Examining the Integration of Conductive Polymer Composites in Robotics

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Composites in Robotics: Background and Objectives

Conductive polymer composites (CPCs) represent a significant advancement in materials science, combining the electrical properties of metals with the mechanical flexibility and lightweight nature of polymers. The evolution of these materials can be traced back to the 1970s with the discovery of conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa, who were awarded the Nobel Prize in Chemistry in 2000 for their groundbreaking work. Since then, CPCs have undergone substantial development, transitioning from laboratory curiosities to commercially viable materials with diverse applications.

The technological trajectory of CPCs has been characterized by continuous improvements in conductivity, mechanical properties, and processing techniques. Early conductive polymers faced significant challenges related to stability, processability, and cost-effectiveness. However, advancements in polymer science and nanotechnology have led to the development of more sophisticated composites incorporating carbon nanotubes, graphene, metal nanoparticles, and other conductive fillers, dramatically enhancing their performance characteristics.

In the context of robotics, CPCs offer unique advantages that address critical limitations of traditional materials. Conventional robots typically rely on rigid metal components and discrete electronic systems, resulting in complex manufacturing processes, increased weight, and limited flexibility. The integration of CPCs presents an opportunity to revolutionize robotic design by enabling the creation of lightweight, flexible, and potentially self-sensing structural components.

The primary technical objectives for CPC integration in robotics include developing materials with optimized electrical conductivity while maintaining mechanical flexibility, creating manufacturing processes suitable for complex robotic components, ensuring long-term stability under various environmental conditions, and achieving cost-effectiveness for commercial viability. Additionally, there is significant interest in exploiting the multifunctional nature of these materials to create components that can simultaneously serve structural, sensing, and actuation functions.

Recent trends indicate a growing convergence between soft robotics and CPCs, as researchers seek to create biomimetic robots with enhanced adaptability and safety for human interaction. This convergence is driving innovation in stretchable electronics, artificial muscles, and self-healing materials. Furthermore, the emergence of 4D printing techniques is opening new possibilities for creating programmable CPC-based structures that can change shape in response to environmental stimuli.

The ultimate goal of CPC integration in robotics is to enable a new generation of robots with enhanced capabilities, including improved human-robot interaction, adaptability to unstructured environments, energy efficiency, and simplified manufacturing processes. These advancements could potentially transform various sectors, from healthcare and manufacturing to exploration and consumer electronics, by allowing robots to perform tasks currently beyond their capabilities.

The technological trajectory of CPCs has been characterized by continuous improvements in conductivity, mechanical properties, and processing techniques. Early conductive polymers faced significant challenges related to stability, processability, and cost-effectiveness. However, advancements in polymer science and nanotechnology have led to the development of more sophisticated composites incorporating carbon nanotubes, graphene, metal nanoparticles, and other conductive fillers, dramatically enhancing their performance characteristics.

In the context of robotics, CPCs offer unique advantages that address critical limitations of traditional materials. Conventional robots typically rely on rigid metal components and discrete electronic systems, resulting in complex manufacturing processes, increased weight, and limited flexibility. The integration of CPCs presents an opportunity to revolutionize robotic design by enabling the creation of lightweight, flexible, and potentially self-sensing structural components.

The primary technical objectives for CPC integration in robotics include developing materials with optimized electrical conductivity while maintaining mechanical flexibility, creating manufacturing processes suitable for complex robotic components, ensuring long-term stability under various environmental conditions, and achieving cost-effectiveness for commercial viability. Additionally, there is significant interest in exploiting the multifunctional nature of these materials to create components that can simultaneously serve structural, sensing, and actuation functions.

Recent trends indicate a growing convergence between soft robotics and CPCs, as researchers seek to create biomimetic robots with enhanced adaptability and safety for human interaction. This convergence is driving innovation in stretchable electronics, artificial muscles, and self-healing materials. Furthermore, the emergence of 4D printing techniques is opening new possibilities for creating programmable CPC-based structures that can change shape in response to environmental stimuli.

The ultimate goal of CPC integration in robotics is to enable a new generation of robots with enhanced capabilities, including improved human-robot interaction, adaptability to unstructured environments, energy efficiency, and simplified manufacturing processes. These advancements could potentially transform various sectors, from healthcare and manufacturing to exploration and consumer electronics, by allowing robots to perform tasks currently beyond their capabilities.

