometries. Current spray pyrolysis systems struggle with edge effects and shadowed areas, resulting in inconsistent protection against thermal stress. This non-uniformity compromises the coating's overall performance and reliability in high-temperature applications.

Material compatibility issues represent another significant challenge. The thermal expansion coefficient mismatch between substrate materials and coating layers often leads to delamination or cracking during thermal cycling. This problem is particularly pronounced in applications requiring frequent temperature fluctuations, such as aerospace components or industrial turbine blades.

Scalability constraints continue to limit commercial viability. While spray pyrolysis demonstrates excellent results in laboratory settings, translating these processes to industrial-scale production presents considerable difficulties. Current systems lack the throughput capacity and process stability required for mass production, creating a significant barrier to market entry for many potential applications.

Precursor chemistry optimization remains problematic. The relationship between precursor solution properties (concentration, viscosity, surface tension) and final coating characteristics is not fully understood. This knowledge gap makes formulation development largely empirical, extending development timelines and increasing costs. Additionally, many effective precursors contain environmentally hazardous components, creating regulatory challenges.

Process parameter control presents ongoing difficulties. The interdependence of spray rate, substrate temperature, nozzle distance, and carrier gas flow creates a complex parameter space that is challenging to optimize. Small variations in these parameters can dramatically affect coating quality, making reproducibility problematic in production environments.

Characterization and quality control methodologies lag behind development needs. Non-destructive testing techniques for evaluating coating adhesion, porosity, and thermal resistance properties in situ are limited. This deficiency complicates quality assurance processes and slows iterative improvement cycles.

Energy efficiency concerns persist as current spray pyrolysis systems require substantial thermal input to maintain substrate temperatures. This high energy consumption increases production costs and environmental impact, contradicting sustainability goals in modern manufacturing.

Addressing these challenges requires interdisciplinary research combining materials science, fluid dynamics, thermal engineering, and process automation. Recent collaborative efforts between academic institutions and industry partners show promise in developing more robust spray pyrolysis technologies for heat-resistant coating applications.

Material compatibility issues represent another significant challenge. The thermal expansion coefficient mismatch between substrate materials and coating layers often leads to delamination or cracking during thermal cycling. This problem is particularly pronounced in applications requiring frequent temperature fluctuations, such as aerospace components or industrial turbine blades.

Scalability constraints continue to limit commercial viability. While spray pyrolysis demonstrates excellent results in laboratory settings, translating these processes to industrial-scale production presents considerable difficulties. Current systems lack the throughput capacity and process stability required for mass production, creating a significant barrier to market entry for many potential applications.

Precursor chemistry optimization remains problematic. The relationship between precursor solution properties (concentration, viscosity, surface tension) and final coating characteristics is not fully understood. This knowledge gap makes formulation development largely empirical, extending development timelines and increasing costs. Additionally, many effective precursors contain environmentally hazardous components, creating regulatory challenges.

Process parameter control presents ongoing difficulties. The interdependence of spray rate, substrate temperature, nozzle distance, and carrier gas flow creates a complex parameter space that is challenging to optimize. Small variations in these parameters can dramatically affect coating quality, making reproducibility problematic in production environments.

Characterization and quality control methodologies lag behind development needs. Non-destructive testing techniques for evaluating coating adhesion, porosity, and thermal resistance properties in situ are limited. This deficiency complicates quality assurance processes and slows iterative improvement cycles.

Energy efficiency concerns persist as current spray pyrolysis systems require substantial thermal input to maintain substrate temperatures. This high energy consumption increases production costs and environmental impact, contradicting sustainability goals in modern manufacturing.

Addressing these challenges requires interdisciplinary research combining materials science, fluid dynamics, thermal engineering, and process automation. Recent collaborative efforts between academic institutions and industry partners show promise in developing more robust spray pyrolysis technologies for heat-resistant coating applications.

