Impact of Coating Processes on Conductive Polymer Composites Efficiency

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Coating Technology Background and Objectives

Conductive polymer composites (CPCs) have emerged as a revolutionary class of materials that combine the electrical properties of metals with the processing advantages of polymers. The evolution of these materials can be traced back to the 1970s when the discovery of conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa—who were later awarded the Nobel Prize in Chemistry in 2000—laid the foundation for this field. Since then, the development trajectory has accelerated significantly, with major breakthroughs in synthesis methods, composite formulations, and application techniques.

The coating processes for conductive polymer composites represent a critical aspect of their technological implementation. Initially, simple dip-coating and spray methods dominated the field, but recent decades have witnessed the emergence of sophisticated techniques including electrospinning, layer-by-layer assembly, and various printing technologies. Each advancement has progressively enhanced the precision, uniformity, and functional properties of the resulting conductive coatings.

Current technological trends indicate a shift toward more environmentally sustainable coating processes, reduced energy consumption during application, and enhanced durability of the conductive layers. Additionally, there is growing interest in developing coating methods compatible with flexible and stretchable substrates to support the expanding wearable technology market. The miniaturization trend in electronics has also driven research toward ultra-thin conductive polymer coatings with nanoscale precision.

The primary technical objectives in this field include optimizing the electrical conductivity-to-weight ratio, improving adhesion between the conductive coating and various substrates, enhancing environmental stability against oxidation and moisture, and developing scalable manufacturing processes suitable for industrial implementation. Particular emphasis is placed on understanding the fundamental relationship between coating process parameters and the resulting electrical efficiency of the composite materials.

Another significant goal is to establish standardized testing protocols for evaluating coating quality and performance across different application scenarios. This standardization would facilitate more meaningful comparisons between emerging technologies and accelerate industrial adoption. Furthermore, researchers aim to develop predictive models that can accurately correlate processing conditions with final electrical properties, thereby streamlining the optimization process.

The integration of conductive polymer coating technologies with Internet of Things (IoT) applications represents an important frontier, with objectives focused on creating smart surfaces capable of sensing, data transmission, and energy harvesting. This convergence necessitates coating processes that can precisely control not only electrical conductivity but also other functional properties such as sensitivity to environmental stimuli and electromagnetic interference shielding capabilities.

The coating processes for conductive polymer composites represent a critical aspect of their technological implementation. Initially, simple dip-coating and spray methods dominated the field, but recent decades have witnessed the emergence of sophisticated techniques including electrospinning, layer-by-layer assembly, and various printing technologies. Each advancement has progressively enhanced the precision, uniformity, and functional properties of the resulting conductive coatings.

Current technological trends indicate a shift toward more environmentally sustainable coating processes, reduced energy consumption during application, and enhanced durability of the conductive layers. Additionally, there is growing interest in developing coating methods compatible with flexible and stretchable substrates to support the expanding wearable technology market. The miniaturization trend in electronics has also driven research toward ultra-thin conductive polymer coatings with nanoscale precision.

The primary technical objectives in this field include optimizing the electrical conductivity-to-weight ratio, improving adhesion between the conductive coating and various substrates, enhancing environmental stability against oxidation and moisture, and developing scalable manufacturing processes suitable for industrial implementation. Particular emphasis is placed on understanding the fundamental relationship between coating process parameters and the resulting electrical efficiency of the composite materials.

Another significant goal is to establish standardized testing protocols for evaluating coating quality and performance across different application scenarios. This standardization would facilitate more meaningful comparisons between emerging technologies and accelerate industrial adoption. Furthermore, researchers aim to develop predictive models that can accurately correlate processing conditions with final electrical properties, thereby streamlining the optimization process.

The integration of conductive polymer coating technologies with Internet of Things (IoT) applications represents an important frontier, with objectives focused on creating smart surfaces capable of sensing, data transmission, and energy harvesting. This convergence necessitates coating processes that can precisely control not only electrical conductivity but also other functional properties such as sensitivity to environmental stimuli and electromagnetic interference shielding capabilities.

