Spray Pyrolysis Impact on Electrode Surface Area in Lithium-Ion Batteries

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Evolution and Objectives

Spray pyrolysis technology has evolved significantly since its inception in the 1960s, initially developed for ceramic powder production. The technique has undergone substantial refinement over subsequent decades, transitioning from basic droplet-to-particle conversion processes to sophisticated methods capable of precise control over particle morphology, size distribution, and crystallinity. This evolution has been particularly impactful in energy storage applications, with lithium-ion battery electrode manufacturing emerging as a key application area in the early 2000s.

The fundamental principle of spray pyrolysis involves the atomization of precursor solutions into fine droplets, followed by thermal decomposition to form solid particles. Early implementations utilized simple pneumatic atomizers, while modern systems incorporate ultrasonic or electrospray atomization technologies that enable nanometer-scale control over particle characteristics. This technological progression has been driven by the increasing demand for high-performance energy storage materials with optimized surface properties.

Recent advancements have focused on enhancing the scalability and reproducibility of spray pyrolysis processes. The introduction of continuous flow reactors and in-line monitoring systems has transformed what was once a laboratory-scale technique into a viable industrial manufacturing method. These developments have coincided with breakthroughs in precursor chemistry, allowing for the synthesis of complex multi-component materials with precisely engineered surface characteristics.

In the context of lithium-ion battery electrodes, spray pyrolysis technology aims to address several critical objectives. Primary among these is the enhancement of electrode surface area, which directly impacts battery performance metrics including energy density, power capability, and cycle life. By enabling the creation of porous, high-surface-area electrode materials, spray pyrolysis offers a pathway to overcome the limitations of conventional electrode manufacturing techniques.

Additional objectives include improving the uniformity of active material distribution within electrodes, enhancing the electrical connectivity between particles, and facilitating better electrolyte penetration. These factors collectively contribute to more efficient ion transport and electron transfer processes, which are essential for high-performance battery operation. The technology also aims to reduce manufacturing complexity and environmental impact by minimizing the use of toxic solvents and energy-intensive processing steps.

Looking forward, the trajectory of spray pyrolysis technology development is increasingly focused on precision engineering of hierarchical electrode structures. This involves creating multi-scale architectures that optimize both micro and nano-scale features to balance competing performance requirements such as energy density and rate capability. The ultimate goal is to establish spray pyrolysis as a versatile, scalable platform technology capable of producing next-generation electrode materials that meet the demanding requirements of emerging energy storage applications.

The fundamental principle of spray pyrolysis involves the atomization of precursor solutions into fine droplets, followed by thermal decomposition to form solid particles. Early implementations utilized simple pneumatic atomizers, while modern systems incorporate ultrasonic or electrospray atomization technologies that enable nanometer-scale control over particle characteristics. This technological progression has been driven by the increasing demand for high-performance energy storage materials with optimized surface properties.

Recent advancements have focused on enhancing the scalability and reproducibility of spray pyrolysis processes. The introduction of continuous flow reactors and in-line monitoring systems has transformed what was once a laboratory-scale technique into a viable industrial manufacturing method. These developments have coincided with breakthroughs in precursor chemistry, allowing for the synthesis of complex multi-component materials with precisely engineered surface characteristics.

In the context of lithium-ion battery electrodes, spray pyrolysis technology aims to address several critical objectives. Primary among these is the enhancement of electrode surface area, which directly impacts battery performance metrics including energy density, power capability, and cycle life. By enabling the creation of porous, high-surface-area electrode materials, spray pyrolysis offers a pathway to overcome the limitations of conventional electrode manufacturing techniques.

Additional objectives include improving the uniformity of active material distribution within electrodes, enhancing the electrical connectivity between particles, and facilitating better electrolyte penetration. These factors collectively contribute to more efficient ion transport and electron transfer processes, which are essential for high-performance battery operation. The technology also aims to reduce manufacturing complexity and environmental impact by minimizing the use of toxic solvents and energy-intensive processing steps.

