Why High-Precision Spray Pyrolysis Matters in Nanotechnology

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Evolution and Precision Goals

Spray pyrolysis technology has evolved significantly since its inception in the 1960s, transitioning from a rudimentary material synthesis method to a sophisticated nanotechnology process. Initially developed for ceramic powder production, early spray pyrolysis systems suffered from poor particle size distribution and limited control over morphology. The 1980s marked a turning point with the introduction of ultrasonic nebulizers, enabling finer droplet generation and improved precursor atomization.

The 1990s witnessed the integration of precise temperature control systems and carrier gas flow regulation, which substantially enhanced process stability. By the early 2000s, researchers began focusing on reaction kinetics and thermodynamics, developing mathematical models to predict particle formation mechanisms. This theoretical foundation facilitated the transition from empirical to knowledge-based process optimization.

Recent technological advancements have centered on achieving unprecedented precision in nanoparticle synthesis. Modern spray pyrolysis systems incorporate real-time monitoring capabilities, feedback control loops, and automated parameter adjustment. The introduction of microfluidic spray pyrolysis represents a paradigm shift, offering exceptional control over droplet size and residence time in the reaction zone.

The evolution trajectory clearly points toward increasing precision and reproducibility. Current technical goals include achieving sub-nanometer control over particle size distribution, with a coefficient of variation below 5%. Industry standards are progressively demanding tighter tolerances, particularly for applications in quantum dot manufacturing, catalysis, and biomedical imaging.

Another critical objective is morphology control at the nanoscale. Researchers are striving to develop protocols for synthesizing complex nanostructures with predefined shapes, including hollow spheres, core-shell architectures, and hierarchical assemblies. These structures exhibit unique properties that cannot be achieved with conventional particles.

Compositional homogeneity represents another frontier in spray pyrolysis development. Modern applications require uniform distribution of dopants and precise stoichiometry control in multi-component systems. The goal is to achieve atomic-level precision in material composition, enabling fine-tuning of electronic, optical, and magnetic properties.

Looking forward, the field is moving toward sustainable and scalable high-precision processes. Research objectives include reducing energy consumption, minimizing waste generation, and developing continuous production systems capable of maintaining nanometer-level precision at industrial scales. The convergence of spray pyrolysis with artificial intelligence for process optimization represents the next evolutionary step, potentially enabling autonomous synthesis of tailor-made nanomaterials with unprecedented precision.

The 1990s witnessed the integration of precise temperature control systems and carrier gas flow regulation, which substantially enhanced process stability. By the early 2000s, researchers began focusing on reaction kinetics and thermodynamics, developing mathematical models to predict particle formation mechanisms. This theoretical foundation facilitated the transition from empirical to knowledge-based process optimization.

Recent technological advancements have centered on achieving unprecedented precision in nanoparticle synthesis. Modern spray pyrolysis systems incorporate real-time monitoring capabilities, feedback control loops, and automated parameter adjustment. The introduction of microfluidic spray pyrolysis represents a paradigm shift, offering exceptional control over droplet size and residence time in the reaction zone.

The evolution trajectory clearly points toward increasing precision and reproducibility. Current technical goals include achieving sub-nanometer control over particle size distribution, with a coefficient of variation below 5%. Industry standards are progressively demanding tighter tolerances, particularly for applications in quantum dot manufacturing, catalysis, and biomedical imaging.

Another critical objective is morphology control at the nanoscale. Researchers are striving to develop protocols for synthesizing complex nanostructures with predefined shapes, including hollow spheres, core-shell architectures, and hierarchical assemblies. These structures exhibit unique properties that cannot be achieved with conventional particles.

Compositional homogeneity represents another frontier in spray pyrolysis development. Modern applications require uniform distribution of dopants and precise stoichiometry control in multi-component systems. The goal is to achieve atomic-level precision in material composition, enabling fine-tuning of electronic, optical, and magnetic properties.

Looking forward, the field is moving toward sustainable and scalable high-precision processes. Research objectives include reducing energy consumption, minimizing waste generation, and developing continuous production systems capable of maintaining nanometer-level precision at industrial scales. The convergence of spray pyrolysis with artificial intelligence for process optimization represents the next evolutionary step, potentially enabling autonomous synthesis of tailor-made nanomaterials with unprecedented precision.

