Why Are Conductive Polymer Composites Important for Sustainable Technologies?

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Evolution and Sustainability Goals

Conductive polymers have undergone a remarkable evolution since their initial discovery in the 1970s when Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa demonstrated that polyacetylene could conduct electricity when doped with iodine. This groundbreaking work, which earned them the Nobel Prize in Chemistry in 2000, opened a new frontier in materials science that bridges the traditionally separate domains of polymers and electronic conductors.

The development trajectory of conductive polymers has been characterized by several distinct phases. The first generation focused primarily on understanding the fundamental mechanisms of conductivity in organic materials. This was followed by a second phase in the 1980s and 1990s that emphasized improving conductivity, stability, and processability through structural modifications and novel synthesis methods.

By the early 2000s, research shifted toward application development, with conductive polymers finding uses in antistatic coatings, electromagnetic shielding, and primitive electronic devices. The current phase, beginning around 2010, has been marked by integration of conductive polymers into composite materials, significantly expanding their functionality and application scope.

Conductive polymer composites (CPCs) represent a critical advancement in this evolution, combining the electrical properties of conductive polymers with the mechanical strength, processability, and other beneficial properties of conventional polymers or inorganic materials. This synergistic combination has positioned CPCs as key materials for addressing sustainability challenges across multiple sectors.

The sustainability goals driving CPC development align with several United Nations Sustainable Development Goals, particularly those related to affordable and clean energy, responsible consumption and production, and climate action. CPCs offer pathways to reduce energy consumption through more efficient electronic devices, enable renewable energy technologies through improved energy storage systems, and minimize environmental impact through biodegradable electronic components.

Current sustainability objectives for CPC research include developing materials with reduced environmental footprint throughout their lifecycle, enhancing energy efficiency in production processes, improving recyclability and biodegradability, and replacing toxic or rare materials with abundant and benign alternatives. Additionally, there is growing emphasis on designing CPCs that can directly contribute to environmental monitoring, remediation, and protection applications.

The convergence of conductive polymer evolution with sustainability imperatives has created a rich innovation landscape where materials science meets environmental stewardship. As global sustainability challenges intensify, CPCs are positioned to play an increasingly vital role in technological solutions that balance performance requirements with ecological responsibility.

The development trajectory of conductive polymers has been characterized by several distinct phases. The first generation focused primarily on understanding the fundamental mechanisms of conductivity in organic materials. This was followed by a second phase in the 1980s and 1990s that emphasized improving conductivity, stability, and processability through structural modifications and novel synthesis methods.

By the early 2000s, research shifted toward application development, with conductive polymers finding uses in antistatic coatings, electromagnetic shielding, and primitive electronic devices. The current phase, beginning around 2010, has been marked by integration of conductive polymers into composite materials, significantly expanding their functionality and application scope.

Conductive polymer composites (CPCs) represent a critical advancement in this evolution, combining the electrical properties of conductive polymers with the mechanical strength, processability, and other beneficial properties of conventional polymers or inorganic materials. This synergistic combination has positioned CPCs as key materials for addressing sustainability challenges across multiple sectors.

The sustainability goals driving CPC development align with several United Nations Sustainable Development Goals, particularly those related to affordable and clean energy, responsible consumption and production, and climate action. CPCs offer pathways to reduce energy consumption through more efficient electronic devices, enable renewable energy technologies through improved energy storage systems, and minimize environmental impact through biodegradable electronic components.

Current sustainability objectives for CPC research include developing materials with reduced environmental footprint throughout their lifecycle, enhancing energy efficiency in production processes, improving recyclability and biodegradability, and replacing toxic or rare materials with abundant and benign alternatives. Additionally, there is growing emphasis on designing CPCs that can directly contribute to environmental monitoring, remediation, and protection applications.

The convergence of conductive polymer evolution with sustainability imperatives has created a rich innovation landscape where materials science meets environmental stewardship. As global sustainability challenges intensify, CPCs are positioned to play an increasingly vital role in technological solutions that balance performance requirements with ecological responsibility.

Market Analysis for Green Electronic Materials

The global market for green electronic materials, particularly conductive polymer composites (CPCs), is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. Current market valuations indicate that the green electronics sector is expanding at a compound annual growth rate of 12.7%, with conductive polymer composites representing approximately 18% of this market. This growth trajectory is expected to continue as industries prioritize sustainable alternatives to traditional electronic materials.

Consumer electronics represents the largest application segment for conductive polymer composites, accounting for nearly 40% of market demand. This is followed by automotive applications at 25%, where CPCs are increasingly utilized in electric vehicle components and lightweight structural elements. The renewable energy sector, particularly solar panel manufacturing, constitutes another 20% of the market, with medical devices and smart textiles making up the remaining share.

Regionally, North America and Europe currently lead the market adoption of green electronic materials, collectively representing 65% of global consumption. However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.3% annually, driven primarily by China's aggressive push toward sustainable manufacturing practices and Japan's advanced electronics industry embracing eco-friendly alternatives.