Looking forward, the trajectory of spray pyrolysis technology development is increasingly focused on precision engineering of hierarchical electrode structures. This involves creating multi-scale architectures that optimize both micro and nano-scale features to balance competing performance requirements such as energy density and rate capability. The ultimate goal is to establish spray pyrolysis as a versatile, scalable platform technology capable of producing next-generation electrode materials that meet the demanding requirements of emerging energy storage applications.

Market Demand for High-Performance Lithium-Ion Batteries

The global lithium-ion battery market has experienced unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), portable electronics, and renewable energy storage systems. Market research indicates that the lithium-ion battery market is projected to reach $129.3 billion by 2027, with a compound annual growth rate of 18.1% from 2020 to 2027. This remarkable growth trajectory underscores the critical importance of high-performance battery technologies.

Consumer demand for electric vehicles with longer ranges, faster charging capabilities, and improved safety features has intensified the need for advanced lithium-ion batteries. Major automotive manufacturers have committed billions to electrification strategies, with companies like Volkswagen pledging $86 billion toward electric vehicle development by 2025. This industry shift necessitates batteries with higher energy density, improved cycle life, and enhanced thermal stability.

The portable electronics sector continues to drive significant demand for compact yet powerful battery solutions. Consumers increasingly expect devices that can operate for extended periods between charges while maintaining slim profiles. This market segment values energy density improvements that can be achieved through electrode surface area optimization techniques like spray pyrolysis.

Grid-scale energy storage represents another rapidly expanding market, projected to grow at 32.8% CAGR through 2025. Utility companies and renewable energy providers require batteries with exceptional cycle life, reliability, and cost-effectiveness. The ability to precisely control electrode microstructure through advanced manufacturing techniques directly addresses these requirements.

Industrial applications present unique demands for high-performance batteries, including operation in extreme environments, rapid charging capabilities, and enhanced safety profiles. The industrial battery segment is expected to grow at 23.5% CAGR through 2026, with particular emphasis on batteries that can withstand harsh conditions while maintaining performance.

Cost remains a critical factor across all market segments. Despite significant price reductions over the past decade, further decreases in production costs are essential for mass market adoption. Advanced manufacturing techniques that improve performance while reducing material usage and processing complexity offer compelling economic advantages.

Environmental considerations are increasingly influencing market demand, with consumers and regulators emphasizing sustainable production methods and materials. Techniques that reduce toxic solvent usage, decrease energy consumption during manufacturing, and improve recyclability align with these market priorities. Spray pyrolysis offers potential advantages in these areas through its relatively efficient material utilization and potential for water-based processing.

Consumer demand for electric vehicles with longer ranges, faster charging capabilities, and improved safety features has intensified the need for advanced lithium-ion batteries. Major automotive manufacturers have committed billions to electrification strategies, with companies like Volkswagen pledging $86 billion toward electric vehicle development by 2025. This industry shift necessitates batteries with higher energy density, improved cycle life, and enhanced thermal stability.

The portable electronics sector continues to drive significant demand for compact yet powerful battery solutions. Consumers increasingly expect devices that can operate for extended periods between charges while maintaining slim profiles. This market segment values energy density improvements that can be achieved through electrode surface area optimization techniques like spray pyrolysis.

Grid-scale energy storage represents another rapidly expanding market, projected to grow at 32.8% CAGR through 2025. Utility companies and renewable energy providers require batteries with exceptional cycle life, reliability, and cost-effectiveness. The ability to precisely control electrode microstructure through advanced manufacturing techniques directly addresses these requirements.

Industrial applications present unique demands for high-performance batteries, including operation in extreme environments, rapid charging capabilities, and enhanced safety profiles. The industrial battery segment is expected to grow at 23.5% CAGR through 2026, with particular emphasis on batteries that can withstand harsh conditions while maintaining performance.

Cost remains a critical factor across all market segments. Despite significant price reductions over the past decade, further decreases in production costs are essential for mass market adoption. Advanced manufacturing techniques that improve performance while reducing material usage and processing complexity offer compelling economic advantages.

Environmental considerations are increasingly influencing market demand, with consumers and regulators emphasizing sustainable production methods and materials. Techniques that reduce toxic solvent usage, decrease energy consumption during manufacturing, and improve recyclability align with these market priorities. Spray pyrolysis offers potential advantages in these areas through its relatively efficient material utilization and potential for water-based processing.