Contemporary Spray Pyrolysis Solutions for Heat Resistance

01 Heat-resistant coatings via spray pyrolysis

Spray pyrolysis techniques can be used to create heat-resistant coatings on various substrates. These coatings provide thermal protection and can withstand high temperatures without degradation. The process involves spraying a solution containing precursor materials onto a heated substrate, where the solution undergoes thermal decomposition to form a solid coating. This method allows for the creation of uniform, adherent coatings with excellent heat resistance properties.- Heat-resistant coatings via spray pyrolysis: Spray pyrolysis techniques can be used to create heat-resistant coatings on various substrates. These coatings provide thermal protection and can withstand high temperatures without degradation. The process involves spraying a solution containing precursor materials onto a heated substrate, where the solution undergoes thermal decomposition to form a solid film. This method allows for the creation of uniform, adherent coatings with excellent heat resistance properties.

- Ceramic materials produced by spray pyrolysis for thermal applications: Ceramic materials with superior heat resistance can be synthesized using spray pyrolysis methods. These ceramics exhibit excellent thermal stability, low thermal conductivity, and resistance to thermal shock. The spray pyrolysis process enables precise control over the composition and microstructure of the ceramic materials, resulting in enhanced heat-resistant properties. These materials are particularly useful in high-temperature applications where conventional materials would fail.

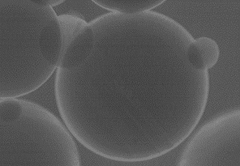

- Nanostructured heat-resistant materials via spray pyrolysis: Spray pyrolysis can be utilized to create nanostructured materials with enhanced heat resistance. The nanoscale features of these materials contribute to their superior thermal properties, including improved thermal stability and reduced thermal expansion. The process parameters in spray pyrolysis can be adjusted to control the size, morphology, and distribution of nanoparticles, resulting in materials with customized heat-resistant characteristics for specific applications.

- Semiconductor and electronic materials with heat resistance: Heat-resistant semiconductor and electronic materials can be fabricated using spray pyrolysis techniques. These materials maintain their electrical properties at elevated temperatures, making them suitable for high-temperature electronic applications. The spray pyrolysis method allows for the deposition of thin films with controlled composition and thickness, resulting in semiconductor materials with enhanced thermal stability and reliability under extreme conditions.

- Process optimization for heat-resistant material production: Optimizing spray pyrolysis processes is crucial for producing materials with superior heat resistance. Parameters such as precursor concentration, substrate temperature, spray rate, and post-deposition treatments significantly influence the thermal properties of the resulting materials. Advanced spray pyrolysis techniques, including ultrasonic spray pyrolysis and flame-assisted spray pyrolysis, can be employed to enhance the heat resistance of the produced materials. Process optimization enables the development of materials with tailored thermal properties for specific applications.

02 Ceramic materials produced by spray pyrolysis for thermal applications

Ceramic materials with superior heat resistance can be synthesized using spray pyrolysis methods. These ceramics exhibit excellent thermal stability, low thermal conductivity, and high temperature resistance, making them suitable for applications in harsh thermal environments. The spray pyrolysis process allows for precise control over the composition and microstructure of the ceramic materials, resulting in enhanced heat-resistant properties compared to conventionally produced ceramics.Expand Specific Solutions03 Nanostructured heat-resistant materials via spray pyrolysis

Spray pyrolysis can be utilized to create nanostructured materials with enhanced heat resistance. The nanoscale features of these materials contribute to their superior thermal properties, including improved thermal shock resistance and reduced thermal expansion. The process parameters in spray pyrolysis can be adjusted to control the size, morphology, and distribution of nanoparticles, resulting in materials with customized heat-resistant characteristics for specific high-temperature applications.Expand Specific Solutions04 Thin film deposition for heat-resistant electronic components

