Research on Spray Pyrolysis for High-Temperature Superconductors

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superconductor Spray Pyrolysis Background and Objectives

Superconductivity, discovered in 1911 by Heike Kamerlingh Onnes, has evolved from a laboratory curiosity to a transformative technology with applications spanning energy transmission, medical diagnostics, and quantum computing. The discovery of high-temperature superconductors (HTS) in 1986 by Bednorz and Müller marked a pivotal advancement, enabling superconductivity at temperatures achievable with liquid nitrogen rather than expensive liquid helium.

Spray pyrolysis has emerged as a promising fabrication technique for HTS materials, offering advantages in scalability, cost-effectiveness, and compositional control. This process involves atomizing precursor solutions into fine droplets that undergo thermal decomposition to form the desired superconducting compounds. The technique's evolution began in the 1990s with simple oxide depositions and has progressively advanced to complex multi-component superconducting systems.

Current technological trends indicate a growing focus on enhancing the critical parameters of HTS materials produced via spray pyrolysis: critical temperature (Tc), critical current density (Jc), and critical magnetic field (Hc). Researchers are exploring novel precursor chemistries, atomization techniques, and post-deposition treatments to optimize these properties. The integration of computational modeling and machine learning approaches is accelerating the discovery and optimization of new superconducting compositions.

The primary objective of this research is to comprehensively evaluate spray pyrolysis as a viable manufacturing technique for high-temperature superconductors with commercial potential. Specifically, we aim to identify optimal processing parameters that yield superconducting films with performance metrics comparable to those produced by more established but costlier methods such as pulsed laser deposition or chemical vapor deposition.

Secondary objectives include developing strategies to overcome current limitations in film thickness uniformity, crystallographic alignment, and oxygen stoichiometry control. We also seek to establish scalable protocols that maintain material quality while increasing production throughput, a critical factor for industrial adoption.

Long-term goals encompass the development of continuous processing methodologies for HTS tapes and wires, which represent the most commercially viable form factors for applications in power transmission and magnetic field generation. Additionally, we aim to explore the potential of spray pyrolysis for fabricating next-generation iron-based superconductors and hydrogen-rich superconducting materials that may operate at even higher temperatures.

This research aligns with global initiatives to develop more energy-efficient technologies and supports the transition toward sustainable energy systems where superconducting components could significantly reduce transmission losses and enable more compact, powerful electromagnetic devices.

Spray pyrolysis has emerged as a promising fabrication technique for HTS materials, offering advantages in scalability, cost-effectiveness, and compositional control. This process involves atomizing precursor solutions into fine droplets that undergo thermal decomposition to form the desired superconducting compounds. The technique's evolution began in the 1990s with simple oxide depositions and has progressively advanced to complex multi-component superconducting systems.

Current technological trends indicate a growing focus on enhancing the critical parameters of HTS materials produced via spray pyrolysis: critical temperature (Tc), critical current density (Jc), and critical magnetic field (Hc). Researchers are exploring novel precursor chemistries, atomization techniques, and post-deposition treatments to optimize these properties. The integration of computational modeling and machine learning approaches is accelerating the discovery and optimization of new superconducting compositions.

The primary objective of this research is to comprehensively evaluate spray pyrolysis as a viable manufacturing technique for high-temperature superconductors with commercial potential. Specifically, we aim to identify optimal processing parameters that yield superconducting films with performance metrics comparable to those produced by more established but costlier methods such as pulsed laser deposition or chemical vapor deposition.

Secondary objectives include developing strategies to overcome current limitations in film thickness uniformity, crystallographic alignment, and oxygen stoichiometry control. We also seek to establish scalable protocols that maintain material quality while increasing production throughput, a critical factor for industrial adoption.

Long-term goals encompass the development of continuous processing methodologies for HTS tapes and wires, which represent the most commercially viable form factors for applications in power transmission and magnetic field generation. Additionally, we aim to explore the potential of spray pyrolysis for fabricating next-generation iron-based superconductors and hydrogen-rich superconducting materials that may operate at even higher temperatures.