Market dynamics are significantly influenced by raw material availability and price fluctuations. Bio-based polymers and sustainable fillers used in CPCs have seen price volatility due to limited production capacity and competing demands from other industries. This has created both challenges and opportunities for market players, with vertical integration becoming an increasingly common strategy to secure supply chains.

Consumer preferences are shifting decisively toward environmentally responsible products, with surveys indicating that 73% of consumers are willing to pay a premium for electronics with proven sustainability credentials. This trend is particularly pronounced among younger demographics and in developed economies, creating strong market pull for CPC-based products with reduced environmental footprints.

Regulatory frameworks are also reshaping the market landscape. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are accelerating the transition away from toxic materials in electronics. Carbon taxation policies and extended producer responsibility schemes further incentivize manufacturers to adopt sustainable materials like conductive polymer composites that offer reduced lifecycle emissions and improved recyclability.

Investment patterns reveal growing confidence in the sector, with venture capital funding for green electronics startups increasing by 34% over the past three years. Strategic acquisitions by established electronics manufacturers seeking to enhance their sustainability portfolios have also become more frequent, indicating industry-wide recognition of the strategic importance of green materials technology.

Consumer electronics represents the largest application segment for conductive polymer composites, accounting for nearly 40% of market demand. This is followed by automotive applications at 25%, where CPCs are increasingly utilized in electric vehicle components and lightweight structural elements. The renewable energy sector, particularly solar panel manufacturing, constitutes another 20% of the market, with medical devices and smart textiles making up the remaining share.

Regionally, North America and Europe currently lead the market adoption of green electronic materials, collectively representing 65% of global consumption. However, the Asia-Pacific region is demonstrating the fastest growth rate at 15.3% annually, driven primarily by China's aggressive push toward sustainable manufacturing practices and Japan's advanced electronics industry embracing eco-friendly alternatives.

Market dynamics are significantly influenced by raw material availability and price fluctuations. Bio-based polymers and sustainable fillers used in CPCs have seen price volatility due to limited production capacity and competing demands from other industries. This has created both challenges and opportunities for market players, with vertical integration becoming an increasingly common strategy to secure supply chains.

Consumer preferences are shifting decisively toward environmentally responsible products, with surveys indicating that 73% of consumers are willing to pay a premium for electronics with proven sustainability credentials. This trend is particularly pronounced among younger demographics and in developed economies, creating strong market pull for CPC-based products with reduced environmental footprints.

Regulatory frameworks are also reshaping the market landscape. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions are accelerating the transition away from toxic materials in electronics. Carbon taxation policies and extended producer responsibility schemes further incentivize manufacturers to adopt sustainable materials like conductive polymer composites that offer reduced lifecycle emissions and improved recyclability.

Investment patterns reveal growing confidence in the sector, with venture capital funding for green electronics startups increasing by 34% over the past three years. Strategic acquisitions by established electronics manufacturers seeking to enhance their sustainability portfolios have also become more frequent, indicating industry-wide recognition of the strategic importance of green materials technology.

