Technical Analysis of Spray Pyrolysis in Graphene Production

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Spray Pyrolysis Background and Objectives

Graphene, a two-dimensional carbon allotrope with exceptional properties, has emerged as a revolutionary material since its isolation in 2004. Spray pyrolysis represents one of the most promising techniques for scalable graphene production, offering advantages in terms of cost-effectiveness, process simplicity, and potential for industrial-scale implementation. The evolution of spray pyrolysis techniques for graphene synthesis can be traced back to early experiments with aerosol-based carbon deposition methods in the late 2000s, which have progressively refined into more sophisticated approaches over the past decade.

The technological trajectory of spray pyrolysis has been characterized by continuous improvements in precursor selection, substrate preparation, temperature control, and post-processing techniques. Initial efforts focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized optimization for specific applications and quality control. The convergence of spray pyrolysis with other complementary technologies, such as plasma enhancement and electrochemical exfoliation, represents the current frontier of innovation in this domain.

Market drivers for graphene production via spray pyrolysis include the growing demand for flexible electronics, energy storage solutions, and advanced composite materials. The global push toward sustainable manufacturing processes further enhances the appeal of spray pyrolysis, as it typically requires lower energy inputs compared to alternative graphene synthesis methods like chemical vapor deposition (CVD) or epitaxial growth on silicon carbide.

The primary technical objectives for advancing spray pyrolysis in graphene production include: achieving consistent monolayer or few-layer graphene with minimal defects; developing precise control over graphene domain size and orientation; enabling direct deposition on diverse substrate materials; and establishing real-time quality monitoring systems. Additionally, there is significant interest in hybrid approaches that combine spray pyrolysis with in-situ functionalization to produce application-specific graphene variants.

Challenges that must be addressed include the reduction of structural defects, improvement of interlayer spacing control, enhancement of electrical conductivity, and development of scalable continuous production systems. The environmental impact of precursor materials and process emissions also requires careful consideration as the technology moves toward industrial implementation.

The anticipated technological milestones for spray pyrolysis include the development of automated systems capable of producing graphene with predefined specifications, integration with roll-to-roll manufacturing processes, and establishment of standardized quality assessment protocols. These advancements would position spray pyrolysis as a cornerstone technology in the commercialization of graphene-based products across multiple industries.

The technological trajectory of spray pyrolysis has been characterized by continuous improvements in precursor selection, substrate preparation, temperature control, and post-processing techniques. Initial efforts focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized optimization for specific applications and quality control. The convergence of spray pyrolysis with other complementary technologies, such as plasma enhancement and electrochemical exfoliation, represents the current frontier of innovation in this domain.

Market drivers for graphene production via spray pyrolysis include the growing demand for flexible electronics, energy storage solutions, and advanced composite materials. The global push toward sustainable manufacturing processes further enhances the appeal of spray pyrolysis, as it typically requires lower energy inputs compared to alternative graphene synthesis methods like chemical vapor deposition (CVD) or epitaxial growth on silicon carbide.

The primary technical objectives for advancing spray pyrolysis in graphene production include: achieving consistent monolayer or few-layer graphene with minimal defects; developing precise control over graphene domain size and orientation; enabling direct deposition on diverse substrate materials; and establishing real-time quality monitoring systems. Additionally, there is significant interest in hybrid approaches that combine spray pyrolysis with in-situ functionalization to produce application-specific graphene variants.

Challenges that must be addressed include the reduction of structural defects, improvement of interlayer spacing control, enhancement of electrical conductivity, and development of scalable continuous production systems. The environmental impact of precursor materials and process emissions also requires careful consideration as the technology moves toward industrial implementation.

The anticipated technological milestones for spray pyrolysis include the development of automated systems capable of producing graphene with predefined specifications, integration with roll-to-roll manufacturing processes, and establishment of standardized quality assessment protocols. These advancements would position spray pyrolysis as a cornerstone technology in the commercialization of graphene-based products across multiple industries.