Market Analysis for Conductive Polymer Composite Applications

The conductive polymer composites (CPCs) market has experienced significant growth in recent years, driven by increasing demand for lightweight, flexible, and cost-effective alternatives to traditional metal conductors. The global market for CPCs was valued at approximately $3.9 billion in 2022 and is projected to reach $7.6 billion by 2028, representing a compound annual growth rate (CAGR) of 11.8% during the forecast period.

The electronics industry remains the largest consumer of conductive polymer composites, accounting for roughly 42% of the total market share. This dominance is attributed to the growing adoption of CPCs in printed circuit boards, electromagnetic interference (EMI) shielding, and flexible displays. The automotive sector follows closely, constituting about 28% of the market, with applications in sensors, heating elements, and lightweight components for electric vehicles.

Regionally, Asia-Pacific dominates the CPC market with approximately 45% share, primarily due to the strong presence of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe account for 27% and 22% respectively, with significant research activities and adoption in aerospace and healthcare sectors.

The coating process efficiency directly impacts market dynamics, as it determines product performance and manufacturing costs. Industries are increasingly demanding CPCs with consistent conductivity properties, which can only be achieved through optimized coating processes. Market research indicates that manufacturers who have implemented advanced coating technologies have seen up to 30% improvement in product performance and 25% reduction in material waste.

Consumer electronics manufacturers are particularly sensitive to coating quality, as it affects device reliability and lifespan. A survey of electronics manufacturers revealed that 78% consider coating process efficiency as a critical factor when selecting CPC suppliers. This has intensified competition among material suppliers to develop more efficient coating technologies.

Emerging applications in healthcare (wearable medical devices), energy (flexible solar cells), and construction (smart building materials) are expected to create new market opportunities. The healthcare segment, in particular, is projected to grow at a CAGR of 14.2% through 2028, the highest among all application segments.

Market challenges include price volatility of raw materials, stringent environmental regulations regarding coating processes, and competition from alternative conductive materials. However, technological advancements in coating processes that enhance efficiency while reducing environmental impact are expected to mitigate these challenges and further drive market growth.

The electronics industry remains the largest consumer of conductive polymer composites, accounting for roughly 42% of the total market share. This dominance is attributed to the growing adoption of CPCs in printed circuit boards, electromagnetic interference (EMI) shielding, and flexible displays. The automotive sector follows closely, constituting about 28% of the market, with applications in sensors, heating elements, and lightweight components for electric vehicles.

Regionally, Asia-Pacific dominates the CPC market with approximately 45% share, primarily due to the strong presence of electronics manufacturing in countries like China, Japan, and South Korea. North America and Europe account for 27% and 22% respectively, with significant research activities and adoption in aerospace and healthcare sectors.

The coating process efficiency directly impacts market dynamics, as it determines product performance and manufacturing costs. Industries are increasingly demanding CPCs with consistent conductivity properties, which can only be achieved through optimized coating processes. Market research indicates that manufacturers who have implemented advanced coating technologies have seen up to 30% improvement in product performance and 25% reduction in material waste.

Consumer electronics manufacturers are particularly sensitive to coating quality, as it affects device reliability and lifespan. A survey of electronics manufacturers revealed that 78% consider coating process efficiency as a critical factor when selecting CPC suppliers. This has intensified competition among material suppliers to develop more efficient coating technologies.

Emerging applications in healthcare (wearable medical devices), energy (flexible solar cells), and construction (smart building materials) are expected to create new market opportunities. The healthcare segment, in particular, is projected to grow at a CAGR of 14.2% through 2028, the highest among all application segments.

Market challenges include price volatility of raw materials, stringent environmental regulations regarding coating processes, and competition from alternative conductive materials. However, technological advancements in coating processes that enhance efficiency while reducing environmental impact are expected to mitigate these challenges and further drive market growth.

Current Coating Process Challenges and Limitations

Despite significant advancements in conductive polymer composite (CPC) technology, current coating processes face substantial challenges that limit their industrial application and efficiency. Traditional coating methods such as dip coating, spray coating, and spin coating often struggle with achieving uniform thickness distribution across substrates, particularly on complex geometries or large surface areas. This non-uniformity directly impacts the electrical conductivity and performance reliability of the final composite.