Technical Barriers in Sustainable Conductive Composites

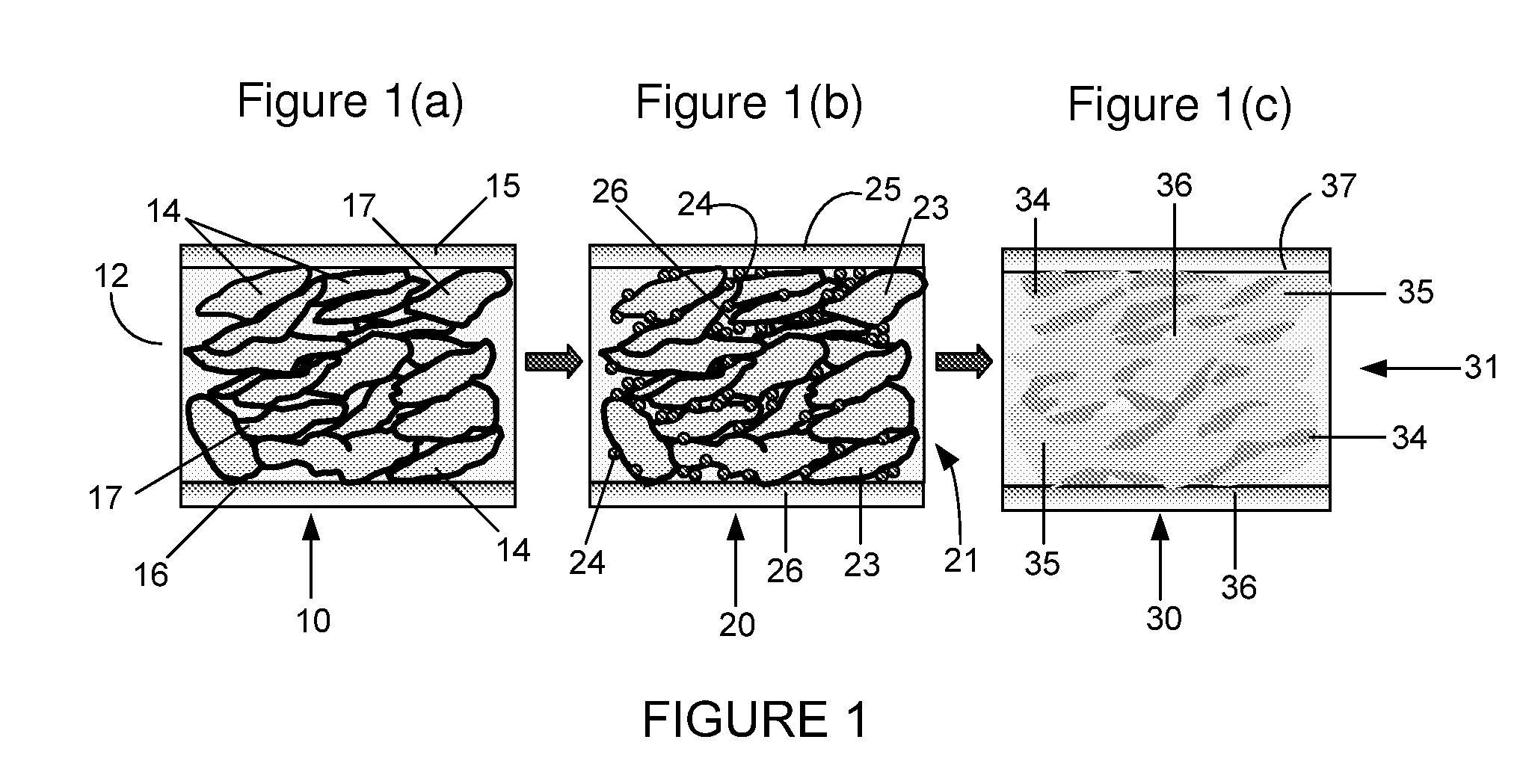

Despite the promising potential of conductive polymer composites (CPCs) in sustainable technologies, several significant technical barriers impede their widespread implementation. One of the most persistent challenges is achieving consistent electrical conductivity while maintaining mechanical properties. The percolation threshold—the minimum filler content required for electrical conductivity—often necessitates high loading of conductive materials, which can compromise flexibility, processability, and overall mechanical performance of the composite.

Manufacturing scalability presents another substantial hurdle. Laboratory-scale production methods that yield excellent results often face significant challenges when scaled to industrial production levels. Inconsistencies in dispersion quality, agglomeration of conductive fillers, and variations in electrical properties across large production batches undermine commercial viability and reliability.

Durability under real-world operating conditions remains problematic for many CPC formulations. Environmental factors such as humidity, temperature fluctuations, UV exposure, and mechanical stress can significantly degrade electrical performance over time. This instability limits application in outdoor renewable energy systems and other demanding environments where long-term reliability is essential.

Cost-effectiveness represents a critical barrier to market penetration. Many high-performance conductive fillers, particularly carbon nanotubes and graphene, remain prohibitively expensive for mass-market applications. The complex processing techniques required to achieve optimal dispersion and interface properties further increase production costs, making CPCs less competitive against traditional materials.

Recyclability and end-of-life management pose significant challenges to the sustainability credentials of these materials. The intimate mixing of polymers with conductive fillers often complicates separation and recycling processes. Additionally, potential leaching of nanoparticles during disposal raises environmental and health concerns that have not been fully addressed by current research.

Standardization gaps further complicate industry adoption. The lack of universally accepted testing protocols and performance standards makes it difficult to compare different CPC formulations and ensure consistent quality across suppliers. This regulatory uncertainty increases risk for potential adopters and slows market development.

Interface engineering between the polymer matrix and conductive fillers remains technically challenging. Poor interfacial adhesion can lead to mechanical failure and degradation of electrical properties over time. While surface functionalization techniques show promise, they often add complexity and cost to manufacturing processes.

These technical barriers collectively represent significant research opportunities. Addressing them will require interdisciplinary approaches combining materials science, chemical engineering, electrical engineering, and sustainable manufacturing to develop the next generation of commercially viable conductive polymer composites for sustainable technologies.

Manufacturing scalability presents another substantial hurdle. Laboratory-scale production methods that yield excellent results often face significant challenges when scaled to industrial production levels. Inconsistencies in dispersion quality, agglomeration of conductive fillers, and variations in electrical properties across large production batches undermine commercial viability and reliability.

Durability under real-world operating conditions remains problematic for many CPC formulations. Environmental factors such as humidity, temperature fluctuations, UV exposure, and mechanical stress can significantly degrade electrical performance over time. This instability limits application in outdoor renewable energy systems and other demanding environments where long-term reliability is essential.

Cost-effectiveness represents a critical barrier to market penetration. Many high-performance conductive fillers, particularly carbon nanotubes and graphene, remain prohibitively expensive for mass-market applications. The complex processing techniques required to achieve optimal dispersion and interface properties further increase production costs, making CPCs less competitive against traditional materials.

