Regulatory Challenges in Spray Pyrolysis Coating Processes

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Coating Regulatory Background and Objectives

Spray pyrolysis coating technology has evolved significantly over the past five decades, transitioning from laboratory-scale experiments to industrial applications. Initially developed in the 1970s for semiconductor applications, this technique has expanded into various sectors including solar cells, protective coatings, and biomedical devices. The evolution of spray pyrolysis has been characterized by continuous improvements in process control, precursor chemistry, and equipment design, leading to enhanced coating quality and reproducibility.

The regulatory landscape surrounding spray pyrolysis coating processes has become increasingly complex as applications diversify. Early regulations primarily focused on occupational safety concerns related to aerosol generation and thermal processes. However, as the technology found applications in sensitive sectors like medical devices and food packaging, regulatory frameworks expanded to address product safety, environmental impact, and quality assurance requirements.

Current global regulatory challenges stem from the fragmented nature of international standards governing chemical processes, aerosol technologies, and nanomaterial production. The European Union's REACH regulation, the US EPA's Clean Air Act provisions, and various ISO standards collectively create a complex compliance environment for manufacturers employing spray pyrolysis techniques. This regulatory heterogeneity presents significant barriers to global market access and technology transfer.

The primary technical objective of this research is to develop a comprehensive understanding of the regulatory challenges specific to spray pyrolysis coating processes across major global markets. This includes identifying regulatory gaps, conflicting requirements, and emerging compliance issues that may impact industrial implementation and commercialization of spray pyrolysis technologies.

Additionally, this research aims to establish a systematic framework for regulatory risk assessment tailored to spray pyrolysis processes, considering variables such as precursor toxicity, aerosol characteristics, thermal decomposition byproducts, and final coating properties. This framework would enable manufacturers to anticipate regulatory hurdles during technology development rather than addressing them retroactively.

The long-term goal is to contribute to the development of harmonized international standards specifically addressing spray pyrolysis coating processes. By identifying best practices and common regulatory concerns across jurisdictions, this research seeks to facilitate the creation of industry-specific guidelines that balance innovation with safety, environmental protection, and product quality considerations.

Understanding the historical regulatory evolution and current compliance landscape will provide valuable context for technology developers, helping them navigate complex approval processes and design spray pyrolysis systems that meet global regulatory requirements from inception rather than through costly modifications.

The regulatory landscape surrounding spray pyrolysis coating processes has become increasingly complex as applications diversify. Early regulations primarily focused on occupational safety concerns related to aerosol generation and thermal processes. However, as the technology found applications in sensitive sectors like medical devices and food packaging, regulatory frameworks expanded to address product safety, environmental impact, and quality assurance requirements.

Current global regulatory challenges stem from the fragmented nature of international standards governing chemical processes, aerosol technologies, and nanomaterial production. The European Union's REACH regulation, the US EPA's Clean Air Act provisions, and various ISO standards collectively create a complex compliance environment for manufacturers employing spray pyrolysis techniques. This regulatory heterogeneity presents significant barriers to global market access and technology transfer.

The primary technical objective of this research is to develop a comprehensive understanding of the regulatory challenges specific to spray pyrolysis coating processes across major global markets. This includes identifying regulatory gaps, conflicting requirements, and emerging compliance issues that may impact industrial implementation and commercialization of spray pyrolysis technologies.

Additionally, this research aims to establish a systematic framework for regulatory risk assessment tailored to spray pyrolysis processes, considering variables such as precursor toxicity, aerosol characteristics, thermal decomposition byproducts, and final coating properties. This framework would enable manufacturers to anticipate regulatory hurdles during technology development rather than addressing them retroactively.

The long-term goal is to contribute to the development of harmonized international standards specifically addressing spray pyrolysis coating processes. By identifying best practices and common regulatory concerns across jurisdictions, this research seeks to facilitate the creation of industry-specific guidelines that balance innovation with safety, environmental protection, and product quality considerations.

Understanding the historical regulatory evolution and current compliance landscape will provide valuable context for technology developers, helping them navigate complex approval processes and design spray pyrolysis systems that meet global regulatory requirements from inception rather than through costly modifications.