Market Demand Analysis for Smart Robotic Materials

The global market for smart robotic materials, particularly conductive polymer composites (CPCs), is experiencing significant growth driven by the increasing demand for advanced robotics across multiple industries. Current market analysis indicates that the smart materials sector for robotics is expanding at a compound annual growth rate of approximately 15% between 2020 and 2025, with conductive polymer composites representing one of the fastest-growing segments.

Healthcare robotics presents a particularly promising market for CPCs, with applications in surgical robots, rehabilitation devices, and prosthetics. The tactile sensing capabilities enabled by these materials are critical for precise surgical procedures and natural movement in prosthetic limbs. This segment is projected to grow substantially as aging populations in developed countries drive increased demand for assistive technologies and minimally invasive surgical procedures.

Industrial automation represents another substantial market opportunity, with manufacturers seeking more adaptive and responsive robotic systems. The integration of CPCs enables robots to operate more safely alongside human workers through improved sensing capabilities, creating new possibilities for collaborative robotics (cobots). This market is particularly strong in automotive, electronics, and logistics sectors where precision handling of varied objects is essential.

Consumer robotics, including household assistants and entertainment robots, constitutes an emerging market for smart materials. As these devices become more sophisticated, the demand for robots capable of safe human interaction and environmental awareness increases, driving adoption of advanced sensing technologies enabled by conductive polymer composites.

Geographically, North America and Europe currently lead in adoption of smart robotic materials, primarily due to their established robotics industries and research infrastructure. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are showing the fastest growth rates as these countries heavily invest in robotics manufacturing and automation technologies.

Key market drivers include the decreasing cost of raw materials for CPCs, increasing research funding for smart materials, and growing consumer acceptance of advanced robotics. Additionally, regulatory frameworks are evolving to accommodate robots with enhanced sensing capabilities, particularly in healthcare and public-facing applications.

Market challenges include the relatively high initial implementation costs, technical integration difficulties with existing robotic platforms, and concerns about long-term durability of polymer-based materials in industrial environments. Despite these challenges, the overall market trajectory remains strongly positive as technological advancements continue to address these limitations.

Healthcare robotics presents a particularly promising market for CPCs, with applications in surgical robots, rehabilitation devices, and prosthetics. The tactile sensing capabilities enabled by these materials are critical for precise surgical procedures and natural movement in prosthetic limbs. This segment is projected to grow substantially as aging populations in developed countries drive increased demand for assistive technologies and minimally invasive surgical procedures.

Industrial automation represents another substantial market opportunity, with manufacturers seeking more adaptive and responsive robotic systems. The integration of CPCs enables robots to operate more safely alongside human workers through improved sensing capabilities, creating new possibilities for collaborative robotics (cobots). This market is particularly strong in automotive, electronics, and logistics sectors where precision handling of varied objects is essential.

Consumer robotics, including household assistants and entertainment robots, constitutes an emerging market for smart materials. As these devices become more sophisticated, the demand for robots capable of safe human interaction and environmental awareness increases, driving adoption of advanced sensing technologies enabled by conductive polymer composites.

Geographically, North America and Europe currently lead in adoption of smart robotic materials, primarily due to their established robotics industries and research infrastructure. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are showing the fastest growth rates as these countries heavily invest in robotics manufacturing and automation technologies.

Key market drivers include the decreasing cost of raw materials for CPCs, increasing research funding for smart materials, and growing consumer acceptance of advanced robotics. Additionally, regulatory frameworks are evolving to accommodate robots with enhanced sensing capabilities, particularly in healthcare and public-facing applications.

Market challenges include the relatively high initial implementation costs, technical integration difficulties with existing robotic platforms, and concerns about long-term durability of polymer-based materials in industrial environments. Despite these challenges, the overall market trajectory remains strongly positive as technological advancements continue to address these limitations.

Current State and Challenges in Polymer-Based Robotics

The field of polymer-based robotics has witnessed significant advancements in recent years, yet continues to face substantial technical challenges. Currently, conductive polymer composites (CPCs) are being integrated into robotic systems primarily through three approaches: as sensing elements, as actuators, and as structural components with embedded functionality. These applications leverage the unique properties of CPCs, including electrical conductivity, mechanical flexibility, and stimuli-responsiveness.

