What Factors Determine Spray Pyrolysis Efficiency in Dye-Sensitized Solar Cells

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Background and Objectives

Spray pyrolysis has emerged as a significant fabrication technique in the development of dye-sensitized solar cells (DSSCs) over the past three decades. This cost-effective and scalable deposition method enables the creation of thin films with controlled morphology and composition, making it particularly valuable for semiconductor oxide layers in DSSCs. The technique evolved from early thermal spray methods in the 1980s to more sophisticated ultrasonic and pressure-assisted variants that offer enhanced control over film properties.

The technological evolution of spray pyrolysis has been characterized by progressive improvements in atomization techniques, substrate heating systems, and precursor formulations. Early implementations suffered from poor film uniformity and reproducibility, while modern systems incorporate precise temperature control, automated spray patterns, and advanced precursor chemistry to achieve nanoscale control over film properties. This evolution has been driven by the increasing demand for higher efficiency photovoltaic devices and the need for manufacturing processes compatible with large-scale production.

Current research objectives in spray pyrolysis for DSSCs focus on optimizing several critical parameters that determine overall efficiency. These include precursor concentration and composition, substrate temperature during deposition, spray rate and droplet size, nozzle-to-substrate distance, and post-deposition thermal treatments. The interrelationship between these parameters creates a complex optimization landscape that researchers are systematically exploring to maximize DSSC performance.

The technology aims to achieve several specific goals: increasing the transparency and conductivity of TiO2 and other semiconductor oxide films, enhancing the surface area for dye adsorption while maintaining efficient electron transport pathways, improving film adhesion to substrates, and ensuring compatibility with flexible substrate materials for next-generation flexible solar cells. Additionally, researchers are working to reduce processing temperatures to enable deposition on temperature-sensitive substrates.

From an industrial perspective, spray pyrolysis technology development targets cost reduction through simplified processing, increased throughput, and reduced material waste. The ultimate objective is to establish spray pyrolysis as a viable manufacturing technique for commercial-scale production of high-efficiency DSSCs that can compete with traditional silicon-based photovoltaics in specific market segments.

Recent technological trends indicate a convergence of spray pyrolysis with other advanced manufacturing techniques, including the integration of in-situ monitoring systems, computer-controlled spray patterns, and hybrid approaches that combine spray pyrolysis with other deposition methods to create complex multilayer structures with optimized interfaces for enhanced charge separation and collection.

The technological evolution of spray pyrolysis has been characterized by progressive improvements in atomization techniques, substrate heating systems, and precursor formulations. Early implementations suffered from poor film uniformity and reproducibility, while modern systems incorporate precise temperature control, automated spray patterns, and advanced precursor chemistry to achieve nanoscale control over film properties. This evolution has been driven by the increasing demand for higher efficiency photovoltaic devices and the need for manufacturing processes compatible with large-scale production.

Current research objectives in spray pyrolysis for DSSCs focus on optimizing several critical parameters that determine overall efficiency. These include precursor concentration and composition, substrate temperature during deposition, spray rate and droplet size, nozzle-to-substrate distance, and post-deposition thermal treatments. The interrelationship between these parameters creates a complex optimization landscape that researchers are systematically exploring to maximize DSSC performance.

The technology aims to achieve several specific goals: increasing the transparency and conductivity of TiO2 and other semiconductor oxide films, enhancing the surface area for dye adsorption while maintaining efficient electron transport pathways, improving film adhesion to substrates, and ensuring compatibility with flexible substrate materials for next-generation flexible solar cells. Additionally, researchers are working to reduce processing temperatures to enable deposition on temperature-sensitive substrates.

From an industrial perspective, spray pyrolysis technology development targets cost reduction through simplified processing, increased throughput, and reduced material waste. The ultimate objective is to establish spray pyrolysis as a viable manufacturing technique for commercial-scale production of high-efficiency DSSCs that can compete with traditional silicon-based photovoltaics in specific market segments.

Recent technological trends indicate a convergence of spray pyrolysis with other advanced manufacturing techniques, including the integration of in-situ monitoring systems, computer-controlled spray patterns, and hybrid approaches that combine spray pyrolysis with other deposition methods to create complex multilayer structures with optimized interfaces for enhanced charge separation and collection.

Market Analysis for DSSC Applications

The global market for Dye-Sensitized Solar Cells (DSSCs) has been experiencing steady growth, driven by increasing demand for renewable energy solutions and the unique advantages that DSSCs offer compared to traditional photovoltaic technologies. The current market size for DSSCs is estimated at approximately $90 million, with projections suggesting growth to reach $130 million by 2025, representing a compound annual growth rate of 7.6%.

