Exploring the Role of Spray Pyrolysis in Battery Material Electrodeposition

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Evolution and Objectives

Spray pyrolysis has evolved significantly since its inception in the 1960s as a simple aerosol deposition technique. Initially utilized for thin film coatings in optical applications, this versatile method has undergone substantial refinement to become a cornerstone technology in advanced materials synthesis, particularly for energy storage applications. The evolution trajectory demonstrates a clear shift from rudimentary setups with limited control parameters to sophisticated systems featuring precise regulation of droplet size, temperature gradients, and atmospheric conditions.

The fundamental principle of spray pyrolysis—converting a solution of precursor materials into fine droplets that undergo thermal decomposition to form solid particles or films—has remained consistent. However, the implementation has transformed dramatically with the integration of ultrasonic atomizers, electrospray mechanisms, and computer-controlled deposition systems that have collectively enhanced reproducibility and scalability.

A significant milestone in spray pyrolysis development occurred in the early 2000s when researchers successfully demonstrated its viability for synthesizing complex metal oxide compositions with controlled stoichiometry, a critical requirement for battery electrode materials. This breakthrough catalyzed intensive research into applying spray pyrolysis specifically for lithium-ion battery cathode materials, where uniform particle morphology and consistent chemical composition directly influence electrochemical performance.

The primary objective of contemporary spray pyrolysis research in battery material electrodeposition centers on optimizing the technique for industrial-scale production while maintaining the exceptional material properties achievable in laboratory settings. This includes developing continuous processing methods, reducing energy consumption during synthesis, and ensuring consistent quality across large production volumes.

Another crucial goal involves tailoring spray pyrolysis parameters to create hierarchical structures and composite materials that address specific battery performance limitations. For instance, researchers aim to develop cathode materials with enhanced lithium-ion diffusion pathways, improved electronic conductivity, and greater structural stability during charge-discharge cycling.

The technology also seeks to enable precise control over dopant incorporation and surface modification of battery materials, which can significantly enhance electrochemical performance and cycling stability. Recent research objectives have expanded to include the development of spray pyrolysis variants suitable for next-generation battery chemistries beyond lithium-ion, such as sodium-ion, potassium-ion, and solid-state batteries.

Environmental considerations have also shaped contemporary research goals, with increasing emphasis on developing water-based precursor solutions to replace toxic organic solvents traditionally used in spray pyrolysis processes. This aligns with broader industry trends toward greener manufacturing practices and sustainable material synthesis approaches.

The fundamental principle of spray pyrolysis—converting a solution of precursor materials into fine droplets that undergo thermal decomposition to form solid particles or films—has remained consistent. However, the implementation has transformed dramatically with the integration of ultrasonic atomizers, electrospray mechanisms, and computer-controlled deposition systems that have collectively enhanced reproducibility and scalability.

A significant milestone in spray pyrolysis development occurred in the early 2000s when researchers successfully demonstrated its viability for synthesizing complex metal oxide compositions with controlled stoichiometry, a critical requirement for battery electrode materials. This breakthrough catalyzed intensive research into applying spray pyrolysis specifically for lithium-ion battery cathode materials, where uniform particle morphology and consistent chemical composition directly influence electrochemical performance.

The primary objective of contemporary spray pyrolysis research in battery material electrodeposition centers on optimizing the technique for industrial-scale production while maintaining the exceptional material properties achievable in laboratory settings. This includes developing continuous processing methods, reducing energy consumption during synthesis, and ensuring consistent quality across large production volumes.

Another crucial goal involves tailoring spray pyrolysis parameters to create hierarchical structures and composite materials that address specific battery performance limitations. For instance, researchers aim to develop cathode materials with enhanced lithium-ion diffusion pathways, improved electronic conductivity, and greater structural stability during charge-discharge cycling.

