What Drives the Adoption of Conductive Polymer Composites in Industry?

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Composites Background and Objectives

Conductive polymer composites (CPCs) represent a significant advancement in materials science, emerging from the convergence of polymer technology and electrical conductivity research. These innovative materials combine the mechanical flexibility, lightweight properties, and processability of polymers with the electrical conductivity typically associated with metals. The evolution of CPCs began in the 1970s with the discovery of conductive polymers, which earned Alan J. Heeger, Alan MacDiarmid, and Hideki Shirakawa the Nobel Prize in Chemistry in 2000.

Over the past few decades, CPCs have undergone substantial development, transitioning from laboratory curiosities to commercially viable materials with diverse applications. The technological trajectory has been characterized by continuous improvements in conductivity, mechanical properties, and processing techniques. Recent advancements have focused on enhancing the dispersion of conductive fillers within polymer matrices, optimizing interfacial interactions, and developing novel composite architectures.

The primary objective in CPC development is to achieve an optimal balance between electrical conductivity and mechanical properties while maintaining cost-effectiveness and processability. This balance is critical for industrial adoption across various sectors. Current research aims to lower percolation thresholds—the minimum concentration of conductive filler needed to create continuous conductive pathways—while preserving the inherent advantages of the polymer matrix.

Industry adoption of CPCs is driven by several factors, including the growing demand for lightweight, flexible electronic components, the push toward miniaturization in electronics, and the need for electromagnetic interference (EMI) shielding solutions. Additionally, sustainability concerns have accelerated interest in CPCs as potential replacements for traditional metal-based conductors in certain applications.

The global trend toward electrification and digitalization further propels CPC development, with particular emphasis on applications in electric vehicles, renewable energy systems, and wearable electronics. These market drivers have catalyzed research into specialized CPCs with tailored properties such as thermal stability, chemical resistance, and environmental durability.

Looking forward, the technical goals for CPC advancement include developing composites with conductivity approaching that of metals, improving long-term stability under various environmental conditions, enhancing scalability of production processes, and reducing manufacturing costs. Emerging research directions also include self-healing CPCs, stimuli-responsive composites, and biodegradable conductive materials that align with circular economy principles.

Over the past few decades, CPCs have undergone substantial development, transitioning from laboratory curiosities to commercially viable materials with diverse applications. The technological trajectory has been characterized by continuous improvements in conductivity, mechanical properties, and processing techniques. Recent advancements have focused on enhancing the dispersion of conductive fillers within polymer matrices, optimizing interfacial interactions, and developing novel composite architectures.

The primary objective in CPC development is to achieve an optimal balance between electrical conductivity and mechanical properties while maintaining cost-effectiveness and processability. This balance is critical for industrial adoption across various sectors. Current research aims to lower percolation thresholds—the minimum concentration of conductive filler needed to create continuous conductive pathways—while preserving the inherent advantages of the polymer matrix.

Industry adoption of CPCs is driven by several factors, including the growing demand for lightweight, flexible electronic components, the push toward miniaturization in electronics, and the need for electromagnetic interference (EMI) shielding solutions. Additionally, sustainability concerns have accelerated interest in CPCs as potential replacements for traditional metal-based conductors in certain applications.

The global trend toward electrification and digitalization further propels CPC development, with particular emphasis on applications in electric vehicles, renewable energy systems, and wearable electronics. These market drivers have catalyzed research into specialized CPCs with tailored properties such as thermal stability, chemical resistance, and environmental durability.

Looking forward, the technical goals for CPC advancement include developing composites with conductivity approaching that of metals, improving long-term stability under various environmental conditions, enhancing scalability of production processes, and reducing manufacturing costs. Emerging research directions also include self-healing CPCs, stimuli-responsive composites, and biodegradable conductive materials that align with circular economy principles.

Market Demand Analysis for Conductive Polymer Applications

The global market for conductive polymer composites has witnessed significant growth in recent years, driven by increasing demand across multiple industries. The electronics sector represents the largest market segment, with applications in electromagnetic interference (EMI) shielding, antistatic packaging, and flexible electronics. According to industry reports, the global conductive polymer composites market was valued at approximately $3.4 billion in 2022 and is projected to reach $5.7 billion by 2027, growing at a CAGR of 10.8%.

The automotive industry has emerged as a rapidly expanding market for conductive polymer composites, particularly with the accelerating transition toward electric vehicles. These materials are increasingly used in fuel cells, battery components, and lightweight structural elements that require electrical conductivity. The shift toward electrification has created a demand surge, with automotive applications of conductive polymers growing at nearly 12% annually.