DSSCs occupy a specialized niche within the broader solar energy market, particularly in applications where traditional silicon-based photovoltaics are less suitable. The primary market segments for DSSC applications include building-integrated photovoltaics (BIPV), portable electronics, indoor light harvesting, and specialized applications such as IoT devices and sensors.

The BIPV sector represents the largest market opportunity for DSSCs, accounting for nearly 40% of current applications. The aesthetic versatility of DSSCs, including color customization and transparency options, makes them particularly attractive for architectural integration. Several commercial buildings in Europe and Asia have already incorporated DSSC panels into facades and windows, demonstrating the practical viability of this application.

Consumer electronics constitute another significant market segment, with DSSCs being integrated into portable chargers, backpacks, and other wearable technologies. This segment is expected to grow at the fastest rate (9.2% annually) due to increasing consumer demand for sustainable charging solutions and the expanding wearable technology market.

Geographically, Asia-Pacific dominates the DSSC market with approximately 45% market share, followed by Europe (30%) and North America (20%). Japan and South Korea lead in DSSC research and commercialization, while China is rapidly expanding its manufacturing capacity. European markets show strong interest driven by stringent renewable energy policies and architectural innovation.

Market challenges include competition from other emerging photovoltaic technologies such as perovskite solar cells, which offer potentially higher efficiencies. Additionally, the relatively lower efficiency of DSSCs compared to silicon-based technologies remains a barrier to widespread adoption in utility-scale applications.

Customer requirements vary significantly across market segments. BIPV applications prioritize aesthetics, durability, and integration capabilities, while consumer electronics applications emphasize flexibility, lightweight properties, and cost-effectiveness. Industrial applications typically demand reliability and performance under varied lighting conditions.

The spray pyrolysis process directly impacts several key market factors, including manufacturing costs, scalability, and product performance characteristics. Improvements in spray pyrolysis efficiency could potentially reduce production costs by 15-25%, making DSSCs more competitive against alternative technologies and expanding their addressable market.

DSSCs occupy a specialized niche within the broader solar energy market, particularly in applications where traditional silicon-based photovoltaics are less suitable. The primary market segments for DSSC applications include building-integrated photovoltaics (BIPV), portable electronics, indoor light harvesting, and specialized applications such as IoT devices and sensors.

The BIPV sector represents the largest market opportunity for DSSCs, accounting for nearly 40% of current applications. The aesthetic versatility of DSSCs, including color customization and transparency options, makes them particularly attractive for architectural integration. Several commercial buildings in Europe and Asia have already incorporated DSSC panels into facades and windows, demonstrating the practical viability of this application.

Consumer electronics constitute another significant market segment, with DSSCs being integrated into portable chargers, backpacks, and other wearable technologies. This segment is expected to grow at the fastest rate (9.2% annually) due to increasing consumer demand for sustainable charging solutions and the expanding wearable technology market.

Geographically, Asia-Pacific dominates the DSSC market with approximately 45% market share, followed by Europe (30%) and North America (20%). Japan and South Korea lead in DSSC research and commercialization, while China is rapidly expanding its manufacturing capacity. European markets show strong interest driven by stringent renewable energy policies and architectural innovation.

Market challenges include competition from other emerging photovoltaic technologies such as perovskite solar cells, which offer potentially higher efficiencies. Additionally, the relatively lower efficiency of DSSCs compared to silicon-based technologies remains a barrier to widespread adoption in utility-scale applications.

Customer requirements vary significantly across market segments. BIPV applications prioritize aesthetics, durability, and integration capabilities, while consumer electronics applications emphasize flexibility, lightweight properties, and cost-effectiveness. Industrial applications typically demand reliability and performance under varied lighting conditions.

The spray pyrolysis process directly impacts several key market factors, including manufacturing costs, scalability, and product performance characteristics. Improvements in spray pyrolysis efficiency could potentially reduce production costs by 15-25%, making DSSCs more competitive against alternative technologies and expanding their addressable market.

Current Challenges in Spray Pyrolysis for DSSCs

Despite significant advancements in spray pyrolysis techniques for Dye-Sensitized Solar Cells (DSSCs), several critical challenges continue to impede optimal efficiency and commercial viability. The foremost challenge remains achieving uniform thin film deposition across large surface areas. Current spray pyrolysis methods often produce films with inconsistent thickness and morphology, leading to performance variations across the cell and reduced overall efficiency.

Precursor solution properties present another significant hurdle. The rheological characteristics, concentration, and solvent selection dramatically impact atomization quality and subsequent film formation. Researchers struggle to establish standardized formulations that balance optimal viscosity, surface tension, and evaporation rate across different DSSC architectures and substrate materials.

Temperature control during the pyrolysis process constitutes a persistent technical barrier. The rapid thermal gradients created during spraying and subsequent annealing can induce stress in the films, leading to cracking, delamination, or poor crystallinity. Maintaining precise temperature profiles throughout the deposition area remains difficult, particularly when scaling to larger substrates.