Market Applications for High-Precision Nanomaterials

The high-precision nanomaterials market has experienced significant growth across multiple sectors, driven by the unique properties these materials offer. In electronics, nanomaterials produced through spray pyrolysis enable the development of smaller, more efficient components for semiconductors, displays, and energy storage devices. The miniaturization trend in consumer electronics continues to fuel demand for nanomaterials with precisely controlled dimensions and compositions, which spray pyrolysis can deliver with remarkable consistency.

Healthcare applications represent another substantial market segment, with nanomaterials finding use in targeted drug delivery systems, diagnostic tools, and antimicrobial coatings. Spray pyrolysis-derived nanoparticles with controlled size distributions and surface properties are particularly valuable for pharmaceutical applications where biocompatibility and consistent performance are critical. The global nanomedicine market, which heavily relies on high-precision nanomaterials, is projected to grow substantially as personalized medicine approaches gain traction.

Energy sector applications constitute a rapidly expanding market for high-precision nanomaterials. Advanced battery technologies, solar cells, and fuel cells all benefit from nanomaterials with carefully engineered properties. Spray pyrolysis enables the production of catalysts, electrode materials, and energy conversion materials with optimized performance characteristics. The push toward renewable energy and energy efficiency is creating sustained demand for these specialized materials.

Environmental applications represent an emerging market with significant growth potential. Nanomaterials produced through spray pyrolysis are being deployed in water purification systems, air filtration technologies, and environmental remediation processes. Their high surface area and customizable surface chemistry make them ideal for capturing pollutants and contaminants with high efficiency.

Automotive and aerospace industries are increasingly incorporating nanomaterials into lightweight composites, coatings, and specialized components. The demand for fuel efficiency and performance enhancement drives adoption of high-precision nanomaterials in these sectors. Spray pyrolysis offers the ability to create materials with specific thermal, mechanical, and electrical properties tailored to these demanding applications.

The construction industry has begun exploring nanomaterial applications in self-cleaning surfaces, thermal insulation, and structural reinforcement. High-precision nanomaterials can enhance concrete strength, provide better insulation properties, and create surfaces resistant to environmental degradation. This market segment shows promising growth as sustainable building practices gain importance globally.

Textile and consumer goods markets are also adopting nanomaterials for antimicrobial fabrics, stain-resistant coatings, and enhanced packaging materials. The ability of spray pyrolysis to create uniform, functional nanoparticles enables manufacturers to develop products with superior performance characteristics and extended lifespans.

Healthcare applications represent another substantial market segment, with nanomaterials finding use in targeted drug delivery systems, diagnostic tools, and antimicrobial coatings. Spray pyrolysis-derived nanoparticles with controlled size distributions and surface properties are particularly valuable for pharmaceutical applications where biocompatibility and consistent performance are critical. The global nanomedicine market, which heavily relies on high-precision nanomaterials, is projected to grow substantially as personalized medicine approaches gain traction.

Energy sector applications constitute a rapidly expanding market for high-precision nanomaterials. Advanced battery technologies, solar cells, and fuel cells all benefit from nanomaterials with carefully engineered properties. Spray pyrolysis enables the production of catalysts, electrode materials, and energy conversion materials with optimized performance characteristics. The push toward renewable energy and energy efficiency is creating sustained demand for these specialized materials.

Environmental applications represent an emerging market with significant growth potential. Nanomaterials produced through spray pyrolysis are being deployed in water purification systems, air filtration technologies, and environmental remediation processes. Their high surface area and customizable surface chemistry make them ideal for capturing pollutants and contaminants with high efficiency.

Automotive and aerospace industries are increasingly incorporating nanomaterials into lightweight composites, coatings, and specialized components. The demand for fuel efficiency and performance enhancement drives adoption of high-precision nanomaterials in these sectors. Spray pyrolysis offers the ability to create materials with specific thermal, mechanical, and electrical properties tailored to these demanding applications.

The construction industry has begun exploring nanomaterial applications in self-cleaning surfaces, thermal insulation, and structural reinforcement. High-precision nanomaterials can enhance concrete strength, provide better insulation properties, and create surfaces resistant to environmental degradation. This market segment shows promising growth as sustainable building practices gain importance globally.