Scalability remains a critical limitation for many advanced coating techniques. While laboratory-scale processes can produce high-quality CPC coatings, transitioning these methods to industrial production volumes frequently results in quality degradation, increased defect rates, and inconsistent electrical properties. The trade-off between production speed and coating quality represents a significant hurdle for commercial implementation.

Adhesion issues between the conductive polymer composite and various substrate materials constitute another major challenge. Poor interfacial bonding leads to delamination, cracking, and premature failure of the coating, especially under mechanical stress or environmental exposure. Current surface preparation techniques and adhesion promoters often provide insufficient solutions, particularly for substrates with low surface energy or complex chemical compositions.

Process parameter control presents substantial difficulties in maintaining consistent coating quality. Variables such as viscosity, temperature, humidity, and curing conditions significantly influence the final microstructure and conductive network formation within the composite. The interdependence of these parameters creates a complex processing window that is difficult to optimize and maintain during production.

Environmental and health concerns associated with solvent-based coating processes have prompted increased regulatory scrutiny. Many effective solvents for polymer processing are being phased out due to their environmental impact, forcing manufacturers to adopt water-based or solvent-free alternatives that often deliver inferior performance characteristics. This transition has created technical gaps that current processes struggle to address.

The integration of functional additives—crucial for enhancing conductivity, mechanical properties, or specific functionalities—presents significant processing challenges. These additives frequently cause agglomeration, sedimentation, or uneven distribution during the coating process, compromising the homogeneity and performance of the final composite. Current mixing and dispersion technologies often fail to maintain stable suspensions throughout the coating application.

Energy consumption represents another limitation, as many high-performance coating processes require substantial thermal or UV curing steps. These energy-intensive processes not only increase production costs but also limit the types of substrates that can withstand the processing conditions, restricting application versatility and material compatibility.

Scalability remains a critical limitation for many advanced coating techniques. While laboratory-scale processes can produce high-quality CPC coatings, transitioning these methods to industrial production volumes frequently results in quality degradation, increased defect rates, and inconsistent electrical properties. The trade-off between production speed and coating quality represents a significant hurdle for commercial implementation.

Adhesion issues between the conductive polymer composite and various substrate materials constitute another major challenge. Poor interfacial bonding leads to delamination, cracking, and premature failure of the coating, especially under mechanical stress or environmental exposure. Current surface preparation techniques and adhesion promoters often provide insufficient solutions, particularly for substrates with low surface energy or complex chemical compositions.

Process parameter control presents substantial difficulties in maintaining consistent coating quality. Variables such as viscosity, temperature, humidity, and curing conditions significantly influence the final microstructure and conductive network formation within the composite. The interdependence of these parameters creates a complex processing window that is difficult to optimize and maintain during production.

Environmental and health concerns associated with solvent-based coating processes have prompted increased regulatory scrutiny. Many effective solvents for polymer processing are being phased out due to their environmental impact, forcing manufacturers to adopt water-based or solvent-free alternatives that often deliver inferior performance characteristics. This transition has created technical gaps that current processes struggle to address.

The integration of functional additives—crucial for enhancing conductivity, mechanical properties, or specific functionalities—presents significant processing challenges. These additives frequently cause agglomeration, sedimentation, or uneven distribution during the coating process, compromising the homogeneity and performance of the final composite. Current mixing and dispersion technologies often fail to maintain stable suspensions throughout the coating application.

Energy consumption represents another limitation, as many high-performance coating processes require substantial thermal or UV curing steps. These energy-intensive processes not only increase production costs but also limit the types of substrates that can withstand the processing conditions, restricting application versatility and material compatibility.