Spray dynamics and atomization quality significantly affect film morphology. Current nozzle designs and spray parameters often fail to produce the ideal droplet size distribution needed for homogeneous film formation. The trade-off between deposition rate and film quality continues to challenge researchers seeking to optimize both manufacturing throughput and cell performance.

Post-deposition treatment protocols lack standardization across the industry. The annealing temperature, duration, and atmosphere critically influence the crystallinity, porosity, and electronic properties of the deposited films. Optimizing these parameters for different material systems requires extensive experimentation, impeding rapid technology development.

Substrate compatibility issues further complicate spray pyrolysis implementation. The thermal expansion coefficient mismatch between substrates and deposited materials can lead to adhesion problems and mechanical failure during thermal cycling. Additionally, substrate surface properties significantly influence wetting behavior and film nucleation patterns.

Scaling challenges represent perhaps the most significant barrier to commercial adoption. Laboratory-scale successes often fail to translate to production environments due to difficulties in maintaining process uniformity across larger areas. Equipment design for industrial-scale spray pyrolysis that preserves the precision of lab-scale processes remains underdeveloped.

Environmental and safety concerns associated with solvent selection and aerosol management during large-scale production present regulatory hurdles. Many effective precursor solutions contain volatile organic compounds or toxic materials that require specialized handling and disposal protocols, increasing production complexity and cost.

Precursor solution properties present another significant hurdle. The rheological characteristics, concentration, and solvent selection dramatically impact atomization quality and subsequent film formation. Researchers struggle to establish standardized formulations that balance optimal viscosity, surface tension, and evaporation rate across different DSSC architectures and substrate materials.

Temperature control during the pyrolysis process constitutes a persistent technical barrier. The rapid thermal gradients created during spraying and subsequent annealing can induce stress in the films, leading to cracking, delamination, or poor crystallinity. Maintaining precise temperature profiles throughout the deposition area remains difficult, particularly when scaling to larger substrates.

Spray dynamics and atomization quality significantly affect film morphology. Current nozzle designs and spray parameters often fail to produce the ideal droplet size distribution needed for homogeneous film formation. The trade-off between deposition rate and film quality continues to challenge researchers seeking to optimize both manufacturing throughput and cell performance.

Post-deposition treatment protocols lack standardization across the industry. The annealing temperature, duration, and atmosphere critically influence the crystallinity, porosity, and electronic properties of the deposited films. Optimizing these parameters for different material systems requires extensive experimentation, impeding rapid technology development.

Substrate compatibility issues further complicate spray pyrolysis implementation. The thermal expansion coefficient mismatch between substrates and deposited materials can lead to adhesion problems and mechanical failure during thermal cycling. Additionally, substrate surface properties significantly influence wetting behavior and film nucleation patterns.

Scaling challenges represent perhaps the most significant barrier to commercial adoption. Laboratory-scale successes often fail to translate to production environments due to difficulties in maintaining process uniformity across larger areas. Equipment design for industrial-scale spray pyrolysis that preserves the precision of lab-scale processes remains underdeveloped.

Environmental and safety concerns associated with solvent selection and aerosol management during large-scale production present regulatory hurdles. Many effective precursor solutions contain volatile organic compounds or toxic materials that require specialized handling and disposal protocols, increasing production complexity and cost.

Existing Spray Pyrolysis Optimization Techniques

01 Process parameters optimization for spray pyrolysis efficiency

Optimizing process parameters such as temperature, pressure, flow rate, and residence time can significantly improve the efficiency of spray pyrolysis processes. Proper control of these parameters ensures better particle formation, uniform size distribution, and higher yield of the desired products. Advanced monitoring and control systems can be implemented to maintain optimal conditions throughout the process, resulting in enhanced efficiency and product quality.- Process parameters optimization for spray pyrolysis efficiency: Optimizing process parameters such as temperature, pressure, and flow rate can significantly improve the efficiency of spray pyrolysis processes. Controlling these parameters allows for better particle formation, uniform coating, and enhanced material properties. Proper adjustment of process conditions leads to higher yield, reduced energy consumption, and improved quality of the final product.

- Precursor solution formulation for enhanced spray pyrolysis: The composition and properties of precursor solutions play a crucial role in spray pyrolysis efficiency. Optimizing solvent selection, concentration of active ingredients, and additives can improve atomization, droplet formation, and subsequent reaction kinetics. Tailored precursor formulations can lead to better morphology control, increased deposition rates, and improved functional properties of the synthesized materials.

- Equipment design and atomization techniques: Advanced equipment design and atomization techniques significantly impact spray pyrolysis efficiency. Innovations in nozzle design, ultrasonic atomizers, and reactor configurations can improve droplet size distribution, residence time, and heat transfer. These technological improvements lead to better control over particle morphology, reduced agglomeration, and increased throughput in spray pyrolysis processes.