Market Demand Analysis for Compliant Coating Technologies

The global market for compliant coating technologies in spray pyrolysis processes has experienced significant growth in recent years, driven primarily by increasing regulatory pressures across multiple industries. Current market analysis indicates that industries including automotive, electronics, medical devices, and aerospace are actively seeking coating solutions that meet stringent environmental and safety regulations while maintaining performance standards.

Market research shows that the demand for environmentally compliant coating technologies is projected to grow at a compound annual rate of 7.2% through 2028, with particularly strong growth in regions with strict regulatory frameworks such as the European Union, North America, and increasingly in parts of Asia. This growth is directly correlated with the implementation of more stringent VOC (Volatile Organic Compound) emission standards and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance requirements.

Customer surveys across manufacturing sectors reveal that approximately 68% of industrial coating users cite regulatory compliance as a primary concern when selecting coating technologies, ranking it above cost considerations. This represents a significant shift from previous market priorities where performance and cost were dominant decision factors.

The healthcare and medical device sectors demonstrate particularly strong demand growth for compliant spray pyrolysis coating technologies, driven by biocompatibility requirements and patient safety regulations. These sectors value coating technologies that can provide both functional performance and regulatory certainty, with willingness-to-pay metrics showing premium pricing acceptance for solutions with proven compliance records.

Regional market analysis indicates varying levels of demand maturity. European markets show the highest immediate demand for compliant technologies due to established regulatory frameworks, while emerging markets in Asia-Pacific demonstrate the fastest growth trajectory as these regions implement similar regulatory standards. North American markets maintain steady demand growth driven by industry self-regulation and anticipated regulatory developments.

Industry surveys indicate that manufacturers are increasingly seeking integrated compliance solutions rather than standalone coating technologies. This trend is creating market opportunities for providers who can offer comprehensive packages including compliant coating technologies, documentation systems, and regulatory navigation services.

The economic impact of non-compliance has become a significant market driver, with companies reporting average regulatory violation costs exceeding $250,000 per incident when including fines, remediation, production delays, and reputational damage. This economic reality has transformed regulatory compliance from a burden to a value proposition in the coating technology marketplace.

Market research shows that the demand for environmentally compliant coating technologies is projected to grow at a compound annual rate of 7.2% through 2028, with particularly strong growth in regions with strict regulatory frameworks such as the European Union, North America, and increasingly in parts of Asia. This growth is directly correlated with the implementation of more stringent VOC (Volatile Organic Compound) emission standards and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance requirements.

Customer surveys across manufacturing sectors reveal that approximately 68% of industrial coating users cite regulatory compliance as a primary concern when selecting coating technologies, ranking it above cost considerations. This represents a significant shift from previous market priorities where performance and cost were dominant decision factors.

The healthcare and medical device sectors demonstrate particularly strong demand growth for compliant spray pyrolysis coating technologies, driven by biocompatibility requirements and patient safety regulations. These sectors value coating technologies that can provide both functional performance and regulatory certainty, with willingness-to-pay metrics showing premium pricing acceptance for solutions with proven compliance records.

Regional market analysis indicates varying levels of demand maturity. European markets show the highest immediate demand for compliant technologies due to established regulatory frameworks, while emerging markets in Asia-Pacific demonstrate the fastest growth trajectory as these regions implement similar regulatory standards. North American markets maintain steady demand growth driven by industry self-regulation and anticipated regulatory developments.

Industry surveys indicate that manufacturers are increasingly seeking integrated compliance solutions rather than standalone coating technologies. This trend is creating market opportunities for providers who can offer comprehensive packages including compliant coating technologies, documentation systems, and regulatory navigation services.

The economic impact of non-compliance has become a significant market driver, with companies reporting average regulatory violation costs exceeding $250,000 per incident when including fines, remediation, production delays, and reputational damage. This economic reality has transformed regulatory compliance from a burden to a value proposition in the coating technology marketplace.

Regulatory Hurdles and Technical Limitations in Spray Pyrolysis

Spray pyrolysis coating processes face significant regulatory challenges across multiple jurisdictions, creating a complex compliance landscape for manufacturers and researchers. Environmental regulations represent the primary hurdle, with strict limitations on volatile organic compound (VOC) emissions during the coating process. The US Environmental Protection Agency's Clean Air Act and the European Union's VOC Solvents Emissions Directive impose stringent thresholds that often necessitate substantial modifications to traditional spray pyrolysis systems.