Textile and consumer goods markets are also adopting nanomaterials for antimicrobial fabrics, stain-resistant coatings, and enhanced packaging materials. The ability of spray pyrolysis to create uniform, functional nanoparticles enables manufacturers to develop products with superior performance characteristics and extended lifespans.

Current Limitations in Spray Pyrolysis Technology

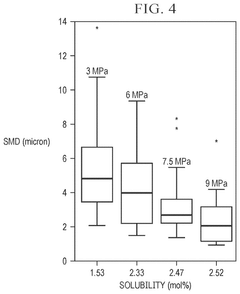

Despite its widespread application in nanotechnology, spray pyrolysis technology faces several significant limitations that hinder its full potential in high-precision nanomaterial synthesis. The primary challenge lies in achieving precise control over particle size distribution. Current spray pyrolysis systems often produce nanoparticles with considerable size variations, typically ranging from 10-30% deviation from target dimensions, which is inadequate for applications requiring uniform properties such as quantum dots or catalytic materials.

Temperature gradient inconsistencies within reaction chambers represent another major limitation. Conventional spray pyrolysis setups struggle to maintain homogeneous thermal environments, resulting in uneven heating of precursor droplets. These thermal fluctuations, which can vary by 50-100°C across different zones of the reaction chamber, lead to inconsistent nucleation and growth processes that compromise material uniformity and reproducibility.

Precursor atomization techniques also present significant constraints. Most commercial systems rely on ultrasonic or pressure nozzles that produce droplets with relatively broad size distributions (polydispersity indices of 0.2-0.4). This initial variability propagates throughout the synthesis process, ultimately affecting the morphology and composition of the final nanomaterials.

Scalability while maintaining precision remains an unresolved challenge. Laboratory-scale systems that achieve reasonable precision typically operate at production rates of only a few grams per hour. When scaled to industrial volumes, precision invariably deteriorates due to flow dynamics complications and heat transfer inefficiencies in larger reaction chambers.

Material composition control presents additional difficulties, particularly for multi-component nanomaterials. Current technology struggles with precise stoichiometric control when working with precursors of varying volatility and decomposition characteristics. This limitation is especially problematic for complex functional materials like doped semiconductors or multi-metal oxides where compositional precision directly impacts performance properties.

Monitoring and real-time process control capabilities are also underdeveloped. Most spray pyrolysis systems operate as "black box" processes with limited in-situ analytical capabilities. The inability to monitor particle formation dynamics in real-time prevents adaptive process control that could otherwise compensate for deviations during synthesis.

Energy efficiency concerns further constrain the technology. Conventional spray pyrolysis systems exhibit thermal efficiencies of only 15-30%, with significant energy losses through exhaust gases and reactor walls. This inefficiency not only increases operational costs but also contributes to environmental impact through excessive energy consumption.

Temperature gradient inconsistencies within reaction chambers represent another major limitation. Conventional spray pyrolysis setups struggle to maintain homogeneous thermal environments, resulting in uneven heating of precursor droplets. These thermal fluctuations, which can vary by 50-100°C across different zones of the reaction chamber, lead to inconsistent nucleation and growth processes that compromise material uniformity and reproducibility.

Precursor atomization techniques also present significant constraints. Most commercial systems rely on ultrasonic or pressure nozzles that produce droplets with relatively broad size distributions (polydispersity indices of 0.2-0.4). This initial variability propagates throughout the synthesis process, ultimately affecting the morphology and composition of the final nanomaterials.

Scalability while maintaining precision remains an unresolved challenge. Laboratory-scale systems that achieve reasonable precision typically operate at production rates of only a few grams per hour. When scaled to industrial volumes, precision invariably deteriorates due to flow dynamics complications and heat transfer inefficiencies in larger reaction chambers.

Material composition control presents additional difficulties, particularly for multi-component nanomaterials. Current technology struggles with precise stoichiometric control when working with precursors of varying volatility and decomposition characteristics. This limitation is especially problematic for complex functional materials like doped semiconductors or multi-metal oxides where compositional precision directly impacts performance properties.