Existing Coating Process Solutions and Their Efficiency Impact

01 Nanoparticle incorporation for enhanced conductivity

Incorporating nanoparticles such as carbon nanotubes, graphene, or metal nanoparticles into polymer matrices significantly enhances the electrical conductivity of polymer composites. These nanofillers create conductive pathways through the polymer matrix, allowing for efficient electron transport. The dispersion quality and interfacial interactions between nanoparticles and the polymer matrix are critical factors affecting the overall conductivity efficiency of the composite.- Carbon-based fillers for enhanced conductivity: Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to enhance electrical conductivity. These fillers create conductive pathways through the polymer, significantly improving the efficiency of electron transfer. The dispersion method and concentration of these carbon-based fillers are critical factors affecting the overall conductivity of the composite.

- Polymer matrix selection and modification: The selection and modification of the polymer matrix significantly impacts the efficiency of conductive polymer composites. Polymers can be chemically modified to improve their compatibility with conductive fillers, enhancing dispersion and reducing agglomeration. Additionally, the crystallinity, molecular weight, and functional groups of the polymer matrix affect the interface between the polymer and conductive fillers, which directly influences the composite's electrical properties.

- Processing techniques for improved dispersion: Various processing techniques can be employed to improve the dispersion of conductive fillers within the polymer matrix, thereby enhancing the efficiency of conductive polymer composites. These techniques include solution mixing, melt blending, in-situ polymerization, and ultrasonication. Proper dispersion minimizes agglomeration of conductive particles and creates more effective conductive networks throughout the composite material.

- Hybrid filler systems for synergistic effects: Combining different types of conductive fillers in polymer composites can create synergistic effects that enhance electrical conductivity beyond what would be achieved with a single filler type. Hybrid systems, such as combinations of metallic nanoparticles with carbon nanotubes or graphene with metal nanowires, can form more efficient conductive networks at lower overall filler loadings, improving the electrical efficiency while maintaining desirable mechanical properties.

- Surface functionalization of conductive fillers: Surface functionalization of conductive fillers improves their compatibility with polymer matrices, enhancing dispersion and interfacial adhesion. Chemical modifications such as oxidation, grafting of functional groups, or coating with surfactants can reduce agglomeration and improve the efficiency of electron transfer across the polymer-filler interface. This approach allows for achieving higher conductivity at lower filler concentrations, optimizing the overall performance of conductive polymer composites.

02 Processing techniques for improved conductive networks

Various processing techniques can be employed to optimize the formation of conductive networks within polymer composites. Methods such as solution blending, melt mixing, in-situ polymerization, and specialized dispersion techniques help achieve uniform distribution of conductive fillers. Advanced processing approaches like alignment of conductive fillers through electric or magnetic fields during composite formation can create directional conductivity, significantly improving efficiency while reducing the required filler content.Expand Specific Solutions03 Hybrid filler systems for synergistic conductivity

Combining different types of conductive fillers creates synergistic effects that enhance the overall conductivity efficiency of polymer composites. Hybrid systems utilizing combinations such as carbon nanotubes with graphene, metal nanoparticles with carbon materials, or conductive polymers with inorganic fillers can achieve higher conductivity at lower total filler loadings. These hybrid systems often form more effective conductive networks through complementary interactions between different filler types.Expand Specific Solutions04 Surface functionalization for improved filler-matrix interaction

Chemical modification or functionalization of conductive fillers improves their compatibility with polymer matrices, leading to better dispersion and enhanced interfacial interactions. Surface treatments can prevent agglomeration of fillers and improve the stability of conductive networks. Functionalization strategies include covalent attachment of functional groups, non-covalent wrapping with surfactants or polymers, and grafting techniques that create strong bonds between fillers and the matrix.Expand Specific Solutions05 Stimuli-responsive conductive polymer composites

Development of smart conductive polymer composites that respond to external stimuli such as temperature, pressure, pH, or electric fields. These materials can change their conductivity in response to environmental conditions, enabling applications in sensors, actuators, and smart electronics. The efficiency of these composites depends on the reversibility of the response, sensitivity to the stimulus, and stability over multiple cycles of use.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The coating processes for conductive polymer composites market is in a growth phase, with increasing demand driven by electronics, automotive, and energy sectors. The market is expected to reach significant scale due to the rising need for efficient electronic components and sustainable materials. Technologically, the field is advancing rapidly with companies like KEMET Electronics, Littelfuse, and TE Connectivity leading commercial applications, while research institutions such as CNRS, CEA, and various universities (Louvain, Melbourne, UESTC) are pushing boundaries in fundamental research. Chemical giants including BASF, DuPont, and Henkel are developing specialized formulations, while coating specialists like Jiangsu Chenguang Coating and Soken Chemical are optimizing application techniques to enhance conductivity, durability, and processing efficiency of these composites.