Consumer electronics manufacturers continue to drive significant demand, as devices become smaller, lighter, and more feature-rich. The need for materials that can provide electromagnetic shielding while maintaining design flexibility has positioned conductive polymer composites as ideal solutions for smartphone casings, wearable technology, and portable computing devices. This segment accounts for approximately 28% of the total market share.

Healthcare applications represent an emerging high-value market, with conductive polymers finding use in biosensors, drug delivery systems, and medical implants. The biocompatibility of certain conductive polymer formulations, combined with their electrical properties, makes them particularly valuable for next-generation medical devices. Market analysts predict this segment will experience the fastest growth rate at 15.3% annually through 2027.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with 27% and 23% market shares respectively, with particular strength in automotive and aerospace applications.

The increasing focus on sustainability has also influenced market dynamics, with growing demand for environmentally friendly conductive polymer composites. Manufacturers are responding by developing bio-based alternatives and improving recyclability of these materials. This trend aligns with regulatory pressures and corporate sustainability initiatives, creating new market opportunities for innovative formulations that maintain performance while reducing environmental impact.

The automotive industry has emerged as a rapidly expanding market for conductive polymer composites, particularly with the accelerating transition toward electric vehicles. These materials are increasingly used in fuel cells, battery components, and lightweight structural elements that require electrical conductivity. The shift toward electrification has created a demand surge, with automotive applications of conductive polymers growing at nearly 12% annually.

Consumer electronics manufacturers continue to drive significant demand, as devices become smaller, lighter, and more feature-rich. The need for materials that can provide electromagnetic shielding while maintaining design flexibility has positioned conductive polymer composites as ideal solutions for smartphone casings, wearable technology, and portable computing devices. This segment accounts for approximately 28% of the total market share.

Healthcare applications represent an emerging high-value market, with conductive polymers finding use in biosensors, drug delivery systems, and medical implants. The biocompatibility of certain conductive polymer formulations, combined with their electrical properties, makes them particularly valuable for next-generation medical devices. Market analysts predict this segment will experience the fastest growth rate at 15.3% annually through 2027.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with 27% and 23% market shares respectively, with particular strength in automotive and aerospace applications.

The increasing focus on sustainability has also influenced market dynamics, with growing demand for environmentally friendly conductive polymer composites. Manufacturers are responding by developing bio-based alternatives and improving recyclability of these materials. This trend aligns with regulatory pressures and corporate sustainability initiatives, creating new market opportunities for innovative formulations that maintain performance while reducing environmental impact.

Technical Status and Challenges in Polymer Conductivity

The global landscape of conductive polymer composites (CPCs) has evolved significantly over the past decade, with research centers across North America, Europe, and Asia-Pacific regions making substantial contributions. Currently, the field faces several critical technical challenges that limit widespread industrial adoption despite promising laboratory results.

The primary technical hurdle remains achieving consistent and reliable conductivity levels while maintaining desirable mechanical properties. Most CPCs exhibit a percolation threshold phenomenon, where conductivity increases dramatically at a specific filler concentration. However, controlling this threshold precisely in industrial-scale production presents significant difficulties, resulting in batch-to-batch variations that hamper quality control processes.

Processing challenges constitute another major obstacle. Traditional polymer processing techniques often damage conductive networks during manufacturing, particularly in injection molding where high shear forces can disrupt filler alignment. This creates a fundamental contradiction: higher filler loadings improve conductivity but simultaneously degrade processability and mechanical properties, forcing manufacturers to make difficult trade-offs.

Long-term stability issues further complicate industrial implementation. Many CPCs demonstrate conductivity degradation over time due to environmental factors such as temperature fluctuations, humidity, UV exposure, and mechanical stress. This aging behavior remains inadequately characterized across different composite systems, creating uncertainty for applications requiring extended service lifetimes.

Interface engineering between polymer matrices and conductive fillers represents a frontier challenge. Poor interfacial adhesion leads to mechanical weakness and inconsistent electrical pathways. While surface functionalization techniques show promise in laboratory settings, scaling these approaches to industrial production volumes remains problematic and cost-prohibitive.

Cost factors significantly impact adoption rates. High-performance conductive fillers like carbon nanotubes and graphene remain expensive compared to traditional materials, with production methods still evolving toward cost-effectiveness. The additional processing steps required for proper dispersion further increase manufacturing expenses.

