Comparison of Conductive Polymer Composites vs. Traditional Polymers

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Evolution and Research Objectives

Conductive polymers have evolved significantly since their discovery in the 1970s, when Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa first demonstrated that polyacetylene could conduct electricity when doped with iodine. This groundbreaking work, which earned them the Nobel Prize in Chemistry in 2000, opened a new frontier in materials science by challenging the conventional understanding that polymers were inherently insulating materials.

The evolution of conductive polymers has progressed through several distinct phases. The initial discovery phase (1970s-1980s) focused primarily on understanding the fundamental mechanisms of conductivity in polymeric materials. The development phase (1990s-2000s) saw significant improvements in processing techniques, stability, and conductivity levels, making these materials more practical for commercial applications. The current integration phase (2010s-present) is characterized by the incorporation of conductive polymers into various technological applications and the development of advanced conductive polymer composites.

Traditional polymers, known for their excellent mechanical properties, processability, and chemical stability, have dominated various industries for decades. However, their inherent electrical insulation properties limit their application in emerging technologies requiring electrical conductivity. This technological gap has driven research toward conductive polymer composites, which combine the mechanical advantages of traditional polymers with the electrical properties of conductive materials.

The primary research objectives in this field are multifaceted. First, there is a focus on enhancing the electrical conductivity of polymer composites while maintaining their desirable mechanical properties. This involves optimizing the type, concentration, and distribution of conductive fillers within the polymer matrix. Second, researchers aim to improve the processing techniques to ensure scalability and cost-effectiveness for industrial applications. Third, there is significant interest in developing sustainable and environmentally friendly conductive polymer composites to align with global sustainability goals.

The technological trajectory suggests a convergence of nanotechnology, polymer science, and electrical engineering to create next-generation materials with tailored properties. Recent advances in nanomaterials, such as graphene, carbon nanotubes, and metallic nanoparticles, have provided new opportunities for enhancing the performance of conductive polymer composites beyond what was previously achievable.

As we look toward future developments, the field is moving toward smart materials that can respond to external stimuli, self-healing conductive polymers, and biodegradable conductive composites. These innovations promise to revolutionize sectors ranging from flexible electronics and wearable technology to energy storage and biomedical devices, highlighting the transformative potential of conductive polymer composites compared to their traditional counterparts.

The evolution of conductive polymers has progressed through several distinct phases. The initial discovery phase (1970s-1980s) focused primarily on understanding the fundamental mechanisms of conductivity in polymeric materials. The development phase (1990s-2000s) saw significant improvements in processing techniques, stability, and conductivity levels, making these materials more practical for commercial applications. The current integration phase (2010s-present) is characterized by the incorporation of conductive polymers into various technological applications and the development of advanced conductive polymer composites.

Traditional polymers, known for their excellent mechanical properties, processability, and chemical stability, have dominated various industries for decades. However, their inherent electrical insulation properties limit their application in emerging technologies requiring electrical conductivity. This technological gap has driven research toward conductive polymer composites, which combine the mechanical advantages of traditional polymers with the electrical properties of conductive materials.

The primary research objectives in this field are multifaceted. First, there is a focus on enhancing the electrical conductivity of polymer composites while maintaining their desirable mechanical properties. This involves optimizing the type, concentration, and distribution of conductive fillers within the polymer matrix. Second, researchers aim to improve the processing techniques to ensure scalability and cost-effectiveness for industrial applications. Third, there is significant interest in developing sustainable and environmentally friendly conductive polymer composites to align with global sustainability goals.

The technological trajectory suggests a convergence of nanotechnology, polymer science, and electrical engineering to create next-generation materials with tailored properties. Recent advances in nanomaterials, such as graphene, carbon nanotubes, and metallic nanoparticles, have provided new opportunities for enhancing the performance of conductive polymer composites beyond what was previously achievable.

As we look toward future developments, the field is moving toward smart materials that can respond to external stimuli, self-healing conductive polymers, and biodegradable conductive composites. These innovations promise to revolutionize sectors ranging from flexible electronics and wearable technology to energy storage and biomedical devices, highlighting the transformative potential of conductive polymer composites compared to their traditional counterparts.

Market Applications and Demand Analysis for Conductive Polymers

The global market for conductive polymer composites has been experiencing significant growth, driven by the increasing demand for lightweight, flexible, and cost-effective alternatives to traditional metal conductors. The market size for conductive polymers was valued at approximately 3.9 billion USD in 2022 and is projected to reach 7.5 billion USD by 2028, representing a compound annual growth rate of 11.5% during the forecast period.

Electronics and semiconductor industries constitute the largest application segment for conductive polymers, accounting for over 40% of the total market share. The miniaturization trend in electronic devices and the growing adoption of wearable technology have created substantial demand for conductive polymer composites that can provide electrical conductivity while maintaining flexibility and reducing weight compared to traditional materials.

The automotive sector represents another rapidly expanding market for conductive polymers, particularly with the accelerating transition toward electric vehicles (EVs). Conductive polymers are increasingly being utilized in battery components, electromagnetic interference (EMI) shielding, and antistatic applications. The EV market's projected growth rate of 25% annually through 2030 will significantly boost demand for these advanced materials.