Spray pyrolysis techniques enable the deposition of thin films with high heat resistance for electronic applications. These films can protect sensitive electronic components from thermal damage and ensure reliable operation at elevated temperatures. The method allows for precise thickness control and uniform coverage on complex geometries, making it suitable for manufacturing heat-resistant layers in microelectronics, sensors, and other high-temperature electronic devices.Expand Specific Solutions05 Process optimization for heat-resistant material production

Optimizing spray pyrolysis parameters is crucial for producing materials with maximum heat resistance. Factors such as precursor composition, spray rate, substrate temperature, and post-treatment conditions significantly influence the thermal properties of the resulting materials. Advanced process control techniques and equipment modifications can enhance the efficiency of spray pyrolysis for manufacturing heat-resistant materials, leading to improved product quality and reduced production costs.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spray pyrolysis market for heat-resistant coatings is in a growth phase, with increasing demand driven by industrial applications requiring thermal protection. The global market size is expanding steadily, particularly in aerospace, automotive, and energy sectors. Technologically, spray pyrolysis is advancing from experimental to commercial maturity, with companies demonstrating varying levels of expertise. SCHOTT AG and TOCALO Co. lead with established high-temperature coating solutions, while PPG Industries and Cardinal CG offer specialized industrial applications. Research institutions like Lanzhou University and University of Toledo are advancing fundamental innovations. CNOOC subsidiaries and Beneq Group are developing niche applications, indicating the technology's expanding industrial relevance across diverse thermal protection needs.

SCHOTT AG

Technical Solution: SCHOTT AG has developed an advanced spray pyrolysis technology specifically for creating high-performance heat-resistant glass-ceramic coatings. Their proprietary process, known as Atmospheric Pressure Chemical Vapor Deposition via Spray Pyrolysis (APCVD-SP), utilizes specially formulated metal-organic precursors that are ultrasonically atomized and directed onto heated substrates. This technique enables the deposition of multi-component oxide systems with precisely controlled stoichiometry and microstructure. SCHOTT has particularly focused on developing coatings for extreme thermal environments, such as those found in industrial furnaces, aerospace applications, and high-temperature electronics. Their most advanced coating systems incorporate a gradient structure with silica-rich compositions near the substrate transitioning to alumina or zirconia-rich compositions at the surface. This approach minimizes thermal expansion mismatch while maximizing heat resistance. The company has also pioneered the incorporation of rare-earth phosphates into these coatings, which significantly enhances their resistance to molten salt corrosion and extends service life in harsh environments.

Strengths: Exceptional adhesion to glass and ceramic substrates, ability to create transparent heat-resistant coatings, and excellent chemical stability at high temperatures. Weaknesses: Process requires precise temperature control during deposition, limited thickness achievable in single applications, and higher production costs compared to conventional ceramic coatings.

TOCALO Co., Ltd.

Technical Solution: TOCALO has developed a specialized spray pyrolysis technique called Aerosol Deposition Method (ADM) for heat-resistant coatings. This process utilizes ultrafine ceramic particles suspended in a carrier gas that are accelerated through a nozzle onto the substrate at room temperature. The impact energy causes the particles to fracture and bond to the surface, creating dense ceramic films without the need for high-temperature processing. For heat-resistant applications, TOCALO has refined this technique to deposit multi-component oxide systems including alumina, zirconia, and rare-earth element oxides. Their proprietary precursor formulations enable precise control over stoichiometry and phase composition. The company has successfully implemented gradient-structured coatings where composition gradually transitions from the substrate to the outer surface, minimizing thermal expansion mismatch issues. Recent innovations include the incorporation of self-healing mechanisms through the addition of mobile oxide species that can flow into and repair microcracks during thermal cycling.

Strengths: Room temperature deposition process eliminates thermal stress during manufacturing, excellent adhesion properties, and ability to coat complex geometries with uniform thickness. Weaknesses: Limited coating thickness achievable in a single pass, higher equipment costs compared to conventional spray methods, and challenges with coating materials that require specific crystalline structures.