Workplace safety regulations constitute another major challenge, as spray pyrolysis typically involves high temperatures and potentially hazardous precursor chemicals. Occupational Safety and Health Administration (OSHA) standards in the US and similar regulations worldwide mandate specific ventilation requirements, personal protective equipment, and exposure monitoring protocols that increase operational complexity and costs.

Chemical registration requirements further complicate implementation, with regulations such as REACH in Europe and TSCA in the United States requiring extensive documentation and testing of chemical substances used in the process. Many specialty precursors used in advanced spray pyrolysis applications face additional scrutiny due to their novel nature or potential environmental persistence.

From a technical perspective, spray pyrolysis faces several inherent limitations that restrict its industrial scalability. Achieving uniform coating thickness across large substrate areas remains problematic, with edge effects and flow inconsistencies creating quality variations that are difficult to control in production environments. This challenge becomes particularly acute when coating complex three-dimensional geometries.

Temperature control represents another significant technical barrier. The rapid thermal gradients inherent in spray pyrolysis can lead to thermal stress, cracking, and delamination in the resulting coatings. These issues become more pronounced as substrate dimensions increase, limiting practical applications to relatively small components in many industries.

Precursor chemistry compatibility issues also constrain spray pyrolysis applications. Many advanced functional coatings require precursor combinations that exhibit poor solubility compatibility or different decomposition kinetics, resulting in phase separation or compositional inhomogeneity in the final coating. This limitation is particularly restrictive for multi-component systems requiring precise stoichiometric control.

The combination of these regulatory hurdles and technical limitations has significantly slowed the industrial adoption of spray pyrolysis coating processes despite their theoretical advantages in terms of cost and simplicity. Addressing these challenges requires a multidisciplinary approach combining chemical engineering innovations, regulatory expertise, and process control advancements.

Workplace safety regulations constitute another major challenge, as spray pyrolysis typically involves high temperatures and potentially hazardous precursor chemicals. Occupational Safety and Health Administration (OSHA) standards in the US and similar regulations worldwide mandate specific ventilation requirements, personal protective equipment, and exposure monitoring protocols that increase operational complexity and costs.

Chemical registration requirements further complicate implementation, with regulations such as REACH in Europe and TSCA in the United States requiring extensive documentation and testing of chemical substances used in the process. Many specialty precursors used in advanced spray pyrolysis applications face additional scrutiny due to their novel nature or potential environmental persistence.

From a technical perspective, spray pyrolysis faces several inherent limitations that restrict its industrial scalability. Achieving uniform coating thickness across large substrate areas remains problematic, with edge effects and flow inconsistencies creating quality variations that are difficult to control in production environments. This challenge becomes particularly acute when coating complex three-dimensional geometries.

Temperature control represents another significant technical barrier. The rapid thermal gradients inherent in spray pyrolysis can lead to thermal stress, cracking, and delamination in the resulting coatings. These issues become more pronounced as substrate dimensions increase, limiting practical applications to relatively small components in many industries.

Precursor chemistry compatibility issues also constrain spray pyrolysis applications. Many advanced functional coatings require precursor combinations that exhibit poor solubility compatibility or different decomposition kinetics, resulting in phase separation or compositional inhomogeneity in the final coating. This limitation is particularly restrictive for multi-component systems requiring precise stoichiometric control.

The combination of these regulatory hurdles and technical limitations has significantly slowed the industrial adoption of spray pyrolysis coating processes despite their theoretical advantages in terms of cost and simplicity. Addressing these challenges requires a multidisciplinary approach combining chemical engineering innovations, regulatory expertise, and process control advancements.

Current Compliance Solutions for Spray Pyrolysis Processes

01 Environmental compliance in spray pyrolysis coating

Spray pyrolysis coating processes face regulatory challenges related to environmental compliance, particularly regarding emissions control and waste management. Manufacturers must adhere to strict air quality regulations due to potential release of volatile organic compounds and particulate matter during the coating process. Advanced filtration systems and emission control technologies are required to meet increasingly stringent environmental standards across different jurisdictions.- Environmental compliance in spray pyrolysis coating: Spray pyrolysis coating processes face regulatory challenges related to environmental compliance, particularly regarding emissions control and waste management. Manufacturers must adhere to strict air quality regulations due to potential release of volatile organic compounds and particulate matter during the coating process. Advanced filtration systems and emission control technologies are required to meet increasingly stringent environmental standards across different jurisdictions.