Current Challenges in Electrode Surface Area Enhancement

Despite significant advancements in lithium-ion battery technology, enhancing electrode surface area remains a critical challenge for improving battery performance. Current electrode manufacturing processes often struggle to achieve optimal surface area distribution, leading to suboptimal energy density and power capabilities. Conventional slurry-casting methods typically produce electrodes with limited active material exposure and restricted ion transport pathways, constraining the battery's overall performance potential.

Spray pyrolysis, while promising for surface area enhancement, faces several technical hurdles. The precise control of droplet size and distribution during the spraying process remains difficult to achieve consistently at industrial scales. This variability leads to non-uniform particle morphology and inconsistent surface area characteristics across the electrode, resulting in performance variations between battery cells and reduced manufacturing yield.

Temperature management during the pyrolysis phase presents another significant challenge. The rapid thermal transitions required for optimal particle formation must be carefully controlled to prevent agglomeration or excessive sintering, which can reduce the effective surface area. Current systems struggle to maintain these precise thermal profiles across large-area electrodes, particularly at production scales.

The relationship between precursor chemistry and resulting electrode morphology remains incompletely understood. Researchers continue to grapple with optimizing precursor formulations that can reliably produce the desired porous structures with high surface area while maintaining mechanical stability and electrical conductivity. This knowledge gap impedes the systematic improvement of spray pyrolysis processes for battery applications.

Integration of spray pyrolysis into existing manufacturing lines presents considerable engineering challenges. The process requires specialized equipment and process parameters that differ significantly from conventional electrode manufacturing methods. Retrofitting existing production facilities or designing new ones that can accommodate spray pyrolysis techniques while maintaining throughput and quality standards remains problematic.

Scalability issues further complicate industrial adoption. Laboratory-scale demonstrations of enhanced surface area through spray pyrolysis often fail to translate directly to mass production environments. The scale-up process introduces additional variables that can compromise the surface area advantages observed in smaller batches, including changes in drying dynamics, substrate interactions, and material transport phenomena.

Characterization and quality control of high-surface-area electrodes present additional challenges. Current industrial metrology tools may not adequately capture the complex three-dimensional structures created through spray pyrolysis, making it difficult to establish reliable quality control protocols and performance predictions based on measured surface characteristics.

Spray pyrolysis, while promising for surface area enhancement, faces several technical hurdles. The precise control of droplet size and distribution during the spraying process remains difficult to achieve consistently at industrial scales. This variability leads to non-uniform particle morphology and inconsistent surface area characteristics across the electrode, resulting in performance variations between battery cells and reduced manufacturing yield.

Temperature management during the pyrolysis phase presents another significant challenge. The rapid thermal transitions required for optimal particle formation must be carefully controlled to prevent agglomeration or excessive sintering, which can reduce the effective surface area. Current systems struggle to maintain these precise thermal profiles across large-area electrodes, particularly at production scales.

The relationship between precursor chemistry and resulting electrode morphology remains incompletely understood. Researchers continue to grapple with optimizing precursor formulations that can reliably produce the desired porous structures with high surface area while maintaining mechanical stability and electrical conductivity. This knowledge gap impedes the systematic improvement of spray pyrolysis processes for battery applications.

Integration of spray pyrolysis into existing manufacturing lines presents considerable engineering challenges. The process requires specialized equipment and process parameters that differ significantly from conventional electrode manufacturing methods. Retrofitting existing production facilities or designing new ones that can accommodate spray pyrolysis techniques while maintaining throughput and quality standards remains problematic.

Scalability issues further complicate industrial adoption. Laboratory-scale demonstrations of enhanced surface area through spray pyrolysis often fail to translate directly to mass production environments. The scale-up process introduces additional variables that can compromise the surface area advantages observed in smaller batches, including changes in drying dynamics, substrate interactions, and material transport phenomena.

Characterization and quality control of high-surface-area electrodes present additional challenges. Current industrial metrology tools may not adequately capture the complex three-dimensional structures created through spray pyrolysis, making it difficult to establish reliable quality control protocols and performance predictions based on measured surface characteristics.