Healthcare applications have emerged as a promising growth segment, with conductive polymers finding applications in biosensors, drug delivery systems, and tissue engineering. The biocompatibility of certain conductive polymers, combined with their electrical properties, makes them ideal for medical devices that interface with biological systems. This segment is expected to grow at the fastest rate among all application areas, with a projected CAGR of 14.2% through 2028.

Regional analysis indicates that Asia-Pacific dominates the conductive polymer market, accounting for approximately 45% of global consumption, followed by North America and Europe. China and South Korea, in particular, have shown substantial growth due to their robust electronics manufacturing sectors and government initiatives supporting advanced materials development.

Consumer preferences are increasingly shifting toward sustainable and environmentally friendly materials, creating opportunities for bio-based conductive polymers. This trend aligns with regulatory pressures in Europe and North America that encourage the development of recyclable electronic components and reduced use of toxic materials in manufacturing processes.

Industry surveys indicate that price sensitivity remains a significant factor influencing market adoption, with conductive polymer composites still commanding a premium over traditional polymers in many applications. However, as production scales increase and manufacturing processes improve, this price gap is expected to narrow, potentially accelerating market penetration across various industries.

Electronics and semiconductor industries constitute the largest application segment for conductive polymers, accounting for over 40% of the total market share. The miniaturization trend in electronic devices and the growing adoption of wearable technology have created substantial demand for conductive polymer composites that can provide electrical conductivity while maintaining flexibility and reducing weight compared to traditional materials.

The automotive sector represents another rapidly expanding market for conductive polymers, particularly with the accelerating transition toward electric vehicles (EVs). Conductive polymers are increasingly being utilized in battery components, electromagnetic interference (EMI) shielding, and antistatic applications. The EV market's projected growth rate of 25% annually through 2030 will significantly boost demand for these advanced materials.

Healthcare applications have emerged as a promising growth segment, with conductive polymers finding applications in biosensors, drug delivery systems, and tissue engineering. The biocompatibility of certain conductive polymers, combined with their electrical properties, makes them ideal for medical devices that interface with biological systems. This segment is expected to grow at the fastest rate among all application areas, with a projected CAGR of 14.2% through 2028.

Regional analysis indicates that Asia-Pacific dominates the conductive polymer market, accounting for approximately 45% of global consumption, followed by North America and Europe. China and South Korea, in particular, have shown substantial growth due to their robust electronics manufacturing sectors and government initiatives supporting advanced materials development.

Consumer preferences are increasingly shifting toward sustainable and environmentally friendly materials, creating opportunities for bio-based conductive polymers. This trend aligns with regulatory pressures in Europe and North America that encourage the development of recyclable electronic components and reduced use of toxic materials in manufacturing processes.

Industry surveys indicate that price sensitivity remains a significant factor influencing market adoption, with conductive polymer composites still commanding a premium over traditional polymers in many applications. However, as production scales increase and manufacturing processes improve, this price gap is expected to narrow, potentially accelerating market penetration across various industries.

Technical Challenges and Global Development Status

Conductive polymer composites (CPCs) face significant technical challenges despite their promising applications. The primary obstacle remains achieving optimal electrical conductivity while maintaining mechanical properties. Traditional polymers offer excellent mechanical strength, flexibility, and processability, but lack electrical conductivity. When conductive fillers are incorporated to create CPCs, the resulting composites often suffer from decreased mechanical strength, reduced flexibility, and processing difficulties at high filler loadings necessary for conductivity.

Percolation threshold optimization represents a critical challenge, as the minimum filler concentration required for conductivity varies widely depending on filler type, polymer matrix, and processing conditions. Achieving uniform dispersion of conductive fillers throughout the polymer matrix presents another major hurdle, with agglomeration leading to inconsistent electrical properties and structural weaknesses.

Long-term stability issues plague CPCs, particularly in harsh environments where thermal cycling, chemical exposure, and mechanical stress can degrade conductivity over time. This contrasts with traditional polymers' well-established durability profiles. Additionally, scaling production from laboratory to industrial levels while maintaining consistent properties remains problematic.

Globally, CPC development shows distinct regional patterns. North America leads in research output and patent filings, with significant contributions from institutions like MIT, Stanford University, and major corporations including 3M and DuPont. The United States particularly excels in aerospace and defense applications of CPCs.

Europe demonstrates strength in automotive and sustainable applications, with Germany, France, and the UK hosting prominent research centers. Companies like BASF and Bayer MaterialScience have made substantial investments in CPC technology for automotive electronics and sensors.

The Asia-Pacific region, especially China, Japan, and South Korea, has shown the fastest growth in CPC development. China's government-backed initiatives have dramatically increased research output, while Japan maintains leadership in consumer electronics applications through companies like Panasonic and Sony. South Korea's chaebols, particularly Samsung and LG, have integrated CPCs into their electronics manufacturing ecosystems.