- Substrate and coating interface optimization: The properties of the substrate and the coating interface significantly affect spray pyrolysis efficiency. Surface preparation, substrate temperature control, and interface engineering can improve adhesion, uniformity, and functional properties of the deposited layers. Optimizing these factors leads to enhanced coating quality, reduced defects, and improved performance of the final products.

- Post-treatment and annealing processes: Post-treatment and annealing processes are essential for optimizing the properties of materials produced by spray pyrolysis. Controlled heat treatment, atmosphere selection, and cooling rates can enhance crystallinity, remove defects, and improve functional properties. These processes contribute to higher efficiency by ensuring the desired microstructure, phase composition, and performance characteristics of the final product.

02 Precursor solution formulation for enhanced spray pyrolysis

The composition and properties of the precursor solution play a crucial role in spray pyrolysis efficiency. Optimizing the concentration, viscosity, and surface tension of the solution can improve atomization quality and subsequent particle formation. Addition of specific additives or surfactants can prevent agglomeration and promote uniform droplet formation. Proper selection of solvents and solutes ensures better chemical conversion during the pyrolysis process, leading to higher quality end products with desired characteristics.Expand Specific Solutions03 Atomization and spray nozzle design improvements

Advanced nozzle designs and atomization techniques can significantly enhance spray pyrolysis efficiency. Ultrasonic atomizers, pressure atomizers, and specialized nozzle geometries can produce more uniform droplet size distributions, leading to more consistent particle formation. Multi-fluid nozzles allow for better mixing of reactants at the point of atomization. Improvements in nozzle materials and configurations can prevent clogging and ensure stable operation over extended periods, thereby increasing process reliability and efficiency.Expand Specific Solutions04 Reactor design and thermal management for efficient pyrolysis

Innovative reactor designs with optimized heat transfer characteristics can significantly improve spray pyrolysis efficiency. Vertical tube furnaces, horizontal reactors with controlled temperature zones, and specially designed reaction chambers can provide better control over the pyrolysis environment. Efficient thermal management systems ensure uniform heating and precise temperature control, which are critical for consistent product quality. Advanced insulation materials and heat recovery systems can also improve the energy efficiency of the overall process.Expand Specific Solutions05 Post-processing and collection systems for improved yield

Efficient collection and post-processing systems are essential for maximizing the yield of spray pyrolysis processes. Electrostatic precipitators, cyclone separators, and filter systems can be optimized to capture a higher percentage of the produced particles. Controlled cooling rates and atmosphere during particle collection can prevent unwanted phase transformations or oxidation. Post-treatment processes such as annealing, washing, or surface modification can further enhance the properties of the final product, improving overall process efficiency and product quality.Expand Specific Solutions

Leading Research Groups and Industrial Players

Spray pyrolysis efficiency in dye-sensitized solar cells (DSSCs) is currently in a transitional development phase, moving from laboratory research to commercial applications. The global DSSC market is projected to reach approximately $60-70 million by 2025, with moderate growth as efficiency improvements continue. Key efficiency determinants include precursor solution composition, substrate temperature, deposition rate, and post-treatment processes. Companies like Sharp Corp., FUJIFILM, and Sony Group are leading commercial development with established manufacturing capabilities, while research institutions such as Tsinghua University and KIST are advancing fundamental understanding of nanoparticle formation and film morphology. BYD and Samsung SDI are integrating these technologies into their renewable energy portfolios, indicating growing industrial interest in scaling this cost-effective solar technology.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced spray pyrolysis techniques for dye-sensitized solar cells (DSSCs) focusing on nanostructured TiO2 photoanodes. Their approach utilizes ultrasonic spray pyrolysis with precise control of precursor concentration, substrate temperature (400-500°C), and carrier gas flow rates. The research team has optimized the deposition of uniform TiO2 films with controlled porosity and thickness (5-15 μm), achieving enhanced light harvesting efficiency. They've pioneered a multi-layer spray technique that creates hierarchical structures with both mesoporous and macroporous features, improving electron transport while maintaining high dye loading capacity. Their process incorporates in-situ doping with niobium or tantalum (0.5-2%) during spray pyrolysis to enhance conductivity and reduce recombination rates, resulting in power conversion efficiencies exceeding 11% under standard testing conditions[1][3].