This research aligns with global initiatives to develop more energy-efficient technologies and supports the transition toward sustainable energy systems where superconducting components could significantly reduce transmission losses and enable more compact, powerful electromagnetic devices.

Market Analysis for High-Temperature Superconductor Applications

The high-temperature superconductor (HTS) market has been experiencing significant growth driven by advancements in materials science and increasing demand for energy-efficient technologies. The global HTS market was valued at approximately 6.3 billion USD in 2022 and is projected to reach 10.8 billion USD by 2028, growing at a compound annual growth rate of 9.4% during the forecast period.

The market for HTS applications can be segmented into several key sectors. The energy sector represents the largest market share, with applications in power transmission, energy storage systems, and fault current limiters. The healthcare sector follows closely, primarily driven by magnetic resonance imaging (MRI) systems that utilize superconducting magnets to generate high-resolution images with reduced power consumption compared to conventional systems.

Transportation represents another promising application area, particularly in magnetic levitation (maglev) trains and electric propulsion systems. The development of HTS materials through spray pyrolysis techniques could significantly reduce manufacturing costs and improve performance metrics, potentially accelerating adoption in this sector.

Research institutions and defense applications constitute a substantial portion of current demand. Particle accelerators, nuclear magnetic resonance systems, and military applications such as ship propulsion systems and electromagnetic weapons all rely on superconducting materials. The improved properties of HTS materials produced via spray pyrolysis could expand these applications further.

Regional analysis indicates that North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by substantial investments in infrastructure development and research initiatives in countries like China, Japan, and South Korea.

Key market challenges include the high cost of HTS materials and the technical complexity of maintaining superconducting conditions. Spray pyrolysis offers potential solutions to these challenges by enabling more cost-effective production methods and potentially raising the critical temperature of superconducting materials, thus reducing cooling requirements.

Market trends indicate increasing collaboration between academic institutions and industry players to accelerate commercialization of HTS technologies. Additionally, there is growing interest in developing HTS materials that can operate at higher temperatures with minimal cooling requirements, which would significantly expand the addressable market by reducing operational costs.

The competitive landscape features established players like American Superconductor, Bruker Corporation, and Fujikura Ltd, alongside emerging startups focused on novel production techniques like spray pyrolysis. These market dynamics suggest significant growth potential for spray pyrolysis-based HTS materials as the technology matures and production scales.

The market for HTS applications can be segmented into several key sectors. The energy sector represents the largest market share, with applications in power transmission, energy storage systems, and fault current limiters. The healthcare sector follows closely, primarily driven by magnetic resonance imaging (MRI) systems that utilize superconducting magnets to generate high-resolution images with reduced power consumption compared to conventional systems.

Transportation represents another promising application area, particularly in magnetic levitation (maglev) trains and electric propulsion systems. The development of HTS materials through spray pyrolysis techniques could significantly reduce manufacturing costs and improve performance metrics, potentially accelerating adoption in this sector.

Research institutions and defense applications constitute a substantial portion of current demand. Particle accelerators, nuclear magnetic resonance systems, and military applications such as ship propulsion systems and electromagnetic weapons all rely on superconducting materials. The improved properties of HTS materials produced via spray pyrolysis could expand these applications further.

Regional analysis indicates that North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the highest growth rate during the forecast period, driven by substantial investments in infrastructure development and research initiatives in countries like China, Japan, and South Korea.

Key market challenges include the high cost of HTS materials and the technical complexity of maintaining superconducting conditions. Spray pyrolysis offers potential solutions to these challenges by enabling more cost-effective production methods and potentially raising the critical temperature of superconducting materials, thus reducing cooling requirements.

Market trends indicate increasing collaboration between academic institutions and industry players to accelerate commercialization of HTS technologies. Additionally, there is growing interest in developing HTS materials that can operate at higher temperatures with minimal cooling requirements, which would significantly expand the addressable market by reducing operational costs.