Standardization gaps persist throughout the industry. The lack of universally accepted testing protocols and performance metrics makes comparing different CPC solutions difficult for potential adopters. This absence of standardization slows technology transfer from research to commercial applications and creates market uncertainty.

Geographically, research leadership is distributed unevenly. North American institutions lead in fundamental research and patent development, while Asian manufacturers (particularly in China, South Korea, and Japan) dominate in scaled production capabilities. European entities excel in specialized applications and sustainability-focused innovations, creating a complex global innovation ecosystem.

The primary technical hurdle remains achieving consistent and reliable conductivity levels while maintaining desirable mechanical properties. Most CPCs exhibit a percolation threshold phenomenon, where conductivity increases dramatically at a specific filler concentration. However, controlling this threshold precisely in industrial-scale production presents significant difficulties, resulting in batch-to-batch variations that hamper quality control processes.

Processing challenges constitute another major obstacle. Traditional polymer processing techniques often damage conductive networks during manufacturing, particularly in injection molding where high shear forces can disrupt filler alignment. This creates a fundamental contradiction: higher filler loadings improve conductivity but simultaneously degrade processability and mechanical properties, forcing manufacturers to make difficult trade-offs.

Long-term stability issues further complicate industrial implementation. Many CPCs demonstrate conductivity degradation over time due to environmental factors such as temperature fluctuations, humidity, UV exposure, and mechanical stress. This aging behavior remains inadequately characterized across different composite systems, creating uncertainty for applications requiring extended service lifetimes.

Interface engineering between polymer matrices and conductive fillers represents a frontier challenge. Poor interfacial adhesion leads to mechanical weakness and inconsistent electrical pathways. While surface functionalization techniques show promise in laboratory settings, scaling these approaches to industrial production volumes remains problematic and cost-prohibitive.

Cost factors significantly impact adoption rates. High-performance conductive fillers like carbon nanotubes and graphene remain expensive compared to traditional materials, with production methods still evolving toward cost-effectiveness. The additional processing steps required for proper dispersion further increase manufacturing expenses.

Standardization gaps persist throughout the industry. The lack of universally accepted testing protocols and performance metrics makes comparing different CPC solutions difficult for potential adopters. This absence of standardization slows technology transfer from research to commercial applications and creates market uncertainty.

Geographically, research leadership is distributed unevenly. North American institutions lead in fundamental research and patent development, while Asian manufacturers (particularly in China, South Korea, and Japan) dominate in scaled production capabilities. European entities excel in specialized applications and sustainability-focused innovations, creating a complex global innovation ecosystem.

Current Technical Solutions for Conductivity Enhancement

01 Carbon-based conductive polymer composites

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into polymer matrices to create conductive composites. These fillers provide excellent electrical conductivity while maintaining the mechanical properties and processability of the polymer. The resulting composites exhibit tunable electrical properties depending on the filler concentration and dispersion quality, making them suitable for various applications including electromagnetic shielding, sensors, and flexible electronics.- Carbon-based conductive polymer composites: Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into polymer matrices to create conductive composites. These fillers provide excellent electrical conductivity while maintaining the mechanical properties and processability of the polymer. The resulting composites can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics.

- Metal-polymer conductive composites: Metal particles or nanowires are dispersed within polymer matrices to create conductive composites with enhanced electrical properties. These composites combine the flexibility and processability of polymers with the high conductivity of metals. Various metals including silver, copper, and nickel are commonly used as conductive fillers. Applications include printed electronics, sensors, and electromagnetic interference shielding materials.

- Intrinsically conductive polymer composites: Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS are combined with other materials to form composites with tunable electrical properties. These polymers conduct electricity through their conjugated backbone structure and can be further enhanced through doping. The resulting composites offer advantages including lightweight construction, flexibility, and solution processability for applications in energy storage, sensors, and actuators.

- Thermal and electrical management composites: Polymer composites designed specifically for thermal and electrical management applications incorporate specialized fillers to achieve both thermal conductivity and electrical properties. These materials are engineered to dissipate heat while maintaining desired electrical characteristics. Applications include thermal interface materials, heat sinks, battery components, and electronic packaging where temperature management is critical alongside electrical performance.

- Processing and manufacturing methods for conductive polymer composites: Various processing techniques are employed to optimize the dispersion of conductive fillers within polymer matrices, including solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. These methods aim to achieve uniform distribution of conductive materials while maintaining processability. Advanced manufacturing approaches such as 3D printing and electrospinning enable the fabrication of complex structures with tailored electrical properties for specific applications.