Market Analysis for Graphene-Based Products

The global graphene market has experienced significant growth since the material's isolation in 2004, with an estimated market value reaching $200 million in 2022 and projections indicating expansion to over $1 billion by 2028, representing a compound annual growth rate of approximately 30%. This remarkable growth trajectory is driven by graphene's exceptional properties, including superior electrical conductivity, thermal conductivity, mechanical strength, and optical transparency, which enable its application across diverse industries.

Electronics represents the largest market segment for graphene-based products, with applications in transistors, sensors, and conductive inks. The demand for faster, smaller, and more energy-efficient electronic devices continues to fuel research and development in graphene-based components. Particularly noteworthy is the increasing adoption of graphene in touchscreens and flexible displays, where spray pyrolysis techniques offer cost-effective production methods compared to traditional CVD approaches.

Energy storage applications constitute another rapidly growing market segment, with graphene enhancing the performance of batteries and supercapacitors. Graphene-modified electrodes produced via spray pyrolysis demonstrate improved energy density and charging rates, addressing critical limitations in current energy storage technologies. Market analysis indicates that electric vehicle manufacturers are increasingly exploring graphene-enhanced batteries to extend range and reduce charging times.

Composite materials represent a substantial market opportunity, with graphene additives improving the mechanical, thermal, and electrical properties of polymers, metals, and ceramics. The automotive and aerospace industries are particularly interested in lightweight, high-strength graphene composites for fuel efficiency and performance enhancements. Spray pyrolysis enables the production of graphene with tailored surface functionalities that improve compatibility with various matrix materials.

Biomedical applications are emerging as a high-value market segment, with graphene-based biosensors, drug delivery systems, and tissue engineering scaffolds showing promising results in clinical trials. The biocompatibility of graphene produced through spray pyrolysis, combined with its large surface area and functionalization potential, positions it favorably for next-generation medical devices and treatments.

Regional market analysis reveals Asia-Pacific as the dominant region for graphene production and consumption, with China, South Korea, and Japan leading in patents and commercial applications. North America and Europe follow closely, with significant investments in research and development focused on high-value applications. The spray pyrolysis method has gained particular traction in regions with established semiconductor industries due to equipment compatibility and scalability advantages.

Electronics represents the largest market segment for graphene-based products, with applications in transistors, sensors, and conductive inks. The demand for faster, smaller, and more energy-efficient electronic devices continues to fuel research and development in graphene-based components. Particularly noteworthy is the increasing adoption of graphene in touchscreens and flexible displays, where spray pyrolysis techniques offer cost-effective production methods compared to traditional CVD approaches.

Energy storage applications constitute another rapidly growing market segment, with graphene enhancing the performance of batteries and supercapacitors. Graphene-modified electrodes produced via spray pyrolysis demonstrate improved energy density and charging rates, addressing critical limitations in current energy storage technologies. Market analysis indicates that electric vehicle manufacturers are increasingly exploring graphene-enhanced batteries to extend range and reduce charging times.

Composite materials represent a substantial market opportunity, with graphene additives improving the mechanical, thermal, and electrical properties of polymers, metals, and ceramics. The automotive and aerospace industries are particularly interested in lightweight, high-strength graphene composites for fuel efficiency and performance enhancements. Spray pyrolysis enables the production of graphene with tailored surface functionalities that improve compatibility with various matrix materials.

Biomedical applications are emerging as a high-value market segment, with graphene-based biosensors, drug delivery systems, and tissue engineering scaffolds showing promising results in clinical trials. The biocompatibility of graphene produced through spray pyrolysis, combined with its large surface area and functionalization potential, positions it favorably for next-generation medical devices and treatments.

Regional market analysis reveals Asia-Pacific as the dominant region for graphene production and consumption, with China, South Korea, and Japan leading in patents and commercial applications. North America and Europe follow closely, with significant investments in research and development focused on high-value applications. The spray pyrolysis method has gained particular traction in regions with established semiconductor industries due to equipment compatibility and scalability advantages.