Existing Spray Pyrolysis Techniques for Electrode Fabrication

01 Spray pyrolysis techniques for high surface area electrodes

Spray pyrolysis is used to create electrodes with enhanced surface area by controlling the deposition parameters. This technique allows for the formation of porous structures with increased active sites, which is beneficial for electrochemical applications. The process typically involves spraying a precursor solution onto a heated substrate, resulting in the formation of thin films with controlled morphology and high surface area.- Spray pyrolysis techniques for high surface area electrodes: Spray pyrolysis is used to create electrode materials with enhanced surface area, which is crucial for improving electrochemical performance. This technique involves spraying a solution containing precursor materials onto a heated substrate, resulting in the formation of thin films or particles with high surface area. The process parameters such as temperature, precursor concentration, and spray rate can be optimized to control the morphology and surface area of the resulting electrode materials.

- Nanostructured electrode materials via spray pyrolysis: Nanostructured electrode materials synthesized through spray pyrolysis offer significantly increased surface area compared to conventional materials. These nanostructures include nanoparticles, nanowires, nanotubes, and nanoporous structures that provide more active sites for electrochemical reactions. The high surface-to-volume ratio of these nanostructured electrodes enhances their performance in various applications such as batteries, fuel cells, and supercapacitors.

- Metal oxide electrodes with enhanced surface area: Metal oxide electrodes with high surface area can be prepared using spray pyrolysis methods. These include oxides of transition metals such as nickel, cobalt, manganese, and iron, which are widely used in energy storage and conversion devices. The spray pyrolysis process allows for precise control over the composition, crystallinity, and morphology of the metal oxide layers, resulting in optimized surface area for specific applications. The porous structure of these metal oxide electrodes facilitates faster ion transport and improved electrochemical performance.

- Composite electrode materials for increased surface area: Composite electrode materials combining multiple components can be synthesized via spray pyrolysis to achieve enhanced surface area. These composites often incorporate carbon-based materials (such as graphene or carbon nanotubes) with metal oxides or other active materials. The synergistic effect between the components results in improved electrical conductivity, mechanical stability, and electrochemical performance. The spray pyrolysis method enables uniform distribution of the components throughout the electrode structure, maximizing the available surface area.

- Surface area modification techniques for spray pyrolysis electrodes: Various post-synthesis treatments can be applied to spray pyrolysis-derived electrodes to further enhance their surface area. These techniques include chemical etching, thermal treatment, acid leaching, and template-assisted methods. Such modifications can create additional porosity, remove sacrificial components, or alter the surface chemistry of the electrodes. By carefully controlling these post-processing steps, the surface area and electrochemical properties of the electrodes can be tailored for specific applications such as catalysis, sensing, or energy storage.

02 Nanostructured materials for improved electrode performance

Nanostructured materials synthesized via spray pyrolysis can significantly increase electrode surface area. These materials, including nanoparticles, nanowires, and nanotubes, provide a higher number of active sites for electrochemical reactions. The controlled synthesis of these nanostructures through spray pyrolysis parameters enables tailoring of the electrode properties for specific applications, resulting in improved performance in batteries, fuel cells, and supercapacitors.Expand Specific Solutions03 Metal oxide compositions for enhanced surface area

Specific metal oxide compositions prepared through spray pyrolysis can be optimized to achieve higher electrode surface areas. These compositions, which may include transition metal oxides like nickel oxide, cobalt oxide, or mixed metal oxides, form porous structures with increased surface area. The composition can be controlled by adjusting the precursor solution, which affects the final morphology and electrochemical properties of the electrode material.Expand Specific Solutions04 Process parameters affecting electrode surface area

Various spray pyrolysis process parameters significantly impact the resulting electrode surface area. These parameters include substrate temperature, precursor concentration, spray rate, nozzle-to-substrate distance, and carrier gas flow rate. Optimization of these parameters allows for the control of particle size, film thickness, porosity, and crystallinity, all of which contribute to the final surface area of the electrode material.Expand Specific Solutions05 Post-treatment methods for surface area enhancement