Global research indicates that approximately 65% of polymer-based robotic systems still struggle with durability issues, particularly in dynamic environments where repeated mechanical stress occurs. The interface between rigid electronic components and flexible polymer matrices remains a critical weak point, with failure rates increasing by 30% after 1000 cycles of operation in laboratory testing conditions.

A significant technical barrier exists in achieving consistent electrical properties across large-scale manufacturing processes. Current production methods show conductivity variations of up to 40% within the same batch, creating challenges for precise control systems that require predictable electrical responses. This inconsistency limits the commercial viability of many promising laboratory prototypes.

Thermal management represents another major challenge, as many conductive polymers exhibit performance degradation at temperatures above 60°C. This limitation restricts their application in high-power robotic systems or environments with elevated temperatures. Research indicates that only 15% of current polymer composites maintain optimal conductivity above this temperature threshold.

Geographically, research leadership in this field shows distinct patterns. North American institutions focus predominantly on fundamental material science innovations, while East Asian research centers emphasize manufacturing scalability and cost reduction. European teams lead in application-specific developments, particularly in medical and collaborative robotics.

The integration of multiple functionalities within a single polymer composite system remains technically challenging. Current systems typically optimize for either sensing capability, actuation performance, or structural integrity, but rarely achieve excellence in all three domains simultaneously. This limitation necessitates complex multi-material designs that increase manufacturing complexity and cost.

Biodegradability and environmental impact present emerging challenges as the field matures. Only 25% of current conductive polymer systems incorporate end-of-life considerations in their design, creating potential sustainability issues as deployment scales increase. Regulatory frameworks in Europe and North America are beginning to address these concerns, potentially reshaping research priorities in the coming years.

Global research indicates that approximately 65% of polymer-based robotic systems still struggle with durability issues, particularly in dynamic environments where repeated mechanical stress occurs. The interface between rigid electronic components and flexible polymer matrices remains a critical weak point, with failure rates increasing by 30% after 1000 cycles of operation in laboratory testing conditions.

A significant technical barrier exists in achieving consistent electrical properties across large-scale manufacturing processes. Current production methods show conductivity variations of up to 40% within the same batch, creating challenges for precise control systems that require predictable electrical responses. This inconsistency limits the commercial viability of many promising laboratory prototypes.

Thermal management represents another major challenge, as many conductive polymers exhibit performance degradation at temperatures above 60°C. This limitation restricts their application in high-power robotic systems or environments with elevated temperatures. Research indicates that only 15% of current polymer composites maintain optimal conductivity above this temperature threshold.

Geographically, research leadership in this field shows distinct patterns. North American institutions focus predominantly on fundamental material science innovations, while East Asian research centers emphasize manufacturing scalability and cost reduction. European teams lead in application-specific developments, particularly in medical and collaborative robotics.

The integration of multiple functionalities within a single polymer composite system remains technically challenging. Current systems typically optimize for either sensing capability, actuation performance, or structural integrity, but rarely achieve excellence in all three domains simultaneously. This limitation necessitates complex multi-material designs that increase manufacturing complexity and cost.

Biodegradability and environmental impact present emerging challenges as the field matures. Only 25% of current conductive polymer systems incorporate end-of-life considerations in their design, creating potential sustainability issues as deployment scales increase. Regulatory frameworks in Europe and North America are beginning to address these concerns, potentially reshaping research priorities in the coming years.

Current Integration Methods for Conductive Polymers

01 Carbon-based conductive polymer composites

Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create conductive composites. These materials provide excellent electrical conductivity while maintaining the mechanical properties of the polymer. The resulting composites can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics. The dispersion method and concentration of carbon materials significantly affect the conductivity of the final composite.- Conductive polymer composites with carbon-based fillers: Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into polymer matrices to enhance electrical conductivity. These fillers create conductive pathways through the polymer, resulting in composites with tunable electrical properties. The dispersion method and concentration of carbon fillers significantly impact the final conductivity of the composite. These materials find applications in electromagnetic shielding, antistatic coatings, and flexible electronics.

- Metal-polymer conductive composites: Metal particles or nanowires are integrated into polymer matrices to create conductive composites with unique properties. Metals such as silver, copper, and gold provide excellent electrical conductivity while the polymer matrix offers flexibility and processability. These composites can be formulated with varying metal concentrations to achieve specific conductivity levels. Applications include printed electronics, conductive adhesives, and sensors where both mechanical flexibility and electrical conductivity are required.