The technology also seeks to enable precise control over dopant incorporation and surface modification of battery materials, which can significantly enhance electrochemical performance and cycling stability. Recent research objectives have expanded to include the development of spray pyrolysis variants suitable for next-generation battery chemistries beyond lithium-ion, such as sodium-ion, potassium-ion, and solid-state batteries.

Environmental considerations have also shaped contemporary research goals, with increasing emphasis on developing water-based precursor solutions to replace toxic organic solvents traditionally used in spray pyrolysis processes. This aligns with broader industry trends toward greener manufacturing practices and sustainable material synthesis approaches.

Market Analysis for Battery Material Deposition Technologies

The global market for battery material deposition technologies has experienced significant growth in recent years, driven primarily by the expanding electric vehicle (EV) sector and increasing demand for high-performance energy storage solutions. The market value for battery material deposition technologies reached approximately $5.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching $23.4 billion by the end of the forecast period.

Spray pyrolysis, as a specific electrodeposition technique, represents a growing segment within this market. Currently accounting for about 12% of the total battery material deposition technology market, spray pyrolysis is gaining traction due to its cost-effectiveness and scalability advantages over competing technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

Regional analysis indicates that Asia-Pacific dominates the market with approximately 58% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for lithium-ion batteries and continue to invest heavily in advanced deposition technologies. North America follows with 22% market share, while Europe accounts for 17%, with the remaining 3% distributed across other regions.

The demand drivers for spray pyrolysis in battery material deposition are multifaceted. Primary factors include the technology's ability to create uniform thin films with precise control over composition and morphology, which directly translates to improved battery performance metrics. Additionally, the relatively low capital investment required for spray pyrolysis equipment compared to vacuum-based deposition systems makes it particularly attractive for emerging markets and smaller manufacturers.

Market segmentation by application shows that lithium-ion battery cathode materials currently represent the largest application segment (63%), followed by anode materials (28%) and solid electrolyte layers (9%). The fastest growth is anticipated in solid-state battery components, where spray pyrolysis offers unique advantages in creating dense, defect-free layers essential for next-generation battery architectures.

Customer demand is increasingly focused on deposition technologies that can deliver higher energy density, improved cycle life, and enhanced safety profiles. Spray pyrolysis addresses these needs through precise control of particle size distribution and crystallinity, which directly impact battery performance parameters. Market research indicates that manufacturers are willing to pay a premium of 15-20% for deposition technologies that can demonstrably improve battery capacity by at least 10% or extend cycle life by 20%.

The competitive landscape features both established equipment manufacturers expanding their offerings to include spray pyrolysis systems and specialized startups focusing exclusively on advanced spray pyrolysis techniques for battery applications. This dynamic market environment is characterized by rapid innovation cycles and increasing patent activity, signaling strong growth potential for spray pyrolysis technology in battery material electrodeposition.

Spray pyrolysis, as a specific electrodeposition technique, represents a growing segment within this market. Currently accounting for about 12% of the total battery material deposition technology market, spray pyrolysis is gaining traction due to its cost-effectiveness and scalability advantages over competing technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

Regional analysis indicates that Asia-Pacific dominates the market with approximately 58% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for lithium-ion batteries and continue to invest heavily in advanced deposition technologies. North America follows with 22% market share, while Europe accounts for 17%, with the remaining 3% distributed across other regions.

The demand drivers for spray pyrolysis in battery material deposition are multifaceted. Primary factors include the technology's ability to create uniform thin films with precise control over composition and morphology, which directly translates to improved battery performance metrics. Additionally, the relatively low capital investment required for spray pyrolysis equipment compared to vacuum-based deposition systems makes it particularly attractive for emerging markets and smaller manufacturers.

Market segmentation by application shows that lithium-ion battery cathode materials currently represent the largest application segment (63%), followed by anode materials (28%) and solid electrolyte layers (9%). The fastest growth is anticipated in solid-state battery components, where spray pyrolysis offers unique advantages in creating dense, defect-free layers essential for next-generation battery architectures.