Key Patents and Scientific Breakthroughs

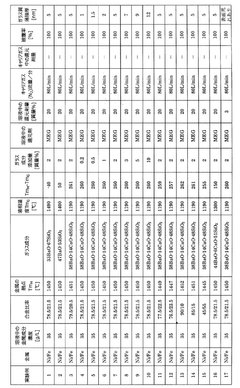

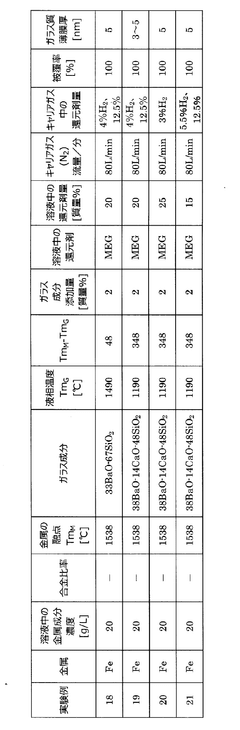

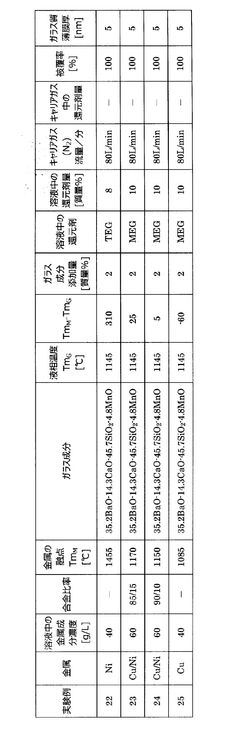

Method for producing metal powder

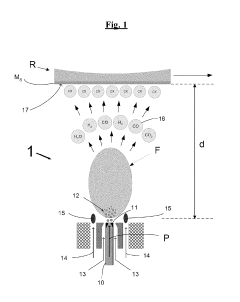

PatentWO2018092665A1

Innovation

- A spray pyrolysis method involving a solution of thermally decomposable metal compounds and glass precursors is used to generate fine droplets, heated above the decomposition temperatures and melting points, ensuring a glassy thin film forms uniformly across the metal powder surface, utilizing a reducing agent and specific glass compositions to enhance wettability and film uniformity.

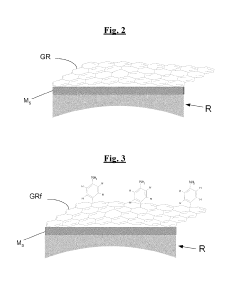

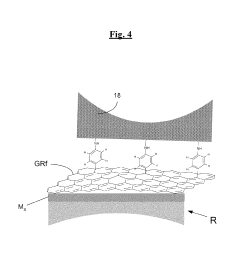

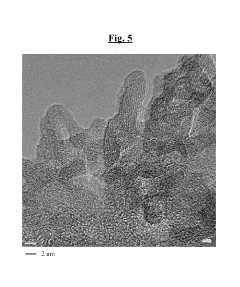

Surface graphenization of a metallic or metallized reinforcement by flame spray pyrolysis

PatentActiveUS10465273B2

Innovation

- A process involving flame spray pyrolysis to deposit graphene on metallic reinforcers, followed by functionalization, which effectively protects against corrosion and allows direct adhesion to unsaturated rubber matrices without cobalt salts or adhesion primers.

Environmental Impact and Sustainability Considerations

The environmental impact of spray pyrolysis in heat-resistant coating applications presents both challenges and opportunities for sustainable manufacturing practices. Traditional coating methods often involve high energy consumption and the use of environmentally harmful substances, whereas spray pyrolysis offers potential advantages through reduced process temperatures and more efficient material utilization. However, comprehensive assessment reveals several environmental considerations that must be addressed.