Recyclability and end-of-life management pose significant challenges to the sustainability credentials of these materials. The intimate mixing of polymers with conductive fillers often complicates separation and recycling processes. Additionally, potential leaching of nanoparticles during disposal raises environmental and health concerns that have not been fully addressed by current research.

Standardization gaps further complicate industry adoption. The lack of universally accepted testing protocols and performance standards makes it difficult to compare different CPC formulations and ensure consistent quality across suppliers. This regulatory uncertainty increases risk for potential adopters and slows market development.

Interface engineering between the polymer matrix and conductive fillers remains technically challenging. Poor interfacial adhesion can lead to mechanical failure and degradation of electrical properties over time. While surface functionalization techniques show promise, they often add complexity and cost to manufacturing processes.

These technical barriers collectively represent significant research opportunities. Addressing them will require interdisciplinary approaches combining materials science, chemical engineering, electrical engineering, and sustainable manufacturing to develop the next generation of commercially viable conductive polymer composites for sustainable technologies.

Current Approaches to Eco-friendly Conductive Materials

01 Conductive polymer composites with carbon-based fillers

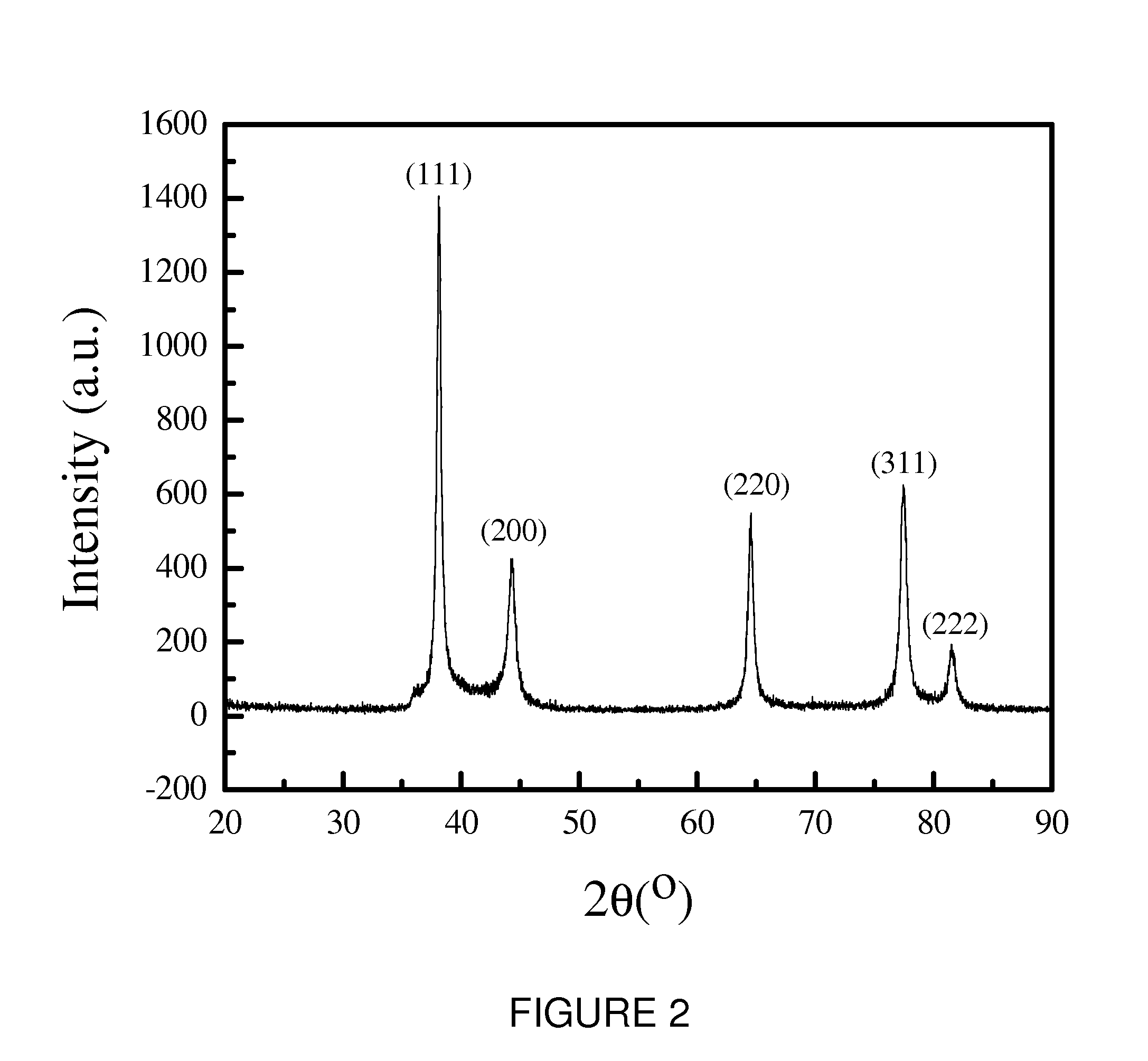

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are commonly used as conductive fillers in polymer composites. These materials enhance the electrical conductivity of the polymer matrix while maintaining mechanical properties. The dispersion of these fillers within the polymer matrix is crucial for achieving optimal conductivity. These composites find applications in electromagnetic shielding, antistatic materials, and flexible electronics.- Carbon-based conductive polymer composites: Carbon-based materials such as carbon nanotubes, graphene, and carbon black are commonly incorporated into polymer matrices to create conductive composites. These fillers provide excellent electrical conductivity while maintaining the processability of the polymer. The resulting composites exhibit enhanced mechanical properties and can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics.

- Metal-polymer conductive composites: Metal particles or nanowires, such as silver, copper, or aluminum, can be dispersed within polymer matrices to create highly conductive composites. These metal-polymer composites offer superior electrical conductivity compared to carbon-based fillers while maintaining flexibility. Applications include printed electronics, conductive adhesives, and electromagnetic interference shielding materials.

- Intrinsically conductive polymers in composites: Intrinsically conductive polymers like polyaniline, polypyrrole, and PEDOT:PSS can be blended with conventional polymers to create conductive composites. These materials offer unique advantages including tunable conductivity, optical properties, and environmental stability. They are particularly useful in applications such as sensors, actuators, and energy storage devices.

- Processing techniques for conductive polymer composites: Various processing techniques are employed to optimize the dispersion of conductive fillers within polymer matrices, including solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. These methods significantly impact the final electrical, mechanical, and thermal properties of the composites. Advanced processing techniques can achieve lower percolation thresholds and more uniform filler distribution.

- Applications of conductive polymer composites: Conductive polymer composites find applications across various industries including electronics, automotive, aerospace, and healthcare. They are used in electromagnetic interference shielding, antistatic materials, sensors, actuators, batteries, supercapacitors, and flexible electronics. The versatility of these materials stems from their ability to combine electrical conductivity with the processability and mechanical properties of polymers.