Collaborative international research efforts have increased, with cross-border partnerships addressing technical challenges through shared expertise. However, intellectual property protection remains contentious, with patent landscapes becoming increasingly complex as applications diversify across industries including electronics, healthcare, automotive, and energy storage.

Percolation threshold optimization represents a critical challenge, as the minimum filler concentration required for conductivity varies widely depending on filler type, polymer matrix, and processing conditions. Achieving uniform dispersion of conductive fillers throughout the polymer matrix presents another major hurdle, with agglomeration leading to inconsistent electrical properties and structural weaknesses.

Long-term stability issues plague CPCs, particularly in harsh environments where thermal cycling, chemical exposure, and mechanical stress can degrade conductivity over time. This contrasts with traditional polymers' well-established durability profiles. Additionally, scaling production from laboratory to industrial levels while maintaining consistent properties remains problematic.

Globally, CPC development shows distinct regional patterns. North America leads in research output and patent filings, with significant contributions from institutions like MIT, Stanford University, and major corporations including 3M and DuPont. The United States particularly excels in aerospace and defense applications of CPCs.

Europe demonstrates strength in automotive and sustainable applications, with Germany, France, and the UK hosting prominent research centers. Companies like BASF and Bayer MaterialScience have made substantial investments in CPC technology for automotive electronics and sensors.

The Asia-Pacific region, especially China, Japan, and South Korea, has shown the fastest growth in CPC development. China's government-backed initiatives have dramatically increased research output, while Japan maintains leadership in consumer electronics applications through companies like Panasonic and Sony. South Korea's chaebols, particularly Samsung and LG, have integrated CPCs into their electronics manufacturing ecosystems.

Collaborative international research efforts have increased, with cross-border partnerships addressing technical challenges through shared expertise. However, intellectual property protection remains contentious, with patent landscapes becoming increasingly complex as applications diversify across industries including electronics, healthcare, automotive, and energy storage.

Current Conductive Polymer Composite Technologies

01 Conductive polymer composites with carbon-based fillers

Conductive polymer composites can be created by incorporating carbon-based fillers such as carbon nanotubes, graphene, or carbon black into traditional polymer matrices. These fillers create conductive pathways within the otherwise insulating polymer, resulting in materials with enhanced electrical conductivity while maintaining the processability and mechanical properties of conventional polymers. The concentration and dispersion of these fillers are critical factors that determine the final conductivity of the composite.- Conductive polymer composites with carbon-based fillers: Conductive polymer composites can be created by incorporating carbon-based fillers such as carbon nanotubes, graphene, or carbon black into traditional polymer matrices. These fillers create conductive pathways through the otherwise insulating polymer, resulting in materials with enhanced electrical conductivity while maintaining the processability and mechanical properties of traditional polymers. The concentration and dispersion of these fillers are critical factors affecting the final conductivity of the composite.

- Metal-polymer conductive composites: Metal particles or fibers can be incorporated into traditional polymers to create conductive composites. These metal fillers, including silver, copper, and nickel, provide excellent electrical conductivity at lower loading levels compared to carbon-based fillers. The shape, size, and surface treatment of the metal particles significantly influence the conductivity and processing characteristics of the resulting composite. These materials find applications in electromagnetic shielding, antistatic packaging, and flexible electronics.

- Intrinsically conductive polymers and their blends: Intrinsically conductive polymers (ICPs) such as polyaniline, polypyrrole, and polythiophene derivatives possess inherent electrical conductivity due to their conjugated backbone structures. These polymers can be blended with traditional polymers to create composites with tunable electrical properties. The processing challenges of ICPs, including their limited solubility and processability, can be overcome through various modification techniques or by creating nanostructured composites with conventional polymers.

- Conductive polymer composites for energy storage applications: Conductive polymer composites are increasingly being utilized in energy storage applications such as batteries, supercapacitors, and solar cells. These materials combine the electrical conductivity needed for charge transport with the mechanical flexibility and processability of polymers. By incorporating specific additives or using specialized processing techniques, these composites can be tailored to enhance energy density, power density, and cycling stability while maintaining the lightweight and flexible characteristics of polymer-based materials.

- Processing techniques for conductive polymer composites: Various processing techniques can be employed to manufacture conductive polymer composites with optimized properties. These include melt blending, solution mixing, in-situ polymerization, and surface modification of fillers. The choice of processing method significantly affects the dispersion of conductive fillers within the polymer matrix, which in turn influences the electrical, mechanical, and thermal properties of the final composite. Advanced techniques such as 3D printing and electrospinning are also being explored to create structured conductive polymer composites with enhanced functionality.