Monitoring and real-time process control capabilities are also underdeveloped. Most spray pyrolysis systems operate as "black box" processes with limited in-situ analytical capabilities. The inability to monitor particle formation dynamics in real-time prevents adaptive process control that could otherwise compensate for deviations during synthesis.

Energy efficiency concerns further constrain the technology. Conventional spray pyrolysis systems exhibit thermal efficiencies of only 15-30%, with significant energy losses through exhaust gases and reactor walls. This inefficiency not only increases operational costs but also contributes to environmental impact through excessive energy consumption.

State-of-the-Art Spray Pyrolysis Methodologies

01 High-precision spray pyrolysis techniques for thin film deposition

Spray pyrolysis techniques have been developed for high-precision deposition of thin films with controlled thickness and uniformity. These methods involve the atomization of precursor solutions followed by thermal decomposition on heated substrates. The process parameters such as nozzle design, spray rate, and substrate temperature can be optimized to achieve precise control over film morphology and properties, making it suitable for applications requiring high-precision coatings.- High-precision thin film deposition techniques: Spray pyrolysis enables the deposition of high-precision thin films with controlled thickness and composition. This technique allows for the formation of uniform layers on various substrates by atomizing precursor solutions and directing them onto heated surfaces. The process parameters can be precisely controlled to achieve specific film properties, making it suitable for applications requiring nanometer-scale precision in electronics, optics, and semiconductor industries.

- Nanoparticle synthesis with controlled morphology: Spray pyrolysis offers a method for synthesizing nanoparticles with precisely controlled size, shape, and composition. By adjusting parameters such as precursor concentration, atomization conditions, and reaction temperature, researchers can produce nanoparticles with specific morphological characteristics. This high-precision approach enables the creation of advanced materials with tailored properties for applications in catalysis, energy storage, and biomedical fields.

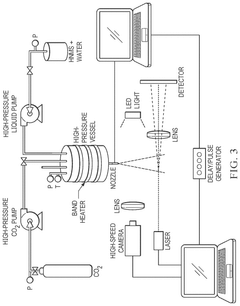

- Advanced spray pyrolysis equipment design: Specialized equipment designs enhance the precision of spray pyrolysis processes. These systems incorporate precise flow controllers, advanced atomization mechanisms, and temperature regulation systems to ensure consistent and reproducible results. Innovations include multi-zone heating chambers, computer-controlled precursor delivery, and in-situ monitoring capabilities that allow for real-time adjustments during the deposition or synthesis process.

- Functional ceramic and oxide material fabrication: High-precision spray pyrolysis enables the fabrication of functional ceramic and oxide materials with specific electrical, optical, and structural properties. This technique allows for the synthesis of complex oxide compositions with homogeneous distribution of dopants and precise stoichiometry. The ability to control crystallinity, phase purity, and microstructure makes spray pyrolysis valuable for producing advanced ceramics for sensors, fuel cells, and electronic components.

- Process optimization for industrial applications: Optimization strategies for spray pyrolysis processes focus on achieving high precision while maintaining industrial scalability. These approaches include mathematical modeling of spray dynamics, statistical process control methods, and automated parameter adjustment systems. Advanced precursor formulations and solvent systems are developed to enhance material quality while reducing defects. These optimizations enable the transition of spray pyrolysis from laboratory to commercial manufacturing of high-precision components.

02 Nanoparticle synthesis using spray pyrolysis for high-precision applications

Spray pyrolysis enables the synthesis of nanoparticles with precisely controlled size, composition, and morphology. The process involves atomizing precursor solutions into fine droplets that undergo rapid evaporation and decomposition to form nanoparticles. By carefully controlling reaction parameters such as temperature, residence time, and precursor concentration, high-precision nanoparticles can be produced for applications in catalysis, electronics, and advanced materials.Expand Specific Solutions03 Equipment and apparatus design for high-precision spray pyrolysis

Specialized equipment has been developed to enhance the precision of spray pyrolysis processes. These designs incorporate features such as ultrasonic or pressure-assisted atomizers, precise temperature control systems, and automated spray pattern controllers. Advanced nozzle designs and droplet formation mechanisms ensure uniform distribution of precursor solutions, while integrated monitoring systems provide real-time feedback for process optimization, resulting in higher precision and reproducibility.Expand Specific Solutions04 Semiconductor and electronic materials fabrication via high-precision spray pyrolysis

