Applications of Conductive Polymer Composites in Flexible Electronics

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Evolution and Research Objectives

Conductive polymers have evolved significantly since their discovery in the 1970s when Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa demonstrated that polyacetylene could conduct electricity when doped with iodine. This groundbreaking work, which earned them the Nobel Prize in Chemistry in 2000, opened a new frontier in materials science that bridges the traditionally separate fields of polymers and electronic conductors.

The evolution of conductive polymers has progressed through several distinct phases. Initially, research focused on understanding the fundamental mechanisms of conductivity in these materials, particularly the role of conjugated backbones and charge carriers. The second phase, spanning the 1980s and 1990s, saw the development of more stable and processable conductive polymers such as polypyrrole, polyaniline, and poly(3,4-ethylenedioxythiophene) (PEDOT). These materials addressed many of the limitations of polyacetylene, particularly its environmental instability.

The third phase, beginning in the early 2000s, has been characterized by the engineering of conductive polymer composites (CPCs) that combine the electrical properties of conductive polymers with the mechanical advantages of conventional polymers. This has been particularly significant for flexible electronics applications, where mechanical flexibility must be balanced with electrical performance.

Recent advancements have focused on enhancing the electrical conductivity of these composites while maintaining their flexibility and stretchability. Strategies include the incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles, as well as the development of novel processing techniques that optimize the dispersion and alignment of conductive fillers within the polymer matrix.

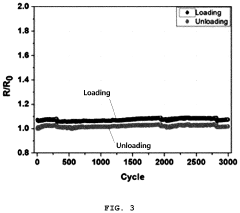

The current research objectives in this field are multifaceted. First, there is a push to develop CPCs with higher conductivity at lower filler loadings to maintain the mechanical properties of the host polymer. Second, researchers are working to improve the stability of these materials under mechanical deformation, as conductivity often degrades with repeated stretching or bending. Third, there is significant interest in developing sustainable and biocompatible CPCs for applications in wearable electronics and biomedical devices.

Another key objective is the scalable manufacturing of these materials. While laboratory-scale production has demonstrated impressive results, transitioning to industrial-scale production while maintaining performance consistency remains challenging. Researchers are exploring various approaches, including roll-to-roll processing, 3D printing, and solution-based deposition techniques.

Looking forward, the field is moving toward multifunctional CPCs that not only conduct electricity but also respond to environmental stimuli, self-heal when damaged, or harvest energy from their surroundings. These advanced materials will enable the next generation of flexible electronics, including fully integrated systems that combine sensing, computing, and communication functions in lightweight, conformable formats.

The evolution of conductive polymers has progressed through several distinct phases. Initially, research focused on understanding the fundamental mechanisms of conductivity in these materials, particularly the role of conjugated backbones and charge carriers. The second phase, spanning the 1980s and 1990s, saw the development of more stable and processable conductive polymers such as polypyrrole, polyaniline, and poly(3,4-ethylenedioxythiophene) (PEDOT). These materials addressed many of the limitations of polyacetylene, particularly its environmental instability.

The third phase, beginning in the early 2000s, has been characterized by the engineering of conductive polymer composites (CPCs) that combine the electrical properties of conductive polymers with the mechanical advantages of conventional polymers. This has been particularly significant for flexible electronics applications, where mechanical flexibility must be balanced with electrical performance.

Recent advancements have focused on enhancing the electrical conductivity of these composites while maintaining their flexibility and stretchability. Strategies include the incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles, as well as the development of novel processing techniques that optimize the dispersion and alignment of conductive fillers within the polymer matrix.

The current research objectives in this field are multifaceted. First, there is a push to develop CPCs with higher conductivity at lower filler loadings to maintain the mechanical properties of the host polymer. Second, researchers are working to improve the stability of these materials under mechanical deformation, as conductivity often degrades with repeated stretching or bending. Third, there is significant interest in developing sustainable and biocompatible CPCs for applications in wearable electronics and biomedical devices.

Another key objective is the scalable manufacturing of these materials. While laboratory-scale production has demonstrated impressive results, transitioning to industrial-scale production while maintaining performance consistency remains challenging. Researchers are exploring various approaches, including roll-to-roll processing, 3D printing, and solution-based deposition techniques.