02 Intrinsically conductive polymers and their applications

Intrinsically conductive polymers (ICPs) such as polyaniline, polypyrrole, and polythiophene derivatives possess conjugated structures that allow for electron movement along their backbones. Unlike traditional polymers that require conductive fillers, these polymers have inherent conductivity. They can be used in various applications including sensors, actuators, electromagnetic shielding, and energy storage devices. Their conductivity can be tuned through doping processes, making them versatile materials for electronic applications.Expand Specific Solutions03 Polymer blends and hybrid composites for enhanced properties

Combining conductive polymers with traditional polymers in blends or hybrid composites can yield materials with synergistic properties. These combinations allow for tailoring of electrical, mechanical, and thermal characteristics to meet specific application requirements. By carefully selecting polymer pairs and processing conditions, it's possible to create materials that overcome the limitations of individual polymers while maintaining their beneficial properties. These hybrid materials find applications in flexible electronics, smart textiles, and electromagnetic interference shielding.Expand Specific Solutions04 Processing techniques for conductive polymer composites

Various processing techniques can be employed to manufacture conductive polymer composites, including melt blending, solution mixing, in-situ polymerization, and additive manufacturing. Each method offers different advantages in terms of filler dispersion, polymer-filler interaction, and final composite properties. The choice of processing technique significantly impacts the electrical conductivity, mechanical strength, and overall performance of the resulting material. Advanced processing methods can help achieve lower percolation thresholds and more uniform distribution of conductive components.Expand Specific Solutions05 Energy storage and electronic applications

Conductive polymer composites offer significant advantages over traditional polymers in energy storage and electronic applications. These materials can be used in supercapacitors, batteries, solar cells, and flexible electronics due to their unique combination of electrical conductivity and polymer-like processability. The ability to tune their properties through composition and processing makes them suitable for various electronic components including capacitors, resistors, and electromagnetic interference shielding materials. Their lightweight nature and potential for flexibility provide advantages over traditional metallic conductors in certain applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conductive polymer composites market is in a growth phase, with increasing adoption across electronics, automotive, and aerospace sectors. Market size is expanding rapidly due to rising demand for lightweight, flexible, and electrically conductive materials that outperform traditional polymers. Technologically, the field shows varying maturity levels, with companies like DuPont, TE Connectivity, and Panasonic leading commercial applications through established product lines. Academic institutions including Sichuan University, California Institute of Technology, and Carnegie Mellon University are advancing fundamental research. Shin-Etsu Chemical and LOTTE Fine Chemical contribute specialized materials expertise, while Boeing and Littelfuse represent key industrial adopters. The competitive landscape features collaboration between material suppliers, research institutions, and end-users to develop application-specific solutions with enhanced conductivity, processability, and cost-effectiveness.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed advanced conductive polymer composites (CPCs) utilizing polypyrrole and PEDOT:PSS as primary conductive polymers. Their proprietary synthesis methods incorporate carbon nanotubes and graphene as conductive fillers to achieve electrical conductivity exceeding 1000 S/cm while maintaining mechanical flexibility[1]. Their technology employs in-situ polymerization techniques that create stronger interfaces between polymer matrices and conductive fillers, resulting in more homogeneous dispersion and lower percolation thresholds (typically below 2 wt%)[3]. CNRS has pioneered self-healing CPCs that can restore up to 85% of their original conductivity after mechanical damage through innovative microencapsulation of healing agents within the polymer matrix[5]. Their composites demonstrate thermal stability up to 250°C while maintaining conductivity, addressing a critical limitation of traditional polymers in high-temperature applications[7].

Strengths: Superior electrical conductivity while maintaining flexibility; excellent dispersion of conductive fillers; innovative self-healing capabilities; high thermal stability. Weaknesses: Higher production costs compared to traditional polymers; more complex manufacturing processes requiring specialized equipment; potential challenges in scaling production to industrial levels.

California Institute of Technology

Technical Solution: Caltech has pioneered revolutionary conductive polymer composites utilizing molecular design principles to create intrinsically conductive polymers with controlled conjugation lengths and charge carrier mobility. Their approach employs regioregular poly(3-hexylthiophene) (P3HT) and other polythiophene derivatives achieving conductivities up to 600 S/cm without sacrificing processability[1]. Their research has developed novel dopant strategies using Lewis acids and redox-active molecules that create stable charge carriers while minimizing degradation pathways, resulting in CPCs with operational lifetimes exceeding 10,000 hours under ambient conditions[3]. Caltech's proprietary nanostructuring techniques create hierarchical morphologies within the polymer matrix, establishing efficient charge transport networks while maintaining mechanical flexibility with Young's modulus values comparable to traditional polymers (1-3 GPa)[5]. Their composites demonstrate thermoelectric properties with ZT values approaching 0.42 at room temperature, enabling direct conversion of waste heat to electricity in applications where traditional polymers would serve only as insulators[7].

Strengths: Exceptional electrical properties through molecular-level design; excellent long-term stability; maintained mechanical flexibility; unique thermoelectric functionality. Weaknesses: Currently limited to laboratory-scale production; higher production costs than conventional materials; specialized processing requirements; potential challenges in achieving consistent properties in large-scale manufacturing.