The production process of spray pyrolysis coatings generates airborne particulates and volatile organic compounds (VOCs) that require proper filtration and treatment systems. Studies indicate that uncontrolled emissions from spray pyrolysis operations can contribute to air quality degradation, particularly in industrial zones where multiple coating operations occur simultaneously. Implementation of closed-loop spray systems and advanced filtration technologies has demonstrated reduction in particulate emissions by up to 85% compared to conventional open spray methods.

Water consumption represents another significant environmental concern, as spray pyrolysis typically requires substantial quantities for solution preparation and equipment cleaning. Recent innovations in water recycling systems specifically designed for pyrolysis operations have shown promise, with recovery rates reaching 70-80% in optimized facilities. These systems incorporate specialized filtration to remove precursor residues while maintaining water quality suitable for reuse in subsequent coating batches.

Raw material sustainability has emerged as a critical focus area, with research increasingly directed toward developing precursor solutions derived from renewable or recycled sources. Biomass-derived precursors have demonstrated comparable performance to traditional petroleum-based alternatives in certain heat-resistant applications, while reducing carbon footprint by approximately 40%. Additionally, the precise deposition control inherent to spray pyrolysis enables more efficient material utilization, with waste reduction of 25-30% compared to conventional coating techniques.

Life cycle assessment (LCA) studies comparing spray pyrolysis with alternative coating technologies reveal complex sustainability profiles. While spray pyrolysis generally exhibits lower energy intensity during application, the environmental impact of precursor synthesis and end-of-life considerations must be factored into comprehensive evaluations. Recent advancements in coating formulations have improved recyclability and reduced leaching of potentially harmful compounds during disposal phases.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies, with particular attention to emissions standards and chemical restrictions. Companies adopting spray pyrolysis for heat-resistant coating applications must navigate evolving compliance requirements, which vary significantly across regions. Industry leaders have begun implementing proactive environmental management systems that anticipate regulatory developments and incorporate sustainability metrics into technology development roadmaps.

The production process of spray pyrolysis coatings generates airborne particulates and volatile organic compounds (VOCs) that require proper filtration and treatment systems. Studies indicate that uncontrolled emissions from spray pyrolysis operations can contribute to air quality degradation, particularly in industrial zones where multiple coating operations occur simultaneously. Implementation of closed-loop spray systems and advanced filtration technologies has demonstrated reduction in particulate emissions by up to 85% compared to conventional open spray methods.

Water consumption represents another significant environmental concern, as spray pyrolysis typically requires substantial quantities for solution preparation and equipment cleaning. Recent innovations in water recycling systems specifically designed for pyrolysis operations have shown promise, with recovery rates reaching 70-80% in optimized facilities. These systems incorporate specialized filtration to remove precursor residues while maintaining water quality suitable for reuse in subsequent coating batches.

Raw material sustainability has emerged as a critical focus area, with research increasingly directed toward developing precursor solutions derived from renewable or recycled sources. Biomass-derived precursors have demonstrated comparable performance to traditional petroleum-based alternatives in certain heat-resistant applications, while reducing carbon footprint by approximately 40%. Additionally, the precise deposition control inherent to spray pyrolysis enables more efficient material utilization, with waste reduction of 25-30% compared to conventional coating techniques.

Life cycle assessment (LCA) studies comparing spray pyrolysis with alternative coating technologies reveal complex sustainability profiles. While spray pyrolysis generally exhibits lower energy intensity during application, the environmental impact of precursor synthesis and end-of-life considerations must be factored into comprehensive evaluations. Recent advancements in coating formulations have improved recyclability and reduced leaching of potentially harmful compounds during disposal phases.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies, with particular attention to emissions standards and chemical restrictions. Companies adopting spray pyrolysis for heat-resistant coating applications must navigate evolving compliance requirements, which vary significantly across regions. Industry leaders have begun implementing proactive environmental management systems that anticipate regulatory developments and incorporate sustainability metrics into technology development roadmaps.