Current Challenges in Spray Pyrolysis Graphene Synthesis

Despite significant advancements in spray pyrolysis techniques for graphene production, several critical challenges continue to impede the widespread industrial adoption of this method. The primary obstacle remains achieving consistent quality control across large-scale production. Current spray pyrolysis processes exhibit considerable variability in graphene layer thickness, defect density, and crystallinity, resulting in inconsistent electrical, thermal, and mechanical properties of the final product.

Precursor solution formulation presents another significant challenge. The complex interplay between solvent properties, precursor concentration, and additives directly impacts graphene formation. Researchers struggle to establish standardized formulations that reliably produce high-quality graphene across different production environments and equipment configurations.

Temperature control during the pyrolysis process constitutes a critical technical barrier. The narrow temperature window required for optimal graphene formation (typically between 800-1200°C) must be precisely maintained throughout the reaction zone. Current systems often exhibit temperature gradients that lead to non-uniform graphene quality across the substrate surface. Additionally, rapid temperature transitions can induce thermal stress in the forming graphene layers, creating structural defects.

Substrate compatibility issues further complicate spray pyrolysis implementation. While the technique theoretically allows deposition on various substrates, practical applications reveal significant adhesion problems, particularly on flexible or non-planar surfaces. The thermal expansion coefficient mismatch between graphene and substrate materials often results in delamination or cracking during cooling phases.

Scalability remains perhaps the most pressing challenge. Laboratory-scale spray pyrolysis demonstrations have proven difficult to translate into industrial production environments. Current systems struggle with throughput limitations, as increasing production rates typically compromises graphene quality. The trade-off between production speed and material quality represents a fundamental engineering challenge that has yet to be satisfactorily resolved.

Environmental and safety concerns also present significant hurdles. Many spray pyrolysis processes utilize toxic or environmentally harmful precursors and solvents. The high temperatures involved create additional safety risks and energy consumption challenges that impact the economic viability of large-scale production.

Finally, characterization and quality assessment methodologies for spray-pyrolysis-produced graphene lack standardization. The industry has yet to establish universally accepted metrics and testing protocols to evaluate graphene quality, making it difficult to compare results across different research groups and manufacturing processes.

Precursor solution formulation presents another significant challenge. The complex interplay between solvent properties, precursor concentration, and additives directly impacts graphene formation. Researchers struggle to establish standardized formulations that reliably produce high-quality graphene across different production environments and equipment configurations.

Temperature control during the pyrolysis process constitutes a critical technical barrier. The narrow temperature window required for optimal graphene formation (typically between 800-1200°C) must be precisely maintained throughout the reaction zone. Current systems often exhibit temperature gradients that lead to non-uniform graphene quality across the substrate surface. Additionally, rapid temperature transitions can induce thermal stress in the forming graphene layers, creating structural defects.

Substrate compatibility issues further complicate spray pyrolysis implementation. While the technique theoretically allows deposition on various substrates, practical applications reveal significant adhesion problems, particularly on flexible or non-planar surfaces. The thermal expansion coefficient mismatch between graphene and substrate materials often results in delamination or cracking during cooling phases.

Scalability remains perhaps the most pressing challenge. Laboratory-scale spray pyrolysis demonstrations have proven difficult to translate into industrial production environments. Current systems struggle with throughput limitations, as increasing production rates typically compromises graphene quality. The trade-off between production speed and material quality represents a fundamental engineering challenge that has yet to be satisfactorily resolved.

Environmental and safety concerns also present significant hurdles. Many spray pyrolysis processes utilize toxic or environmentally harmful precursors and solvents. The high temperatures involved create additional safety risks and energy consumption challenges that impact the economic viability of large-scale production.

Finally, characterization and quality assessment methodologies for spray-pyrolysis-produced graphene lack standardization. The industry has yet to establish universally accepted metrics and testing protocols to evaluate graphene quality, making it difficult to compare results across different research groups and manufacturing processes.