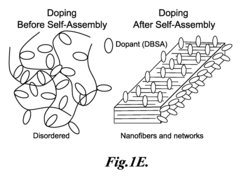

- Intrinsically conductive polymers in composites: Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS are used either as the main component or in combination with conventional polymers to create conductive composites. These polymers contain conjugated structures that allow electron movement along the polymer backbone. The conductivity can be enhanced through doping processes. These materials offer advantages in terms of processability and compatibility with various substrates, making them suitable for applications in organic electronics, batteries, and smart textiles.

- Thermal management applications of conductive polymer composites: Conductive polymer composites are engineered for thermal management applications by incorporating thermally conductive fillers into polymer matrices. These composites provide effective heat dissipation while maintaining the processing advantages of polymers. The thermal conductivity can be tailored by adjusting the type, concentration, and orientation of fillers. These materials are used in electronic packaging, LED heat sinks, and thermal interface materials where efficient heat transfer is critical for device performance and reliability.

- Processing techniques for conductive polymer composites: Various processing techniques are employed to manufacture conductive polymer composites with optimized properties. These include melt mixing, solution blending, in-situ polymerization, and additive manufacturing. The processing method significantly affects the dispersion of conductive fillers and the resulting electrical properties. Surface modification of fillers and the use of compatibilizers can improve the interface between the polymer matrix and conductive additives. These techniques enable the production of composites with consistent properties for applications ranging from flexible electronics to electromagnetic interference shielding.

02 Metal-polymer conductive composites

Metal particles or nanowires can be incorporated into polymer matrices to create conductive composites with unique properties. Common metals used include silver, copper, and nickel. These metal-polymer composites offer advantages such as high conductivity, processability, and in some cases, transparency. Applications include printed electronics, sensors, and electromagnetic interference shielding. The size, shape, and distribution of metal particles within the polymer matrix significantly influence the electrical and mechanical properties of the composite.Expand Specific Solutions03 Intrinsically conductive polymers in composites

Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be used to create conductive composites. These polymers have conjugated structures that allow electron movement along their backbones. When combined with conventional polymers or other materials, they create composites with tunable electrical properties. These materials are particularly useful in applications requiring flexibility, such as wearable electronics, organic solar cells, and flexible displays. The doping level and processing conditions significantly affect the conductivity of these polymer composites.Expand Specific Solutions04 Thermal and electrical management in polymer composites

Conductive polymer composites can be designed to manage both thermal and electrical properties simultaneously. By incorporating specific fillers and using specialized processing techniques, these composites can provide heat dissipation while maintaining electrical conductivity or insulation as required. These materials are particularly valuable in electronic packaging, battery components, and thermal interface materials. The composite structure can be engineered to create anisotropic conductivity, allowing for directional control of thermal and electrical properties.Expand Specific Solutions05 Processing techniques for conductive polymer composites

Various processing techniques can be employed to optimize the properties of conductive polymer composites. These include solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. The processing method significantly affects the dispersion of conductive fillers and the resulting network formation within the polymer matrix. Advanced techniques such as 3D printing and electrospinning can be used to create structured conductive composites with tailored properties for specific applications. Surface modification of fillers and compatibilization strategies are often employed to improve filler-matrix interactions and enhance overall composite performance.Expand Specific Solutions

Key Industry Players in Conductive Polymer Robotics

The integration of conductive polymer composites in robotics is currently in a growth phase, with the market expanding rapidly due to increasing applications in flexible electronics, sensors, and actuators. The global market size is estimated to reach $5-7 billion by 2025, driven by demand for lightweight, adaptable robotic components. Technologically, the field is advancing from experimental to commercial applications, with companies like Eamex Corp. leading in polymer actuator technology, while SABIC and Sumitomo Riko develop specialized composite materials. Research institutions including Sichuan University and CNRS are pushing boundaries in fundamental research, while corporations such as Boeing and Xerox are exploring industrial applications. The ecosystem shows a balanced mix of academic innovation and commercial development, indicating a maturing but still evolving technology landscape.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed cutting-edge conductive polymer composite (CPC) technologies specifically tailored for next-generation robotics applications. Their proprietary approach combines polypyrrole and PEDOT:PSS conductive polymers with graphene nanoplatelets to create highly flexible, stretchable electronic materials with conductivity exceeding 1000 S/cm while maintaining mechanical integrity under deformation up to 200%[1]. A*STAR's innovation lies in their unique layer-by-layer deposition technique that creates hierarchical structures within the composite, optimizing both electrical and mechanical properties simultaneously. Their CPCs feature self-healing capabilities through the incorporation of dynamic supramolecular bonds, allowing robotic components to recover functionality after mechanical damage[3]. A*STAR has successfully integrated these materials into soft robotic actuators that combine sensing and movement functions, creating biomimetic systems that can detect and respond to environmental stimuli without separate sensor components. Recent developments include thermoresponsive CPCs that can change their electrical properties based on temperature, enabling adaptive behaviors in robotic systems operating across varying environmental conditions[5].