Customer demand is increasingly focused on deposition technologies that can deliver higher energy density, improved cycle life, and enhanced safety profiles. Spray pyrolysis addresses these needs through precise control of particle size distribution and crystallinity, which directly impact battery performance parameters. Market research indicates that manufacturers are willing to pay a premium of 15-20% for deposition technologies that can demonstrably improve battery capacity by at least 10% or extend cycle life by 20%.

The competitive landscape features both established equipment manufacturers expanding their offerings to include spray pyrolysis systems and specialized startups focusing exclusively on advanced spray pyrolysis techniques for battery applications. This dynamic market environment is characterized by rapid innovation cycles and increasing patent activity, signaling strong growth potential for spray pyrolysis technology in battery material electrodeposition.

Current Spray Pyrolysis Techniques and Barriers

Spray pyrolysis has emerged as a versatile technique for the electrodeposition of battery materials, offering significant advantages in terms of scalability, cost-effectiveness, and control over material properties. Currently, several spray pyrolysis techniques are employed in battery material synthesis, each with distinct characteristics and applications.

Ultrasonic spray pyrolysis represents one of the most widely adopted methods, utilizing high-frequency vibrations to generate fine aerosol droplets from precursor solutions. This technique enables precise control over particle size distribution and morphology, critical factors in battery performance. However, it faces challenges related to scaling production while maintaining uniform droplet size and preventing nozzle clogging during continuous operation.

Pressure-assisted spray pyrolysis employs mechanical pressure to force precursor solutions through specialized nozzles. While this approach offers higher throughput compared to ultrasonic methods, it typically produces larger droplets with broader size distributions, potentially compromising the electrochemical performance of the resulting battery materials. The technique also requires careful optimization of pressure parameters to prevent inconsistent material deposition.

Electrostatic spray pyrolysis incorporates electrical charging of precursor droplets, allowing for more controlled deposition patterns through electrostatic guidance. This method shows promise for creating structured electrode materials but faces challenges in maintaining stable electrical fields during scale-up and managing the complexity of the equipment required.

Flame spray pyrolysis, which involves the combustion of precursor solutions to form nanoparticles, offers rapid processing and high-temperature synthesis capabilities. However, controlling the reaction environment presents significant challenges, particularly in preventing particle agglomeration and ensuring consistent chemical composition across batches.

Several technical barriers currently limit the broader adoption of spray pyrolysis in battery material electrodeposition. Temperature gradient management during the pyrolysis process remains problematic, often resulting in non-uniform material properties across the substrate. This heterogeneity can lead to inconsistent electrochemical performance in the final battery products.

Precursor chemistry optimization presents another significant challenge. The complex relationship between precursor formulation, spray parameters, and final material properties requires extensive experimentation and characterization. Additionally, the limited understanding of reaction kinetics during the rapid thermal decomposition process complicates the development of predictive models for material synthesis.

Substrate compatibility issues also pose barriers to implementation, as different substrate materials interact uniquely with the spray pyrolysis process. This can affect adhesion, uniformity, and electrochemical properties of the deposited materials, necessitating substrate-specific process optimization.

Scaling production while maintaining quality consistency represents perhaps the most significant industrial challenge. Laboratory-scale successes often prove difficult to translate to manufacturing environments due to changes in heat transfer dynamics, precursor delivery systems, and deposition uniformity at larger scales.

Ultrasonic spray pyrolysis represents one of the most widely adopted methods, utilizing high-frequency vibrations to generate fine aerosol droplets from precursor solutions. This technique enables precise control over particle size distribution and morphology, critical factors in battery performance. However, it faces challenges related to scaling production while maintaining uniform droplet size and preventing nozzle clogging during continuous operation.

Pressure-assisted spray pyrolysis employs mechanical pressure to force precursor solutions through specialized nozzles. While this approach offers higher throughput compared to ultrasonic methods, it typically produces larger droplets with broader size distributions, potentially compromising the electrochemical performance of the resulting battery materials. The technique also requires careful optimization of pressure parameters to prevent inconsistent material deposition.