Looking forward, the field is moving toward multifunctional CPCs that not only conduct electricity but also respond to environmental stimuli, self-heal when damaged, or harvest energy from their surroundings. These advanced materials will enable the next generation of flexible electronics, including fully integrated systems that combine sensing, computing, and communication functions in lightweight, conformable formats.

Market Analysis for Flexible Electronics Applications

The flexible electronics market has experienced remarkable growth in recent years, driven by increasing demand for lightweight, portable, and bendable electronic devices. The global flexible electronics market was valued at approximately $29.28 billion in 2020 and is projected to reach $73.43 billion by 2027, growing at a CAGR of 14.2% during the forecast period. Conductive polymer composites (CPCs) have emerged as critical materials enabling this market expansion due to their unique combination of electrical conductivity and mechanical flexibility.

Consumer electronics represents the largest application segment for flexible electronics incorporating CPCs, accounting for roughly 35% of the total market share. This segment includes flexible displays, wearable devices, and foldable smartphones. The healthcare sector follows closely, with applications in electronic skin patches, flexible biosensors, and implantable medical devices, constituting about 28% of the market.

Regional analysis reveals that Asia-Pacific dominates the flexible electronics market with approximately 42% share, led by manufacturing powerhouses like South Korea, Japan, China, and Taiwan. North America holds about 30% of the market share, with significant contributions from research institutions and technology companies focused on advanced applications. Europe accounts for roughly 22% of the market, with particular strength in automotive and healthcare applications.

The automotive industry represents a rapidly growing application area for CPC-based flexible electronics, with applications in interior lighting, touch-sensitive controls, and conformable sensors. This segment is expected to grow at a CAGR of 16.8% through 2027, outpacing the overall market growth rate.

Key market drivers include the miniaturization trend in electronics, growing demand for Internet of Things (IoT) devices, and increasing adoption of wearable technology. The push for sustainable and environmentally friendly electronics has also boosted interest in CPCs as alternatives to traditional rigid circuit boards and toxic materials.

Market challenges include high production costs compared to conventional electronics, technical limitations in performance metrics such as conductivity and durability, and scaling issues for mass production. The average manufacturing cost for flexible electronic components remains approximately 30-40% higher than their rigid counterparts, though this gap is narrowing as production technologies mature.

Consumer preference surveys indicate strong market pull for flexible devices, with 68% of respondents expressing interest in foldable displays and 72% showing preference for wearable devices with improved comfort through flexibility. This consumer demand is expected to continue driving market growth for CPC applications in flexible electronics across multiple sectors.

Consumer electronics represents the largest application segment for flexible electronics incorporating CPCs, accounting for roughly 35% of the total market share. This segment includes flexible displays, wearable devices, and foldable smartphones. The healthcare sector follows closely, with applications in electronic skin patches, flexible biosensors, and implantable medical devices, constituting about 28% of the market.

Regional analysis reveals that Asia-Pacific dominates the flexible electronics market with approximately 42% share, led by manufacturing powerhouses like South Korea, Japan, China, and Taiwan. North America holds about 30% of the market share, with significant contributions from research institutions and technology companies focused on advanced applications. Europe accounts for roughly 22% of the market, with particular strength in automotive and healthcare applications.

The automotive industry represents a rapidly growing application area for CPC-based flexible electronics, with applications in interior lighting, touch-sensitive controls, and conformable sensors. This segment is expected to grow at a CAGR of 16.8% through 2027, outpacing the overall market growth rate.

Key market drivers include the miniaturization trend in electronics, growing demand for Internet of Things (IoT) devices, and increasing adoption of wearable technology. The push for sustainable and environmentally friendly electronics has also boosted interest in CPCs as alternatives to traditional rigid circuit boards and toxic materials.

Market challenges include high production costs compared to conventional electronics, technical limitations in performance metrics such as conductivity and durability, and scaling issues for mass production. The average manufacturing cost for flexible electronic components remains approximately 30-40% higher than their rigid counterparts, though this gap is narrowing as production technologies mature.

Consumer preference surveys indicate strong market pull for flexible devices, with 68% of respondents expressing interest in foldable displays and 72% showing preference for wearable devices with improved comfort through flexibility. This consumer demand is expected to continue driving market growth for CPC applications in flexible electronics across multiple sectors.