- Worker safety and occupational health regulations: Regulatory frameworks for worker safety present significant challenges for spray pyrolysis coating operations. These regulations address exposure limits to hazardous materials, requirements for personal protective equipment, ventilation standards, and monitoring protocols. Companies must implement comprehensive safety training programs and engineering controls to minimize worker exposure to potentially harmful chemicals and particulates generated during the spray pyrolysis process.

- Chemical substance registration and compliance: Spray pyrolysis coating processes often involve various chemical substances that require registration and compliance with chemical management regulations such as REACH in Europe, TSCA in the United States, and similar frameworks in other regions. Manufacturers must maintain detailed documentation of chemical inventories, conduct risk assessments, and potentially reformulate coatings to eliminate substances of very high concern. This regulatory landscape is complex and constantly evolving, requiring ongoing vigilance and adaptation.

- Quality control and product certification standards: Regulatory challenges exist in meeting quality control and product certification standards for spray pyrolysis coatings. These include adherence to industry-specific performance requirements, durability standards, and testing protocols. Manufacturers must implement robust quality management systems to ensure consistency in coating thickness, adhesion, and functional properties. Third-party certification may be required for specific applications, particularly in highly regulated industries such as automotive, aerospace, and medical devices.

- Equipment validation and process standardization: Regulatory frameworks often require validation of spray pyrolysis coating equipment and standardization of processes to ensure reproducibility and safety. This includes calibration requirements, maintenance protocols, and documentation of operating procedures. Manufacturers must demonstrate that their equipment meets design specifications and that processes are conducted under controlled conditions. Automated monitoring systems may be required to verify compliance with established parameters and to maintain records for regulatory inspections.

02 Worker safety and occupational health regulations

Regulatory frameworks governing worker safety present significant challenges for spray pyrolysis coating operations. These include requirements for proper ventilation systems, personal protective equipment, and exposure monitoring for potentially hazardous materials used in the coating process. Companies must implement comprehensive training programs and safety protocols to comply with occupational health standards and prevent workplace injuries or long-term health effects from chemical exposure.Expand Specific Solutions03 Quality control and standardization requirements

Spray pyrolysis coating processes are subject to strict quality control regulations and standardization requirements across different industries. These include adherence to specific coating thickness tolerances, uniformity standards, and performance specifications. Manufacturers must implement robust testing protocols and documentation procedures to demonstrate compliance with industry-specific standards, which may vary significantly between sectors such as electronics, automotive, and medical devices.Expand Specific Solutions04 Chemical substance registration and restrictions

Regulatory challenges arise from the need to register and manage chemical substances used in spray pyrolysis coating processes. Various global regulations such as REACH in Europe and similar frameworks in other regions impose requirements for testing, documentation, and sometimes substitution of certain chemicals. Manufacturers must navigate complex chemical inventories, authorization processes, and potential restrictions on substances of high concern, which can impact formulation options and process design.Expand Specific Solutions05 International trade and compliance variations

Spray pyrolysis coating processes face regulatory challenges related to international trade and regional compliance variations. Manufacturers operating globally must navigate different regulatory frameworks across countries, including import/export restrictions, tariffs, and varying technical requirements. This necessitates adaptable production processes and comprehensive compliance strategies to address regional differences in environmental standards, product safety requirements, and certification procedures.Expand Specific Solutions

Key Industry Players and Regulatory Stakeholders

The regulatory landscape for Spray Pyrolysis Coating Processes is evolving within a rapidly growing market, currently in its early maturity phase with significant expansion potential. The technology is advancing through various stages of commercialization, with key players demonstrating different levels of technical maturity. Beneq Group leads with advanced atomic layer deposition capabilities, while established chemical manufacturers like BASF, Merck Patent GmbH, and L'Oréal are investing in scalable applications. Research institutions including Fudan University and the National Research Council of Canada are driving fundamental innovations. Industrial players such as Ford Motor Co. and Nordson Corp. are adapting the technology for specialized coating applications, creating a competitive environment where regulatory compliance is becoming a critical differentiator as the technology moves toward widespread industrial adoption.