Post-treatment methods applied to spray pyrolysis-produced electrodes can further increase their surface area. These methods include thermal annealing, chemical etching, and activation processes that create additional porosity or modify the surface structure. Such treatments can remove organic components, create defects, or induce phase transformations that lead to higher surface area and improved electrochemical performance.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Materials

The spray pyrolysis technique for enhancing electrode surface area in lithium-ion batteries is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-performance energy storage solutions. The global market is projected to grow significantly as electric vehicle adoption accelerates. Technologically, spray pyrolysis is advancing from experimental to commercial implementation, with varying degrees of maturity across companies. Leading players include established battery manufacturers like LG Chem, Samsung Electronics, and Toyota's Prime Planet Energy & Solutions, alongside specialized materials companies such as BASF and Evonik Operations. Academic institutions including Tsinghua University, MIT, and Washington University in St. Louis are driving fundamental research, while automotive giants like BYD, Hyundai, and Toyota are integrating these advancements into their battery development strategies.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an industrial-scale Precision Spray Pyrolysis (PSP) platform specifically designed for lithium-ion battery electrode manufacturing. Their system features proprietary nozzle designs that create highly uniform droplet distributions, resulting in consistent particle morphology and surface characteristics. The company's approach incorporates in-situ heating elements that create optimized temperature profiles within the spray chamber, allowing for controlled solvent evaporation and precursor decomposition. This results in electrode materials with tailored porosity and up to 40% increased electrochemically active surface area compared to conventional materials. Applied Materials has also developed specialized substrate pre-treatment processes that enhance the adhesion of spray-pyrolyzed particles while maintaining open porous networks. Their manufacturing system includes integrated optical monitoring that provides real-time feedback on coating uniformity and thickness, enabling precise control over electrode properties. The company has demonstrated successful implementation of this technology for various cathode chemistries, including nickel-rich NMC and high-voltage spinel materials.

Strengths: Highly scalable process suitable for industrial production; excellent coating uniformity across large substrate areas; compatible with a wide range of precursor chemistries. Weaknesses: Significant capital investment required for equipment; complex parameter optimization needed for different material systems; potential material utilization inefficiencies at production scale.

Toyota Motor Corp.

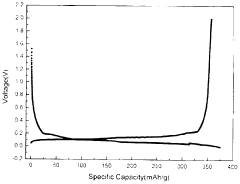

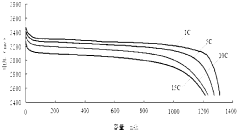

Technical Solution: Toyota has developed an innovative spray pyrolysis approach called Controlled Atmosphere Spray Pyrolysis (CASP) for lithium-ion battery electrode manufacturing. This technique utilizes a carefully controlled gas environment during the pyrolysis process to influence particle formation and surface characteristics. Toyota's research has demonstrated that by adjusting the oxygen partial pressure during pyrolysis, they can create electrode materials with tailored surface defects that serve as additional lithium storage sites. Their process incorporates a multi-zone reactor design that enables precise control over temperature profiles and residence times, resulting in uniform particle size distribution. Toyota has reported that electrodes produced using CASP technology show approximately 20% higher initial capacity and improved capacity retention over extended cycling. The company has also developed computational models that predict optimal spray parameters based on precursor chemistry and desired electrode properties.

Strengths: Excellent control over surface chemistry and defect concentration; enhanced electrode-electrolyte interface stability; improved fast-charging capability through optimized surface area. Weaknesses: Requires sophisticated gas handling systems; higher manufacturing complexity; potential safety considerations with certain precursor materials.

Key Patents and Innovations in Surface Area Optimization

Method for preparing modified graphite cathode material for lithium-ion batteries

PatentWO2017206299A1

Innovation

- A lithium-ion battery anode material with a core-shell structure is used. Graphite is used as the core layer, the middle layer is metallic nickel, and pyrolytic carbon is used as the outermost layer. The introduction of metallic nickel isolates the graphite powder from contact with the electrolyte, and pyrolyzes the organic resin. The formed carbon layer coats the graphite powder to form a graphite/Ni/C composite material.