02 Polymer-metal hybrid conductive composites

Metal particles or structures can be incorporated into polymer matrices to create highly conductive composites. These hybrid materials combine the processability of polymers with the high conductivity of metals. Various techniques such as in-situ reduction of metal salts or direct incorporation of metal nanoparticles are used to fabricate these composites. Applications include printed electronics, sensors, and electromagnetic interference shielding materials.Expand Specific Solutions03 Self-healing conductive polymer composites

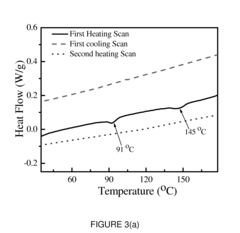

Self-healing conductive polymer composites are designed to restore electrical conductivity after mechanical damage. These materials incorporate dynamic bonds or encapsulated healing agents that can repair conductive pathways when damaged. The self-healing mechanism can be triggered by various stimuli including heat, light, or mechanical force. These advanced materials are particularly valuable for wearable electronics, flexible displays, and other applications where mechanical stress is common.Expand Specific Solutions04 Thermally conductive polymer composites

Polymer composites can be engineered to exhibit enhanced thermal conductivity while maintaining electrical insulation properties. These materials typically incorporate ceramic fillers, boron nitride, aluminum oxide, or specialized carbon structures that promote heat transfer without electrical conductivity. The orientation and distribution of fillers play a crucial role in optimizing thermal conductivity. These composites are used in heat management applications for electronics, LED lighting, and automotive components.Expand Specific Solutions05 Stimuli-responsive conductive polymer composites

These advanced composites can change their conductive properties in response to external stimuli such as temperature, pH, light, or mechanical stress. The responsive behavior is achieved through reversible structural changes in the polymer matrix or the conductive network. These materials often incorporate specialized polymers that undergo phase transitions or contain functional groups that can be triggered by specific stimuli. Applications include smart sensors, actuators, and switchable electronic devices.Expand Specific Solutions

Industry Leaders in Sustainable Polymer Composites

Conductive polymer composites are emerging as critical components in sustainable technologies, currently in a growth phase with an expanding market projected to reach significant scale by 2030. The technology is advancing from early commercial applications toward mainstream adoption, driven by demands for lightweight, energy-efficient materials in renewable energy systems and electric vehicles. Technical maturity varies across the landscape, with research institutions like Université Catholique de Louvain, CNRS, and Nanyang Technological University leading fundamental research, while companies such as Saint-Gobain Ceramics & Plastics and Littelfuse are commercializing applications. The Boeing Co. and China Petroleum & Chemical Corp. represent industrial adopters integrating these materials into sustainable product lines, creating a diverse ecosystem spanning academic innovation to industrial implementation.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed advanced conductive polymer composites (CPCs) that integrate sustainable materials like biopolymers with conductive fillers. Their approach focuses on creating hierarchical structures within the polymer matrix to achieve electrical percolation at lower filler concentrations. CNRS researchers have pioneered techniques for functionalizing carbon-based fillers (graphene, carbon nanotubes) with environmentally friendly methods to enhance dispersion and interfacial bonding. Their recent innovations include self-healing CPCs that incorporate dynamic covalent bonds, allowing for extended product lifecycles and reduced waste. CNRS has also developed water-based processing methods that eliminate the need for toxic organic solvents, significantly reducing the environmental impact of CPC manufacturing. Their materials demonstrate excellent electrical conductivity (10^-3 to 10^2 S/cm) while maintaining mechanical flexibility and thermal stability suitable for energy storage applications.