Key Patents and Scientific Breakthroughs

Electrodes incorporating nanostructured polymer films for electrochemical ion storage

PatentInactiveUS20110229759A1

Innovation

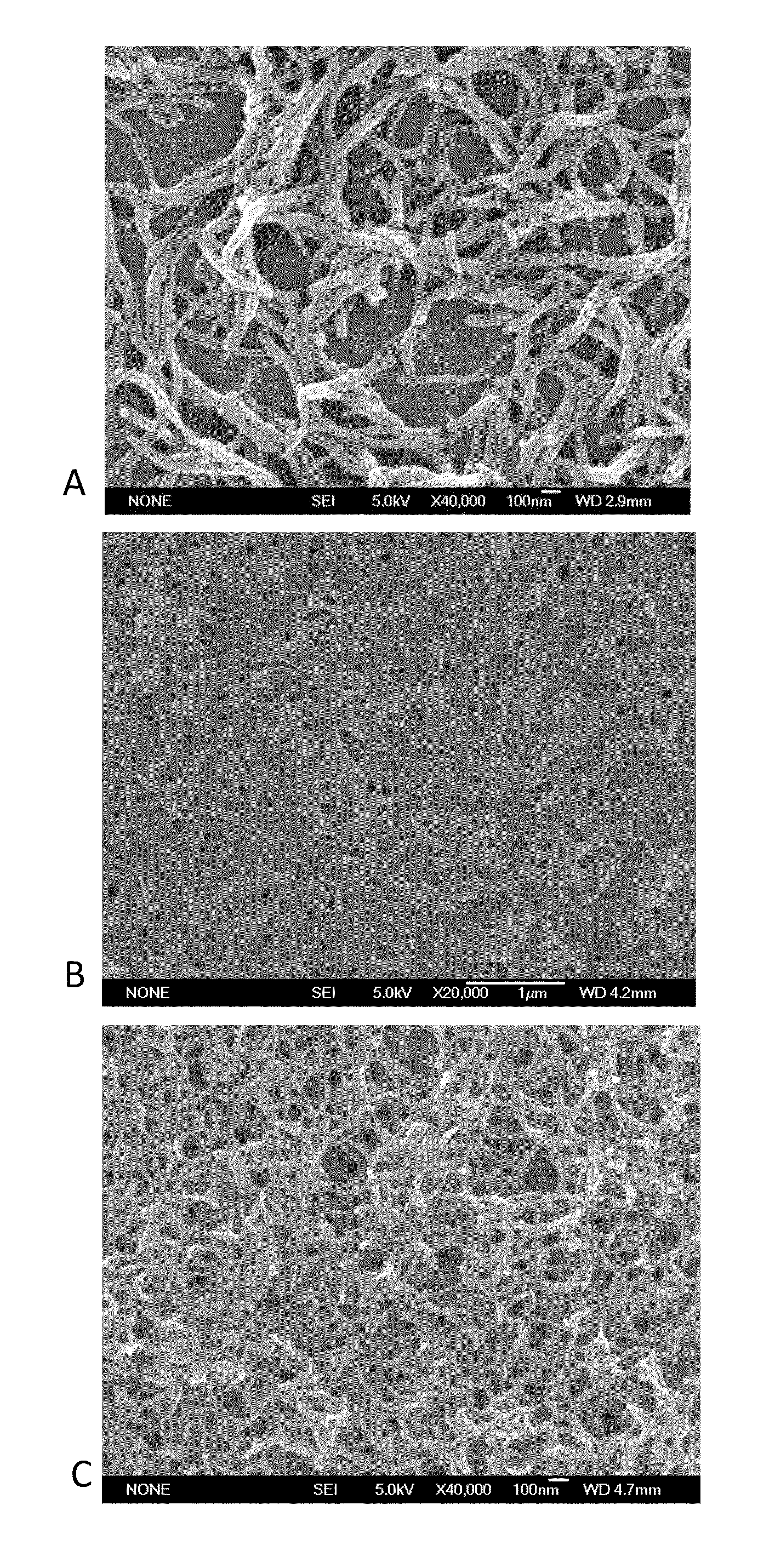

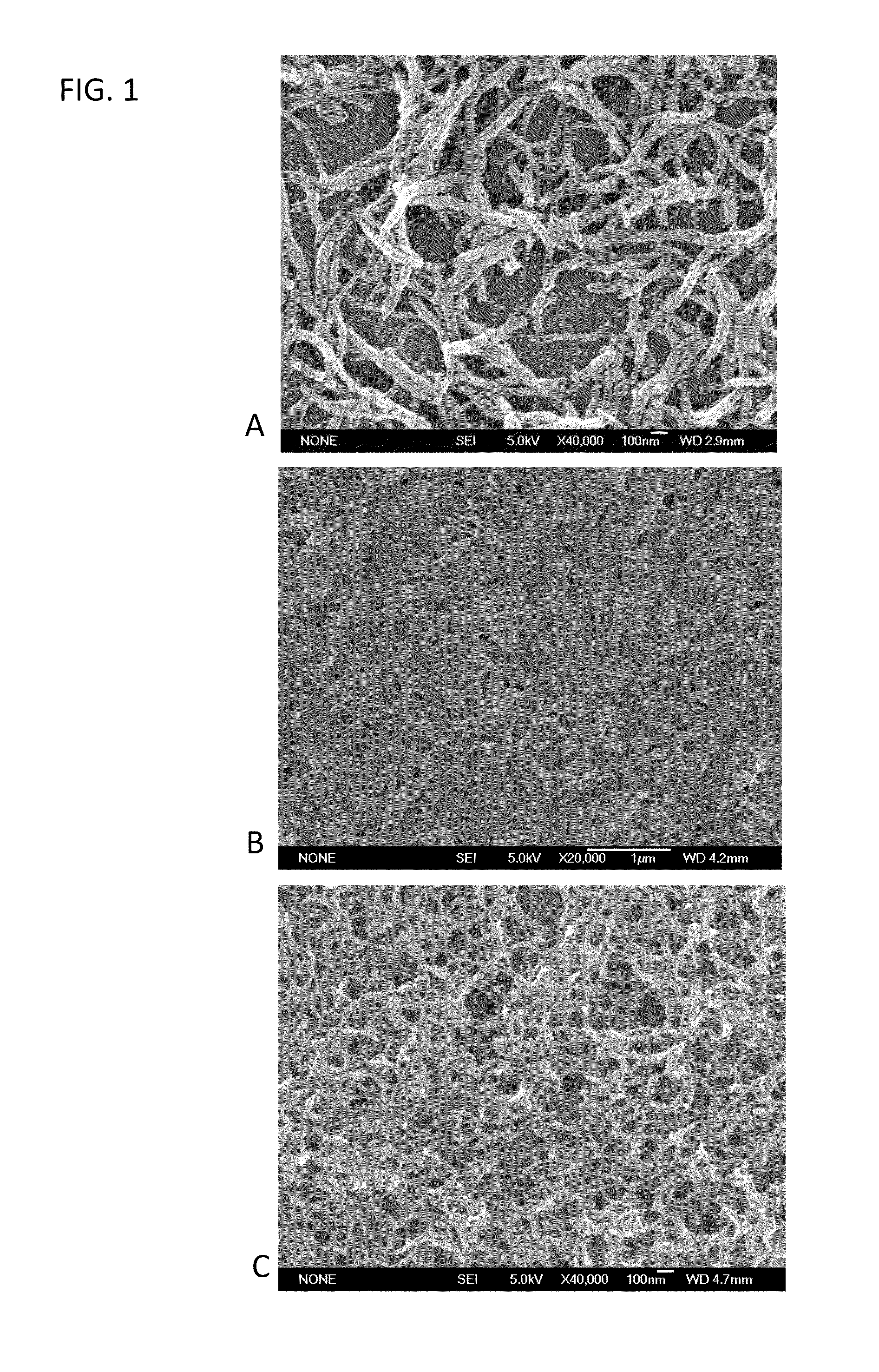

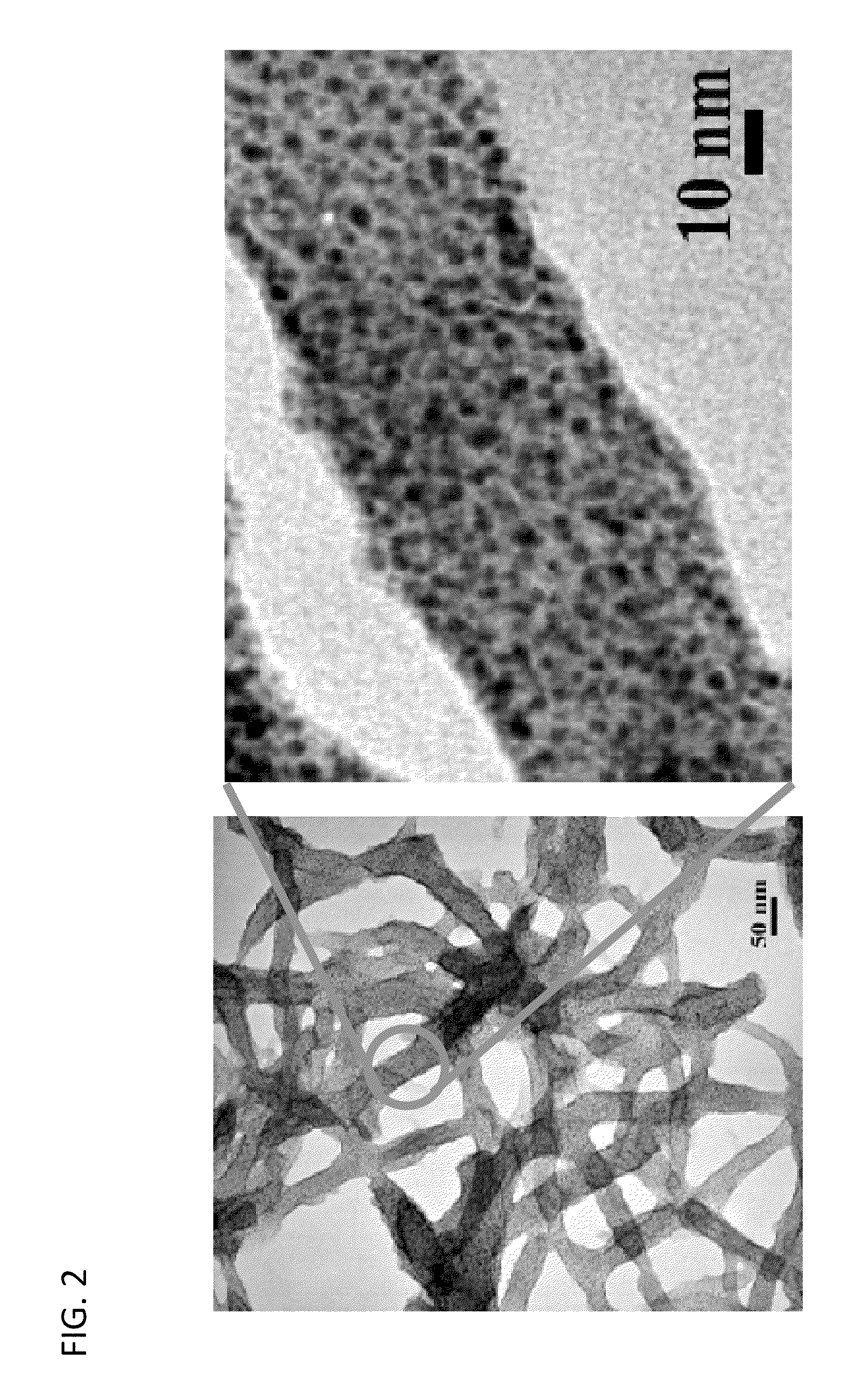

- Development of nanostructured polymer films with doped amphoteric conjugate polymer nanofibers, specifically with diameters between 1 to 100 nm and lengths of 2 to 30 μm, deposited on substrates using techniques like Marangoni flow, allowing for improved ion storage capabilities in electrochemical devices.

Conductive polymer composite

PatentActiveEP3172746A1

Innovation

- A conductive polymer composite comprising immiscible polymers with conductive particles predominantly dispersed in one polymer, achieving a reduced percolation threshold and eliminating the NTC effect, allowing for flexible and cost-effective heating elements with enhanced PTC performance.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive polymer composites (CPCs) versus traditional polymers represents a critical consideration in material selection for modern applications. Traditional polymers, while cost-effective and versatile, typically derive from petroleum resources and contribute significantly to environmental degradation through their production processes and end-of-life disposal challenges. The manufacturing of conventional polymers consumes substantial fossil fuel resources and generates considerable greenhouse gas emissions, with many traditional polymers requiring hundreds of years to decompose in landfills.