02 Metal-polymer conductive composites

Metal particles or nanowires are incorporated into polymer matrices to create conductive composites with enhanced electrical properties. Common metals used include silver, copper, and nickel. These metal-polymer composites offer advantages such as high conductivity, flexibility, and the ability to be processed using conventional polymer processing techniques. The electrical properties can be tailored by adjusting the metal content, particle size, and distribution within the polymer matrix.Expand Specific Solutions03 Intrinsically conductive polymers in composites

Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS are used either as the matrix or as components in polymer blends to create conductive composites. These polymers possess conjugated structures that allow electron movement along the polymer backbone. When combined with conventional polymers or inorganic materials, they create composites with unique electrical, optical, and electrochemical properties suitable for applications in batteries, supercapacitors, and organic electronics.Expand Specific Solutions04 Processing techniques for conductive polymer composites

Various processing techniques are employed to manufacture conductive polymer composites with optimized properties. These include solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. The processing method significantly affects the dispersion of conductive fillers and the resulting electrical properties of the composite. Advanced techniques such as 3D printing and electrospinning are also used to create structured conductive polymer composites with tailored geometries and properties.Expand Specific Solutions05 Applications of conductive polymer composites

Conductive polymer composites find applications across various industries due to their unique combination of electrical conductivity and polymer properties. They are used in electromagnetic interference shielding, antistatic coatings, sensors, actuators, energy storage devices, and flexible electronics. Recent developments include their use in wearable technology, smart textiles, and biomedical devices. The versatility of these materials allows for customization to meet specific application requirements through adjustments in composition and processing.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The conductive polymer composites (CPCs) market is currently in a growth phase, characterized by increasing adoption across multiple industries due to their unique electrical properties combined with mechanical flexibility. The global market size is expanding rapidly, estimated to reach several billion dollars by 2025, driven by applications in electronics, automotive, aerospace, and healthcare sectors. Technologically, CPCs are advancing from early commercial applications toward mainstream adoption, with varying maturity levels across different applications. Leading players like DuPont, SABIC, and Boeing are focusing on high-performance applications, while research institutions including Sichuan University, Donghua University, and Johns Hopkins University are pioneering next-generation formulations. Academic-industrial collaborations between CNRS, Heraeus, and Littelfuse are accelerating innovation, particularly in enhancing conductivity, processing techniques, and environmental sustainability.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered conductive polymer composites through their STAT-KON™ and NORYL™ product lines, which incorporate various conductive fillers including carbon black, carbon fiber, and metallic particles into engineering thermoplastics. Their technology focuses on creating a three-dimensional conductive network within the polymer matrix while minimizing impact on mechanical properties. SABIC's approach includes surface modification of conductive fillers to enhance polymer-filler compatibility and improve dispersion. Their manufacturing process employs twin-screw extrusion with specialized mixing elements to ensure homogeneous distribution of conductive particles. SABIC's CPCs achieve volume resistivity values ranging from 10^2 to 10^9 ohm-cm, suitable for applications requiring electrostatic discharge protection to moderate electrical conductivity.

Strengths: Global manufacturing capability, diverse portfolio of base polymers, and strong technical service support for customers implementing CPCs. Their materials offer excellent processability and consistent quality. Weaknesses: Limited offerings in transparent conductive composites and higher loading levels sometimes required for certain conductivity targets.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed groundbreaking research in conductive polymer composites, particularly focusing on nanostructured carbon-based fillers in polymer matrices. Their approach involves precise control of the hierarchical structure of conductive networks through innovative processing techniques like freeze-casting and layer-by-layer assembly. CNRS researchers have pioneered the use of functionalized graphene and carbon nanotubes to create strong interfacial interactions with polymer matrices, resulting in enhanced electrical properties at lower filler loadings. Their work has demonstrated CPCs with electrical conductivities reaching 10^3 S/m while maintaining mechanical flexibility. CNRS has also developed stimuli-responsive CPCs that can change their conductivity in response to external triggers like temperature, pH, or mechanical deformation, opening new possibilities for sensing applications and smart materials.

Strengths: Cutting-edge fundamental research capabilities, innovative approaches to nanostructure control, and development of multifunctional composites with sensing capabilities. Their materials often achieve conductivity at lower filler loadings than conventional approaches. Weaknesses: Technologies may require scaling and industrialization efforts, and some advanced processing methods may be challenging to implement in high-volume manufacturing.