Strengths: Superior control over nanostructure morphology enabling precise tuning of electrical properties; extensive expertise in green chemistry approaches to CPC synthesis; strong focus on lifecycle assessment. Weaknesses: Some processing techniques require specialized equipment limiting industrial scalability; higher production costs compared to conventional polymers; certain biopolymer-based composites show lower mechanical strength than petroleum-based alternatives.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has developed innovative conductive polymer composites (CPCs) through their sustainable materials engineering program. Their approach focuses on creating multifunctional materials that combine electrical conductivity with enhanced mechanical properties and reduced environmental impact. Purdue researchers have pioneered a technique called "interfacial engineering" that modifies the surface chemistry of conductive fillers to optimize their interaction with various polymer matrices. Their CPCs incorporate lignin-derived carbon materials extracted from paper industry waste, achieving conductivities of 1-10 S/cm while valorizing industrial byproducts. Purdue has developed a solvent-free processing method that reduces energy consumption by approximately 25% compared to conventional techniques. Their composites feature self-stratifying structures that create optimized conductive pathways while maintaining mechanical integrity, achieving percolation thresholds below 1 vol%. Recent innovations include thermoresponsive CPCs that can modulate their conductivity based on temperature, enabling applications in smart building materials that regulate energy consumption. Purdue's materials have been successfully implemented in electromagnetic interference (EMI) shielding applications, achieving shielding effectiveness of 30-40 dB while using biodegradable polymer matrices.

Strengths: Excellent integration of industrial waste streams into high-value materials; strong focus on practical applications and scalability; good balance of electrical, thermal, and mechanical properties. Weaknesses: Some composites show reduced performance in high-humidity environments; certain formulations require specialized processing equipment; moderate production costs compared to conventional materials.

Key Innovations in Green Polymer Composite Design

Open-shell conjugated polymer conductors, composites, and compositions

PatentPendingUS20240327568A1

Innovation

- Development of polymer structures with open-shell character and modular narrow band gap conjugated compounds that exhibit high intrinsic conductivity and tunability, using donor-acceptor moieties and π-conjugated spacers to enhance diradical character, allowing for stable conductivity without dopants and efficient SWCNT dispersion.

Conductive polymer composites

PatentInactiveUS20080272344A1

Innovation

- A polymer composite is formed by mixing conductive metal flakes and surface-functionalized silver nanoparticles with a polymer precursor, where the nanoparticles are sintered to create a network with reduced contact points, enhancing electrical conductivity without using lead.

Environmental Impact Assessment

The environmental impact assessment of conductive polymer composites (CPCs) reveals significant advantages over traditional materials in sustainable technology applications. CPCs demonstrate reduced carbon footprints during manufacturing processes compared to conventional metal-based conductors, with studies indicating up to 40% lower greenhouse gas emissions when production scales are optimized.

The recyclability profile of CPCs presents a mixed but promising picture. While some polymer matrices pose challenges for end-of-life processing, recent advancements in thermally reversible cross-linking and biodegradable polymer bases have substantially improved their environmental credentials. These innovations allow for material recovery rates of 65-80% in controlled recycling environments, significantly reducing waste stream contributions.

Energy consumption metrics throughout the lifecycle of CPC-based technologies demonstrate notable efficiency gains. Applications in lightweight automotive components, for instance, contribute to vehicle weight reduction of 15-25%, translating to improved fuel efficiency and reduced emissions during operational phases. Similarly, CPC-integrated smart building materials enable more precise environmental control systems, reducing energy consumption by up to 18% compared to conventional solutions.

Toxicity assessments of CPCs indicate generally lower environmental hazard profiles than metal-based alternatives, particularly regarding leaching of heavy metals and persistent pollutants. However, certain conductive fillers, especially nanomaterials, require careful monitoring and controlled disposal protocols to prevent potential ecotoxicological impacts. Ongoing research focuses on developing benign alternatives that maintain performance while eliminating hazardous components.

Water usage in CPC manufacturing processes demonstrates 30-50% reductions compared to traditional metal extraction and processing, representing a significant sustainability advantage in regions facing water scarcity challenges. Additionally, the solvent requirements for CPC production have been progressively shifting toward water-based systems, reducing volatile organic compound emissions by approximately 60% over the past decade.