Current Limitations and Technical Barriers

Despite the promising potential of conductive polymer composites (CPCs) in flexible electronics, several significant technical barriers currently limit their widespread commercial adoption. The electrical conductivity of CPCs remains substantially lower than traditional metallic conductors, typically by several orders of magnitude. This limitation restricts their application in high-performance electronic circuits where signal integrity and power efficiency are critical. The conductivity-flexibility trade-off presents another fundamental challenge, as increasing conductive filler content to enhance electrical properties often results in reduced mechanical flexibility and increased brittleness.

Manufacturing scalability poses a significant hurdle for CPC implementation. Current production methods for high-quality CPCs often involve complex processes that are difficult to scale up while maintaining consistent material properties. Batch-to-batch variations in electrical conductivity, mechanical properties, and thermal stability remain problematic for mass production scenarios, creating reliability concerns for commercial applications.

Environmental stability represents another critical limitation. Many conductive polymers exhibit performance degradation when exposed to oxygen, moisture, UV radiation, and temperature fluctuations. This vulnerability necessitates sophisticated encapsulation techniques that add complexity and cost to the final products while potentially compromising flexibility advantages.

Interface engineering between the polymer matrix and conductive fillers remains challenging. Poor interfacial adhesion leads to phase separation during mechanical deformation, resulting in unstable electrical properties under strain. This instability manifests as significant resistance fluctuations during bending, stretching, or twisting operations, limiting reliability in wearable and flexible device applications.

The cost-performance ratio of CPCs currently lags behind conventional electronics materials. High-quality conductive fillers such as carbon nanotubes, graphene, and silver nanowires remain expensive for mass-market applications. Additionally, the specialized processing techniques required for optimal dispersion and network formation further increase production costs.

Standardization issues compound these challenges, as the lack of universally accepted testing protocols and performance metrics makes it difficult to compare different CPC formulations across research groups and manufacturers. This absence of standardization slows industry adoption and complicates quality control processes.

Finally, integration challenges exist at the system level. Connecting CPC-based components with traditional electronic elements requires specialized interface solutions to address differences in electrical, mechanical, and thermal properties. These integration complexities often necessitate complete redesigns of electronic systems rather than simple component substitutions, creating significant barriers to adoption in established product ecosystems.

Manufacturing scalability poses a significant hurdle for CPC implementation. Current production methods for high-quality CPCs often involve complex processes that are difficult to scale up while maintaining consistent material properties. Batch-to-batch variations in electrical conductivity, mechanical properties, and thermal stability remain problematic for mass production scenarios, creating reliability concerns for commercial applications.

Environmental stability represents another critical limitation. Many conductive polymers exhibit performance degradation when exposed to oxygen, moisture, UV radiation, and temperature fluctuations. This vulnerability necessitates sophisticated encapsulation techniques that add complexity and cost to the final products while potentially compromising flexibility advantages.

Interface engineering between the polymer matrix and conductive fillers remains challenging. Poor interfacial adhesion leads to phase separation during mechanical deformation, resulting in unstable electrical properties under strain. This instability manifests as significant resistance fluctuations during bending, stretching, or twisting operations, limiting reliability in wearable and flexible device applications.

The cost-performance ratio of CPCs currently lags behind conventional electronics materials. High-quality conductive fillers such as carbon nanotubes, graphene, and silver nanowires remain expensive for mass-market applications. Additionally, the specialized processing techniques required for optimal dispersion and network formation further increase production costs.

Standardization issues compound these challenges, as the lack of universally accepted testing protocols and performance metrics makes it difficult to compare different CPC formulations across research groups and manufacturers. This absence of standardization slows industry adoption and complicates quality control processes.

Finally, integration challenges exist at the system level. Connecting CPC-based components with traditional electronic elements requires specialized interface solutions to address differences in electrical, mechanical, and thermal properties. These integration complexities often necessitate complete redesigns of electronic systems rather than simple component substitutions, creating significant barriers to adoption in established product ecosystems.

Current Implementation Approaches

01 Carbon-based conductive polymer composites

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into polymer matrices to create conductive composites. These fillers provide excellent electrical conductivity while maintaining the mechanical properties of the polymer. The resulting composites can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics. The dispersion method and filler concentration significantly affect the final conductivity of the composite.- Carbon-based conductive polymer composites: Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into polymer matrices to create conductive composites. These fillers provide excellent electrical conductivity while maintaining the mechanical properties of the polymer. The resulting composites can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics. The dispersion method and filler concentration significantly affect the conductivity and performance of these composites.