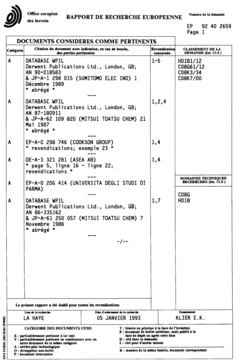

Core Patents and Innovations in Polymer Conductivity

Conductive composite material, coating and sensor by using this conductive material

PatentInactiveEP0537047A1

Innovation

- Combining conductive polymer monomers with phyllosilicate clays, such as montmorillonite, to facilitate two-dimensional polymerization and prevent chain interlocking, resulting in improved conductivity and mechanical properties by dispersing clay sheets in an insulating binder matrix.

Conductive polymer composite

PatentActiveEP3172746A1

Innovation

- A conductive polymer composite comprising immiscible polymers with conductive particles predominantly dispersed in one polymer, achieving a reduced percolation threshold and eliminating the NTC effect, allowing for flexible and cost-effective heating elements with enhanced PTC performance.

Sustainability and Environmental Impact Assessment

The environmental impact of conductive polymer composites (CPCs) represents a critical factor influencing their industrial adoption. Traditional electronic materials often contain toxic heavy metals and hazardous substances that pose significant environmental risks during manufacturing, use, and disposal. In contrast, many CPCs offer reduced environmental footprints through lower processing temperatures, decreased toxic material content, and enhanced recyclability potential.

Life cycle assessment (LCA) studies indicate that CPCs can reduce energy consumption by up to 30-40% compared to conventional metal-based conductors during production phases. This energy efficiency stems from lower processing temperatures and simplified manufacturing techniques that CPCs enable. Furthermore, the carbon footprint associated with CPC production typically measures 25-35% lower than traditional conductive materials, presenting a compelling environmental advantage in increasingly carbon-conscious industrial sectors.

Waste reduction represents another significant sustainability benefit driving CPC adoption. The precise application methods possible with these materials, such as inkjet printing and selective deposition, minimize material waste compared to traditional subtractive manufacturing processes. Industries report material utilization improvements of 15-20% when transitioning to CPC-based solutions for certain applications, directly impacting production economics while simultaneously addressing environmental concerns.

Regulatory compliance increasingly influences material selection decisions across industries. With strengthening global regulations like RoHS, REACH, and various e-waste directives, CPCs offer advantages through reduced hazardous substance content. Many formulations avoid restricted substances entirely, simplifying compliance documentation and reducing regulatory risks that might otherwise impede market access or increase compliance costs.

End-of-life considerations further enhance the sustainability profile of CPCs. While challenges remain in separating and recovering polymeric materials from complex products, certain CPC formulations demonstrate improved recyclability compared to traditional electronic materials. Research indicates potential recovery rates of 60-75% for some CPC materials under optimized recycling conditions, though commercial-scale implementation remains limited.

Water usage and pollution metrics also favor CPCs in many applications. Manufacturing processes for these materials typically consume 40-50% less water than conventional metal plating and etching processes used for traditional conductors. Additionally, wastewater treatment requirements are often less intensive, reducing both environmental impact and operational costs for manufacturing facilities implementing CPC technologies.

Life cycle assessment (LCA) studies indicate that CPCs can reduce energy consumption by up to 30-40% compared to conventional metal-based conductors during production phases. This energy efficiency stems from lower processing temperatures and simplified manufacturing techniques that CPCs enable. Furthermore, the carbon footprint associated with CPC production typically measures 25-35% lower than traditional conductive materials, presenting a compelling environmental advantage in increasingly carbon-conscious industrial sectors.

Waste reduction represents another significant sustainability benefit driving CPC adoption. The precise application methods possible with these materials, such as inkjet printing and selective deposition, minimize material waste compared to traditional subtractive manufacturing processes. Industries report material utilization improvements of 15-20% when transitioning to CPC-based solutions for certain applications, directly impacting production economics while simultaneously addressing environmental concerns.

Regulatory compliance increasingly influences material selection decisions across industries. With strengthening global regulations like RoHS, REACH, and various e-waste directives, CPCs offer advantages through reduced hazardous substance content. Many formulations avoid restricted substances entirely, simplifying compliance documentation and reducing regulatory risks that might otherwise impede market access or increase compliance costs.