The competitive landscape features established players like American Superconductor, Bruker Corporation, and Fujikura Ltd, alongside emerging startups focused on novel production techniques like spray pyrolysis. These market dynamics suggest significant growth potential for spray pyrolysis-based HTS materials as the technology matures and production scales.

Current Challenges in Spray Pyrolysis Technology

Spray pyrolysis technology for high-temperature superconductors faces several significant challenges that impede its widespread industrial application. The primary obstacle remains the precise control of stoichiometry during the deposition process. Even minor deviations in the chemical composition can dramatically affect the superconducting properties, requiring extremely tight process controls that are difficult to maintain consistently at scale.

Temperature uniformity across the substrate presents another major challenge. The formation of high-quality superconducting phases demands precise thermal conditions, yet achieving homogeneous temperature distribution becomes increasingly difficult with larger substrate dimensions. This limitation has restricted spray pyrolysis primarily to laboratory-scale production rather than industrial manufacturing.

Precursor solution chemistry poses complex challenges, as the ideal solvent must balance several competing requirements: complete dissolution of all precursor compounds, appropriate viscosity for atomization, suitable surface tension for droplet formation, and controlled evaporation rate. Current solvent systems often compromise on one or more of these parameters, leading to inconsistent film quality.

The atomization process itself remains problematic, with conventional pneumatic and ultrasonic atomizers producing droplet size distributions that are too broad. This variability leads to non-uniform deposition and inconsistent film morphology. Advanced atomization technologies with narrower size distributions exist but introduce significant cost and complexity barriers.

Post-deposition thermal treatment represents another critical challenge. The transformation from as-deposited amorphous or partially crystalline films to the desired superconducting phases requires precise annealing protocols. Current approaches often result in microcracking, delamination, or incomplete phase formation, particularly for thicker films needed for practical current-carrying applications.

Substrate compatibility issues further complicate matters. Many high-temperature superconductor compositions react with common substrate materials during high-temperature processing, forming unwanted interfacial compounds that degrade superconducting properties. While buffer layers can mitigate this problem, they add process complexity and cost.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial production. The deposition rate of conventional spray pyrolysis is relatively slow compared to competing techniques, and maintaining quality over large areas remains problematic. Current industrial systems struggle to achieve the thickness uniformity required for practical superconducting devices across substrates larger than a few centimeters.

Environmental and safety concerns also present significant hurdles. Many precursor solutions contain toxic or environmentally harmful compounds, and the aerosol generation process creates potential inhalation hazards requiring sophisticated containment and ventilation systems that add substantial cost to production facilities.

Temperature uniformity across the substrate presents another major challenge. The formation of high-quality superconducting phases demands precise thermal conditions, yet achieving homogeneous temperature distribution becomes increasingly difficult with larger substrate dimensions. This limitation has restricted spray pyrolysis primarily to laboratory-scale production rather than industrial manufacturing.

Precursor solution chemistry poses complex challenges, as the ideal solvent must balance several competing requirements: complete dissolution of all precursor compounds, appropriate viscosity for atomization, suitable surface tension for droplet formation, and controlled evaporation rate. Current solvent systems often compromise on one or more of these parameters, leading to inconsistent film quality.

The atomization process itself remains problematic, with conventional pneumatic and ultrasonic atomizers producing droplet size distributions that are too broad. This variability leads to non-uniform deposition and inconsistent film morphology. Advanced atomization technologies with narrower size distributions exist but introduce significant cost and complexity barriers.

Post-deposition thermal treatment represents another critical challenge. The transformation from as-deposited amorphous or partially crystalline films to the desired superconducting phases requires precise annealing protocols. Current approaches often result in microcracking, delamination, or incomplete phase formation, particularly for thicker films needed for practical current-carrying applications.

Substrate compatibility issues further complicate matters. Many high-temperature superconductor compositions react with common substrate materials during high-temperature processing, forming unwanted interfacial compounds that degrade superconducting properties. While buffer layers can mitigate this problem, they add process complexity and cost.