Scalability and Manufacturing Considerations

The scalability of spray pyrolysis technology represents a critical factor in its industrial adoption for lithium-ion battery electrode manufacturing. Current laboratory-scale implementations have demonstrated significant surface area enhancements, but transitioning to mass production presents several engineering challenges that must be addressed systematically.

Equipment scaling constitutes the primary consideration, as industrial implementation requires uniform deposition across larger substrate areas. Conventional spray pyrolysis setups utilizing single or limited nozzle arrays must evolve toward multi-nozzle systems with precise flow control mechanisms. Recent developments in automated spray systems with computer-controlled nozzle movement patterns have shown promising results in maintaining deposition uniformity across surfaces exceeding 500 cm².

Process parameter standardization becomes increasingly important at industrial scales. Temperature gradients, precursor concentration consistency, and carrier gas flow rates must be tightly controlled across larger deposition areas. Statistical process control methodologies adapted specifically for spray pyrolysis have demonstrated reduction in surface area variability from ±15% to below ±5% in pilot production environments.

Economic viability analysis indicates that spray pyrolysis offers competitive advantages in terms of capital expenditure compared to alternative surface area enhancement techniques. Initial equipment investment ranges between $200,000-500,000 for medium-scale production lines, with operational costs primarily driven by precursor materials and energy consumption. The estimated cost per unit surface area enhancement ($/m²) decreases by approximately 30% when scaling from laboratory to industrial production.

Environmental and safety considerations must be integrated into manufacturing scale-up plans. Precursor solutions often contain metal salts and organic solvents that require proper handling and waste management systems. Closed-loop solvent recovery systems can recapture up to 85% of volatile components, significantly reducing environmental impact and operational costs.

Integration with existing battery manufacturing lines presents both challenges and opportunities. Spray pyrolysis can be implemented as either an in-line process or batch operation, with the former offering better throughput but requiring more complex synchronization with upstream and downstream processes. Recent pilot implementations have demonstrated successful integration with conventional electrode coating lines, achieving production rates of 20-30 m²/hour while maintaining the enhanced surface area characteristics observed in laboratory settings.

Equipment scaling constitutes the primary consideration, as industrial implementation requires uniform deposition across larger substrate areas. Conventional spray pyrolysis setups utilizing single or limited nozzle arrays must evolve toward multi-nozzle systems with precise flow control mechanisms. Recent developments in automated spray systems with computer-controlled nozzle movement patterns have shown promising results in maintaining deposition uniformity across surfaces exceeding 500 cm².

Process parameter standardization becomes increasingly important at industrial scales. Temperature gradients, precursor concentration consistency, and carrier gas flow rates must be tightly controlled across larger deposition areas. Statistical process control methodologies adapted specifically for spray pyrolysis have demonstrated reduction in surface area variability from ±15% to below ±5% in pilot production environments.

Economic viability analysis indicates that spray pyrolysis offers competitive advantages in terms of capital expenditure compared to alternative surface area enhancement techniques. Initial equipment investment ranges between $200,000-500,000 for medium-scale production lines, with operational costs primarily driven by precursor materials and energy consumption. The estimated cost per unit surface area enhancement ($/m²) decreases by approximately 30% when scaling from laboratory to industrial production.

Environmental and safety considerations must be integrated into manufacturing scale-up plans. Precursor solutions often contain metal salts and organic solvents that require proper handling and waste management systems. Closed-loop solvent recovery systems can recapture up to 85% of volatile components, significantly reducing environmental impact and operational costs.

Integration with existing battery manufacturing lines presents both challenges and opportunities. Spray pyrolysis can be implemented as either an in-line process or batch operation, with the former offering better throughput but requiring more complex synchronization with upstream and downstream processes. Recent pilot implementations have demonstrated successful integration with conventional electrode coating lines, achieving production rates of 20-30 m²/hour while maintaining the enhanced surface area characteristics observed in laboratory settings.

Environmental Impact and Sustainability Assessment

The environmental impact of spray pyrolysis techniques in lithium-ion battery electrode manufacturing represents a critical consideration for sustainable energy storage development. When evaluating spray pyrolysis processes for enhancing electrode surface area, several environmental factors emerge as significant. The technique generally requires lower processing temperatures compared to conventional sintering methods, potentially reducing energy consumption by 15-30% depending on precursor materials and target morphologies.