Beneq Group Oy

Technical Solution: Beneq has developed advanced Atomic Layer Deposition (ALD) technology that complements their spray pyrolysis coating processes. Their regulatory compliance approach integrates precise thickness control mechanisms that allow for nanometer-level film deposition while maintaining strict environmental standards. Their proprietary TFS (Thin Film Systems) technology enables conformal coatings on complex geometries while minimizing chemical waste and emissions. Beneq's systems incorporate real-time monitoring of precursor delivery and exhaust treatment systems that capture and neutralize potentially harmful byproducts before release. The company has implemented comprehensive safety protocols that address both occupational exposure risks and environmental concerns, including closed-loop precursor handling systems that minimize operator exposure to chemicals. Their equipment designs incorporate multiple redundant safety features and automated shutdown procedures that activate when parameters exceed regulatory thresholds.

Strengths: Industry-leading expertise in thin film deposition with exceptional precision control capabilities that facilitate regulatory compliance. Their closed systems minimize worker exposure to chemicals and reduce environmental emissions. Weaknesses: Higher implementation costs compared to conventional coating technologies and requires specialized technical expertise for operation and maintenance.

BASF Corp.

Technical Solution: BASF has developed an integrated regulatory compliance framework for spray pyrolysis coating processes that addresses both environmental and occupational safety challenges. Their approach incorporates advanced precursor formulations that minimize hazardous air pollutants (HAPs) while maintaining coating performance characteristics. BASF's technology includes proprietary catalyst systems that reduce VOC emissions during the thermal decomposition phase of the spray pyrolysis process. The company has implemented comprehensive life cycle assessment methodologies that evaluate environmental impacts from raw material sourcing through end-of-life considerations for their coating systems. Their approach includes specialized waste stream management protocols that address the unique challenges of metal-organic precursor disposal and recovery. BASF has developed water-based precursor alternatives for traditionally solvent-based systems, significantly reducing VOC emissions while maintaining coating quality and adhesion properties. Their regulatory compliance strategy incorporates predictive modeling tools that simulate emissions profiles under various operating conditions, allowing for process optimization before implementation.

Strengths: Extensive chemical expertise that enables the development of environmentally optimized precursor formulations with reduced toxicity profiles. Their comprehensive approach addresses the entire coating process lifecycle, from material formulation to waste management. Weaknesses: Implementation requires significant process modifications for facilities transitioning from conventional coating technologies and may involve extended validation periods to ensure coating performance meets specifications.

Critical Patents and Technical Standards for Regulatory Compliance

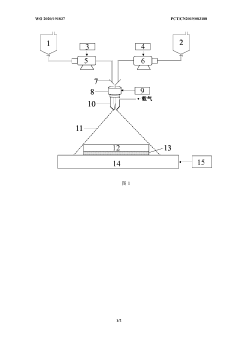

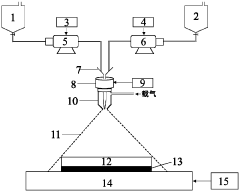

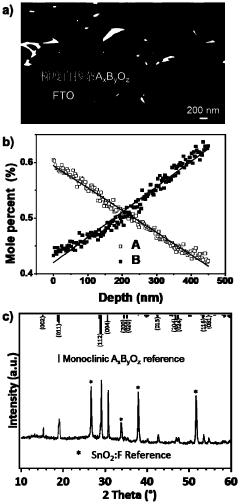

Spray pyrolysis preparation method for gradient self-doping multi-element metal oxide semiconductor film

PatentWO2020191837A1

Innovation

- By precisely controlling the feed flow rate and feed flow rate gradient of the metal A and B precursor solutions, the proportion of metal ions is regulated during the spray pyrolysis deposition coating process, avoiding high-temperature thermal diffusion assistance, and achieving metal ion dispersion from the bottom to the top of the film. A/B ratio gradient changes to ensure controllability of films with different thicknesses.