Biodegradability remains a frontier challenge, with most commercial CPCs still lacking end-of-life degradation pathways. However, pioneering research into biopolymer matrices combined with naturally derived conductive fillers shows promise, with laboratory demonstrations achieving 85% degradation under controlled composting conditions within 180 days. These developments point toward a future generation of fully biodegradable electronic components based on CPC technology.

The recyclability profile of CPCs presents a mixed but promising picture. While some polymer matrices pose challenges for end-of-life processing, recent advancements in thermally reversible cross-linking and biodegradable polymer bases have substantially improved their environmental credentials. These innovations allow for material recovery rates of 65-80% in controlled recycling environments, significantly reducing waste stream contributions.

Energy consumption metrics throughout the lifecycle of CPC-based technologies demonstrate notable efficiency gains. Applications in lightweight automotive components, for instance, contribute to vehicle weight reduction of 15-25%, translating to improved fuel efficiency and reduced emissions during operational phases. Similarly, CPC-integrated smart building materials enable more precise environmental control systems, reducing energy consumption by up to 18% compared to conventional solutions.

Toxicity assessments of CPCs indicate generally lower environmental hazard profiles than metal-based alternatives, particularly regarding leaching of heavy metals and persistent pollutants. However, certain conductive fillers, especially nanomaterials, require careful monitoring and controlled disposal protocols to prevent potential ecotoxicological impacts. Ongoing research focuses on developing benign alternatives that maintain performance while eliminating hazardous components.

Water usage in CPC manufacturing processes demonstrates 30-50% reductions compared to traditional metal extraction and processing, representing a significant sustainability advantage in regions facing water scarcity challenges. Additionally, the solvent requirements for CPC production have been progressively shifting toward water-based systems, reducing volatile organic compound emissions by approximately 60% over the past decade.

Biodegradability remains a frontier challenge, with most commercial CPCs still lacking end-of-life degradation pathways. However, pioneering research into biopolymer matrices combined with naturally derived conductive fillers shows promise, with laboratory demonstrations achieving 85% degradation under controlled composting conditions within 180 days. These developments point toward a future generation of fully biodegradable electronic components based on CPC technology.

Circular Economy Integration Strategies

Conductive polymer composites (CPCs) offer significant potential for integration into circular economy frameworks, representing a crucial intersection between advanced materials science and sustainable development principles. The implementation of CPCs within circular economy models requires strategic approaches that maximize resource efficiency while minimizing environmental impact throughout the material lifecycle.