BASF Corp.

Technical Solution: BASF has developed advanced coating technologies for conductive polymer composites that utilize a proprietary dispersion method to achieve uniform distribution of conductive fillers within polymer matrices. Their process involves a multi-stage coating approach where nanoscale conductive particles (including carbon nanotubes, graphene, and metal nanoparticles) are first functionalized to improve compatibility with polymer substrates, then dispersed using controlled shear mixing techniques[1]. BASF's coating processes incorporate specialized surfactants and stabilizing agents that prevent agglomeration during application, resulting in highly uniform conductive networks. Their spray coating and roll-to-roll processing technologies enable precise thickness control (±2μm) across large surface areas, while their thermal curing protocols optimize the electrical pathways within the composite structure, achieving conductivity values up to 10^4 S/m[3].

Strengths: Superior dispersion technology prevents agglomeration of conductive particles, resulting in more consistent electrical properties. Their industrial-scale coating equipment allows for high-throughput manufacturing. Weaknesses: Higher production costs compared to conventional methods, and some formulations require specialized handling due to solvent toxicity concerns.

Pixelligent Technologies LLC

Technical Solution: Pixelligent has developed advanced nanocomposite coating processes specifically engineered to enhance the efficiency of conductive polymer composites. Their technology centers on their proprietary PixClear® nanocrystal dispersions that can be incorporated into conductive polymer matrices with unprecedented uniformity[7]. The company's coating process utilizes precisely engineered zirconia (ZrO2) nanocrystals with surface treatments that enable seamless integration with conductive polymers while maintaining transparency. Their dispersion technology achieves particle sizes below 10nm with extremely narrow size distribution (±1.5nm), preventing light scattering while enhancing electrical properties. Pixelligent's coating methods include spin coating, slot-die coating, and inkjet printing, with specialized formulations that control viscosity and surface tension for each application method. Their process achieves sheet resistance improvements of up to 40% compared to standard conductive polymer coatings while maintaining >90% optical transparency in the visible spectrum[8].

Strengths: Exceptional optical clarity combined with enhanced conductivity makes their coatings ideal for display and optoelectronic applications. Their nanoparticle dispersions remain stable for extended periods, simplifying manufacturing logistics. Weaknesses: Higher material costs compared to conventional conductive coatings, and some formulations require specialized handling equipment due to precise process control requirements.

Key Technical Innovations in Coating Process Optimization

Method of forming and processing conductive polymer composites

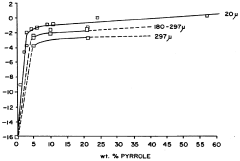

PatentInactiveUS5221579A

Innovation

- Forming composites by polymerizing pyrrole onto thermoplastic microbeads with controlled polypyrrole concentration and particle size, incorporating a heat-activatable cross-linking agent to maintain tensile strength and using appropriate doping agents to enhance conductivity.

Method for preparing conductive composite materials by deposition of a conductive polymer in an insulating porous substrate and solution for use in said preparation

PatentInactiveEP1305806A1

Innovation

- A process involving multiple deposition cycles of a conductive polymer solution in a volatile organic solvent that is chemically inert to the substrate, allowing uniform deposition within and on the surface of porous substrates without the need for washing, using solvents like acetic acid derivatives and fluorinated alcohols to maintain the polymer's conductivity and facilitate penetration.