Electrostatic spray pyrolysis incorporates electrical charging of precursor droplets, allowing for more controlled deposition patterns through electrostatic guidance. This method shows promise for creating structured electrode materials but faces challenges in maintaining stable electrical fields during scale-up and managing the complexity of the equipment required.

Flame spray pyrolysis, which involves the combustion of precursor solutions to form nanoparticles, offers rapid processing and high-temperature synthesis capabilities. However, controlling the reaction environment presents significant challenges, particularly in preventing particle agglomeration and ensuring consistent chemical composition across batches.

Several technical barriers currently limit the broader adoption of spray pyrolysis in battery material electrodeposition. Temperature gradient management during the pyrolysis process remains problematic, often resulting in non-uniform material properties across the substrate. This heterogeneity can lead to inconsistent electrochemical performance in the final battery products.

Precursor chemistry optimization presents another significant challenge. The complex relationship between precursor formulation, spray parameters, and final material properties requires extensive experimentation and characterization. Additionally, the limited understanding of reaction kinetics during the rapid thermal decomposition process complicates the development of predictive models for material synthesis.

Substrate compatibility issues also pose barriers to implementation, as different substrate materials interact uniquely with the spray pyrolysis process. This can affect adhesion, uniformity, and electrochemical properties of the deposited materials, necessitating substrate-specific process optimization.

Scaling production while maintaining quality consistency represents perhaps the most significant industrial challenge. Laboratory-scale successes often prove difficult to translate to manufacturing environments due to changes in heat transfer dynamics, precursor delivery systems, and deposition uniformity at larger scales.

Contemporary Spray Pyrolysis Solutions for Batteries

01 Spray pyrolysis techniques for thin film deposition

Spray pyrolysis is a versatile technique for depositing thin films of various materials. This process involves spraying a solution onto a heated substrate, where the solution undergoes thermal decomposition to form a solid film. The technique allows for control over film thickness, composition, and morphology by adjusting parameters such as substrate temperature, solution concentration, and spray rate. It is particularly useful for creating uniform coatings for electronic, optical, and energy applications.- Spray pyrolysis techniques for thin film deposition: Spray pyrolysis is a versatile technique for depositing thin films of various materials. In this process, a precursor solution is atomized and sprayed onto a heated substrate, where it undergoes thermal decomposition to form a solid film. This method allows for the control of film thickness, morphology, and composition by adjusting parameters such as precursor concentration, substrate temperature, and spray rate. It is particularly useful for creating uniform coatings on large or complex surfaces.

- Electrodeposition combined with pyrolysis for advanced materials: The combination of electrodeposition and pyrolysis offers a powerful approach for synthesizing advanced functional materials. In this hybrid process, materials are first electrodeposited onto a substrate and then subjected to controlled pyrolysis to achieve desired properties. This technique enables the production of materials with enhanced electrical, optical, or catalytic properties. The process parameters, including electrodeposition voltage, current density, and pyrolysis temperature, can be optimized to tailor the final material characteristics.

- Nanostructured materials fabrication via spray pyrolysis electrodeposition: Spray pyrolysis electrodeposition is particularly effective for creating nanostructured materials with controlled morphology and composition. This technique allows for the synthesis of nanoparticles, nanowires, and nanocomposites with unique properties. The process typically involves spraying a precursor solution onto an electrically charged substrate, where both electrochemical reactions and thermal decomposition occur simultaneously. The resulting nanostructured materials exhibit enhanced surface area, improved reactivity, and novel electronic properties suitable for various applications.