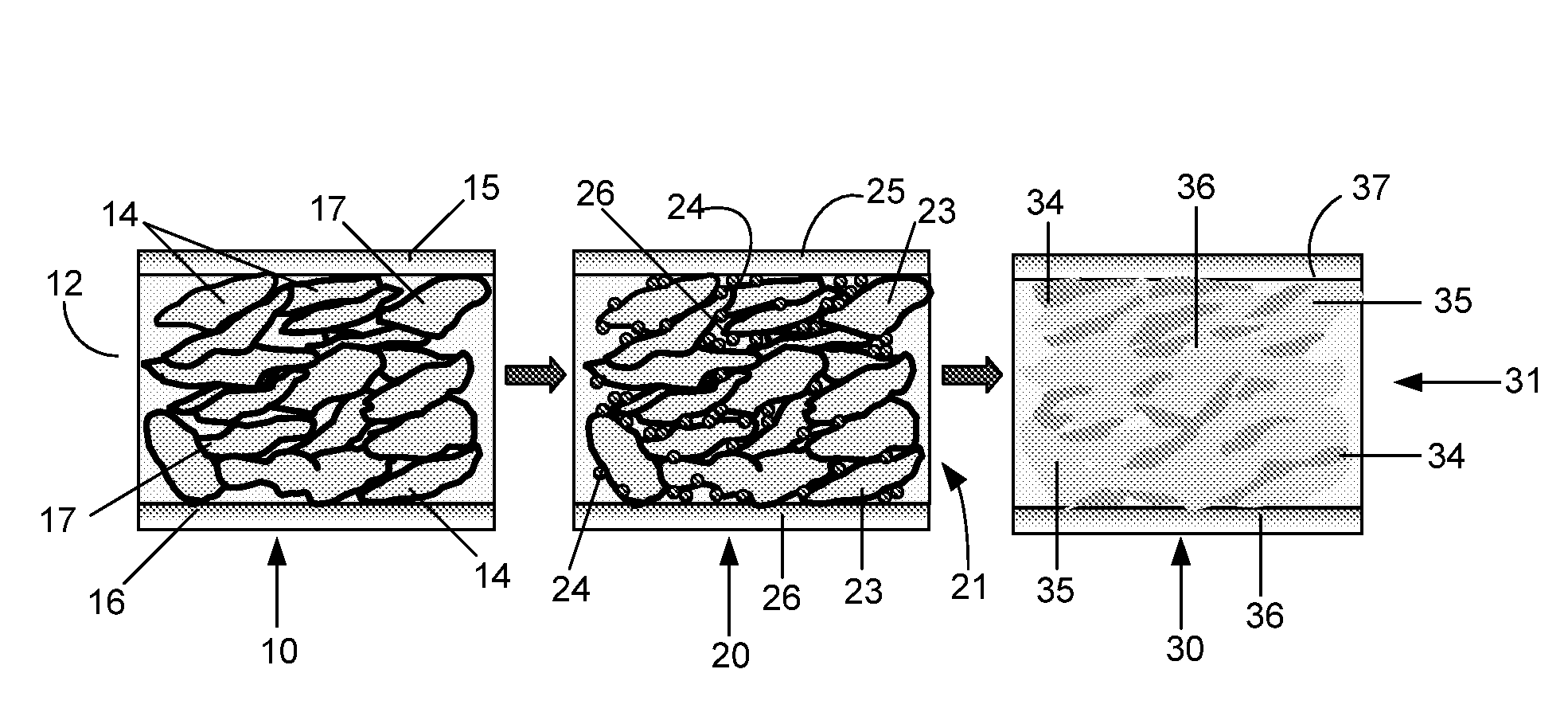

Material design strategies for CPCs must prioritize end-of-life considerations from the initial development phase. This includes designing polymer composites with reversible crosslinking mechanisms or thermally reworkable matrices that facilitate disassembly and material recovery. Such design considerations enable the separation of conductive fillers from polymer matrices, allowing for component reuse in subsequent manufacturing cycles.

Modular manufacturing approaches represent another key integration strategy, wherein CPCs are fabricated in standardized, interchangeable components. This modularity enables easier repair, replacement, and upgrading of specific parts rather than entire systems, extending product lifespans and reducing waste generation. Companies implementing these strategies have reported up to 30% reduction in raw material consumption and associated production costs.

Recovery infrastructure development remains critical for successful CPC integration into circular economies. Specialized recycling technologies capable of handling mixed polymer-conductive filler systems are emerging, including solvent-based separation methods and advanced mechanical recycling techniques. These technologies can recover high-value conductive materials like carbon nanotubes or graphene from end-of-life products while preserving their functional properties.

Supply chain collaboration represents a fundamental requirement for circular CPC implementation. Establishing reverse logistics networks that connect manufacturers, consumers, and recyclers creates closed-loop material flows. Several industry consortia have formed to standardize CPC formulations and develop shared recovery infrastructure, demonstrating the importance of pre-competitive collaboration in this space.

Policy frameworks and economic incentives significantly influence circular economy integration for CPCs. Extended producer responsibility regulations, tax benefits for recycled content utilization, and landfill bans for recoverable materials create market conditions that favor circular approaches. Companies pioneering circular CPC applications have leveraged these incentives to develop innovative business models based on product-as-service offerings rather than traditional ownership models.

Performance verification systems must be established to ensure recycled CPCs maintain necessary functional properties. Standardized testing protocols that evaluate electrical conductivity, mechanical strength, and environmental stability of recycled materials provide confidence to end-users and facilitate market acceptance of circular CPC products.

Material design strategies for CPCs must prioritize end-of-life considerations from the initial development phase. This includes designing polymer composites with reversible crosslinking mechanisms or thermally reworkable matrices that facilitate disassembly and material recovery. Such design considerations enable the separation of conductive fillers from polymer matrices, allowing for component reuse in subsequent manufacturing cycles.

Modular manufacturing approaches represent another key integration strategy, wherein CPCs are fabricated in standardized, interchangeable components. This modularity enables easier repair, replacement, and upgrading of specific parts rather than entire systems, extending product lifespans and reducing waste generation. Companies implementing these strategies have reported up to 30% reduction in raw material consumption and associated production costs.

Recovery infrastructure development remains critical for successful CPC integration into circular economies. Specialized recycling technologies capable of handling mixed polymer-conductive filler systems are emerging, including solvent-based separation methods and advanced mechanical recycling techniques. These technologies can recover high-value conductive materials like carbon nanotubes or graphene from end-of-life products while preserving their functional properties.

Supply chain collaboration represents a fundamental requirement for circular CPC implementation. Establishing reverse logistics networks that connect manufacturers, consumers, and recyclers creates closed-loop material flows. Several industry consortia have formed to standardize CPC formulations and develop shared recovery infrastructure, demonstrating the importance of pre-competitive collaboration in this space.

Policy frameworks and economic incentives significantly influence circular economy integration for CPCs. Extended producer responsibility regulations, tax benefits for recycled content utilization, and landfill bans for recoverable materials create market conditions that favor circular approaches. Companies pioneering circular CPC applications have leveraged these incentives to develop innovative business models based on product-as-service offerings rather than traditional ownership models.

Performance verification systems must be established to ensure recycled CPCs maintain necessary functional properties. Standardized testing protocols that evaluate electrical conductivity, mechanical strength, and environmental stability of recycled materials provide confidence to end-users and facilitate market acceptance of circular CPC products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!