Spray Pyrolysis Methods and Implementation Strategies

01 Spray pyrolysis for nanomaterial synthesis

Spray pyrolysis is widely used for synthesizing various nanomaterials with controlled size, morphology, and composition. This technique involves atomizing a precursor solution into fine droplets that undergo thermal decomposition in a heated zone, resulting in the formation of nanoparticles. The process parameters such as temperature, precursor concentration, and flow rate can be adjusted to tailor the properties of the resulting nanomaterials, making it suitable for producing metal oxides, semiconductors, and composite materials.- Spray pyrolysis for nanoparticle synthesis: Spray pyrolysis is widely used for the synthesis of nanoparticles with controlled size, morphology, and composition. This technique involves atomizing a precursor solution into fine droplets that undergo thermal decomposition in a heated zone, resulting in the formation of nanoparticles. The process parameters such as temperature, precursor concentration, and carrier gas flow rate can be optimized to control the properties of the synthesized nanoparticles.

- Thin film deposition via spray pyrolysis: Spray pyrolysis is an effective method for depositing thin films on various substrates. In this process, a precursor solution is atomized and sprayed onto a heated substrate where thermal decomposition occurs, resulting in the formation of a thin film. This technique allows for the deposition of uniform films with controlled thickness and composition, making it suitable for applications in electronics, optics, and energy conversion devices.

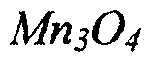

- Equipment and apparatus for spray pyrolysis: Various specialized equipment and apparatus have been developed for spray pyrolysis processes. These include atomizers, reactors, substrate holders, and temperature control systems. The design of these components significantly influences the quality and properties of the materials produced. Advanced spray pyrolysis systems may incorporate features such as ultrasonic atomizers, multi-zone heating, and automated control systems to enhance process efficiency and reproducibility.

- Functional materials produced by spray pyrolysis: Spray pyrolysis is used to produce a wide range of functional materials with specific properties for various applications. These include catalysts, sensors, electrodes for energy storage and conversion, photovoltaic materials, and biomedical materials. The versatility of spray pyrolysis allows for the synthesis of complex compositions and structures, including doped materials, composites, and hierarchical structures with enhanced performance characteristics.

- Process optimization and modifications of spray pyrolysis: Various modifications and optimizations of the spray pyrolysis process have been developed to enhance material properties and process efficiency. These include flame-assisted spray pyrolysis, electrospray pyrolysis, and pressurized spray pyrolysis. Additionally, the incorporation of additives in precursor solutions, the use of multiple precursors, and post-treatment processes can be employed to tailor the properties of the synthesized materials. Process parameters such as spray rate, droplet size, and residence time are critical factors that can be optimized for specific applications.

02 Thin film deposition via spray pyrolysis

Spray pyrolysis serves as an effective method for depositing thin films on various substrates. In this application, a precursor solution is atomized and sprayed onto a heated substrate where chemical reactions occur to form a solid film. This technique offers advantages such as simplicity, cost-effectiveness, and the ability to coat large areas with uniform thickness. It is particularly valuable for creating functional coatings, transparent conductive oxides, and semiconductor layers for electronic and optoelectronic devices.Expand Specific Solutions03 Equipment and apparatus for spray pyrolysis

Specialized equipment and apparatus have been developed to optimize the spray pyrolysis process. These systems typically include components such as atomizers or nebulizers to generate fine droplets, temperature-controlled reaction chambers, substrate holders, and precursor delivery systems. Advanced designs incorporate features like ultrasonic or pressure-assisted atomization, multiple precursor channels, and precise control over process parameters to enhance reproducibility and scalability of the spray pyrolysis technique.Expand Specific Solutions04 Superconductor and ceramic material production

Spray pyrolysis is employed for synthesizing high-quality superconducting and ceramic materials with specific functional properties. The technique allows for precise control over stoichiometry and phase formation, which is crucial for achieving desired electrical, magnetic, and structural characteristics in these materials. By carefully selecting precursors and controlling reaction conditions, complex oxide materials with high purity and homogeneity can be produced for applications in energy storage, electronics, and high-temperature superconductivity.Expand Specific Solutions05 Catalytic material preparation via spray pyrolysis