Scaling challenges persist in transitioning from laboratory demonstrations to industrial production. The deposition rate of conventional spray pyrolysis is relatively slow compared to competing techniques, and maintaining quality over large areas remains problematic. Current industrial systems struggle to achieve the thickness uniformity required for practical superconducting devices across substrates larger than a few centimeters.

Environmental and safety concerns also present significant hurdles. Many precursor solutions contain toxic or environmentally harmful compounds, and the aerosol generation process creates potential inhalation hazards requiring sophisticated containment and ventilation systems that add substantial cost to production facilities.

State-of-the-Art Spray Pyrolysis Techniques

01 Spray pyrolysis techniques for superconductor synthesis

Spray pyrolysis is a versatile technique for synthesizing high-temperature superconductor materials. This process involves atomizing a precursor solution containing metal salts and spraying it into a heated chamber, where the droplets undergo evaporation, decomposition, and crystallization to form superconducting particles. The technique allows for precise control of composition, morphology, and particle size, which are critical factors affecting the superconducting properties of the final material.- Spray pyrolysis techniques for superconductor synthesis: Spray pyrolysis is a versatile method for synthesizing high-temperature superconductor materials. This process involves atomizing a precursor solution containing metal salts and spraying it into a heated chamber where the droplets undergo rapid evaporation, decomposition, and crystallization to form superconducting particles. The technique allows for precise control of composition, morphology, and particle size, which are critical factors affecting the superconducting properties of the final material.

- Precursor solution formulations for spray pyrolysis: The composition and properties of precursor solutions significantly influence the quality of high-temperature superconductors produced by spray pyrolysis. These solutions typically contain metal salts (such as nitrates, acetates, or chlorides) of elements like yttrium, barium, copper, bismuth, or rare earth metals dissolved in appropriate solvents. Additives such as complexing agents, pH modifiers, and viscosity controllers can be incorporated to enhance solution stability, improve atomization characteristics, and control the morphology of the resulting superconducting particles.

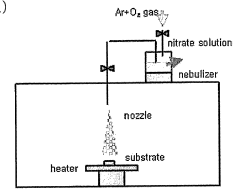

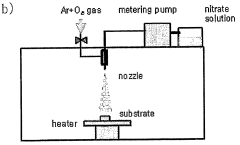

- Equipment and apparatus design for spray pyrolysis: Specialized equipment designs for spray pyrolysis of high-temperature superconductors include atomizers, reaction chambers, temperature control systems, and collection mechanisms. Ultrasonic or pressure-based atomizers create uniform droplets from precursor solutions. Reaction chambers with precisely controlled temperature zones facilitate the transformation of precursor droplets into superconducting particles. Advanced designs incorporate features for controlling atmosphere composition, pressure conditions, and residence time to optimize the formation of superconducting phases with desired properties.

- Post-processing treatments for spray-pyrolyzed superconductors: After initial synthesis by spray pyrolysis, high-temperature superconductor materials often require post-processing treatments to achieve optimal superconducting properties. These treatments include thermal annealing in controlled atmospheres to promote phase formation and oxygen content optimization, mechanical processing to improve density and grain alignment, and surface treatments to enhance stability and reduce degradation. Additional processing steps may involve the application of protective coatings or the integration of the superconducting material into composite structures for practical applications.

- Thin film deposition of superconductors using spray pyrolysis: Spray pyrolysis can be adapted for the deposition of high-temperature superconductor thin films on various substrates. This approach involves directing the atomized precursor solution onto a heated substrate where chemical reactions occur to form the superconducting film. Parameters such as substrate temperature, solution flow rate, and nozzle-to-substrate distance critically affect film quality. This method offers advantages including relatively low equipment costs, scalability for large-area deposition, and compatibility with complex substrate geometries, making it suitable for manufacturing superconducting devices and components.