End-of-life considerations further enhance the sustainability profile of CPCs. While challenges remain in separating and recovering polymeric materials from complex products, certain CPC formulations demonstrate improved recyclability compared to traditional electronic materials. Research indicates potential recovery rates of 60-75% for some CPC materials under optimized recycling conditions, though commercial-scale implementation remains limited.

Water usage and pollution metrics also favor CPCs in many applications. Manufacturing processes for these materials typically consume 40-50% less water than conventional metal plating and etching processes used for traditional conductors. Additionally, wastewater treatment requirements are often less intensive, reducing both environmental impact and operational costs for manufacturing facilities implementing CPC technologies.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for conductive polymer composites (CPCs) represents a critical factor in their industrial adoption. Current production methods vary significantly in their ability to scale, with solution mixing and melt blending showing the greatest potential for high-volume manufacturing. These techniques leverage existing polymer processing infrastructure, allowing companies to transition to CPC production without prohibitive capital investments. However, achieving consistent electrical properties across large production batches remains challenging, as minor variations in filler dispersion can dramatically alter conductivity profiles.

Cost analysis reveals that raw material expenses constitute 60-75% of total production costs for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) representing the most significant cost drivers. Recent advancements in filler production technology have reduced prices by approximately 30% over the past five years, yet these materials remain 5-10 times more expensive than conventional polymer additives. Labor costs vary by manufacturing method, with in-situ polymerization requiring more specialized personnel and quality control measures than melt processing techniques.

Energy consumption during manufacturing presents another significant cost consideration. High-shear mixing processes necessary for proper filler dispersion can increase energy requirements by 40-60% compared to conventional polymer processing. This energy premium diminishes at scale but remains a factor in total cost calculations. Additionally, specialized equipment for quality testing and characterization adds to capital expenditure requirements, though these costs can be amortized across larger production volumes.

Yield rates in CPC manufacturing have improved substantially, with industry leaders reporting 85-92% usable product from raw materials. This improvement stems from better understanding of processing parameters and enhanced dispersion techniques. However, these yield rates still lag behind those of conventional polymers (typically 95-98%), representing an ongoing opportunity for cost reduction through process optimization.

Regional manufacturing economics also influence adoption patterns, with labor-intensive processes favoring regions with lower labor costs, while energy-intensive methods prove more economical in areas with affordable energy. This dynamic has created distinct regional specializations in CPC manufacturing, with different production techniques predominating in various global markets.

The economic threshold for CPC adoption appears to be approaching an inflection point, as manufacturing improvements and increasing production volumes drive costs downward while performance continues to improve. Industry analysts project that within 3-5 years, several CPC formulations will achieve price parity with traditional materials when total lifecycle costs are considered, particularly in applications where weight reduction and multifunctionality provide additional value.

Cost analysis reveals that raw material expenses constitute 60-75% of total production costs for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) representing the most significant cost drivers. Recent advancements in filler production technology have reduced prices by approximately 30% over the past five years, yet these materials remain 5-10 times more expensive than conventional polymer additives. Labor costs vary by manufacturing method, with in-situ polymerization requiring more specialized personnel and quality control measures than melt processing techniques.

Energy consumption during manufacturing presents another significant cost consideration. High-shear mixing processes necessary for proper filler dispersion can increase energy requirements by 40-60% compared to conventional polymer processing. This energy premium diminishes at scale but remains a factor in total cost calculations. Additionally, specialized equipment for quality testing and characterization adds to capital expenditure requirements, though these costs can be amortized across larger production volumes.

Yield rates in CPC manufacturing have improved substantially, with industry leaders reporting 85-92% usable product from raw materials. This improvement stems from better understanding of processing parameters and enhanced dispersion techniques. However, these yield rates still lag behind those of conventional polymers (typically 95-98%), representing an ongoing opportunity for cost reduction through process optimization.

Regional manufacturing economics also influence adoption patterns, with labor-intensive processes favoring regions with lower labor costs, while energy-intensive methods prove more economical in areas with affordable energy. This dynamic has created distinct regional specializations in CPC manufacturing, with different production techniques predominating in various global markets.

The economic threshold for CPC adoption appears to be approaching an inflection point, as manufacturing improvements and increasing production volumes drive costs downward while performance continues to improve. Industry analysts project that within 3-5 years, several CPC formulations will achieve price parity with traditional materials when total lifecycle costs are considered, particularly in applications where weight reduction and multifunctionality provide additional value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!