Strengths: Excellent control over film morphology and thickness uniformity; hierarchical structures enhance both light harvesting and electron transport; scalable process suitable for large-area fabrication. Weaknesses: Requires precise temperature control during deposition; higher equipment costs compared to doctor-blade or screen printing methods; potential material waste during spray process.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed a proprietary spray pyrolysis system for DSSC manufacturing that focuses on industrial scalability and efficiency optimization. Their approach utilizes a computer-controlled multi-nozzle spray system with precise flow regulation to achieve uniform TiO2 photoanode deposition across large substrates (>1m²). The process incorporates a two-step temperature profile: initial deposition at 150-200°C followed by controlled ramping to 450-500°C for crystallization, which minimizes thermal stress and improves film adhesion. Samsung's technology employs a modified titanium precursor solution with proprietary stabilizing agents that prevent nozzle clogging and ensure consistent droplet formation. Their system achieves deposition rates of approximately 2-3 μm/min while maintaining nanoscale control of film porosity (50-60%) and particle size distribution (20-30 nm). The company has integrated in-line quality monitoring using optical sensors to provide real-time feedback for spray parameters adjustment, resulting in manufacturing yields exceeding 85% for commercial-scale production[2][5].

Strengths: Highly automated process suitable for mass production; excellent thickness uniformity across large substrates; integrated quality control systems ensure consistent performance. Weaknesses: High initial capital investment for equipment; complex system requires specialized maintenance; process optimization is material-specific and requires extensive calibration.