02 Precursor solution formulations for spray pyrolysis

The composition of precursor solutions plays a crucial role in spray pyrolysis for high-temperature superconductors. These solutions typically contain metal salts (such as nitrates, acetates, or chlorides) of elements like yttrium, barium, copper, bismuth, strontium, calcium, and rare earth metals dissolved in appropriate solvents. Additives such as complexing agents, pH modifiers, and viscosity controllers can be incorporated to improve solution stability, spray characteristics, and the quality of the resulting superconducting materials.Expand Specific Solutions03 Equipment and apparatus design for spray pyrolysis

Specialized equipment designs are essential for effective spray pyrolysis of high-temperature superconductors. These systems typically include atomizer units (ultrasonic, pressure, or electrostatic), temperature-controlled reaction chambers, substrate heating mechanisms, and precise gas flow controllers. Advanced systems may incorporate features such as multi-zone heating, controlled atmosphere capabilities, and in-situ monitoring tools to optimize the deposition process and enhance the quality of the superconducting films or powders produced.Expand Specific Solutions04 Post-processing treatments for spray-pyrolyzed superconductors

After spray pyrolysis deposition, high-temperature superconductor materials often require post-processing treatments to achieve optimal superconducting properties. These treatments may include thermal annealing in controlled atmospheres (oxygen, nitrogen, or inert gases) to promote crystallization and oxygen incorporation, mechanical densification to improve connectivity between particles, and chemical treatments to remove impurities or modify surface properties. Such post-processing steps are crucial for enhancing critical current density, transition temperature, and other key performance parameters.Expand Specific Solutions05 Thin film and multilayer superconductor fabrication

Spray pyrolysis enables the fabrication of high-temperature superconductor thin films and multilayer structures with controlled thickness and composition. This approach allows for the deposition of superconducting materials on various substrates including ceramics, metals, and flexible polymers. By adjusting process parameters such as substrate temperature, spray rate, and solution concentration, the microstructure and orientation of the films can be tailored. Multilayer structures combining superconductors with buffer layers, protective coatings, or functional materials can be created through sequential spray pyrolysis steps.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The spray pyrolysis technology for high-temperature superconductors is currently in an emerging growth phase, with the market expanding as applications in electronics, energy, and medical sectors develop. The global market is estimated to reach significant scale as superconducting materials become increasingly important for next-generation technologies. From a technical maturity perspective, the field shows varying levels of development across key players. Research institutions like Chinese Academy of Sciences, Swiss Federal Institute of Technology, and Centre National de la Recherche Scientifique lead fundamental research, while companies including Shoei Chemical, Merck Patent GmbH, and Beneq Group demonstrate commercial applications through specialized coating technologies. GlobalFoundries and DuPont are leveraging spray pyrolysis for semiconductor applications, while NGK Insulators and Cabot Corp focus on industrial ceramic implementations.

Chinese Academy of Science Guanzhou Energy Research Institute

Technical Solution: The Chinese Academy of Science Guangzhou Energy Research Institute has developed an innovative spray pyrolysis system specifically optimized for high-temperature superconductor production. Their approach utilizes a modified ultrasonic spray pyrolysis technique with multiple atomizing nozzles arranged in a circular configuration to ensure uniform deposition over large substrate areas (>200 cm²). The institute's researchers have formulated proprietary precursor solutions containing rare earth nitrates, barium compounds, and copper salts with specific additives that enhance film adhesion and reduce crack formation during thermal processing. Their system incorporates a gradient temperature furnace with five independently controlled heating zones, allowing precise management of the pyrolysis, crystallization, and oxidation processes. This results in YBCO films with critical temperatures consistently above 90K and critical current densities reaching 2.5 MA/cm² at 77K. A key innovation in their approach is the integration of in-situ oxygen plasma treatment during the cooling phase, which optimizes oxygen content in the superconducting structure without requiring extended annealing times. The institute has successfully demonstrated the scalability of this technique for continuous production of superconducting tapes up to 10 meters in length with consistent properties throughout.

