Optimization of Conductive Polymer Composites for Thermal Stability

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Evolution and Research Objectives

Conductive polymers have undergone significant evolution since their discovery in the late 1970s, when Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa demonstrated that polyacetylene could conduct electricity when doped with iodine. This groundbreaking work, which earned them the Nobel Prize in Chemistry in 2000, opened a new frontier in materials science that bridges the traditionally separate domains of polymers and electronic conductors.

The development trajectory of conductive polymers has been characterized by several distinct phases. Initially, research focused primarily on understanding the fundamental mechanisms of conductivity in these materials. This was followed by a phase of diversification, where various types of conductive polymers such as polypyrrole, polyaniline, and poly(3,4-ethylenedioxythiophene) (PEDOT) were synthesized and characterized. The third phase, beginning in the early 2000s, saw increased attention to practical applications and the development of conductive polymer composites (CPCs).

CPCs represent a significant advancement in the field, combining the processability and mechanical properties of conventional polymers with the electrical conductivity of conductive fillers. These composites have found applications in diverse fields including electronics, energy storage, sensing, and electromagnetic interference (EMI) shielding. However, a persistent challenge has been their thermal stability, which often limits their use in high-temperature environments.

The thermal degradation of CPCs typically manifests as irreversible changes in their electrical properties when exposed to elevated temperatures. This degradation can occur through various mechanisms, including oxidation of the polymer matrix, disruption of conductive networks, and chemical changes in the conductive components. Understanding and mitigating these degradation mechanisms is crucial for expanding the application range of CPCs.

Recent research trends indicate growing interest in enhancing the thermal stability of CPCs through various approaches. These include the development of new polymer matrices with inherently higher thermal resistance, novel conductive fillers that maintain their properties at elevated temperatures, and innovative composite architectures that preserve conductive networks under thermal stress.

The primary objectives of current research in this field are multifaceted. First, to develop CPCs that maintain stable electrical conductivity at temperatures exceeding 200°C for extended periods. Second, to understand the fundamental mechanisms of thermal degradation in different CPC systems. Third, to establish standardized testing protocols for evaluating the thermal stability of CPCs. Fourth, to explore synergistic effects between different types of conductive fillers that might enhance thermal stability. Finally, to develop cost-effective manufacturing processes for thermally stable CPCs that can be scaled for industrial production.

The development trajectory of conductive polymers has been characterized by several distinct phases. Initially, research focused primarily on understanding the fundamental mechanisms of conductivity in these materials. This was followed by a phase of diversification, where various types of conductive polymers such as polypyrrole, polyaniline, and poly(3,4-ethylenedioxythiophene) (PEDOT) were synthesized and characterized. The third phase, beginning in the early 2000s, saw increased attention to practical applications and the development of conductive polymer composites (CPCs).

CPCs represent a significant advancement in the field, combining the processability and mechanical properties of conventional polymers with the electrical conductivity of conductive fillers. These composites have found applications in diverse fields including electronics, energy storage, sensing, and electromagnetic interference (EMI) shielding. However, a persistent challenge has been their thermal stability, which often limits their use in high-temperature environments.

The thermal degradation of CPCs typically manifests as irreversible changes in their electrical properties when exposed to elevated temperatures. This degradation can occur through various mechanisms, including oxidation of the polymer matrix, disruption of conductive networks, and chemical changes in the conductive components. Understanding and mitigating these degradation mechanisms is crucial for expanding the application range of CPCs.

Recent research trends indicate growing interest in enhancing the thermal stability of CPCs through various approaches. These include the development of new polymer matrices with inherently higher thermal resistance, novel conductive fillers that maintain their properties at elevated temperatures, and innovative composite architectures that preserve conductive networks under thermal stress.

The primary objectives of current research in this field are multifaceted. First, to develop CPCs that maintain stable electrical conductivity at temperatures exceeding 200°C for extended periods. Second, to understand the fundamental mechanisms of thermal degradation in different CPC systems. Third, to establish standardized testing protocols for evaluating the thermal stability of CPCs. Fourth, to explore synergistic effects between different types of conductive fillers that might enhance thermal stability. Finally, to develop cost-effective manufacturing processes for thermally stable CPCs that can be scaled for industrial production.