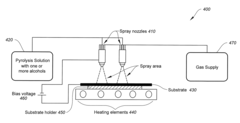

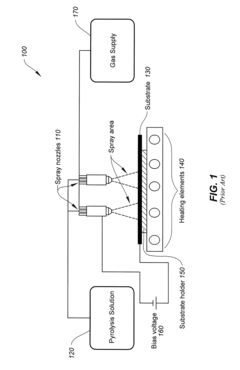

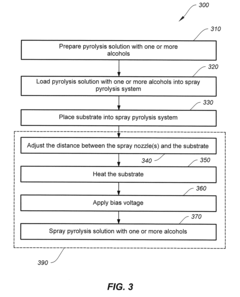

Methods and systems for spray pyrolysis with addition of volatile non-polar materials

PatentInactiveUS20120064699A1

Innovation

- Incorporating volatile non-polar materials like alcohols (methanol, ethanol, isopropyl alcohol) into the pyrolysis solution, which have higher volatility and lower heat capacity than water, to adjust the heat of vaporization and deposition process, allowing for lower temperature deposition, reduced energy consumption, and improved material utilization through controlled gasification and reduced nozzle clogging.

Environmental Impact Assessment and Sustainability Considerations

Spray pyrolysis coating processes, while technologically advantageous, present significant environmental challenges that require comprehensive assessment. The environmental footprint of these processes extends across multiple dimensions, including air emissions, water usage, waste generation, and energy consumption. Volatile organic compounds (VOCs), particulate matter, and potentially hazardous metal aerosols released during spraying operations can contribute to air pollution and pose health risks to workers and surrounding communities if not properly controlled.

Water consumption represents another critical environmental concern, particularly in regions facing water scarcity. The process typically requires substantial volumes for solution preparation, equipment cleaning, and cooling systems. Wastewater generated often contains chemical residues, metal ions, and other contaminants that necessitate treatment before discharge to prevent ecosystem damage and groundwater contamination.

Energy intensity of spray pyrolysis processes further compounds their environmental impact. High-temperature operations, particularly during thermal decomposition and annealing stages, contribute significantly to greenhouse gas emissions when powered by fossil fuel sources. The carbon footprint varies considerably depending on energy source, process efficiency, and operational parameters.

Sustainability considerations must address the entire lifecycle of spray pyrolysis coating technologies. Raw material sourcing represents a starting point for sustainability assessment, with particular attention to rare or critical materials that may face supply constraints or originate from regions with questionable environmental practices. Opportunities for incorporating recycled precursors or developing circular economy approaches should be thoroughly evaluated.

Process optimization offers substantial potential for environmental improvement. Techniques such as precursor reformulation to eliminate toxic components, equipment redesign for higher material transfer efficiency, and implementation of closed-loop systems for solvent recovery can dramatically reduce environmental impacts while potentially improving economic performance. Advanced monitoring systems that enable precise control of spray parameters can minimize overspray and material waste.

Regulatory frameworks increasingly emphasize life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. Companies implementing spray pyrolysis technologies must consider not only immediate compliance requirements but also anticipate evolving standards that may impose stricter limitations on emissions, waste generation, and resource consumption. Early adoption of sustainability metrics and environmental management systems can position organizations advantageously as regulatory landscapes evolve.

Water consumption represents another critical environmental concern, particularly in regions facing water scarcity. The process typically requires substantial volumes for solution preparation, equipment cleaning, and cooling systems. Wastewater generated often contains chemical residues, metal ions, and other contaminants that necessitate treatment before discharge to prevent ecosystem damage and groundwater contamination.

Energy intensity of spray pyrolysis processes further compounds their environmental impact. High-temperature operations, particularly during thermal decomposition and annealing stages, contribute significantly to greenhouse gas emissions when powered by fossil fuel sources. The carbon footprint varies considerably depending on energy source, process efficiency, and operational parameters.

Sustainability considerations must address the entire lifecycle of spray pyrolysis coating technologies. Raw material sourcing represents a starting point for sustainability assessment, with particular attention to rare or critical materials that may face supply constraints or originate from regions with questionable environmental practices. Opportunities for incorporating recycled precursors or developing circular economy approaches should be thoroughly evaluated.

Process optimization offers substantial potential for environmental improvement. Techniques such as precursor reformulation to eliminate toxic components, equipment redesign for higher material transfer efficiency, and implementation of closed-loop systems for solvent recovery can dramatically reduce environmental impacts while potentially improving economic performance. Advanced monitoring systems that enable precise control of spray parameters can minimize overspray and material waste.