Strengths: Excellent scalability for industrial production with demonstrated capability for continuous processing of long-length superconducting tapes. The multi-zone heating system provides exceptional control over phase formation and oxygen content. Weaknesses: The complex multi-nozzle spray system requires precise alignment and maintenance to ensure uniform deposition. The process is somewhat sensitive to variations in ambient humidity which can affect precursor atomization efficiency.

Swiss Federal Institute of Technology

Technical Solution: The Swiss Federal Institute of Technology (ETH Zurich) has developed a cutting-edge spray pyrolysis technique for high-temperature superconductors that combines aerosol-assisted chemical vapor deposition with epitaxial growth control. Their approach utilizes precisely engineered precursor solutions containing fluorine-free metal-organic compounds that decompose cleanly during the pyrolysis process. The system employs a unique oscillating nozzle design that ensures uniform droplet distribution across the substrate surface, resulting in exceptionally homogeneous film formation. ETH researchers have optimized the process for REBCO superconductors, achieving critical current densities exceeding 4 MA/cm² at 77K in self-field conditions. Their innovation includes a controlled atmosphere processing chamber that enables precise management of oxygen partial pressure throughout the deposition and annealing stages. This results in superior oxygen stoichiometry control in the final superconducting phase. The technology incorporates a two-step deposition process where an initial seed layer is deposited at lower temperatures (600-650°C) followed by the main growth at higher temperatures (750-800°C), which significantly improves epitaxial quality and reduces substrate interdiffusion issues.

Strengths: Achieves exceptional film quality with minimal defects through precise precursor chemistry and deposition control. The fluorine-free process eliminates environmental concerns associated with traditional TFA-based methods. Weaknesses: The two-step deposition process increases production time and complexity. The technique requires highly specialized precursor compounds that may be costly to synthesize at industrial scales.

Critical Patents and Scientific Breakthroughs

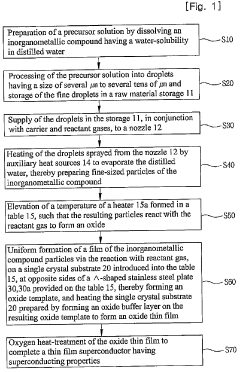

Method and apparatus for fabrication of thin film superconductor by spray pyrolysis chemical vapor deposition method

PatentWO2008038856A1

Innovation

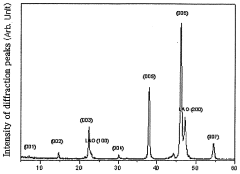

- A method utilizing inexpensive inorganometallic compounds like nitrates, chlorides, and sulfates dissolved in distilled water for spray pyrolysis chemical vapor deposition, forming a precursor solution that is processed into fine droplets, sprayed onto a substrate, and reacted with gases to form a superconducting thin film of REBa2Cu3O7-x with a specific cation ratio, using a Λ shaped stainless steel plate and oxygen heat-treatment to achieve epitaxial deposition.

Spray pyrolysis process for preparing superconductive films

PatentInactiveUS5021399A

Innovation

- The improved spray pyrolysis methods, namely the melt-quench and flux-sinter processes, involve specific temperature and heat treatment steps to densify the films, using a solution of Bi, Sr, and Cu salts with optional fluxing agents like sodium nitrate or potassium fluoride, which are sprayed onto heated substrates and undergo controlled heating and cooling cycles to achieve dense, oriented superconducting films.

Materials Science Considerations and Limitations

Spray pyrolysis for high-temperature superconductors faces several critical materials science considerations and limitations that impact the quality, performance, and scalability of the resulting superconducting films. The precursor solution composition represents a fundamental challenge, as it must maintain proper stoichiometry while ensuring adequate solubility of all constituent elements. Achieving homogeneous mixing at the molecular level is essential for uniform superconducting properties, yet differences in solubility and precipitation rates among various metal salts often lead to compositional variations in the final product.