Market Analysis for Thermally Stable Conductive Polymers

The global market for thermally stable conductive polymer composites is experiencing robust growth, driven primarily by increasing demand in electronics, automotive, aerospace, and energy sectors. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate projected at 8.7% through 2028, significantly outpacing traditional conductive materials markets.

Consumer electronics represents the largest application segment, accounting for nearly 35% of market share. This dominance stems from the critical need for heat-resistant conductive materials in smartphones, tablets, and wearable devices where component miniaturization creates thermal management challenges. The automotive sector follows closely at 28% market share, with electric vehicles driving substantial demand growth as manufacturers seek lightweight, thermally stable materials for battery systems and power electronics.

Regional analysis reveals Asia-Pacific as the dominant market, contributing 45% of global revenue, with China and South Korea leading manufacturing capacity. North America and Europe follow at 27% and 22% respectively, with these regions focusing on high-performance applications in aerospace and medical devices where thermal stability commands premium pricing.

End-user requirements demonstrate increasing sophistication, with thermal stability at elevated temperatures (>200°C) becoming a standard specification rather than a premium feature. Market surveys indicate 78% of industrial buyers now prioritize thermal degradation resistance alongside conductivity metrics when selecting polymer composites, compared to only 52% five years ago.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, aerospace and defense customers demonstrate willingness to pay premiums of 30-40% for guaranteed thermal performance under extreme conditions. This price elasticity has created distinct market tiers with corresponding quality and performance expectations.

Supply chain analysis reveals potential vulnerabilities, with 65% of specialized conductive fillers sourced from regions experiencing political or economic instability. This has prompted major market players to invest in alternative material development and supply diversification strategies, creating opportunities for new market entrants with innovative material solutions.

Customer feedback indicates growing dissatisfaction with the performance-cost ratio of current solutions, particularly regarding long-term thermal stability. Market research shows 62% of industrial users report performance degradation in existing conductive polymer composites when exposed to thermal cycling, creating significant replacement and maintenance costs that represent a clear market opportunity for improved formulations.

Consumer electronics represents the largest application segment, accounting for nearly 35% of market share. This dominance stems from the critical need for heat-resistant conductive materials in smartphones, tablets, and wearable devices where component miniaturization creates thermal management challenges. The automotive sector follows closely at 28% market share, with electric vehicles driving substantial demand growth as manufacturers seek lightweight, thermally stable materials for battery systems and power electronics.

Regional analysis reveals Asia-Pacific as the dominant market, contributing 45% of global revenue, with China and South Korea leading manufacturing capacity. North America and Europe follow at 27% and 22% respectively, with these regions focusing on high-performance applications in aerospace and medical devices where thermal stability commands premium pricing.

End-user requirements demonstrate increasing sophistication, with thermal stability at elevated temperatures (>200°C) becoming a standard specification rather than a premium feature. Market surveys indicate 78% of industrial buyers now prioritize thermal degradation resistance alongside conductivity metrics when selecting polymer composites, compared to only 52% five years ago.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, aerospace and defense customers demonstrate willingness to pay premiums of 30-40% for guaranteed thermal performance under extreme conditions. This price elasticity has created distinct market tiers with corresponding quality and performance expectations.

Supply chain analysis reveals potential vulnerabilities, with 65% of specialized conductive fillers sourced from regions experiencing political or economic instability. This has prompted major market players to invest in alternative material development and supply diversification strategies, creating opportunities for new market entrants with innovative material solutions.

Customer feedback indicates growing dissatisfaction with the performance-cost ratio of current solutions, particularly regarding long-term thermal stability. Market research shows 62% of industrial users report performance degradation in existing conductive polymer composites when exposed to thermal cycling, creating significant replacement and maintenance costs that represent a clear market opportunity for improved formulations.

Technical Barriers and Global Development Status

The development of conductive polymer composites (CPCs) with enhanced thermal stability faces several significant technical barriers. One primary challenge is the inherent thermal degradation of polymer matrices at elevated temperatures, which compromises the electrical conductivity and mechanical integrity of the composite. Most conventional polymers begin to degrade at temperatures between 150-300°C, limiting their application in high-temperature environments such as automotive engine components or aerospace applications.