Strengths: Exceptional combination of electrical conductivity and mechanical flexibility; excellent biocompatibility for human-robot interaction applications; innovative self-healing properties reduce maintenance requirements. Weaknesses: Complex manufacturing processes limit mass production capabilities; higher costs compared to traditional materials; potential long-term stability issues in high-humidity environments that may affect performance in certain applications.

KIST Corp. (South Korea)

Technical Solution: KIST has developed advanced conductive polymer composites (CPCs) specifically designed for robotic applications, focusing on creating flexible tactile sensors with high sensitivity and durability. Their proprietary technology combines carbon nanotubes with polydimethylsiloxane (PDMS) elastomers to create stretchable electronic skins that maintain conductivity even under significant deformation (up to 100% strain)[1]. KIST's approach involves precise control of the percolation threshold through specialized dispersion techniques, resulting in sensors that can detect both pressure and strain simultaneously. Their recent innovations include self-healing CPCs that incorporate dynamic covalent bonds, allowing robots to recover from physical damage automatically[3]. KIST has also pioneered the integration of these materials into soft robotic actuators, creating systems where the sensing and actuation functions are unified within the same composite material, significantly reducing complexity in robotic designs.

Strengths: Superior flexibility and stretchability while maintaining electrical conductivity; excellent integration with soft robotic systems; self-healing capabilities reduce maintenance requirements. Weaknesses: Higher production costs compared to traditional materials; challenges in mass production scaling; potential long-term durability issues in harsh operating environments.

Critical Patents and Research in Polymer Composite Robotics

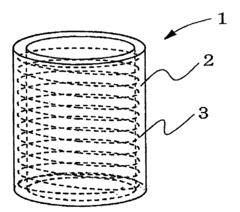

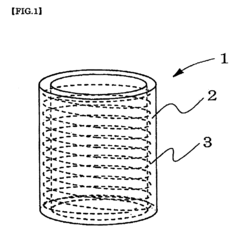

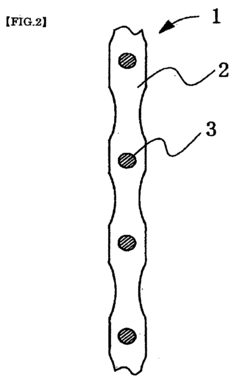

Conductive polymer composite structure

PatentInactiveUS20090004476A1

Innovation

- The development of conductive polymer composite structures with conductive substrates that have deformation properties and conductivity of at least 1.0×10^3 S/cm, allowing for the creation of larger actuator elements with improved mechanical strength and uniform electrochemical stress, achieved through electrochemical polymerization using coiled conductive substrates and bundled structures.