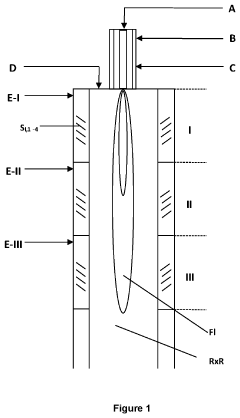

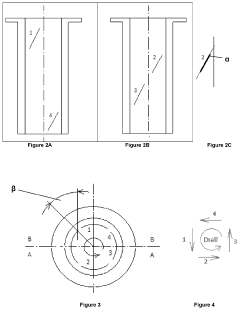

- Equipment and apparatus for spray pyrolysis electrodeposition: Specialized equipment and apparatus have been developed for spray pyrolysis electrodeposition processes. These systems typically include components for solution preparation, atomization, substrate heating, and electrical connections for electrodeposition. Advanced setups may incorporate features such as ultrasonic atomizers, controlled atmosphere chambers, precise temperature controllers, and programmable power supplies. The design of such equipment aims to ensure uniform deposition, reproducibility, and scalability of the process for industrial applications.

- Applications of spray pyrolysis electrodeposition in energy and electronics: Spray pyrolysis electrodeposition has found significant applications in energy conversion devices and electronic components. This technique is used to fabricate electrodes for solar cells, fuel cells, and batteries, as well as semiconductor layers for electronic devices. The process allows for the deposition of functional materials with controlled composition, thickness, and microstructure, which are critical for device performance. Additionally, the relatively low cost and scalability of this method make it attractive for commercial production of energy and electronic materials.

02 Electrodeposition combined with pyrolysis for nanomaterial synthesis

The combination of electrodeposition and pyrolysis offers a powerful approach for synthesizing advanced nanomaterials. In this hybrid process, materials are first electrodeposited onto a substrate and then subjected to pyrolysis treatment to achieve desired crystallinity, porosity, or composition. This method enables the production of complex nanostructures with controlled properties, which are valuable for applications in energy storage, catalysis, and sensing technologies.Expand Specific Solutions03 Semiconductor and oxide film fabrication using spray pyrolysis

Spray pyrolysis is widely employed for fabricating semiconductor and oxide films with specific electrical and optical properties. The process allows for the deposition of doped and undoped metal oxides, chalcogenides, and other semiconductor materials. By controlling the precursor chemistry and deposition conditions, films with tailored bandgap, conductivity, and transparency can be produced for applications in photovoltaics, transparent conductors, and optoelectronic devices.Expand Specific Solutions04 Equipment and apparatus design for spray pyrolysis electrodeposition

Specialized equipment and apparatus designs are crucial for effective spray pyrolysis electrodeposition processes. These systems typically include components for solution preparation, atomization, substrate heating, and precise control of electrodeposition parameters. Advanced designs incorporate features such as ultrasonic or pneumatic atomizers, temperature-controlled substrate holders, and automated control systems to ensure reproducible film quality and properties across large substrate areas.Expand Specific Solutions05 Functional materials and coatings produced by spray pyrolysis electrodeposition

Spray pyrolysis electrodeposition enables the production of various functional materials and coatings with enhanced properties. These include catalytic layers, corrosion-resistant coatings, superconducting films, and materials for energy conversion and storage. The process allows for the incorporation of dopants, creation of composite structures, and formation of gradient compositions, resulting in materials with superior performance characteristics for specific industrial and technological applications.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Materials