Conductive polymer composites offer several environmental advantages over their traditional counterparts. Many CPCs can be formulated using bio-based polymers or incorporate recycled materials as their matrix, reducing dependence on virgin petroleum resources. The conductive fillers in these composites, particularly carbon-based materials like graphene or carbon nanotubes, can be produced from renewable sources such as agricultural waste through pyrolysis processes, further enhancing their sustainability profile.

The extended functional lifespan of CPC-based products presents another environmental benefit. Due to their enhanced electrical, thermal, and mechanical properties, products manufactured with CPCs often demonstrate superior durability and performance longevity compared to traditional polymer alternatives. This extended service life translates to reduced replacement frequency and consequently lower material consumption and waste generation over time.

Energy efficiency during the use phase represents a significant environmental advantage for certain CPC applications. In electromagnetic shielding, thermal management systems, and antistatic applications, CPCs can operate more efficiently than traditional solutions, resulting in lower energy consumption throughout product lifecycles. Additionally, the multifunctionality of CPCs often enables the replacement of multiple components with a single material, streamlining manufacturing processes and reducing overall material requirements.

End-of-life management presents both challenges and opportunities for CPCs. While the composite nature of these materials can complicate recycling processes compared to homogeneous traditional polymers, emerging technologies such as selective dissolution and advanced sorting systems are improving recyclability prospects. Some CPCs feature reversible crosslinking or thermally triggered disassembly mechanisms that facilitate the separation of conductive fillers from polymer matrices, enabling more effective material recovery.

Lifecycle assessment studies comparing CPCs to traditional polymers indicate that despite potentially higher environmental impacts during production, the overall environmental footprint of CPCs can be lower when considering their complete lifecycle, particularly for applications where electrical conductivity delivers significant operational benefits. However, continued research into green synthesis methods, biodegradable conductive composites, and closed-loop recycling systems remains essential to fully realize the sustainability potential of these advanced materials.

Conductive polymer composites offer several environmental advantages over their traditional counterparts. Many CPCs can be formulated using bio-based polymers or incorporate recycled materials as their matrix, reducing dependence on virgin petroleum resources. The conductive fillers in these composites, particularly carbon-based materials like graphene or carbon nanotubes, can be produced from renewable sources such as agricultural waste through pyrolysis processes, further enhancing their sustainability profile.