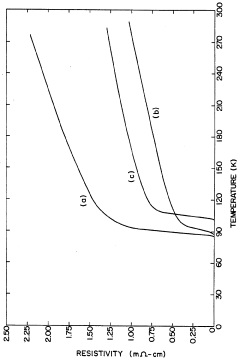

Temperature control during the pyrolysis process presents another significant limitation. The transformation from precursor solution to crystalline superconducting phase requires precise thermal management, with temperature gradients potentially causing non-uniform crystallization and phase segregation. Many high-temperature superconductors, particularly YBCO (YBa₂Cu₃O₇-ₓ) and BSCCO (Bi₂Sr₂CaCu₂O₈+ₓ) systems, exhibit complex phase diagrams with narrow windows for optimal superconducting phase formation.

Substrate compatibility issues further constrain material selection and processing parameters. The lattice mismatch between substrate and superconducting film can induce strain, dislocations, and other structural defects that degrade superconducting properties. Additionally, chemical reactions at the substrate-film interface during high-temperature processing may lead to unwanted diffusion and secondary phase formation.

Oxygen stoichiometry control represents a particularly challenging aspect for cuprate-based high-temperature superconductors, where oxygen content directly influences the carrier concentration and superconducting transition temperature. The spray pyrolysis environment must be carefully regulated to achieve optimal oxygen incorporation during film growth and subsequent annealing treatments.

Film thickness limitations also affect practical applications, as spray pyrolysis typically produces relatively thin films (100-500 nm). Thicker films often develop cracks and delamination due to thermal expansion mismatches and internal stresses during crystallization. This thickness constraint limits current-carrying capacity in applications requiring high critical currents.

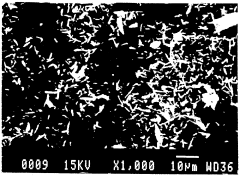

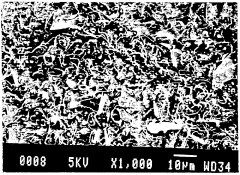

Microstructural defects including porosity, grain boundaries, and secondary phases significantly impact superconducting performance. While some controlled defects can enhance flux pinning properties, uncontrolled defect formation during spray pyrolysis often degrades critical current density and transition temperature. Advanced characterization techniques and process optimization are essential to minimize detrimental defects while incorporating beneficial pinning centers.

Temperature control during the pyrolysis process presents another significant limitation. The transformation from precursor solution to crystalline superconducting phase requires precise thermal management, with temperature gradients potentially causing non-uniform crystallization and phase segregation. Many high-temperature superconductors, particularly YBCO (YBa₂Cu₃O₇-ₓ) and BSCCO (Bi₂Sr₂CaCu₂O₈+ₓ) systems, exhibit complex phase diagrams with narrow windows for optimal superconducting phase formation.

Substrate compatibility issues further constrain material selection and processing parameters. The lattice mismatch between substrate and superconducting film can induce strain, dislocations, and other structural defects that degrade superconducting properties. Additionally, chemical reactions at the substrate-film interface during high-temperature processing may lead to unwanted diffusion and secondary phase formation.

Oxygen stoichiometry control represents a particularly challenging aspect for cuprate-based high-temperature superconductors, where oxygen content directly influences the carrier concentration and superconducting transition temperature. The spray pyrolysis environment must be carefully regulated to achieve optimal oxygen incorporation during film growth and subsequent annealing treatments.

Film thickness limitations also affect practical applications, as spray pyrolysis typically produces relatively thin films (100-500 nm). Thicker films often develop cracks and delamination due to thermal expansion mismatches and internal stresses during crystallization. This thickness constraint limits current-carrying capacity in applications requiring high critical currents.

Microstructural defects including porosity, grain boundaries, and secondary phases significantly impact superconducting performance. While some controlled defects can enhance flux pinning properties, uncontrolled defect formation during spray pyrolysis often degrades critical current density and transition temperature. Advanced characterization techniques and process optimization are essential to minimize detrimental defects while incorporating beneficial pinning centers.