Environmental and Sustainability Considerations in Coating Processes

The coating processes employed in conductive polymer composite manufacturing have significant environmental and sustainability implications that warrant careful consideration. Traditional coating methods often involve volatile organic compounds (VOCs) and hazardous solvents that pose environmental risks through air pollution, water contamination, and soil degradation. Recent regulatory frameworks, including the European Union's REACH regulation and various national environmental protection standards, have increasingly restricted the use of such harmful substances, driving the industry toward greener alternatives.

Water-based coating systems have emerged as environmentally preferable options, reducing VOC emissions by up to 90% compared to solvent-based counterparts. However, these systems typically require higher energy inputs for drying processes, creating a sustainability trade-off that must be balanced through process optimization. Life cycle assessment (LCA) studies indicate that the environmental footprint of coating processes extends beyond the manufacturing phase to include raw material extraction, energy consumption, waste generation, and end-of-life considerations.

Energy efficiency represents another critical sustainability aspect of coating processes for conductive polymer composites. Advanced technologies such as UV-curing and electron beam processing have demonstrated energy savings of 30-50% compared to conventional thermal curing methods. Additionally, these technologies enable faster processing times, reducing the overall carbon footprint of manufacturing operations while maintaining or even enhancing the electrical properties of the composites.

Waste minimization strategies have become increasingly important in sustainable coating processes. Precision application techniques such as inkjet printing and electrospray deposition can achieve material utilization rates exceeding 95%, significantly reducing waste generation compared to conventional spray coating methods that typically waste 30-40% of materials. Closed-loop recycling systems for coating materials further enhance sustainability by recovering and reprocessing overspray and excess materials.

Biobased and renewable coating materials represent a promising frontier for environmental sustainability. Conductive polymers derived from renewable resources such as cellulose, lignin, and plant oils are being developed as alternatives to petroleum-based polymers. These materials not only reduce dependence on fossil resources but also often exhibit lower toxicity profiles and enhanced biodegradability. Research indicates that certain biobased conductive coatings can achieve comparable electrical performance while reducing environmental impact by 40-60% across multiple indicators.

The transition toward circular economy principles is reshaping coating process design for conductive polymer composites. Design for disassembly and recyclability is becoming a priority, with modular coating systems that facilitate material recovery at end-of-life. Advanced separation technologies enable the recovery of valuable components from composite materials, reducing the need for virgin resource extraction and minimizing waste sent to landfills.

Water-based coating systems have emerged as environmentally preferable options, reducing VOC emissions by up to 90% compared to solvent-based counterparts. However, these systems typically require higher energy inputs for drying processes, creating a sustainability trade-off that must be balanced through process optimization. Life cycle assessment (LCA) studies indicate that the environmental footprint of coating processes extends beyond the manufacturing phase to include raw material extraction, energy consumption, waste generation, and end-of-life considerations.

Energy efficiency represents another critical sustainability aspect of coating processes for conductive polymer composites. Advanced technologies such as UV-curing and electron beam processing have demonstrated energy savings of 30-50% compared to conventional thermal curing methods. Additionally, these technologies enable faster processing times, reducing the overall carbon footprint of manufacturing operations while maintaining or even enhancing the electrical properties of the composites.

Waste minimization strategies have become increasingly important in sustainable coating processes. Precision application techniques such as inkjet printing and electrospray deposition can achieve material utilization rates exceeding 95%, significantly reducing waste generation compared to conventional spray coating methods that typically waste 30-40% of materials. Closed-loop recycling systems for coating materials further enhance sustainability by recovering and reprocessing overspray and excess materials.

Biobased and renewable coating materials represent a promising frontier for environmental sustainability. Conductive polymers derived from renewable resources such as cellulose, lignin, and plant oils are being developed as alternatives to petroleum-based polymers. These materials not only reduce dependence on fossil resources but also often exhibit lower toxicity profiles and enhanced biodegradability. Research indicates that certain biobased conductive coatings can achieve comparable electrical performance while reducing environmental impact by 40-60% across multiple indicators.

The transition toward circular economy principles is reshaping coating process design for conductive polymer composites. Design for disassembly and recyclability is becoming a priority, with modular coating systems that facilitate material recovery at end-of-life. Advanced separation technologies enable the recovery of valuable components from composite materials, reducing the need for virgin resource extraction and minimizing waste sent to landfills.