- Metal-polymer conductive composites: Metal particles or nanowires, such as silver, copper, or aluminum, are incorporated into polymer matrices to create conductive composites. These metal fillers provide high electrical conductivity and can be used in applications requiring lower resistance than carbon-based composites. The metal-polymer composites often exhibit excellent thermal conductivity alongside electrical conductivity, making them suitable for thermal management applications. Processing techniques must be carefully controlled to prevent aggregation of metal particles and ensure uniform conductivity.

- Intrinsically conductive polymers in composites: Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS are used either as the matrix or as additives in polymer composites. These materials provide conductivity through their conjugated backbone structure without requiring additional conductive fillers. The conductivity can be tuned through doping processes, and these composites often offer advantages in processability and flexibility. Applications include sensors, actuators, and organic electronics where traditional metal conductors may not be suitable.

- Hybrid conductive polymer composites: Hybrid composites combine multiple types of conductive fillers (such as carbon nanotubes with metal particles) or blend different polymers to achieve synergistic effects in conductivity and mechanical properties. These hybrid systems often achieve higher conductivity at lower filler loadings due to the formation of more efficient conductive networks. The combination of different materials can also provide multifunctional properties such as simultaneous thermal and electrical conductivity or self-healing capabilities alongside conductivity.

- Processing and manufacturing techniques for conductive polymer composites: Various processing techniques are employed to manufacture conductive polymer composites, including melt blending, solution mixing, in-situ polymerization, and 3D printing. These methods significantly impact the dispersion of conductive fillers and the resulting electrical properties of the composites. Surface modification of fillers and the use of compatibilizers can improve the interface between the polymer matrix and conductive additives. Advanced manufacturing techniques allow for the creation of complex structures with controlled conductivity patterns for specialized applications.

02 Metal-polymer conductive composites

Metal particles or nanowires are incorporated into polymer matrices to create conductive composites with enhanced electrical properties. Common metals used include silver, copper, and nickel. These composites offer advantages such as high conductivity, flexibility, and processability. The metal-polymer interface plays a crucial role in determining the overall performance of the composite. Applications include printed electronics, sensors, and electromagnetic interference shielding materials.Expand Specific Solutions03 Intrinsically conductive polymers and their composites

Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS are used either alone or in combination with conventional polymers to create conductive composites. These materials offer conductivity without requiring additional conductive fillers. The conductivity can be tuned through doping processes, and the composites maintain flexibility and processability. Applications include organic electronics, batteries, capacitors, and smart textiles.Expand Specific Solutions04 Thermal and electrical management in polymer composites

Conductive polymer composites are designed specifically for thermal management and electrical applications. These materials combine high thermal conductivity with electrical properties suitable for heat dissipation in electronic devices. The composites can be engineered to have anisotropic conductivity, allowing for directional heat flow. Fillers such as boron nitride, aluminum oxide, and specialized carbon materials are used to enhance thermal conductivity while maintaining or controlling electrical properties.Expand Specific Solutions05 Processing techniques for conductive polymer composites

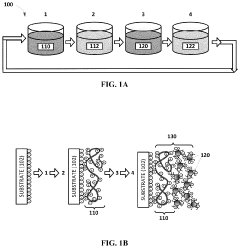

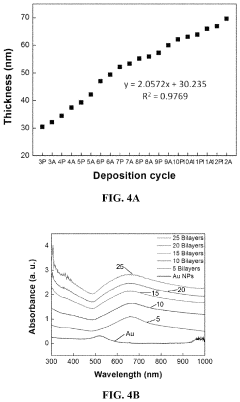

Various processing techniques are employed to manufacture conductive polymer composites with optimized properties. These include solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. The processing method significantly affects the dispersion of conductive fillers and the resulting electrical properties. Advanced techniques such as 3D printing and electrospinning are also used to create structured conductive composites with tailored properties for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions

The flexible electronics market is experiencing rapid growth, with conductive polymer composites (CPCs) emerging as a key enabling technology. Currently in the early commercialization phase, this sector is projected to reach significant market size due to increasing demand for wearable devices and IoT applications. Leading research institutions like KIST Corp., Georgia Tech Research Corp., and Carnegie Mellon University are advancing fundamental CPC science, while industrial players including DuPont, Toyobo, and Peratech are commercializing applications. The technology maturity varies across applications, with established companies like DuPont offering market-ready solutions, while startups like Pixelligent Technologies focus on next-generation nanocomposites. Academic-industrial partnerships are accelerating innovation, positioning CPCs as critical materials for future flexible electronic devices.