Energy Efficiency and Scalability Assessment

The energy efficiency of spray pyrolysis processes for high-temperature superconductor (HTS) production represents a critical factor in determining commercial viability. Current spray pyrolysis systems demonstrate variable efficiency levels, with laboratory-scale operations typically operating at 30-45% energy efficiency. This relatively low efficiency stems primarily from heat losses during atomization and thermal treatment phases, where significant energy is expended to maintain precise temperature profiles necessary for proper crystal formation.

Industrial implementation requires substantial improvement in these metrics, with benchmark targets suggesting minimum efficiency thresholds of 60-70% for economically sustainable large-scale production. Recent innovations in atomizer design and heating element configuration have demonstrated promising efficiency gains of 15-20% in pilot studies, particularly through recapturing waste heat and optimizing spray parameters.

Scalability assessment reveals several critical challenges that must be addressed for industrial adoption. The transition from laboratory-scale production (typically producing grams of material) to industrial quantities (kilograms to tons) introduces significant engineering hurdles. Maintaining uniform droplet size distribution and consistent precursor chemistry becomes increasingly difficult as production volumes increase. Current technology demonstrates acceptable uniformity at laboratory scale but experiences degradation in quality parameters when scaled beyond 100g/hour production rates.

Equipment scaling follows non-linear cost curves, with capital expenditure increasing approximately as a power function (n≈0.7) of capacity. This relationship favors larger installations but introduces higher initial investment barriers. Continuous processing innovations, particularly in-line monitoring and feedback control systems, have shown potential to mitigate some scaling challenges by enabling real-time adjustments to process parameters.

Material throughput represents another key scalability metric, with current advanced systems achieving 0.2-0.5 kg/hour of finished HTS material. Industry requirements for commercial viability typically cite minimum throughput targets of 2-5 kg/hour, highlighting a significant gap between current capabilities and commercial requirements. Recent developments in multi-nozzle array configurations and continuous belt processing have demonstrated promising pathways to address this throughput limitation.

Energy consumption scaling presents a particular concern, with current systems requiring 75-120 kWh per kilogram of produced superconductor material. Efficiency improvements through process optimization and equipment redesign could potentially reduce this to 40-60 kWh/kg, representing a critical threshold for economic viability in many applications.

Industrial implementation requires substantial improvement in these metrics, with benchmark targets suggesting minimum efficiency thresholds of 60-70% for economically sustainable large-scale production. Recent innovations in atomizer design and heating element configuration have demonstrated promising efficiency gains of 15-20% in pilot studies, particularly through recapturing waste heat and optimizing spray parameters.

Scalability assessment reveals several critical challenges that must be addressed for industrial adoption. The transition from laboratory-scale production (typically producing grams of material) to industrial quantities (kilograms to tons) introduces significant engineering hurdles. Maintaining uniform droplet size distribution and consistent precursor chemistry becomes increasingly difficult as production volumes increase. Current technology demonstrates acceptable uniformity at laboratory scale but experiences degradation in quality parameters when scaled beyond 100g/hour production rates.

Equipment scaling follows non-linear cost curves, with capital expenditure increasing approximately as a power function (n≈0.7) of capacity. This relationship favors larger installations but introduces higher initial investment barriers. Continuous processing innovations, particularly in-line monitoring and feedback control systems, have shown potential to mitigate some scaling challenges by enabling real-time adjustments to process parameters.

Material throughput represents another key scalability metric, with current advanced systems achieving 0.2-0.5 kg/hour of finished HTS material. Industry requirements for commercial viability typically cite minimum throughput targets of 2-5 kg/hour, highlighting a significant gap between current capabilities and commercial requirements. Recent developments in multi-nozzle array configurations and continuous belt processing have demonstrated promising pathways to address this throughput limitation.

Energy consumption scaling presents a particular concern, with current systems requiring 75-120 kWh per kilogram of produced superconductor material. Efficiency improvements through process optimization and equipment redesign could potentially reduce this to 40-60 kWh/kg, representing a critical threshold for economic viability in many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!