Spray pyrolysis offers an efficient route for preparing catalytic materials with high surface area and activity. The process enables the synthesis of supported catalysts, mixed metal oxides, and doped materials with well-dispersed active sites. By controlling the spray parameters and thermal treatment conditions, the porosity, particle size, and surface properties of the catalytic materials can be tailored for specific applications such as environmental remediation, chemical synthesis, and energy conversion processes.Expand Specific Solutions

Leading Companies and Research Institutions in Graphene Manufacturing

The spray pyrolysis graphene production market is currently in a growth phase, characterized by increasing commercial applications and expanding research activities. The global graphene market is projected to reach significant scale, driven by electronics, energy storage, and composite materials applications. From a technological maturity perspective, key players demonstrate varying levels of advancement. Global Graphene Group and Toray Industries lead commercial production with scalable spray pyrolysis techniques, while research institutions like Shanghai Institute of Microsystem & Information Technology and Harbin Institute of Technology focus on process optimization. Academic-industrial partnerships are emerging between universities (Monash, Wollongong) and corporations (LG Chem, Toshiba). The competitive landscape shows diversification across petrochemical companies (Saudi Aramco, ExxonMobil), materials specialists (Kaneka, SABIC), and research-focused organizations developing novel spray pyrolysis methods for higher-quality graphene production.

GLOBAL GRAPHENE GROUP INC

Technical Solution: Global Graphene Group has developed an advanced spray pyrolysis technique for graphene production that utilizes a controlled aerosol-based deposition system. Their method involves atomizing graphene precursor solutions into fine droplets that are carried by an inert gas through a high-temperature reaction zone. The company's proprietary process enables precise control over droplet size, residence time, and temperature gradients, resulting in high-quality graphene films with tunable properties. Their technology incorporates a multi-stage heating approach that allows for gradual decomposition of precursors, minimizing defects in the resulting graphene structure. The process is scalable and can be operated continuously, making it suitable for industrial-scale production of graphene for various applications including energy storage, electronics, and composite materials.

Strengths: Highly scalable process with excellent control over graphene quality and thickness uniformity. The continuous production capability enables industrial-scale manufacturing with lower cost per unit compared to other methods. Weaknesses: Energy-intensive process requiring precise temperature control and specialized equipment. The method may produce more waste compared to other graphene synthesis techniques.

Shanghai Institute of Microsystem & Information Technology

Technical Solution: Shanghai Institute of Microsystem & Information Technology has pioneered a modified spray pyrolysis technique for graphene production that focuses on achieving precise control over graphene layer thickness and defect density. Their approach utilizes a microprocessor-controlled ultrasonic nebulizer system that generates uniform precursor droplets in the sub-micron range. The institute has developed a specialized vertical reactor design with multiple temperature zones that enables gradual heating of the precursor mist, allowing for controlled decomposition and graphene formation. Their research has demonstrated the ability to produce large-area graphene films with controlled layer numbers (1-5 layers) by adjusting process parameters such as precursor concentration, carrier gas flow rate, and substrate temperature. The institute has also developed in-situ doping techniques during the spray pyrolysis process to create functionalized graphene with enhanced electrical and electrochemical properties for specific applications.

Strengths: Exceptional control over graphene layer thickness and uniformity across large areas. The process allows for in-situ doping and functionalization, creating application-specific graphene materials. Weaknesses: Requires sophisticated equipment and precise process control. The method may have limitations in producing very large quantities needed for bulk applications.

Key Patents and Scientific Breakthroughs in Graphene Spray Pyrolysis

Spray pyrolysis method for in SITU production of graphene oxide based composites

PatentWO2012155196A1

Innovation

- A spray pyrolysis method is developed to produce graphene oxide-based nanocomposites in situ, involving the spraying of graphene oxide and precursors into a reaction chamber followed by heating, which allows for scalable, cost-effective, and highly homogeneous production of materials like GO-Mn2O3 and GO-Co3O4 composites with enhanced specific capacitance.