Spray pyrolysis technology for battery material electrodeposition is currently in a growth phase, with the global market expanding as demand for advanced battery materials increases. The technology demonstrates moderate maturity, with key players including Applied Materials and Samsung Electronics leading commercial applications, while academic institutions like MIT and Michigan contribute fundamental research advancements. CATL and LG Energy Solution are integrating this technology into their battery production processes, while specialized companies like Prieto Battery focus on innovative implementations. The competitive landscape features collaboration between industry leaders and research institutions, with companies like GEM and Bangpu developing sustainable applications for recycled materials. As the technology evolves, we anticipate increased adoption across the battery manufacturing ecosystem, particularly for next-generation energy storage solutions.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced spray pyrolysis systems for battery material electrodeposition that enable precise control over film thickness, composition, and morphology. Their technology utilizes ultrasonic atomization to create fine droplets of precursor solution that are directed onto heated substrates, where decomposition and film formation occur simultaneously. The company's systems incorporate multi-zone temperature control allowing for gradient deposition profiles and in-situ annealing capabilities. Applied Materials' approach enables the creation of complex multi-layer electrode structures with controlled porosity and surface area, critical for high-performance battery applications. Their equipment features automated process control systems that monitor and adjust deposition parameters in real-time, ensuring consistent quality across large substrate areas suitable for industrial-scale production. The technology has demonstrated particular success in depositing lithium transition metal oxide cathode materials with enhanced electrochemical properties compared to conventional methods.

Strengths: Superior thickness uniformity across large substrates; excellent reproducibility through automated process control; capability for industrial-scale production with high throughput. Weaknesses: Higher initial capital investment compared to simpler deposition methods; requires precise control of multiple process parameters; potential material waste during atomization process.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has engineered an advanced spray pyrolysis system for battery material electrodeposition that focuses on silicon-based anode materials and high-voltage cathode coatings. Their technology utilizes a dual-fluid atomization approach where precursor solutions are dispersed into fine droplets using high-pressure carrier gases, allowing for precise control over droplet size and velocity. Samsung's system incorporates a vertical reactor design with counter-current gas flow that maximizes precursor utilization efficiency while minimizing material waste. The company has developed specialized precursor chemistries that enable the formation of silicon-carbon composite structures with engineered void spaces to accommodate volume expansion during lithiation. Their spray pyrolysis process operates at lower temperatures than conventional methods, reducing energy consumption and enabling the use of temperature-sensitive substrate materials. Samsung's technology also features rapid thermal processing capabilities that allow for flash heating and quenching, creating metastable phases with enhanced electrochemical properties. The system has demonstrated particular success in creating protective surface coatings on high-nickel cathode materials that significantly improve cycling stability and thermal safety.

Strengths: Excellent precursor utilization efficiency reducing material waste; capability to create complex composite structures with engineered porosity; lower operating temperatures expanding substrate compatibility. Weaknesses: More complex equipment design increasing maintenance requirements; challenges in achieving uniform deposition over highly textured surfaces; sensitivity to precursor solution properties requiring tight quality control.

Critical Patents and Breakthroughs in Electrodeposition

Method for producing electrodes for battery cells

PatentWO2019020724A1

Innovation

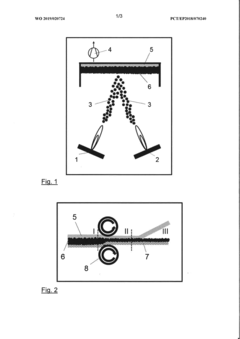

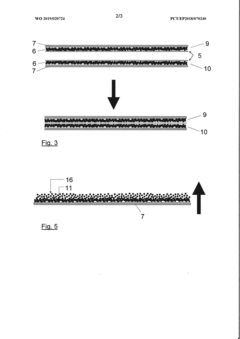

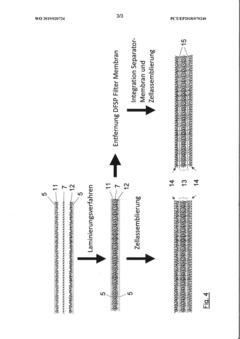

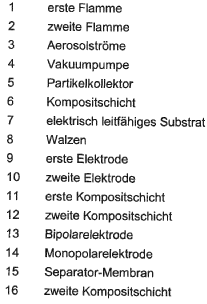

- A method using double flame spray pyrolysis to synthesize battery active materials and carbon additives directly onto an electrically conductive substrate in a two-step process, eliminating the need for prefabricated materials, binders, and solvents, while allowing for flexible production of composite layers with controlled porosity and properties.