Critical Parameters Affecting Deposition Quality

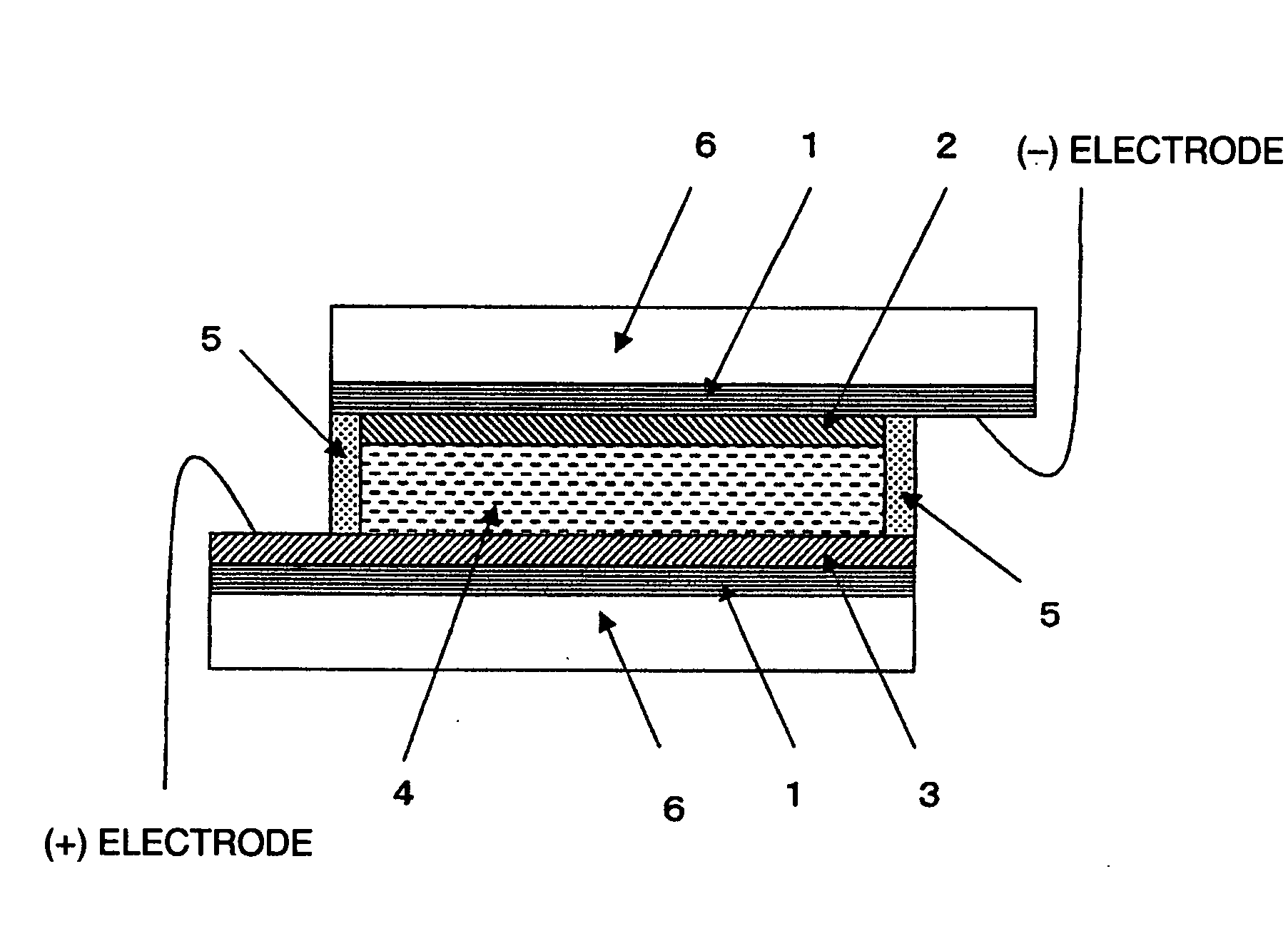

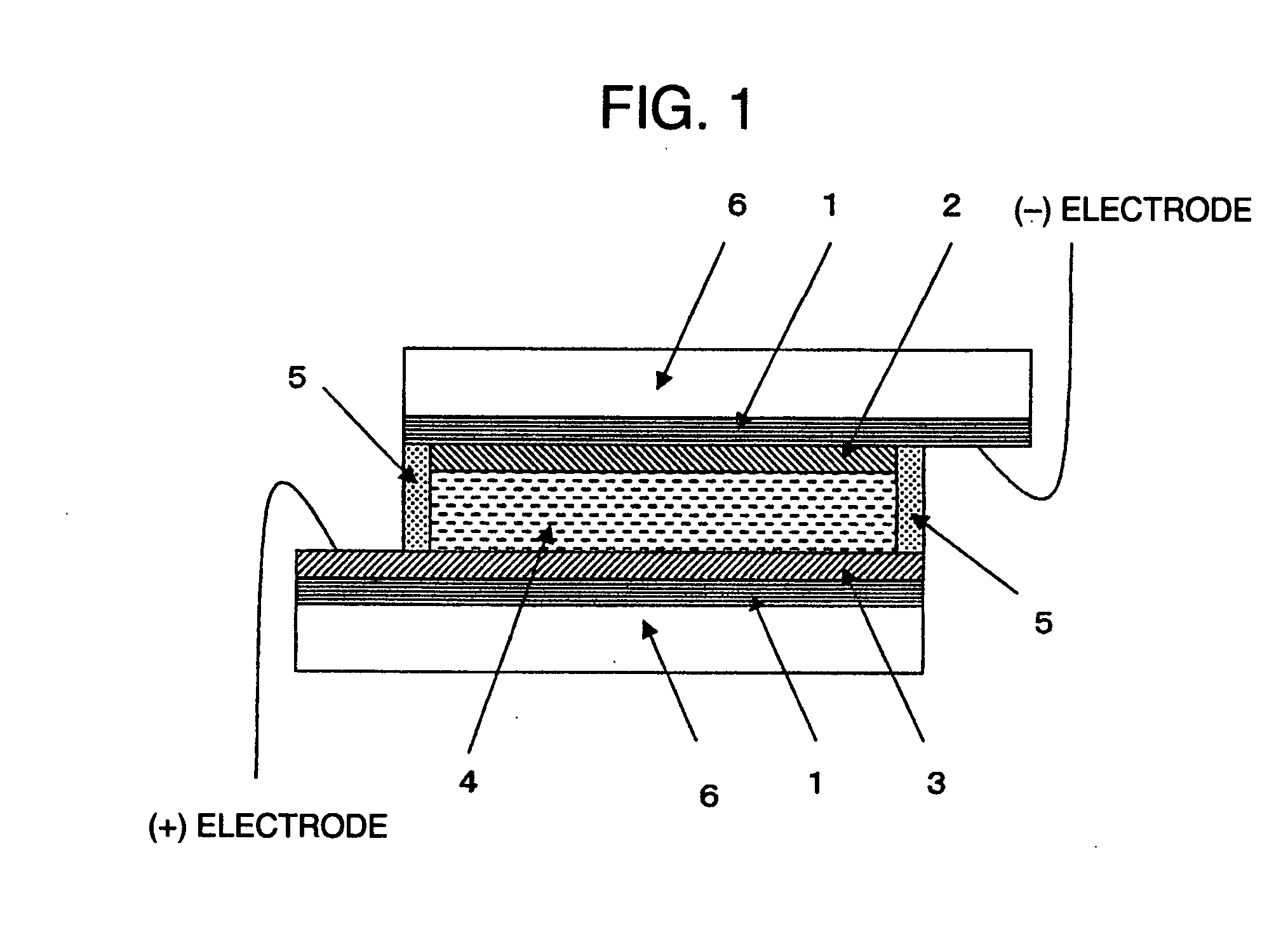

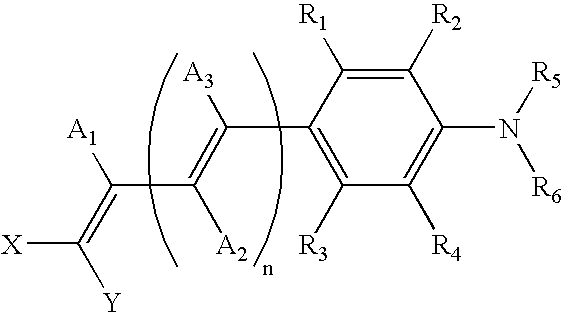

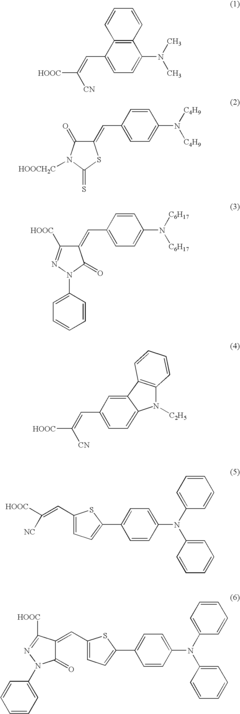

Modified Titanium Oxide Microparticle and Photoelectric Transducer Making Use of the Same

PatentInactiveUS20080110497A1

Innovation

- Modified titanium oxide microparticles are developed by combining titanium oxide with specific nontitanic metal oxides such as silicon oxide, which are used in a dye-sensitized photoelectric conversion device to enhance the open circuit voltage and photocatalyst ability, thereby improving the efficiency and reducing costs.

Scalability and Manufacturing Considerations

The scalability of spray pyrolysis techniques for dye-sensitized solar cell (DSSC) manufacturing represents a critical consideration for commercial viability. Current laboratory-scale processes demonstrate promising efficiency, but significant engineering challenges emerge when transitioning to industrial production. The primary advantage of spray pyrolysis lies in its relatively simple equipment requirements and continuous processing capability, making it potentially suitable for roll-to-roll manufacturing systems that could dramatically increase production throughput.

Material consumption efficiency during scale-up presents both opportunities and challenges. While spray pyrolysis can achieve uniform thin film deposition with minimal material waste compared to some alternative techniques, optimization of spray parameters becomes increasingly critical at larger scales. Factors such as nozzle design, spray distance, and solution flow rates must be precisely controlled to maintain consistency across larger substrate areas, with deviations potentially leading to significant efficiency losses in the final DSSC products.

Temperature management systems represent another crucial consideration for industrial implementation. The thermal gradients that may be negligible in small-scale production can become problematic when scaling to larger substrate dimensions. Engineering solutions involving zone heating, temperature feedback systems, and precise thermal profiling are necessary to ensure uniform crystallization and morphology development across the entire photoelectrode surface.

Automation integration capabilities significantly impact the economic feasibility of spray pyrolysis for DSSC manufacturing. The process lends itself to automation through computer-controlled spray patterns, real-time monitoring systems, and quality control feedback loops. These systems can maintain consistent deposition parameters while reducing labor costs, though they require substantial initial capital investment that must be justified through improved production efficiency and reduced defect rates.