Regulatory frameworks increasingly emphasize life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. Companies implementing spray pyrolysis technologies must consider not only immediate compliance requirements but also anticipate evolving standards that may impose stricter limitations on emissions, waste generation, and resource consumption. Early adoption of sustainability metrics and environmental management systems can position organizations advantageously as regulatory landscapes evolve.

Cross-Border Regulatory Harmonization Strategies

The global nature of spray pyrolysis coating technologies necessitates a coordinated approach to regulatory frameworks across different jurisdictions. Currently, manufacturers face significant challenges when operating across borders due to disparate regulatory requirements, testing protocols, and safety standards. This regulatory fragmentation increases compliance costs, delays market entry, and creates technical barriers to trade in advanced coating applications.

A comprehensive harmonization strategy requires multilateral engagement between major regulatory bodies including the EU's REACH, the US EPA, China's MEE, and Japan's METI. Initial efforts should focus on establishing mutual recognition agreements (MRAs) for testing data and certification processes, reducing redundant compliance procedures while maintaining safety standards. The International Organization for Standardization (ISO) could serve as a neutral platform for developing globally recognized technical standards specific to spray pyrolysis processes.

Industry consortia play a crucial role in regulatory harmonization by aggregating resources and presenting unified positions to regulatory authorities. Organizations such as the International Nanotechnology Industries Association have successfully advocated for science-based regulatory approaches that balance innovation with safety considerations. These collaborative models should be expanded to include more stakeholders from emerging economies where spray pyrolysis technologies are gaining traction.

Regulatory sandboxes represent an innovative approach to cross-border harmonization, allowing controlled testing of spray pyrolysis technologies under flexible regulatory frameworks. Several successful pilot programs in Singapore, the UK, and Australia have demonstrated how these experimental regulatory spaces can generate valuable data for evidence-based policymaking while facilitating technological advancement.

Digital compliance tools and blockchain-based certification systems offer promising solutions for streamlining cross-border regulatory processes. These technologies can create immutable records of compliance documentation, material safety data, and certification status accessible to regulators across multiple jurisdictions, significantly reducing administrative burdens while enhancing transparency and traceability throughout global supply chains.

Capacity building initiatives targeting regulatory authorities in developing markets are essential for sustainable harmonization efforts. Technical assistance programs, knowledge transfer partnerships, and regulatory diplomat exchanges can help establish consistent interpretation and enforcement of standards across diverse regulatory environments, creating a more predictable global marketplace for spray pyrolysis coating technologies.

A comprehensive harmonization strategy requires multilateral engagement between major regulatory bodies including the EU's REACH, the US EPA, China's MEE, and Japan's METI. Initial efforts should focus on establishing mutual recognition agreements (MRAs) for testing data and certification processes, reducing redundant compliance procedures while maintaining safety standards. The International Organization for Standardization (ISO) could serve as a neutral platform for developing globally recognized technical standards specific to spray pyrolysis processes.

Industry consortia play a crucial role in regulatory harmonization by aggregating resources and presenting unified positions to regulatory authorities. Organizations such as the International Nanotechnology Industries Association have successfully advocated for science-based regulatory approaches that balance innovation with safety considerations. These collaborative models should be expanded to include more stakeholders from emerging economies where spray pyrolysis technologies are gaining traction.

Regulatory sandboxes represent an innovative approach to cross-border harmonization, allowing controlled testing of spray pyrolysis technologies under flexible regulatory frameworks. Several successful pilot programs in Singapore, the UK, and Australia have demonstrated how these experimental regulatory spaces can generate valuable data for evidence-based policymaking while facilitating technological advancement.

Digital compliance tools and blockchain-based certification systems offer promising solutions for streamlining cross-border regulatory processes. These technologies can create immutable records of compliance documentation, material safety data, and certification status accessible to regulators across multiple jurisdictions, significantly reducing administrative burdens while enhancing transparency and traceability throughout global supply chains.

Capacity building initiatives targeting regulatory authorities in developing markets are essential for sustainable harmonization efforts. Technical assistance programs, knowledge transfer partnerships, and regulatory diplomat exchanges can help establish consistent interpretation and enforcement of standards across diverse regulatory environments, creating a more predictable global marketplace for spray pyrolysis coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!