Method for producing metal oxides by means of spray pyrolysis

PatentActiveUS11434146B2

Innovation

- A process involving flame spray pyrolysis with a reaction space containing double-walled internals that introduce gas or vapor through slots to rotate the flame, increasing the residence time and adjusting the flame's geometry, which enhances the conversion and crystallinity of metal oxides by modifying the reaction conditions.

Sustainability Impact of Spray Pyrolysis Processes

The sustainability impact of spray pyrolysis processes in battery material electrodeposition represents a critical dimension of this technology's overall value proposition. When evaluated through an environmental lens, spray pyrolysis demonstrates several advantages over conventional manufacturing methods. The process operates at lower temperatures compared to solid-state reactions, resulting in reduced energy consumption and associated carbon emissions. Additionally, the precise control over material composition and morphology leads to more efficient use of raw materials, minimizing waste generation.

Water consumption in spray pyrolysis is significantly lower than in traditional wet chemical processes, addressing growing concerns about industrial water usage. The process typically employs aqueous or alcohol-based solutions rather than toxic organic solvents, substantially reducing the environmental hazard potential and improving workplace safety conditions. These characteristics align well with increasingly stringent environmental regulations and corporate sustainability commitments.

From a life-cycle perspective, batteries manufactured using spray pyrolysis-derived materials often exhibit enhanced performance characteristics, including improved capacity retention and longer operational lifespans. This extended durability translates directly into reduced waste generation and resource consumption over time, as fewer replacement batteries are required for the same service period.

The scalability of spray pyrolysis processes further enhances their sustainability profile. The technology can be implemented in modular systems that grow with demand, avoiding the resource-intensive overbuilding common in traditional manufacturing facilities. This adaptability supports more efficient resource allocation and reduces the environmental footprint of production infrastructure.

Circular economy considerations also favor spray pyrolysis approaches. The precise control over particle size and composition facilitates more effective recycling of battery materials at end-of-life. Research indicates that cathode materials synthesized via spray pyrolysis maintain higher structural integrity during recycling processes, enabling more efficient material recovery and reuse in subsequent battery generations.

Economic sustainability metrics reveal that while initial implementation costs for spray pyrolysis systems may exceed conventional alternatives, the operational efficiencies and reduced environmental compliance costs typically result in favorable long-term economics. Companies adopting these technologies often report reduced waste management expenses and lower regulatory compliance costs, contributing to overall business sustainability.

Water consumption in spray pyrolysis is significantly lower than in traditional wet chemical processes, addressing growing concerns about industrial water usage. The process typically employs aqueous or alcohol-based solutions rather than toxic organic solvents, substantially reducing the environmental hazard potential and improving workplace safety conditions. These characteristics align well with increasingly stringent environmental regulations and corporate sustainability commitments.

From a life-cycle perspective, batteries manufactured using spray pyrolysis-derived materials often exhibit enhanced performance characteristics, including improved capacity retention and longer operational lifespans. This extended durability translates directly into reduced waste generation and resource consumption over time, as fewer replacement batteries are required for the same service period.

The scalability of spray pyrolysis processes further enhances their sustainability profile. The technology can be implemented in modular systems that grow with demand, avoiding the resource-intensive overbuilding common in traditional manufacturing facilities. This adaptability supports more efficient resource allocation and reduces the environmental footprint of production infrastructure.

Circular economy considerations also favor spray pyrolysis approaches. The precise control over particle size and composition facilitates more effective recycling of battery materials at end-of-life. Research indicates that cathode materials synthesized via spray pyrolysis maintain higher structural integrity during recycling processes, enabling more efficient material recovery and reuse in subsequent battery generations.

Economic sustainability metrics reveal that while initial implementation costs for spray pyrolysis systems may exceed conventional alternatives, the operational efficiencies and reduced environmental compliance costs typically result in favorable long-term economics. Companies adopting these technologies often report reduced waste management expenses and lower regulatory compliance costs, contributing to overall business sustainability.