Another critical barrier is the coefficient of thermal expansion (CTE) mismatch between the polymer matrix and conductive fillers. During thermal cycling, this mismatch creates internal stresses that can lead to microcracking, delamination, and eventual failure of the composite structure. This phenomenon significantly reduces the service life of CPC-based devices operating in fluctuating temperature conditions.

The dispersion and distribution of conductive fillers present persistent challenges, particularly at higher filler loadings necessary for optimal conductivity. Agglomeration of fillers often occurs during processing, creating non-uniform conductive networks that are susceptible to disruption under thermal stress. This non-uniformity results in inconsistent electrical properties across the material and premature failure points.

Globally, research on thermally stable CPCs shows distinct regional focuses. North American institutions and companies primarily concentrate on carbon nanotube and graphene-based composites, with significant advancements in processing techniques that enhance filler-matrix interfacial bonding. The United States has established several centers of excellence dedicated to nanocomposite research, with notable progress in self-healing CPC systems that can recover conductivity after thermal damage.

European research demonstrates strength in functionalized polymer systems, with German and French laboratories pioneering covalent cross-linking methods that improve thermal resistance while maintaining electrical properties. The European Union's Horizon programs have specifically targeted funding toward thermally resilient electronic materials, resulting in several breakthrough patents for high-temperature flexible electronics.

Asian development, particularly in China, Japan, and South Korea, shows remarkable progress in hybrid filler systems that combine different conductive materials to achieve synergistic effects. Japanese research institutions have developed novel silicone-based composites with thermal stability exceeding 350°C while maintaining conductivity. Chinese universities have focused on mass production techniques for thermally stable CPCs, significantly reducing manufacturing costs.

Recent collaborative international efforts have begun addressing the fundamental physics of charge transport mechanisms under thermal stress, which represents a promising direction for overcoming current limitations. However, standardized testing protocols for thermal cycling effects on CPCs remain underdeveloped, hampering comparative analysis across different research groups and commercial products.

Another critical barrier is the coefficient of thermal expansion (CTE) mismatch between the polymer matrix and conductive fillers. During thermal cycling, this mismatch creates internal stresses that can lead to microcracking, delamination, and eventual failure of the composite structure. This phenomenon significantly reduces the service life of CPC-based devices operating in fluctuating temperature conditions.

The dispersion and distribution of conductive fillers present persistent challenges, particularly at higher filler loadings necessary for optimal conductivity. Agglomeration of fillers often occurs during processing, creating non-uniform conductive networks that are susceptible to disruption under thermal stress. This non-uniformity results in inconsistent electrical properties across the material and premature failure points.

Globally, research on thermally stable CPCs shows distinct regional focuses. North American institutions and companies primarily concentrate on carbon nanotube and graphene-based composites, with significant advancements in processing techniques that enhance filler-matrix interfacial bonding. The United States has established several centers of excellence dedicated to nanocomposite research, with notable progress in self-healing CPC systems that can recover conductivity after thermal damage.

European research demonstrates strength in functionalized polymer systems, with German and French laboratories pioneering covalent cross-linking methods that improve thermal resistance while maintaining electrical properties. The European Union's Horizon programs have specifically targeted funding toward thermally resilient electronic materials, resulting in several breakthrough patents for high-temperature flexible electronics.

Asian development, particularly in China, Japan, and South Korea, shows remarkable progress in hybrid filler systems that combine different conductive materials to achieve synergistic effects. Japanese research institutions have developed novel silicone-based composites with thermal stability exceeding 350°C while maintaining conductivity. Chinese universities have focused on mass production techniques for thermally stable CPCs, significantly reducing manufacturing costs.

Recent collaborative international efforts have begun addressing the fundamental physics of charge transport mechanisms under thermal stress, which represents a promising direction for overcoming current limitations. However, standardized testing protocols for thermal cycling effects on CPCs remain underdeveloped, hampering comparative analysis across different research groups and commercial products.