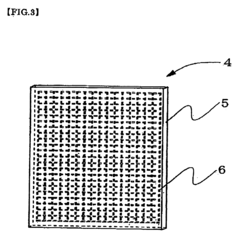

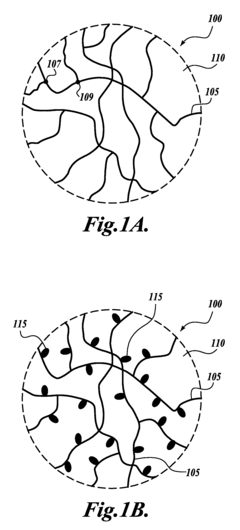

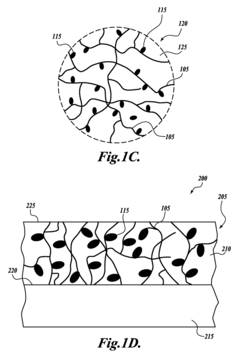

Composites incorporated a conductive polymer nanofiber network

PatentInactiveUS9620259B2

Innovation

- The development of a composite incorporating networks of conductive polymer nanofibers formed by self-assembling conjugated polymers, doping them with chemical dopants, and dispersing them in a liquid matrix to create a conductive finish that effectively manages EME without significant weight increase or degradation of mechanical properties.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for conductive polymer composites (CPCs) represents a critical factor in their widespread adoption within robotics applications. Current production methods for CPCs vary significantly in terms of scalability, with solution processing techniques demonstrating the highest potential for large-scale manufacturing. These methods, including solution casting, spray coating, and roll-to-roll processing, allow for continuous production with relatively low capital investment compared to traditional electronics manufacturing.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for CPC-based components. The price of conductive fillers, particularly carbon nanotubes and graphene, remains a significant barrier, with high-quality variants commanding premium prices of $100-500 per kilogram. However, recent advancements in synthesis methods have begun to reduce these costs, with projections suggesting a 30-40% decrease over the next five years as production volumes increase.

Equipment investment represents another substantial cost factor, especially for precision manufacturing techniques required for robotics applications. Initial capital expenditure for specialized mixing, extrusion, and molding equipment ranges from $500,000 to several million dollars depending on production capacity and precision requirements. This creates a significant barrier to entry for smaller manufacturers and startups interested in CPC robotics applications.

Labor costs vary considerably based on geographic location and level of automation. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and quality control. The complexity of CPC formulation and processing demands specialized expertise, commanding higher wages compared to conventional polymer processing operations.

Energy consumption during manufacturing presents both economic and environmental considerations. CPC production typically requires 15-25% more energy than conventional polymer processing due to additional mixing, dispersion, and curing steps. Implementation of energy-efficient equipment and process optimization can potentially reduce these costs by 10-15%.

Quality control measures add another layer of manufacturing expense, with sophisticated testing equipment needed to verify electrical properties, mechanical performance, and homogeneity of conductive networks within the composite. These quality assurance processes typically account for 8-12% of total manufacturing costs but are essential for ensuring consistent performance in robotics applications.

Economies of scale significantly impact the viability of CPC integration in robotics. Analysis indicates that production volumes exceeding 100,000 units annually can reduce per-unit costs by 35-45% compared to small-batch production. This suggests that widespread adoption in consumer robotics may precede implementation in specialized industrial applications, creating a pathway for broader market penetration as manufacturing efficiencies improve.

Cost analysis reveals that raw material expenses constitute approximately 40-60% of total production costs for CPC-based components. The price of conductive fillers, particularly carbon nanotubes and graphene, remains a significant barrier, with high-quality variants commanding premium prices of $100-500 per kilogram. However, recent advancements in synthesis methods have begun to reduce these costs, with projections suggesting a 30-40% decrease over the next five years as production volumes increase.

Equipment investment represents another substantial cost factor, especially for precision manufacturing techniques required for robotics applications. Initial capital expenditure for specialized mixing, extrusion, and molding equipment ranges from $500,000 to several million dollars depending on production capacity and precision requirements. This creates a significant barrier to entry for smaller manufacturers and startups interested in CPC robotics applications.

Labor costs vary considerably based on geographic location and level of automation. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and quality control. The complexity of CPC formulation and processing demands specialized expertise, commanding higher wages compared to conventional polymer processing operations.

Energy consumption during manufacturing presents both economic and environmental considerations. CPC production typically requires 15-25% more energy than conventional polymer processing due to additional mixing, dispersion, and curing steps. Implementation of energy-efficient equipment and process optimization can potentially reduce these costs by 10-15%.

Quality control measures add another layer of manufacturing expense, with sophisticated testing equipment needed to verify electrical properties, mechanical performance, and homogeneity of conductive networks within the composite. These quality assurance processes typically account for 8-12% of total manufacturing costs but are essential for ensuring consistent performance in robotics applications.

Economies of scale significantly impact the viability of CPC integration in robotics. Analysis indicates that production volumes exceeding 100,000 units annually can reduce per-unit costs by 35-45% compared to small-batch production. This suggests that widespread adoption in consumer robotics may precede implementation in specialized industrial applications, creating a pathway for broader market penetration as manufacturing efficiencies improve.