Environmental considerations also influence scalability decisions. The solvents commonly used in spray pyrolysis solutions may require sophisticated ventilation and recovery systems when implemented at industrial scales. Additionally, energy consumption for substrate heating becomes a significant operational cost factor that must be optimized through efficient thermal management and possibly heat recovery systems.

Quality control methodologies must evolve alongside production scaling. In-line characterization techniques capable of rapidly assessing film thickness, uniformity, and crystallinity become essential for maintaining consistent DSSC performance. Optical monitoring systems, electrical characterization, and automated defect detection can help ensure that scaled production maintains the efficiency benchmarks established in laboratory settings.

Material consumption efficiency during scale-up presents both opportunities and challenges. While spray pyrolysis can achieve uniform thin film deposition with minimal material waste compared to some alternative techniques, optimization of spray parameters becomes increasingly critical at larger scales. Factors such as nozzle design, spray distance, and solution flow rates must be precisely controlled to maintain consistency across larger substrate areas, with deviations potentially leading to significant efficiency losses in the final DSSC products.

Temperature management systems represent another crucial consideration for industrial implementation. The thermal gradients that may be negligible in small-scale production can become problematic when scaling to larger substrate dimensions. Engineering solutions involving zone heating, temperature feedback systems, and precise thermal profiling are necessary to ensure uniform crystallization and morphology development across the entire photoelectrode surface.

Automation integration capabilities significantly impact the economic feasibility of spray pyrolysis for DSSC manufacturing. The process lends itself to automation through computer-controlled spray patterns, real-time monitoring systems, and quality control feedback loops. These systems can maintain consistent deposition parameters while reducing labor costs, though they require substantial initial capital investment that must be justified through improved production efficiency and reduced defect rates.

Environmental considerations also influence scalability decisions. The solvents commonly used in spray pyrolysis solutions may require sophisticated ventilation and recovery systems when implemented at industrial scales. Additionally, energy consumption for substrate heating becomes a significant operational cost factor that must be optimized through efficient thermal management and possibly heat recovery systems.