High-precision spray pyrolysis has been applied to the fabrication of semiconductor and electronic materials with specific electrical, optical, and structural properties. The technique allows for the deposition of doped and multi-component oxide films with precise stoichiometry and thickness control. This approach enables the production of functional layers for solar cells, sensors, and other electronic devices with enhanced performance characteristics and reliability.Expand Specific Solutions05 Process optimization methods for high-precision spray pyrolysis

Various optimization methods have been developed to achieve high precision in spray pyrolysis processes. These include computational fluid dynamics modeling to predict spray patterns and deposition profiles, statistical design of experiments to identify optimal process parameters, and in-situ characterization techniques to monitor film growth. Advanced precursor formulations and solvent systems have also been developed to improve solution properties and enhance the precision of the resulting materials.Expand Specific Solutions

Leading Research Institutions and Commercial Entities

High-precision spray pyrolysis technology in nanotechnology is currently in a growth phase, with increasing adoption across research institutions and commercial applications. The market is expanding rapidly, driven by demand for advanced nanomaterials in electronics, energy storage, and medical applications. The technology has reached moderate maturity, with established players like Shoei Chemical and Cabot Corp leading commercial applications, while research institutions such as Swiss Federal Institute of Technology and CNRS advance fundamental capabilities. Academic-industrial partnerships are accelerating development, with Purdue Research Foundation and Beneq Group Oy bridging research and commercialization. Companies like Taiheiyo Cement and Thermo Finnigan are expanding applications into specialized markets, indicating the technology's growing commercial viability and cross-sector potential.

Swiss Federal Institute of Technology

Technical Solution: ETH Zurich has developed a revolutionary approach to high-precision spray pyrolysis called Pulsed Aerosol Synthesis (PAS) that combines controlled droplet generation with precisely timed thermal processing. Their system utilizes acoustic excitation to produce monodisperse precursor droplets with size variation below 5%, while incorporating synchronized thermal pulses that enable unprecedented control over nucleation and growth kinetics. The technology features a proprietary reactor design with laminar flow characteristics that minimize turbulence-induced variability, maintaining consistent residence times within ±50ms. ETH researchers have implemented advanced in-situ monitoring using laser-induced breakdown spectroscopy that provides real-time compositional analysis during particle formation. Their method has demonstrated particular success in creating complex multi-component nanomaterials with precisely controlled dopant distributions, achieving compositional accuracy within 0.5 atomic percent across production batches. The system has been validated for producing high-performance catalytic materials showing activity enhancements of 25-35% compared to conventionally synthesized alternatives.

Strengths: Exceptional control over particle nucleation and growth kinetics; ability to create metastable phases not accessible through conventional methods; excellent reproducibility. Weaknesses: Complex synchronization systems requiring specialized maintenance; higher initial capital costs; limited throughput compared to continuous production systems.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has pioneered a sophisticated spray pyrolysis approach called Controlled Aerosol Deposition (CAD) that integrates electrospray atomization with precision thermal processing. Their system generates charged aerosol droplets in the sub-micron range (200-800nm) using high-voltage field control, allowing unprecedented manipulation of particle trajectories during synthesis. The technology incorporates a multi-stage thermal processing unit with independently controlled temperature zones accurate to ±0.5°C, enabling precise control over nucleation, growth, and crystallization processes. CNRS researchers have developed proprietary precursor formulations that enhance solution stability and control decomposition kinetics, resulting in nanoparticles with narrow size distributions (coefficient of variation <10%). Their approach has been particularly successful in synthesizing complex functional nanomaterials for catalytic applications, demonstrating activity improvements of 30-40% compared to conventionally prepared catalysts due to superior control over surface properties and active site distribution.

Strengths: Exceptional control over particle size distribution and morphology; ability to create complex hierarchical nanostructures; high reproducibility between batches. Weaknesses: Complex system setup requiring specialized expertise; higher energy consumption than some alternative methods; challenges with scaling to very high production volumes.