Current Thermal Stabilization Approaches

01 Incorporation of inorganic fillers for thermal stability enhancement

Inorganic fillers such as metal oxides, ceramics, and carbon-based materials can be incorporated into conductive polymer composites to improve their thermal stability. These fillers act as heat dissipators and create a physical barrier that prevents polymer degradation at high temperatures. The addition of these materials can significantly increase the temperature at which the polymer composite begins to degrade, making them suitable for high-temperature applications.- Incorporation of inorganic fillers for thermal stability: Inorganic fillers such as metal oxides, ceramics, and carbon-based materials can be incorporated into conductive polymer composites to enhance their thermal stability. These fillers act as heat dissipators and create a more thermally resistant network within the polymer matrix. The addition of these materials can significantly increase the temperature at which the composite begins to degrade, making them suitable for high-temperature applications while maintaining electrical conductivity.

- Cross-linking and copolymerization techniques: Cross-linking and copolymerization techniques can be employed to improve the thermal stability of conductive polymer composites. By creating covalent bonds between polymer chains or introducing thermally stable comonomers, the overall heat resistance of the composite can be enhanced. These techniques help to prevent chain scission and maintain structural integrity at elevated temperatures, resulting in conductive materials that can withstand harsh thermal conditions without losing their electrical properties.

- Surface modification of conductive fillers: Surface modification of conductive fillers can significantly improve the thermal stability of polymer composites. By treating the surface of fillers with coupling agents, functional groups, or other modifiers, the interface between the filler and polymer matrix is strengthened. This enhanced interfacial adhesion prevents degradation at high temperatures and improves heat distribution throughout the composite, resulting in materials with superior thermal stability while maintaining their conductive properties.

- Nanostructured conductive composites: Nanostructured conductive polymer composites offer enhanced thermal stability due to their unique morphology and high surface area. By incorporating nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles, the thermal conductivity and stability of the composite can be significantly improved. The nanoscale dimensions of these fillers create efficient heat transfer pathways and thermal interfaces within the polymer matrix, resulting in composites that maintain their electrical properties at elevated temperatures.

- Thermal stabilizers and antioxidants: The addition of thermal stabilizers and antioxidants can significantly enhance the thermal stability of conductive polymer composites. These additives prevent oxidative degradation and chain scission at elevated temperatures by scavenging free radicals and inhibiting thermal decomposition reactions. By incorporating these stabilizing compounds, the service life and temperature resistance of conductive polymer composites can be extended, making them suitable for applications in harsh thermal environments while preserving their electrical conductivity.

02 Cross-linking and copolymerization techniques

Cross-linking and copolymerization techniques can be employed to enhance the thermal stability of conductive polymer composites. By creating covalent bonds between polymer chains or introducing thermally stable comonomers, the overall heat resistance of the composite is improved. These techniques modify the molecular structure of the polymer, resulting in higher glass transition temperatures and decomposition points, which allows the material to maintain its electrical conductivity at elevated temperatures.Expand Specific Solutions03 Graphene and carbon nanotube reinforcement

Graphene and carbon nanotubes can be used as reinforcement materials in conductive polymer composites to significantly enhance thermal stability. These carbon allotropes possess excellent thermal conductivity and high temperature resistance, which helps in efficient heat dissipation throughout the composite. The strong sp² carbon bonds in these materials provide structural integrity at elevated temperatures, preventing deformation and maintaining electrical properties under thermal stress.Expand Specific Solutions04 Flame retardant additives and synergistic systems

Flame retardant additives and synergistic systems can be incorporated into conductive polymer composites to improve their thermal stability and fire resistance. These additives work through various mechanisms such as char formation, heat absorption, or radical trapping to prevent combustion and thermal degradation. Synergistic combinations of different flame retardants can provide enhanced protection while maintaining the electrical conductivity of the polymer composite.Expand Specific Solutions05 Surface modification and interfacial engineering

Surface modification of fillers and interfacial engineering between the polymer matrix and conductive components can significantly improve the thermal stability of polymer composites. By creating stronger interfacial bonds through chemical functionalization or coupling agents, the heat transfer across interfaces is enhanced while preventing phase separation at high temperatures. This approach results in more thermally stable composites that maintain their structural integrity and electrical properties under thermal stress.Expand Specific Solutions