Scalability Challenges for Industrial Implementation

The transition from laboratory-scale spray pyrolysis to industrial-scale production presents significant challenges that must be addressed for commercial viability. Current industrial implementation faces equipment scaling limitations, as laboratory setups typically process materials in gram quantities, while commercial battery production requires kilogram to ton-scale output. This substantial scale difference necessitates redesigning spray nozzle arrays, deposition chambers, and thermal control systems to maintain uniform coating quality across larger substrate areas.

Process consistency represents another major hurdle in industrial implementation. As production scales increase, maintaining precise control over droplet size distribution, substrate temperature uniformity, and precursor concentration becomes exponentially more difficult. Minor variations in these parameters can lead to significant inconsistencies in the electrodeposited material's morphology, crystallinity, and electrochemical performance, ultimately affecting battery quality and reliability.

Energy consumption considerations also impact industrial feasibility. Spray pyrolysis requires substantial thermal energy to maintain elevated temperatures throughout the deposition process. When scaled to industrial levels, this energy demand increases dramatically, potentially undermining the economic and environmental sustainability of the manufacturing process. Innovative approaches to heat recovery and process optimization are essential to address this challenge.

Material utilization efficiency presents further complications at industrial scale. Laboratory-scale spray pyrolysis typically achieves 30-60% material utilization, with significant precursor loss occurring through overspray and incomplete decomposition. At industrial scale, these inefficiencies translate to substantial material waste and increased production costs, necessitating the development of more efficient delivery systems and precursor recovery mechanisms.

Quality control methodologies must also evolve for industrial implementation. Current laboratory characterization techniques like SEM, XRD, and electrochemical testing are time-consuming and unsuitable for real-time production monitoring. The development of inline quality control systems capable of detecting coating defects, thickness variations, and compositional inconsistencies in real-time represents a critical need for industrial adoption.

Regulatory compliance adds another layer of complexity to industrial implementation. Scaled production of battery materials through spray pyrolysis must address workplace safety concerns related to aerosolized precursors, thermal hazards, and potential environmental impacts. Developing closed-loop systems that minimize emissions and worker exposure while meeting stringent regulatory requirements remains an ongoing challenge for industrial adoption.

Process consistency represents another major hurdle in industrial implementation. As production scales increase, maintaining precise control over droplet size distribution, substrate temperature uniformity, and precursor concentration becomes exponentially more difficult. Minor variations in these parameters can lead to significant inconsistencies in the electrodeposited material's morphology, crystallinity, and electrochemical performance, ultimately affecting battery quality and reliability.

Energy consumption considerations also impact industrial feasibility. Spray pyrolysis requires substantial thermal energy to maintain elevated temperatures throughout the deposition process. When scaled to industrial levels, this energy demand increases dramatically, potentially undermining the economic and environmental sustainability of the manufacturing process. Innovative approaches to heat recovery and process optimization are essential to address this challenge.

Material utilization efficiency presents further complications at industrial scale. Laboratory-scale spray pyrolysis typically achieves 30-60% material utilization, with significant precursor loss occurring through overspray and incomplete decomposition. At industrial scale, these inefficiencies translate to substantial material waste and increased production costs, necessitating the development of more efficient delivery systems and precursor recovery mechanisms.

Quality control methodologies must also evolve for industrial implementation. Current laboratory characterization techniques like SEM, XRD, and electrochemical testing are time-consuming and unsuitable for real-time production monitoring. The development of inline quality control systems capable of detecting coating defects, thickness variations, and compositional inconsistencies in real-time represents a critical need for industrial adoption.

Regulatory compliance adds another layer of complexity to industrial implementation. Scaled production of battery materials through spray pyrolysis must address workplace safety concerns related to aerosolized precursors, thermal hazards, and potential environmental impacts. Developing closed-loop systems that minimize emissions and worker exposure while meeting stringent regulatory requirements remains an ongoing challenge for industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!