Breakthrough Patents in Precision Control Systems

Manufacturing of multifunctional nanostructures using supercritical co2-assisted spray deposition

PatentPendingUS20250115482A1

Innovation

- The use of supercritical CO2-assisted spray deposition combined with hybrid nanomaterials systems (HNMS) to deposit nanostructures with engineered patterns, allowing for controlled droplet properties and precise pattern formation.

Environmental Impact and Sustainability Considerations

High-precision spray pyrolysis technology, while offering significant advancements in nanotechnology, presents important environmental considerations that must be addressed for sustainable implementation. The process involves aerosolization of precursor solutions and thermal decomposition, which can generate waste products including particulate matter, volatile organic compounds (VOCs), and potentially toxic metal residues. These byproducts require careful management to prevent environmental contamination and health hazards in laboratory and industrial settings.

Energy consumption represents another significant environmental concern. Spray pyrolysis typically requires high temperatures (400-1000°C) for extended periods, resulting in substantial energy demands. This energy footprint can be mitigated through process optimization, including precise temperature control systems, improved reactor designs, and integration of renewable energy sources to power heating elements.

Water usage efficiency has emerged as a critical sustainability factor in spray pyrolysis operations. Traditional methods often utilize substantial quantities of water in precursor solutions and cleaning processes. Advanced systems now incorporate closed-loop water recycling, solvent recovery mechanisms, and alternative carrier mediums to reduce freshwater consumption and minimize wastewater generation.

The life cycle assessment (LCA) of nanomaterials produced via spray pyrolysis reveals opportunities for environmental improvement. Researchers have documented that optimized high-precision spray pyrolysis can reduce environmental impact by up to 40% compared to conventional nanomaterial synthesis methods. This improvement stems from reduced material waste, lower processing temperatures, and more efficient precursor utilization.

Regulatory frameworks worldwide are increasingly addressing nanomaterial production sustainability. The European Union's REACH regulations and similar initiatives in North America and Asia now incorporate specific provisions for nanomaterial synthesis processes, including spray pyrolysis. These regulations emphasize waste reduction, energy efficiency, and responsible end-of-life management of nanomaterials.

Recent innovations in green chemistry principles applied to spray pyrolysis have yielded promising sustainability advances. These include the development of bio-derived precursors, non-toxic solvents, and catalyst systems that function effectively at lower temperatures. Additionally, precision control mechanisms have enabled significant reductions in precursor quantities while maintaining or improving nanomaterial quality, thereby minimizing resource consumption and waste generation.

The environmental benefits of high-precision spray pyrolysis must be weighed against potential ecological risks associated with nanomaterial release. Current research indicates the importance of implementing robust containment systems, filtration technologies, and workplace protocols to prevent unintended environmental exposure throughout the nanomaterial lifecycle.

Energy consumption represents another significant environmental concern. Spray pyrolysis typically requires high temperatures (400-1000°C) for extended periods, resulting in substantial energy demands. This energy footprint can be mitigated through process optimization, including precise temperature control systems, improved reactor designs, and integration of renewable energy sources to power heating elements.

Water usage efficiency has emerged as a critical sustainability factor in spray pyrolysis operations. Traditional methods often utilize substantial quantities of water in precursor solutions and cleaning processes. Advanced systems now incorporate closed-loop water recycling, solvent recovery mechanisms, and alternative carrier mediums to reduce freshwater consumption and minimize wastewater generation.

The life cycle assessment (LCA) of nanomaterials produced via spray pyrolysis reveals opportunities for environmental improvement. Researchers have documented that optimized high-precision spray pyrolysis can reduce environmental impact by up to 40% compared to conventional nanomaterial synthesis methods. This improvement stems from reduced material waste, lower processing temperatures, and more efficient precursor utilization.

Regulatory frameworks worldwide are increasingly addressing nanomaterial production sustainability. The European Union's REACH regulations and similar initiatives in North America and Asia now incorporate specific provisions for nanomaterial synthesis processes, including spray pyrolysis. These regulations emphasize waste reduction, energy efficiency, and responsible end-of-life management of nanomaterials.

Recent innovations in green chemistry principles applied to spray pyrolysis have yielded promising sustainability advances. These include the development of bio-derived precursors, non-toxic solvents, and catalyst systems that function effectively at lower temperatures. Additionally, precision control mechanisms have enabled significant reductions in precursor quantities while maintaining or improving nanomaterial quality, thereby minimizing resource consumption and waste generation.