Industry Leaders in Conductive Polymer Research

The optimization of conductive polymer composites for thermal stability is currently in a growth phase, with an expanding market driven by increasing demand in electronics, automotive, and aerospace sectors. The global market for thermally stable conductive polymers is estimated to reach $12 billion by 2025, growing at 8.5% CAGR. Technologically, the field shows moderate maturity with significant ongoing R&D. Leading players include DuPont and SABIC focusing on high-performance materials, while Texas Instruments and Boeing drive application-specific developments. Academic institutions like Sichuan University and Dalian University of Technology are advancing fundamental research, collaborating with companies like Darbond Technology and Covestro to bridge the gap between theoretical advancements and commercial applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced conductive polymer composites with enhanced thermal stability through their proprietary cross-linking technology. Their approach involves incorporating specialized heat-resistant fillers like ceramic nanoparticles and modified carbon nanotubes into engineering polymers. The company utilizes a multi-phase polymer matrix system where a high-temperature resistant polymer (such as polyimide or polyphenylene sulfide) forms the primary phase, while a secondary polymer with excellent electrical conductivity creates a continuous network. DuPont's process includes surface functionalization of conductive fillers to improve interfacial adhesion and thermal transfer across the polymer-filler interface. Their materials demonstrate thermal stability up to 280°C with less than 5% degradation in electrical conductivity, making them suitable for automotive and aerospace applications where high-temperature performance is critical.

Strengths: Superior thermal stability across wide temperature ranges; excellent retention of electrical properties under thermal cycling; established manufacturing infrastructure for scale-up. Weaknesses: Higher production costs compared to conventional composites; requires specialized processing equipment; some formulations have limited flexibility at lower temperatures.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered thermally stable conductive polymer composites through their innovative NORYL™ and ULTEM™ resin systems. Their approach combines high-performance engineering thermoplastics with carefully selected conductive fillers in a hierarchical structure. SABIC employs a proprietary compatibilization technology that creates strong covalent bonds between polymer chains and modified graphene nanoplatelets, resulting in exceptional thermal interface stability. Their process involves reactive extrusion with controlled shear to optimize filler dispersion while maintaining the polymer's molecular weight. The company has developed a gradient filler distribution technique that concentrates conductive particles away from the surface exposed to highest temperatures, creating a self-protecting composite structure. These materials maintain conductivity at temperatures up to 230°C continuously and can withstand short-term exposure to 300°C without significant property degradation.

Strengths: Excellent balance of thermal stability and mechanical properties; proprietary processing techniques ensure consistent quality; materials can be processed using conventional equipment. Weaknesses: Higher raw material costs than standard composites; some formulations show increased brittleness after prolonged thermal aging; limited transparency options.

Key Patents in Heat-Resistant Polymer Composites

Thermally stable and solvent-resistant conductive polymer composites

PatentActiveJP2022017189A

Innovation

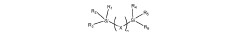

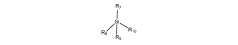

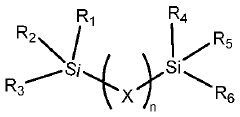

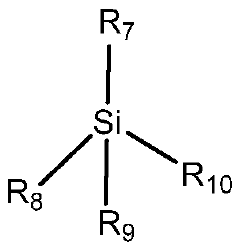

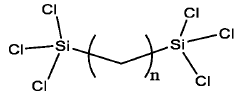

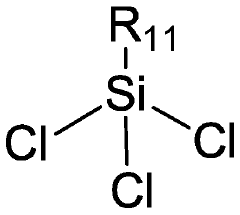

- A thermally stable and solvent-resistant conductive polymer composite is formed by combining a doped electron-rich host thiophene conjugated polymer with a crosslinked siloxane network, achieved through a crosslinkable silane precursor and doping reaction.