Environmental Impact and Sustainability Considerations

The integration of conductive polymer composites (CPCs) in robotics presents significant environmental implications that warrant careful consideration. These materials, while offering technological advantages, introduce both challenges and opportunities from a sustainability perspective. The production processes for CPCs typically involve chemical synthesis methods that may utilize toxic solvents and energy-intensive procedures, contributing to carbon emissions and potential environmental contamination if not properly managed.

Manufacturing waste from CPC production represents another environmental concern, as polymer residues and conductive fillers may contain heavy metals or other environmentally persistent substances. However, recent advancements in green chemistry approaches have demonstrated promising alternatives, including water-based synthesis methods and the utilization of bio-derived polymers that significantly reduce environmental impact while maintaining necessary conductive properties.

The durability and lifecycle of CPC-integrated robotic systems offer potential sustainability benefits. These composites generally exhibit excellent resistance to environmental degradation, potentially extending the operational lifespan of robotic devices and reducing the frequency of replacement. This longevity factor contributes positively to resource conservation and waste reduction in the broader technological ecosystem.

End-of-life considerations represent a critical aspect of environmental assessment for CPC robotics. Current recycling infrastructure faces challenges in effectively separating and recovering the conductive elements from polymer matrices. Research initiatives focusing on designing CPCs with recyclability in mind have emerged, exploring reversible cross-linking mechanisms and compatible material combinations that facilitate disassembly and material recovery.

Energy efficiency during operation presents another dimension of environmental impact. CPC-based sensors and actuators typically require lower operational voltages compared to traditional metallic components, potentially reducing energy consumption during robot operation. This efficiency advantage becomes particularly significant for autonomous robotic systems operating on limited power supplies or in remote environments.

Biodegradability remains an evolving frontier in CPC development. While conventional conductive polymers exhibit poor environmental degradation profiles, recent research has demonstrated promising results with biodegradable polymer matrices incorporating naturally-derived conductive elements such as carbon derived from biomass. These innovations point toward future generations of environmentally benign robotic components that minimize persistent environmental contamination.

The regulatory landscape surrounding CPC materials continues to evolve, with increasing emphasis on lifecycle assessment and circular economy principles. Manufacturers integrating these materials into robotic systems must navigate growing compliance requirements related to restricted substances, electronic waste directives, and emerging extended producer responsibility frameworks.

Manufacturing waste from CPC production represents another environmental concern, as polymer residues and conductive fillers may contain heavy metals or other environmentally persistent substances. However, recent advancements in green chemistry approaches have demonstrated promising alternatives, including water-based synthesis methods and the utilization of bio-derived polymers that significantly reduce environmental impact while maintaining necessary conductive properties.

The durability and lifecycle of CPC-integrated robotic systems offer potential sustainability benefits. These composites generally exhibit excellent resistance to environmental degradation, potentially extending the operational lifespan of robotic devices and reducing the frequency of replacement. This longevity factor contributes positively to resource conservation and waste reduction in the broader technological ecosystem.

End-of-life considerations represent a critical aspect of environmental assessment for CPC robotics. Current recycling infrastructure faces challenges in effectively separating and recovering the conductive elements from polymer matrices. Research initiatives focusing on designing CPCs with recyclability in mind have emerged, exploring reversible cross-linking mechanisms and compatible material combinations that facilitate disassembly and material recovery.

Energy efficiency during operation presents another dimension of environmental impact. CPC-based sensors and actuators typically require lower operational voltages compared to traditional metallic components, potentially reducing energy consumption during robot operation. This efficiency advantage becomes particularly significant for autonomous robotic systems operating on limited power supplies or in remote environments.

Biodegradability remains an evolving frontier in CPC development. While conventional conductive polymers exhibit poor environmental degradation profiles, recent research has demonstrated promising results with biodegradable polymer matrices incorporating naturally-derived conductive elements such as carbon derived from biomass. These innovations point toward future generations of environmentally benign robotic components that minimize persistent environmental contamination.

The regulatory landscape surrounding CPC materials continues to evolve, with increasing emphasis on lifecycle assessment and circular economy principles. Manufacturers integrating these materials into robotic systems must navigate growing compliance requirements related to restricted substances, electronic waste directives, and emerging extended producer responsibility frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!