KIST Corp. (South Korea)

Technical Solution: KIST (Korea Institute of Science and Technology) has developed advanced conductive polymer composite technologies specifically engineered for next-generation flexible electronics. Their flagship approach involves nanocomposites combining PEDOT:PSS with silver nanowires (AgNWs) and graphene oxide, creating highly conductive yet mechanically robust materials. KIST's proprietary processing techniques include controlled solvent treatment and thermal annealing protocols that significantly enhance electrical conductivity (achieving >3000 S/cm) while maintaining excellent mechanical properties. Their materials demonstrate exceptional stability under mechanical deformation, retaining over 90% of original conductivity after 10,000 bending cycles at a radius of 2mm. KIST researchers have pioneered innovative surface modification techniques that improve adhesion between the conductive polymer layers and various flexible substrates including polyimide, PET, and textiles. Their recent breakthroughs include stretchable conductor formulations that maintain connectivity at strains exceeding 100% through engineered microcrack propagation control mechanisms. These materials have been successfully implemented in transparent electrodes for flexible displays, wearable biomedical sensors, and energy harvesting devices.

Strengths: Industry-leading combination of high conductivity and mechanical durability; excellent optical transparency (>90% in visible range) for display applications; comprehensive manufacturing protocols compatible with existing production infrastructure. Weaknesses: Some formulations show sensitivity to environmental humidity affecting long-term performance stability; higher material costs compared to conventional rigid electronics; requires specialized handling during manufacturing process.

Toyobo Co., Ltd.

Technical Solution: Toyobo has developed innovative conductive polymer composite technologies specifically designed for flexible electronic applications. Their COCOMI™ platform represents a breakthrough in textile-integrated electronics, featuring ultra-thin conductive fibers with diameters as small as 22 micrometers that can be seamlessly woven into fabrics. These fibers utilize a proprietary polymer composite structure with a conductive polymer coating over an elastic core, maintaining electrical functionality even when stretched to 150% of original length. Toyobo's manufacturing process employs specialized wet-spinning techniques followed by controlled doping procedures to achieve optimal conductivity while preserving mechanical properties. Their materials demonstrate remarkable durability, withstanding over 200 washing cycles without significant performance degradation. Recent advancements include hybrid systems combining PEDOT:PSS with silver nanoparticles to enhance conductivity while maintaining flexibility. Toyobo has also pioneered environmentally friendly formulations that eliminate harmful solvents from the manufacturing process, addressing sustainability concerns while maintaining performance specifications for applications in wearable health monitoring, smart textiles, and flexible displays.

Strengths: Exceptional integration capability with existing textile manufacturing processes; superior durability under repeated mechanical stress and washing cycles; environmentally conscious formulations reduce ecological impact. Weaknesses: Higher production costs compared to conventional electronics; some limitations in maximum achievable conductivity compared to rigid alternatives; requires specialized equipment for optimal implementation in manufacturing settings.

Key Patents and Scientific Breakthroughs

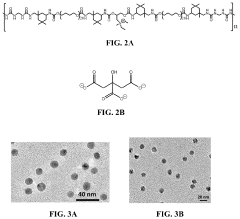

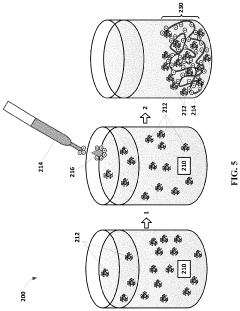

Stretchable composite conductors for flexible electronics, stretchable plasmonic devices, optical filters, and implantable devices and methods for manufacture thereof

PatentInactiveUS10629324B2

Innovation

- Development of stretchable electrically conductive composite materials comprising an elastic polymer with a plurality of conductive nanoparticles, such as gold nanoparticles, which exhibit high conductivity even at significant tensile strains through layer-by-layer assembly or vacuum-assisted flocculation processes, allowing for the creation of materials with conductivities exceeding 500 S/cm at strains up to 75%.