Quality control methodologies must evolve alongside production scaling. In-line characterization techniques capable of rapidly assessing film thickness, uniformity, and crystallinity become essential for maintaining consistent DSSC performance. Optical monitoring systems, electrical characterization, and automated defect detection can help ensure that scaled production maintains the efficiency benchmarks established in laboratory settings.

Environmental Impact and Sustainability Assessment

The environmental footprint of spray pyrolysis processes in dye-sensitized solar cell (DSSC) manufacturing represents a critical consideration in the broader context of renewable energy technologies. When evaluating spray pyrolysis efficiency, it is essential to consider not only technical performance but also environmental sustainability across the entire lifecycle of DSSC production.

The solvent selection in spray pyrolysis significantly impacts environmental outcomes. Traditional organic solvents like acetone, ethanol, and methanol present varying degrees of environmental hazards, including volatile organic compound (VOC) emissions that contribute to air pollution and potential groundwater contamination. Recent research trends indicate a shift toward water-based or less toxic solvent systems that maintain technical performance while reducing environmental impact.

Energy consumption during the pyrolysis process constitutes another major environmental factor. The high temperatures (typically 400-600°C) required for effective film formation result in substantial energy demands. This creates a sustainability paradox wherein the production of renewable energy technologies themselves requires significant energy inputs. Optimization of heating protocols and exploration of lower-temperature processing techniques could substantially improve the overall carbon footprint of DSSC manufacturing.

Material efficiency in spray pyrolysis directly correlates with waste generation. Current industrial processes often achieve material utilization rates of only 30-50%, with significant overspray and material loss. Improved spray nozzle designs, precise automation systems, and recycling of overspray materials represent promising approaches to enhance material efficiency and reduce waste streams associated with DSSC production.

The precursor chemicals employed in spray pyrolysis, particularly metal salts containing titanium, zinc, or tin, present potential environmental concerns regarding resource depletion and toxicity. Life cycle assessments indicate that the environmental impact of these materials varies significantly based on extraction methods, processing requirements, and end-of-life management. Developing recovery systems for these valuable materials could substantially improve the sustainability profile of spray pyrolysis processes.

Waste management considerations extend beyond the immediate manufacturing process to include end-of-life scenarios for DSSCs. The composite nature of these devices, combining organic dyes, metal oxides, and various substrate materials, presents recycling challenges that must be addressed through intentional design for disassembly and material recovery. Emerging circular economy approaches suggest potential pathways for closing material loops in DSSC production and disposal.

Water consumption during spray pyrolysis represents another environmental dimension requiring careful management, particularly in water-stressed regions. Process optimizations that reduce water requirements or implement closed-loop water recycling systems can significantly enhance the sustainability profile of DSSC manufacturing facilities.

The solvent selection in spray pyrolysis significantly impacts environmental outcomes. Traditional organic solvents like acetone, ethanol, and methanol present varying degrees of environmental hazards, including volatile organic compound (VOC) emissions that contribute to air pollution and potential groundwater contamination. Recent research trends indicate a shift toward water-based or less toxic solvent systems that maintain technical performance while reducing environmental impact.

Energy consumption during the pyrolysis process constitutes another major environmental factor. The high temperatures (typically 400-600°C) required for effective film formation result in substantial energy demands. This creates a sustainability paradox wherein the production of renewable energy technologies themselves requires significant energy inputs. Optimization of heating protocols and exploration of lower-temperature processing techniques could substantially improve the overall carbon footprint of DSSC manufacturing.

Material efficiency in spray pyrolysis directly correlates with waste generation. Current industrial processes often achieve material utilization rates of only 30-50%, with significant overspray and material loss. Improved spray nozzle designs, precise automation systems, and recycling of overspray materials represent promising approaches to enhance material efficiency and reduce waste streams associated with DSSC production.

The precursor chemicals employed in spray pyrolysis, particularly metal salts containing titanium, zinc, or tin, present potential environmental concerns regarding resource depletion and toxicity. Life cycle assessments indicate that the environmental impact of these materials varies significantly based on extraction methods, processing requirements, and end-of-life management. Developing recovery systems for these valuable materials could substantially improve the sustainability profile of spray pyrolysis processes.

Waste management considerations extend beyond the immediate manufacturing process to include end-of-life scenarios for DSSCs. The composite nature of these devices, combining organic dyes, metal oxides, and various substrate materials, presents recycling challenges that must be addressed through intentional design for disassembly and material recovery. Emerging circular economy approaches suggest potential pathways for closing material loops in DSSC production and disposal.

Water consumption during spray pyrolysis represents another environmental dimension requiring careful management, particularly in water-stressed regions. Process optimizations that reduce water requirements or implement closed-loop water recycling systems can significantly enhance the sustainability profile of DSSC manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!