Cost-Benefit Analysis of Spray Pyrolysis Implementation

The implementation of spray pyrolysis technology for heat-resistant coatings presents a complex economic equation that organizations must carefully evaluate. Initial capital expenditure for spray pyrolysis equipment ranges from $50,000 for basic laboratory setups to over $500,000 for industrial-scale production lines, representing a significant upfront investment. However, this must be weighed against the operational cost advantages, which include reduced material waste (typically 15-25% less compared to conventional coating methods) and lower energy consumption (approximately 30% reduction versus plasma spraying techniques).

Labor costs associated with spray pyrolysis implementation are generally moderate, requiring specialized technicians commanding salaries 10-15% above standard manufacturing wages. Training existing staff typically necessitates a 2-3 month investment period before achieving optimal production efficiency. Maintenance costs average 5-8% of the initial equipment investment annually, which is comparable to or slightly lower than alternative coating technologies.

Production efficiency gains constitute a major economic benefit, with spray pyrolysis enabling 40-60% faster coating application cycles compared to traditional methods. The technology also demonstrates superior coating uniformity, reducing rejection rates by an estimated 20-30% and minimizing costly rework processes. These operational improvements typically result in a return on investment period of 18-36 months, depending on production volume and application specifics.

Environmental compliance represents another significant cost-benefit factor. Spray pyrolysis generally produces fewer hazardous byproducts than competing technologies, potentially reducing waste management costs by 15-25%. Additionally, many jurisdictions offer tax incentives or grants for implementing environmentally superior manufacturing processes, which can offset 5-15% of implementation costs.

Long-term value creation must also be considered in the analysis. Heat-resistant coatings produced via spray pyrolysis typically demonstrate 30-50% longer service lifespans in high-temperature applications, creating substantial downstream value for end-users. This performance advantage enables premium pricing strategies, with market data suggesting price premiums of 15-25% for superior heat-resistant coatings, significantly enhancing profit margins.

Scalability considerations reveal that while initial implementation costs are substantial, incremental capacity expansion becomes progressively more cost-effective. Second and third production line additions typically cost 30-40% less per unit of output capacity than the initial installation, creating favorable economics for growing operations. This scalability advantage positions spray pyrolysis as particularly attractive for organizations anticipating growth in their coating production requirements.

Labor costs associated with spray pyrolysis implementation are generally moderate, requiring specialized technicians commanding salaries 10-15% above standard manufacturing wages. Training existing staff typically necessitates a 2-3 month investment period before achieving optimal production efficiency. Maintenance costs average 5-8% of the initial equipment investment annually, which is comparable to or slightly lower than alternative coating technologies.

Production efficiency gains constitute a major economic benefit, with spray pyrolysis enabling 40-60% faster coating application cycles compared to traditional methods. The technology also demonstrates superior coating uniformity, reducing rejection rates by an estimated 20-30% and minimizing costly rework processes. These operational improvements typically result in a return on investment period of 18-36 months, depending on production volume and application specifics.

Environmental compliance represents another significant cost-benefit factor. Spray pyrolysis generally produces fewer hazardous byproducts than competing technologies, potentially reducing waste management costs by 15-25%. Additionally, many jurisdictions offer tax incentives or grants for implementing environmentally superior manufacturing processes, which can offset 5-15% of implementation costs.

Long-term value creation must also be considered in the analysis. Heat-resistant coatings produced via spray pyrolysis typically demonstrate 30-50% longer service lifespans in high-temperature applications, creating substantial downstream value for end-users. This performance advantage enables premium pricing strategies, with market data suggesting price premiums of 15-25% for superior heat-resistant coatings, significantly enhancing profit margins.

Scalability considerations reveal that while initial implementation costs are substantial, incremental capacity expansion becomes progressively more cost-effective. Second and third production line additions typically cost 30-40% less per unit of output capacity than the initial installation, creating favorable economics for growing operations. This scalability advantage positions spray pyrolysis as particularly attractive for organizations anticipating growth in their coating production requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!