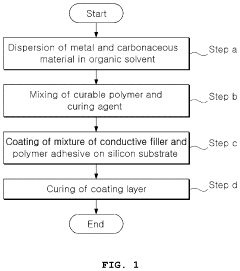

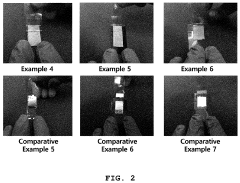

Conductive polymer composite for adhesion to flexible substrate and method for preparing same

PatentActiveUS11866623B2

Innovation

- A conductive polymer composite is developed, comprising a polymer adhesive with a curable polymer and curing agent, and a conductive filler of metal and carbonaceous materials, specifically silver and multi-walled carbon nanotubes, which is formulated to provide improved adhesion, flexibility, and stretchability on flexible substrates.

Manufacturing Scalability Considerations

The scalability of manufacturing processes represents a critical challenge for the widespread adoption of conductive polymer composites (CPCs) in flexible electronics. Current laboratory-scale production methods often fail to translate efficiently to industrial-scale manufacturing, creating a significant barrier to commercialization. The primary manufacturing techniques for CPCs include solution processing, melt processing, and in-situ polymerization, each presenting unique scalability considerations.

Solution processing methods, while offering excellent control over composite properties at small scales, face challenges in maintaining uniform dispersion of conductive fillers when scaled up. Industrial implementation requires sophisticated mixing equipment and precise process control to prevent agglomeration of conductive particles, which can significantly degrade electrical performance. Additionally, solvent recovery systems become essential at scale to address environmental concerns and reduce operational costs.

Melt processing techniques demonstrate better scalability potential, as they can leverage existing polymer processing infrastructure. However, the high viscosity of polymer melts containing conductive fillers often necessitates specialized equipment modifications. The processing window becomes narrower at scale, requiring tighter temperature and shear rate controls to maintain consistent electrical properties across large production volumes.

Roll-to-roll (R2R) manufacturing represents the most promising approach for high-volume production of flexible CPC electronics. This continuous process allows for efficient coating, printing, and lamination of conductive polymer layers on flexible substrates. Nevertheless, R2R implementation demands significant capital investment and presents challenges in maintaining registration accuracy and layer uniformity across wide webs at high speeds.

Quality control methodologies must evolve alongside manufacturing scale-up. Inline monitoring systems capable of detecting defects and variations in electrical properties become essential when transitioning from batch to continuous production. The development of rapid, non-destructive testing protocols represents a crucial aspect of manufacturing scalability.

Cost considerations also shift dramatically with scale. While material costs typically decrease through bulk purchasing, capital equipment expenses and process optimization costs increase substantially. The economic viability of CPC-based flexible electronics ultimately depends on achieving sufficient production volumes to amortize these fixed costs while maintaining product performance consistency.

Sustainability aspects of manufacturing scalability cannot be overlooked. Large-scale production amplifies environmental impacts, necessitating the development of greener synthesis routes, reduced solvent usage, and implementation of effective recycling strategies for production waste. These considerations are increasingly important as regulatory frameworks around sustainable manufacturing continue to evolve globally.

Solution processing methods, while offering excellent control over composite properties at small scales, face challenges in maintaining uniform dispersion of conductive fillers when scaled up. Industrial implementation requires sophisticated mixing equipment and precise process control to prevent agglomeration of conductive particles, which can significantly degrade electrical performance. Additionally, solvent recovery systems become essential at scale to address environmental concerns and reduce operational costs.

Melt processing techniques demonstrate better scalability potential, as they can leverage existing polymer processing infrastructure. However, the high viscosity of polymer melts containing conductive fillers often necessitates specialized equipment modifications. The processing window becomes narrower at scale, requiring tighter temperature and shear rate controls to maintain consistent electrical properties across large production volumes.

Roll-to-roll (R2R) manufacturing represents the most promising approach for high-volume production of flexible CPC electronics. This continuous process allows for efficient coating, printing, and lamination of conductive polymer layers on flexible substrates. Nevertheless, R2R implementation demands significant capital investment and presents challenges in maintaining registration accuracy and layer uniformity across wide webs at high speeds.

Quality control methodologies must evolve alongside manufacturing scale-up. Inline monitoring systems capable of detecting defects and variations in electrical properties become essential when transitioning from batch to continuous production. The development of rapid, non-destructive testing protocols represents a crucial aspect of manufacturing scalability.

Cost considerations also shift dramatically with scale. While material costs typically decrease through bulk purchasing, capital equipment expenses and process optimization costs increase substantially. The economic viability of CPC-based flexible electronics ultimately depends on achieving sufficient production volumes to amortize these fixed costs while maintaining product performance consistency.