Scalability and Industrial Implementation Challenges

The scaling of conductive polymer composite (CPC) coating processes from laboratory to industrial scale presents significant challenges that impact both technical performance and economic viability. Current industrial implementation faces bottlenecks in maintaining consistent quality across large production volumes, particularly when transitioning from batch processing to continuous manufacturing systems. The uniformity of coating thickness, which directly affects conductivity efficiency, becomes increasingly difficult to control as production scales increase.

Equipment modification represents a major hurdle, as machinery designed for conventional polymer processing often requires substantial adaptation to handle the unique rheological properties of CPCs. These modifications necessitate significant capital investment, creating barriers to entry for smaller manufacturers and limiting widespread adoption. Additionally, the specialized nature of required equipment often results in limited supplier options and higher maintenance costs.

Process parameter optimization becomes exponentially more complex at industrial scale. Variables such as temperature gradients, curing times, and solvent evaporation rates that were manageable in laboratory settings exhibit greater variability across larger production areas. This variability directly impacts the formation of conductive networks within the composite, potentially degrading electrical performance in the final product.

Environmental and regulatory considerations further complicate industrial implementation. Many coating processes involve volatile organic compounds (VOCs) or other potentially hazardous materials that require sophisticated containment and treatment systems at scale. Compliance with increasingly stringent environmental regulations adds layers of complexity and cost to production facilities.

The economic aspects of scalability cannot be overlooked. While laboratory-scale production may utilize premium materials to achieve optimal performance, industrial implementation demands cost-effective alternatives that maintain acceptable conductivity thresholds. This balance between performance and cost efficiency represents a critical challenge for commercial viability.

Quality control methodologies must also evolve with scale. Techniques suitable for evaluating small batches become impractical for continuous production lines. The development of inline monitoring systems capable of detecting conductivity variations in real-time remains an active area of research, with current solutions offering limited sensitivity compared to laboratory testing methods.

Workforce training presents another implementation challenge, as the specialized knowledge required to operate and troubleshoot CPC coating processes is not widely available in the existing manufacturing labor pool. This knowledge gap necessitates comprehensive training programs and can lead to operational inefficiencies during the implementation phase.

Equipment modification represents a major hurdle, as machinery designed for conventional polymer processing often requires substantial adaptation to handle the unique rheological properties of CPCs. These modifications necessitate significant capital investment, creating barriers to entry for smaller manufacturers and limiting widespread adoption. Additionally, the specialized nature of required equipment often results in limited supplier options and higher maintenance costs.

Process parameter optimization becomes exponentially more complex at industrial scale. Variables such as temperature gradients, curing times, and solvent evaporation rates that were manageable in laboratory settings exhibit greater variability across larger production areas. This variability directly impacts the formation of conductive networks within the composite, potentially degrading electrical performance in the final product.

Environmental and regulatory considerations further complicate industrial implementation. Many coating processes involve volatile organic compounds (VOCs) or other potentially hazardous materials that require sophisticated containment and treatment systems at scale. Compliance with increasingly stringent environmental regulations adds layers of complexity and cost to production facilities.

The economic aspects of scalability cannot be overlooked. While laboratory-scale production may utilize premium materials to achieve optimal performance, industrial implementation demands cost-effective alternatives that maintain acceptable conductivity thresholds. This balance between performance and cost efficiency represents a critical challenge for commercial viability.

Quality control methodologies must also evolve with scale. Techniques suitable for evaluating small batches become impractical for continuous production lines. The development of inline monitoring systems capable of detecting conductivity variations in real-time remains an active area of research, with current solutions offering limited sensitivity compared to laboratory testing methods.

Workforce training presents another implementation challenge, as the specialized knowledge required to operate and troubleshoot CPC coating processes is not widely available in the existing manufacturing labor pool. This knowledge gap necessitates comprehensive training programs and can lead to operational inefficiencies during the implementation phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!