The environmental benefits of high-precision spray pyrolysis must be weighed against potential ecological risks associated with nanomaterial release. Current research indicates the importance of implementing robust containment systems, filtration technologies, and workplace protocols to prevent unintended environmental exposure throughout the nanomaterial lifecycle.

Scalability Challenges for Industrial Implementation

Despite the promising potential of high-precision spray pyrolysis in nanotechnology, transitioning from laboratory-scale production to industrial implementation presents significant scalability challenges. The primary obstacle lies in maintaining precise control over particle size distribution and morphology when scaling up production volumes. Laboratory settings typically involve processing small quantities under carefully controlled conditions, whereas industrial applications require consistent output at orders of magnitude higher throughput.

Equipment design represents a critical bottleneck in scaling spray pyrolysis processes. Current industrial-scale atomizers and reactors often struggle to deliver the uniform droplet sizes and thermal environments necessary for high-precision nanoparticle synthesis. The engineering complexity increases exponentially when attempting to maintain nanometer-level precision across larger production volumes, requiring sophisticated monitoring systems and feedback controls.

Process parameter optimization becomes increasingly difficult at industrial scales. Variables such as precursor concentration, flow rates, and temperature gradients must be precisely controlled throughout larger reaction chambers. Minor variations that might be negligible in laboratory settings can lead to significant product inconsistencies when amplified across industrial production volumes, resulting in batch-to-batch variability that undermines product reliability.

Economic considerations further complicate scalability efforts. The capital investment required for specialized equipment capable of high-precision spray pyrolysis at industrial scales remains prohibitively high for many manufacturers. Operating costs, including energy consumption for maintaining precise thermal conditions and expensive precursor materials, create additional barriers to commercial viability. These economic factors often force compromises between production volume and precision.

Quality control and characterization present additional challenges at industrial scales. Current analytical techniques that work well for laboratory samples become impractical for continuous monitoring of large-scale production. Real-time characterization methods capable of providing immediate feedback on nanoparticle properties during industrial production remain underdeveloped, limiting the ability to implement adaptive process controls.

Regulatory compliance adds another layer of complexity to industrial implementation. As production volumes increase, so do concerns regarding worker safety, environmental impact, and waste management. Nanoparticle handling at industrial scales requires specialized containment systems and safety protocols that may not be fully established for high-precision spray pyrolysis processes, potentially delaying commercial adoption despite technological readiness.

Equipment design represents a critical bottleneck in scaling spray pyrolysis processes. Current industrial-scale atomizers and reactors often struggle to deliver the uniform droplet sizes and thermal environments necessary for high-precision nanoparticle synthesis. The engineering complexity increases exponentially when attempting to maintain nanometer-level precision across larger production volumes, requiring sophisticated monitoring systems and feedback controls.

Process parameter optimization becomes increasingly difficult at industrial scales. Variables such as precursor concentration, flow rates, and temperature gradients must be precisely controlled throughout larger reaction chambers. Minor variations that might be negligible in laboratory settings can lead to significant product inconsistencies when amplified across industrial production volumes, resulting in batch-to-batch variability that undermines product reliability.

Economic considerations further complicate scalability efforts. The capital investment required for specialized equipment capable of high-precision spray pyrolysis at industrial scales remains prohibitively high for many manufacturers. Operating costs, including energy consumption for maintaining precise thermal conditions and expensive precursor materials, create additional barriers to commercial viability. These economic factors often force compromises between production volume and precision.

Quality control and characterization present additional challenges at industrial scales. Current analytical techniques that work well for laboratory samples become impractical for continuous monitoring of large-scale production. Real-time characterization methods capable of providing immediate feedback on nanoparticle properties during industrial production remain underdeveloped, limiting the ability to implement adaptive process controls.

Regulatory compliance adds another layer of complexity to industrial implementation. As production volumes increase, so do concerns regarding worker safety, environmental impact, and waste management. Nanoparticle handling at industrial scales requires specialized containment systems and safety protocols that may not be fully established for high-precision spray pyrolysis processes, potentially delaying commercial adoption despite technological readiness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!