Sustainability aspects of manufacturing scalability cannot be overlooked. Large-scale production amplifies environmental impacts, necessitating the development of greener synthesis routes, reduced solvent usage, and implementation of effective recycling strategies for production waste. These considerations are increasingly important as regulatory frameworks around sustainable manufacturing continue to evolve globally.

Environmental Impact and Sustainability

The environmental impact of conductive polymer composites (CPCs) in flexible electronics represents a critical consideration as these materials gain wider adoption. Traditional electronic manufacturing processes often involve toxic chemicals, heavy metals, and energy-intensive procedures that contribute significantly to environmental degradation. In contrast, many conductive polymers offer potentially more sustainable alternatives, being synthesizable from renewable resources and requiring less energy-intensive processing methods.

The production of CPCs typically generates a smaller carbon footprint compared to conventional metal-based conductors. For instance, the synthesis of PEDOT:PSS, a widely used conductive polymer in flexible electronics, can be achieved through aqueous processing methods that eliminate the need for harmful organic solvents. Additionally, the lower processing temperatures required for polymer-based electronics (often below 200°C) contrast favorably with the high-temperature processes needed for silicon-based electronics, resulting in reduced energy consumption.

End-of-life considerations present both challenges and opportunities for CPC-based flexible electronics. The composite nature of these materials—combining polymers with conductive fillers like carbon nanotubes or metal nanoparticles—can complicate recycling efforts. However, research into biodegradable conductive polymers shows promising results, with materials like polypyrrole-cellulose composites demonstrating both electrical functionality and environmental degradability under controlled conditions.

Life cycle assessment (LCA) studies indicate that flexible electronics utilizing CPCs can reduce environmental impact by up to 30% compared to rigid electronics with similar functionality, primarily due to material efficiency and reduced transportation emissions resulting from their lighter weight. Furthermore, the extended lifespan of flexible devices, which are more resistant to mechanical damage, contributes to waste reduction in the electronics sector.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable electronics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated research into environmentally benign conductive materials. This regulatory pressure has catalyzed innovation in "green" conductive polymers that avoid toxic dopants and additives while maintaining electrical performance.

The sustainability advantages of CPC-based flexible electronics extend beyond manufacturing and disposal. Their application in energy harvesting devices, such as flexible solar cells and piezoelectric generators, contributes to renewable energy adoption. Additionally, their use in smart packaging can reduce food waste through improved monitoring, while wearable health monitors enable more efficient healthcare delivery, demonstrating how these materials can support broader sustainability goals across multiple sectors.

The production of CPCs typically generates a smaller carbon footprint compared to conventional metal-based conductors. For instance, the synthesis of PEDOT:PSS, a widely used conductive polymer in flexible electronics, can be achieved through aqueous processing methods that eliminate the need for harmful organic solvents. Additionally, the lower processing temperatures required for polymer-based electronics (often below 200°C) contrast favorably with the high-temperature processes needed for silicon-based electronics, resulting in reduced energy consumption.

End-of-life considerations present both challenges and opportunities for CPC-based flexible electronics. The composite nature of these materials—combining polymers with conductive fillers like carbon nanotubes or metal nanoparticles—can complicate recycling efforts. However, research into biodegradable conductive polymers shows promising results, with materials like polypyrrole-cellulose composites demonstrating both electrical functionality and environmental degradability under controlled conditions.

Life cycle assessment (LCA) studies indicate that flexible electronics utilizing CPCs can reduce environmental impact by up to 30% compared to rigid electronics with similar functionality, primarily due to material efficiency and reduced transportation emissions resulting from their lighter weight. Furthermore, the extended lifespan of flexible devices, which are more resistant to mechanical damage, contributes to waste reduction in the electronics sector.

Regulatory frameworks worldwide are increasingly emphasizing the importance of sustainable electronics. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have accelerated research into environmentally benign conductive materials. This regulatory pressure has catalyzed innovation in "green" conductive polymers that avoid toxic dopants and additives while maintaining electrical performance.

The sustainability advantages of CPC-based flexible electronics extend beyond manufacturing and disposal. Their application in energy harvesting devices, such as flexible solar cells and piezoelectric generators, contributes to renewable energy adoption. Additionally, their use in smart packaging can reduce food waste through improved monitoring, while wearable health monitors enable more efficient healthcare delivery, demonstrating how these materials can support broader sustainability goals across multiple sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!