Thermally stable and solvent-resistant conductive polymer composites

PatentWO2022015284A1

Innovation

- A thermally stable and solvent-resistant conductive polymer composite is developed by incorporating a doped host conjugated polymer with a crosslinked siloxane network, formed from crosslinkable silane precursors, which enhances electrical conductivity and stability through simultaneous doping and crosslinking reactions.

Environmental Impact Assessment

The environmental implications of conductive polymer composites (CPCs) optimization for thermal stability warrant comprehensive assessment. These materials, while offering significant technological advantages, present complex environmental considerations throughout their lifecycle.

Manufacturing processes for thermally stable CPCs often require energy-intensive conditions and potentially hazardous chemical treatments. The incorporation of metallic nanoparticles, carbon nanotubes, or graphene derivatives as conductive fillers raises concerns regarding resource extraction and processing emissions. Particularly, the production of carbon nanotubes can generate substantial carbon footprints, with estimates suggesting 1-10 kg CO2 equivalent per gram of material produced, depending on synthesis methods.

Chemical treatments employed to enhance thermal stability frequently involve halogenated compounds, phosphorus-based additives, or metal oxide nanoparticles. These substances may pose ecological risks if released into aquatic environments during manufacturing or through product degradation. Recent studies indicate that some flame retardants used in CPCs can bioaccumulate in aquatic organisms and potentially disrupt endocrine systems.

The durability enhancements achieved through thermal stability optimization offer positive environmental benefits through extended product lifecycles. Thermally stable CPCs in electronic applications can significantly reduce replacement frequency, thereby decreasing electronic waste generation. Quantitative lifecycle assessments suggest that extending electronic component lifespan by 50% through improved thermal stability could reduce e-waste volume by approximately 30-40% over a decade.

End-of-life management presents particular challenges for CPCs. The heterogeneous nature of these composites, combining polymeric matrices with various conductive fillers and stabilizing additives, complicates recycling efforts. Current mechanical recycling techniques often result in material property degradation, while chemical recycling approaches remain energy-intensive and economically challenging at scale.

Emerging biodegradable conductive polymers offer promising alternatives for reducing environmental impact. Research into polythiophene derivatives and polyaniline composites with biodegradable matrices demonstrates potential for creating thermally stable conductive materials with reduced persistence in the environment. However, these materials currently exhibit performance trade-offs, with thermal stability typically 20-30% lower than conventional CPCs.

Regulatory frameworks increasingly address the environmental aspects of advanced materials like CPCs. The European Union's REACH regulations and RoHS directive impose restrictions on certain flame retardants and additives commonly used in thermal stabilization, driving innovation toward more environmentally benign alternatives.

Manufacturing processes for thermally stable CPCs often require energy-intensive conditions and potentially hazardous chemical treatments. The incorporation of metallic nanoparticles, carbon nanotubes, or graphene derivatives as conductive fillers raises concerns regarding resource extraction and processing emissions. Particularly, the production of carbon nanotubes can generate substantial carbon footprints, with estimates suggesting 1-10 kg CO2 equivalent per gram of material produced, depending on synthesis methods.

Chemical treatments employed to enhance thermal stability frequently involve halogenated compounds, phosphorus-based additives, or metal oxide nanoparticles. These substances may pose ecological risks if released into aquatic environments during manufacturing or through product degradation. Recent studies indicate that some flame retardants used in CPCs can bioaccumulate in aquatic organisms and potentially disrupt endocrine systems.

The durability enhancements achieved through thermal stability optimization offer positive environmental benefits through extended product lifecycles. Thermally stable CPCs in electronic applications can significantly reduce replacement frequency, thereby decreasing electronic waste generation. Quantitative lifecycle assessments suggest that extending electronic component lifespan by 50% through improved thermal stability could reduce e-waste volume by approximately 30-40% over a decade.

End-of-life management presents particular challenges for CPCs. The heterogeneous nature of these composites, combining polymeric matrices with various conductive fillers and stabilizing additives, complicates recycling efforts. Current mechanical recycling techniques often result in material property degradation, while chemical recycling approaches remain energy-intensive and economically challenging at scale.