The extended functional lifespan of CPC-based products presents another environmental benefit. Due to their enhanced electrical, thermal, and mechanical properties, products manufactured with CPCs often demonstrate superior durability and performance longevity compared to traditional polymer alternatives. This extended service life translates to reduced replacement frequency and consequently lower material consumption and waste generation over time.

Energy efficiency during the use phase represents a significant environmental advantage for certain CPC applications. In electromagnetic shielding, thermal management systems, and antistatic applications, CPCs can operate more efficiently than traditional solutions, resulting in lower energy consumption throughout product lifecycles. Additionally, the multifunctionality of CPCs often enables the replacement of multiple components with a single material, streamlining manufacturing processes and reducing overall material requirements.

End-of-life management presents both challenges and opportunities for CPCs. While the composite nature of these materials can complicate recycling processes compared to homogeneous traditional polymers, emerging technologies such as selective dissolution and advanced sorting systems are improving recyclability prospects. Some CPCs feature reversible crosslinking or thermally triggered disassembly mechanisms that facilitate the separation of conductive fillers from polymer matrices, enabling more effective material recovery.

Lifecycle assessment studies comparing CPCs to traditional polymers indicate that despite potentially higher environmental impacts during production, the overall environmental footprint of CPCs can be lower when considering their complete lifecycle, particularly for applications where electrical conductivity delivers significant operational benefits. However, continued research into green synthesis methods, biodegradable conductive composites, and closed-loop recycling systems remains essential to fully realize the sustainability potential of these advanced materials.

Cost-Benefit Analysis of Implementation

The implementation of conductive polymer composites (CPCs) requires careful cost-benefit analysis when compared to traditional polymers. Initial investment costs for CPCs are significantly higher, with raw material expenses typically 30-50% greater than conventional polymers. This price premium stems from specialized manufacturing processes, higher-grade carbon additives, and more complex formulation requirements. Equipment modifications for processing CPCs may require additional capital expenditure, particularly for precision dispersion systems and specialized extrusion equipment.

Production efficiency presents another cost consideration, as CPCs often require slower processing speeds and more stringent quality control measures. Cycle times may increase by 15-25% compared to traditional polymer processing, reducing overall manufacturing throughput. Specialized training for technical staff represents an additional implementation cost that organizations must factor into their transition planning.

Despite these higher upfront costs, CPCs offer substantial long-term benefits that can justify the investment. The multifunctionality of CPCs—combining electrical conductivity with mechanical properties—eliminates the need for separate components in many applications, potentially reducing overall system costs by 20-40%. This integration capability translates to simplified assembly processes, reduced part counts, and lower labor costs in finished products.

Energy efficiency gains represent another significant benefit. Products utilizing CPCs for electromagnetic shielding, static dissipation, or thermal management typically demonstrate 15-30% improved energy efficiency compared to traditional solutions. The extended service life of CPC-based products—often 1.5-2 times longer than conventional alternatives—further enhances their lifetime value proposition.

Market differentiation provides additional economic benefits. Products incorporating CPCs command premium pricing in specialized markets, with margins typically 20-35% higher than traditional polymer alternatives. This premium positioning can offset the higher implementation costs while establishing competitive advantages in high-value applications.

Return on investment timelines vary significantly by application. Consumer electronics implementations typically achieve ROI within 12-18 months, while automotive and aerospace applications may require 24-36 months to realize full economic benefits. The most favorable cost-benefit scenarios occur in applications where CPCs replace multiple components or materials, particularly in high-reliability environments where failure costs are substantial.

Production efficiency presents another cost consideration, as CPCs often require slower processing speeds and more stringent quality control measures. Cycle times may increase by 15-25% compared to traditional polymer processing, reducing overall manufacturing throughput. Specialized training for technical staff represents an additional implementation cost that organizations must factor into their transition planning.

Despite these higher upfront costs, CPCs offer substantial long-term benefits that can justify the investment. The multifunctionality of CPCs—combining electrical conductivity with mechanical properties—eliminates the need for separate components in many applications, potentially reducing overall system costs by 20-40%. This integration capability translates to simplified assembly processes, reduced part counts, and lower labor costs in finished products.

Energy efficiency gains represent another significant benefit. Products utilizing CPCs for electromagnetic shielding, static dissipation, or thermal management typically demonstrate 15-30% improved energy efficiency compared to traditional solutions. The extended service life of CPC-based products—often 1.5-2 times longer than conventional alternatives—further enhances their lifetime value proposition.

Market differentiation provides additional economic benefits. Products incorporating CPCs command premium pricing in specialized markets, with margins typically 20-35% higher than traditional polymer alternatives. This premium positioning can offset the higher implementation costs while establishing competitive advantages in high-value applications.

Return on investment timelines vary significantly by application. Consumer electronics implementations typically achieve ROI within 12-18 months, while automotive and aerospace applications may require 24-36 months to realize full economic benefits. The most favorable cost-benefit scenarios occur in applications where CPCs replace multiple components or materials, particularly in high-reliability environments where failure costs are substantial.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!