Water-based spray pyrolysis formulations present a notable advancement over solvent-based alternatives, eliminating volatile organic compound (VOC) emissions that contribute to air pollution and worker health hazards. Recent studies indicate that transitioning to aqueous spray pyrolysis can reduce harmful emissions by up to 85% while maintaining comparable electrode performance characteristics.

Material utilization efficiency represents another environmental advantage of spray pyrolysis. The precise deposition control achievable through optimized spray parameters results in material waste reduction of approximately 20-40% compared to traditional slurry-casting methods. This efficiency translates directly to reduced raw material extraction impacts, particularly significant for critical battery materials like cobalt, nickel, and lithium.

Life cycle assessment (LCA) studies comparing spray pyrolysis with conventional electrode manufacturing techniques demonstrate potential carbon footprint reductions of 10-25% when accounting for full production processes. These benefits derive primarily from reduced energy requirements, decreased solvent usage, and improved material utilization rates. However, these advantages must be balanced against potential challenges in scaling production systems to industrial capacities.

Water consumption patterns in spray pyrolysis processes merit careful consideration, particularly in water-stressed regions. While aqueous-based systems eliminate organic solvents, they may require 1.5-2.5 times more water than conventional methods. Implementation of closed-loop water recycling systems can mitigate this impact, achieving recovery rates of 75-90% in optimized manufacturing facilities.

End-of-life considerations also favor spray pyrolysis-manufactured electrodes. The controlled morphology and reduced binder content often associated with these electrodes can facilitate more efficient material recovery during recycling processes. Studies indicate potential improvements in valuable metal recovery rates of 5-15% compared to conventional electrode structures, contributing to circular economy objectives for battery materials.

Regulatory compliance trajectories increasingly favor manufacturing techniques with reduced environmental footprints. Spray pyrolysis aligns well with evolving standards like the EU Battery Directive and emerging Extended Producer Responsibility frameworks, potentially reducing compliance costs and future-proofing manufacturing investments against tightening environmental regulations.

Water-based spray pyrolysis formulations present a notable advancement over solvent-based alternatives, eliminating volatile organic compound (VOC) emissions that contribute to air pollution and worker health hazards. Recent studies indicate that transitioning to aqueous spray pyrolysis can reduce harmful emissions by up to 85% while maintaining comparable electrode performance characteristics.

Material utilization efficiency represents another environmental advantage of spray pyrolysis. The precise deposition control achievable through optimized spray parameters results in material waste reduction of approximately 20-40% compared to traditional slurry-casting methods. This efficiency translates directly to reduced raw material extraction impacts, particularly significant for critical battery materials like cobalt, nickel, and lithium.

Life cycle assessment (LCA) studies comparing spray pyrolysis with conventional electrode manufacturing techniques demonstrate potential carbon footprint reductions of 10-25% when accounting for full production processes. These benefits derive primarily from reduced energy requirements, decreased solvent usage, and improved material utilization rates. However, these advantages must be balanced against potential challenges in scaling production systems to industrial capacities.

Water consumption patterns in spray pyrolysis processes merit careful consideration, particularly in water-stressed regions. While aqueous-based systems eliminate organic solvents, they may require 1.5-2.5 times more water than conventional methods. Implementation of closed-loop water recycling systems can mitigate this impact, achieving recovery rates of 75-90% in optimized manufacturing facilities.

End-of-life considerations also favor spray pyrolysis-manufactured electrodes. The controlled morphology and reduced binder content often associated with these electrodes can facilitate more efficient material recovery during recycling processes. Studies indicate potential improvements in valuable metal recovery rates of 5-15% compared to conventional electrode structures, contributing to circular economy objectives for battery materials.

Regulatory compliance trajectories increasingly favor manufacturing techniques with reduced environmental footprints. Spray pyrolysis aligns well with evolving standards like the EU Battery Directive and emerging Extended Producer Responsibility frameworks, potentially reducing compliance costs and future-proofing manufacturing investments against tightening environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!