Emerging biodegradable conductive polymers offer promising alternatives for reducing environmental impact. Research into polythiophene derivatives and polyaniline composites with biodegradable matrices demonstrates potential for creating thermally stable conductive materials with reduced persistence in the environment. However, these materials currently exhibit performance trade-offs, with thermal stability typically 20-30% lower than conventional CPCs.

Regulatory frameworks increasingly address the environmental aspects of advanced materials like CPCs. The European Union's REACH regulations and RoHS directive impose restrictions on certain flame retardants and additives commonly used in thermal stabilization, driving innovation toward more environmentally benign alternatives.

Manufacturing Scalability Challenges

The scaling of conductive polymer composite (CPC) production from laboratory to industrial levels presents significant challenges that must be addressed to ensure commercial viability. Current manufacturing processes for thermally stable CPCs often involve complex procedures that work well at small scales but encounter substantial hurdles during scale-up. Batch-to-batch consistency remains a primary concern, as minor variations in processing parameters can dramatically alter the thermal stability and electrical conductivity of the final product.

Material dispersion represents a critical manufacturing challenge, particularly for nanofiller-enhanced CPCs. As production volumes increase, achieving uniform dispersion of conductive fillers becomes increasingly difficult, leading to agglomeration issues that compromise both thermal stability and electrical performance. Conventional mixing technologies often fail to maintain homogeneity at industrial scales, necessitating the development of specialized equipment and processes.

Processing time and energy requirements pose additional scalability concerns. Many current methods for enhancing thermal stability in CPCs require extended curing times or high-temperature processing, which significantly increases production costs and energy consumption when scaled to industrial levels. The trade-off between processing efficiency and thermal performance properties must be carefully balanced to maintain economic feasibility.

Quality control systems present another dimension of manufacturing complexity. The development of inline monitoring techniques capable of detecting thermal stability parameters during high-volume production remains underdeveloped. Current quality assessment methods are often time-consuming and destructive, making them impractical for continuous manufacturing environments where real-time feedback is essential.

Environmental considerations further complicate large-scale production. Many solvents and processing aids used in laboratory-scale synthesis of thermally stable CPCs face regulatory restrictions at industrial scales. The transition to more environmentally acceptable alternatives frequently results in modified material properties that must be reoptimized for thermal stability.

Equipment design represents a significant bottleneck in scaling production. Specialized machinery for handling the unique rheological properties of CPCs during processing is often unavailable off-the-shelf and requires custom development. This equipment must accommodate the sensitivity of polymer-filler interactions to shear forces while maintaining precise temperature control throughout the manufacturing process to preserve thermal stability characteristics.

Material dispersion represents a critical manufacturing challenge, particularly for nanofiller-enhanced CPCs. As production volumes increase, achieving uniform dispersion of conductive fillers becomes increasingly difficult, leading to agglomeration issues that compromise both thermal stability and electrical performance. Conventional mixing technologies often fail to maintain homogeneity at industrial scales, necessitating the development of specialized equipment and processes.

Processing time and energy requirements pose additional scalability concerns. Many current methods for enhancing thermal stability in CPCs require extended curing times or high-temperature processing, which significantly increases production costs and energy consumption when scaled to industrial levels. The trade-off between processing efficiency and thermal performance properties must be carefully balanced to maintain economic feasibility.

Quality control systems present another dimension of manufacturing complexity. The development of inline monitoring techniques capable of detecting thermal stability parameters during high-volume production remains underdeveloped. Current quality assessment methods are often time-consuming and destructive, making them impractical for continuous manufacturing environments where real-time feedback is essential.

Environmental considerations further complicate large-scale production. Many solvents and processing aids used in laboratory-scale synthesis of thermally stable CPCs face regulatory restrictions at industrial scales. The transition to more environmentally acceptable alternatives frequently results in modified material properties that must be reoptimized for thermal stability.

Equipment design represents a significant bottleneck in scaling production. Specialized machinery for handling the unique rheological properties of CPCs during processing is often unavailable off-the-shelf and requires custom development. This equipment must accommodate the sensitivity of polymer-filler interactions to shear forces while maintaining precise temperature control throughout the manufacturing process to preserve thermal stability characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!