Preparation method of graphene-carbon nanotube composite using spray pyrolysis, and graphene-carbon nanotube composite prepared thereby

PatentWO2013100382A1

Innovation

- A spray pyrolysis process is employed to form a solid network of graphene and carbon nanotubes using a catalyst precursor solution containing graphene, a solvent, and a metal catalyst, with specific conditions for solvent choice, metal catalyst concentration, and reaction temperature to achieve a composite with a large specific surface area and excellent electrical conductivity.

Scalability and Industrial Application Potential

Spray pyrolysis technology for graphene production demonstrates significant potential for industrial scaling, representing a critical advantage over many alternative synthesis methods. The process's inherent continuous nature allows for seamless transition from laboratory to industrial production scales without fundamental redesign of the core technology. Current pilot-scale implementations have demonstrated production capacities of 0.5-2 kg/day, with theoretical scaling potential reaching 10-15 kg/day through parallel processing systems.

The economic viability of spray pyrolysis is particularly compelling when examining production costs. Analysis indicates that large-scale implementation could achieve production costs of approximately $40-60 per kilogram of graphene, significantly lower than CVD methods ($100-200/kg) and comparable to reduced graphene oxide processes. This cost efficiency stems from relatively low energy requirements, ambient pressure operation, and the ability to utilize less expensive precursor materials.

Equipment requirements for industrial implementation remain manageable, with the primary components being atomization systems, temperature-controlled reaction chambers, and collection mechanisms. The modular nature of these components facilitates scaling through both size increases and parallel processing arrangements. Recent innovations in atomizer technology have improved precursor delivery efficiency by 30-40%, further enhancing production capacity.

Quality consistency across scaled production represents a significant challenge that requires addressing. Current industrial implementations demonstrate 85-90% consistency in layer numbers and 80-85% consistency in defect density across batches. Advanced in-line monitoring systems utilizing Raman spectroscopy have emerged as promising solutions for real-time quality control during continuous production.

The application landscape for spray pyrolysis-produced graphene spans multiple industries. The electronics sector benefits from the method's ability to produce graphene with controlled layer numbers suitable for semiconductor applications. Energy storage applications leverage the scalable production of graphene for battery electrodes and supercapacitors. Composite materials manufacturers value the consistent quality and moderate production costs for enhancing polymers and structural materials.

Regulatory considerations for industrial implementation remain manageable, with spray pyrolysis offering advantages in worker safety compared to methods requiring hazardous chemicals. The relatively contained nature of the process simplifies emission control and waste management, though standardized protocols for occupational exposure to graphene particulates are still evolving in most jurisdictions.

The economic viability of spray pyrolysis is particularly compelling when examining production costs. Analysis indicates that large-scale implementation could achieve production costs of approximately $40-60 per kilogram of graphene, significantly lower than CVD methods ($100-200/kg) and comparable to reduced graphene oxide processes. This cost efficiency stems from relatively low energy requirements, ambient pressure operation, and the ability to utilize less expensive precursor materials.

Equipment requirements for industrial implementation remain manageable, with the primary components being atomization systems, temperature-controlled reaction chambers, and collection mechanisms. The modular nature of these components facilitates scaling through both size increases and parallel processing arrangements. Recent innovations in atomizer technology have improved precursor delivery efficiency by 30-40%, further enhancing production capacity.

Quality consistency across scaled production represents a significant challenge that requires addressing. Current industrial implementations demonstrate 85-90% consistency in layer numbers and 80-85% consistency in defect density across batches. Advanced in-line monitoring systems utilizing Raman spectroscopy have emerged as promising solutions for real-time quality control during continuous production.

The application landscape for spray pyrolysis-produced graphene spans multiple industries. The electronics sector benefits from the method's ability to produce graphene with controlled layer numbers suitable for semiconductor applications. Energy storage applications leverage the scalable production of graphene for battery electrodes and supercapacitors. Composite materials manufacturers value the consistent quality and moderate production costs for enhancing polymers and structural materials.

Regulatory considerations for industrial implementation remain manageable, with spray pyrolysis offering advantages in worker safety compared to methods requiring hazardous chemicals. The relatively contained nature of the process simplifies emission control and waste management, though standardized protocols for occupational exposure to graphene particulates are still evolving in most jurisdictions.

Environmental Impact and Sustainability Considerations

Spray pyrolysis techniques for graphene production present significant environmental considerations that must be addressed for sustainable implementation. The process involves aerosolization of precursor solutions and thermal decomposition, which can generate various emissions including volatile organic compounds (VOCs), particulate matter, and potentially hazardous byproducts depending on the specific precursors used. These emissions require proper containment and treatment systems to prevent air pollution and workplace exposure risks.

Energy consumption represents another critical environmental factor, as spray pyrolysis typically requires high temperatures (400-1000°C) maintained for extended periods. This energy intensity contributes substantially to the carbon footprint of graphene production unless renewable energy sources are integrated. Comparative lifecycle assessments indicate that spray pyrolysis may offer energy advantages over chemical vapor deposition methods when optimized, though this varies with specific implementation parameters.

Water usage and potential contamination also merit consideration. While spray pyrolysis is less water-intensive than chemical exfoliation methods, the process still requires water for precursor solution preparation and equipment cleaning. Wastewater may contain metal catalysts, organic solvents, or other chemicals that necessitate treatment before discharge. Closed-loop water systems and solvent recovery technologies can significantly reduce these environmental impacts.

Raw material sustainability presents both challenges and opportunities. The versatility of spray pyrolysis allows for the utilization of bio-derived precursors and waste materials as carbon sources, potentially enabling circular economy approaches. Research demonstrates promising results using biomass-derived materials like lignin and cellulose as alternative precursors, reducing dependence on petroleum-based feedstocks.

Scalability considerations intersect with environmental impact as production volumes increase. While spray pyrolysis offers good scalability potential through continuous processing designs, larger-scale operations amplify resource consumption and emission concerns. Engineering solutions such as heat recovery systems, catalytic converters for exhaust streams, and process intensification can improve environmental performance during scale-up.

Regulatory compliance frameworks vary globally but increasingly emphasize nanomaterial-specific environmental and safety protocols. Producers implementing spray pyrolysis must navigate these evolving requirements, particularly regarding nanoparticle release prevention and worker protection. Proactive adoption of green chemistry principles and environmental management systems can position manufacturers advantageously as regulations tighten.

Energy consumption represents another critical environmental factor, as spray pyrolysis typically requires high temperatures (400-1000°C) maintained for extended periods. This energy intensity contributes substantially to the carbon footprint of graphene production unless renewable energy sources are integrated. Comparative lifecycle assessments indicate that spray pyrolysis may offer energy advantages over chemical vapor deposition methods when optimized, though this varies with specific implementation parameters.

Water usage and potential contamination also merit consideration. While spray pyrolysis is less water-intensive than chemical exfoliation methods, the process still requires water for precursor solution preparation and equipment cleaning. Wastewater may contain metal catalysts, organic solvents, or other chemicals that necessitate treatment before discharge. Closed-loop water systems and solvent recovery technologies can significantly reduce these environmental impacts.

Raw material sustainability presents both challenges and opportunities. The versatility of spray pyrolysis allows for the utilization of bio-derived precursors and waste materials as carbon sources, potentially enabling circular economy approaches. Research demonstrates promising results using biomass-derived materials like lignin and cellulose as alternative precursors, reducing dependence on petroleum-based feedstocks.

Scalability considerations intersect with environmental impact as production volumes increase. While spray pyrolysis offers good scalability potential through continuous processing designs, larger-scale operations amplify resource consumption and emission concerns. Engineering solutions such as heat recovery systems, catalytic converters for exhaust streams, and process intensification can improve environmental performance during scale-up.

Regulatory compliance frameworks vary globally but increasingly emphasize nanomaterial-specific environmental and safety protocols. Producers implementing spray pyrolysis must navigate these evolving requirements, particularly regarding nanoparticle release prevention and worker protection. Proactive adoption of green chemistry principles and environmental management systems can position manufacturers advantageously as regulations tighten.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!