Investigation of Electrolyte Effects on Conductive Polymer Composites

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyte-Polymer Composite Background and Objectives

Conductive polymer composites (CPCs) represent a significant advancement in materials science, combining the electrical conductivity of metals with the processability and lightweight nature of polymers. The evolution of these materials began in the 1970s with the discovery of conductive polymers by Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa, who were later awarded the Nobel Prize in Chemistry in 2000. Since then, research in this field has expanded dramatically, with particular focus on enhancing conductivity through various fillers and processing techniques.

The interaction between electrolytes and polymer composites has emerged as a critical area of investigation over the past decade. Electrolytes, which are substances containing free ions that make them electrically conductive, can significantly alter the electrical, mechanical, and chemical properties of polymer composites. This relationship has profound implications for applications ranging from energy storage devices to smart materials and biomedical sensors.

Recent technological trends indicate a growing interest in developing responsive and adaptive CPCs that can change their properties in response to external stimuli, with electrolyte interactions being a key mechanism for achieving this functionality. The integration of ionic liquids, solid-state electrolytes, and gel electrolytes into polymer matrices represents cutting-edge approaches that are reshaping the capabilities of these materials.

The primary objective of this investigation is to comprehensively understand how different electrolytes affect the conductivity, stability, and performance of polymer composites across various operating conditions. Specifically, we aim to elucidate the mechanisms by which electrolytes influence charge transport within the polymer matrix, identify optimal electrolyte compositions for specific applications, and develop predictive models for designing next-generation conductive polymer composites.

Additionally, this research seeks to address current limitations in CPC technology, such as conductivity degradation over time, sensitivity to environmental conditions, and challenges in achieving uniform dispersion of conductive fillers. By systematically studying electrolyte effects, we anticipate developing strategies to overcome these barriers and expand the practical applications of these materials.

The technological goal extends beyond mere performance enhancement to include sustainability considerations, exploring bio-derived electrolytes and environmentally friendly processing methods that align with global trends toward greener manufacturing practices. This holistic approach reflects the evolving demands of both industry and society for materials that combine high performance with environmental responsibility.

Understanding the fundamental science of electrolyte-polymer interactions will ultimately enable the design of tailored composite materials with precisely controlled properties, opening new possibilities in flexible electronics, wearable technology, energy harvesting, and next-generation batteries and supercapacitors.

The interaction between electrolytes and polymer composites has emerged as a critical area of investigation over the past decade. Electrolytes, which are substances containing free ions that make them electrically conductive, can significantly alter the electrical, mechanical, and chemical properties of polymer composites. This relationship has profound implications for applications ranging from energy storage devices to smart materials and biomedical sensors.

Recent technological trends indicate a growing interest in developing responsive and adaptive CPCs that can change their properties in response to external stimuli, with electrolyte interactions being a key mechanism for achieving this functionality. The integration of ionic liquids, solid-state electrolytes, and gel electrolytes into polymer matrices represents cutting-edge approaches that are reshaping the capabilities of these materials.

The primary objective of this investigation is to comprehensively understand how different electrolytes affect the conductivity, stability, and performance of polymer composites across various operating conditions. Specifically, we aim to elucidate the mechanisms by which electrolytes influence charge transport within the polymer matrix, identify optimal electrolyte compositions for specific applications, and develop predictive models for designing next-generation conductive polymer composites.

Additionally, this research seeks to address current limitations in CPC technology, such as conductivity degradation over time, sensitivity to environmental conditions, and challenges in achieving uniform dispersion of conductive fillers. By systematically studying electrolyte effects, we anticipate developing strategies to overcome these barriers and expand the practical applications of these materials.

The technological goal extends beyond mere performance enhancement to include sustainability considerations, exploring bio-derived electrolytes and environmentally friendly processing methods that align with global trends toward greener manufacturing practices. This holistic approach reflects the evolving demands of both industry and society for materials that combine high performance with environmental responsibility.

Understanding the fundamental science of electrolyte-polymer interactions will ultimately enable the design of tailored composite materials with precisely controlled properties, opening new possibilities in flexible electronics, wearable technology, energy harvesting, and next-generation batteries and supercapacitors.

Market Applications and Demand Analysis

The market for conductive polymer composites (CPCs) has been experiencing significant growth, driven by the increasing demand for lightweight, flexible, and cost-effective electronic components across various industries. The investigation of electrolyte effects on these materials is particularly relevant as it directly impacts their performance characteristics and application potential.

The global conductive polymer market was valued at approximately 3.9 billion USD in 2022 and is projected to reach 7.5 billion USD by 2030, growing at a CAGR of around 8.5% during the forecast period. Within this broader market, electrolyte-enhanced CPCs represent an emerging segment with substantial growth potential due to their improved conductivity and performance characteristics.

The automotive industry represents one of the largest application areas for electrolyte-modified CPCs, particularly in electric vehicles where these materials are used in battery components, sensors, and electromagnetic interference (EMI) shielding. The global shift toward vehicle electrification has created a surge in demand for advanced conductive materials that can withstand harsh operating conditions while maintaining consistent electrical properties.

Consumer electronics constitutes another major market segment, with applications in flexible displays, wearable technology, and touch-sensitive interfaces. The miniaturization trend in electronics has intensified the need for conductive materials that can be processed into increasingly complex and compact forms, where electrolyte-modified CPCs offer significant advantages over traditional metallic conductors.

Healthcare applications represent a rapidly growing market for these materials, particularly in biosensors, drug delivery systems, and medical devices. The biocompatibility of certain conductive polymer composites, combined with their electrical properties, makes them ideal for implantable and wearable medical technologies. The global medical wearable market alone is expected to reach 30 billion USD by 2026, creating substantial opportunities for advanced CPCs.

The energy sector, particularly renewable energy systems, has emerged as another significant application area. Solar panels, fuel cells, and energy storage systems all benefit from the unique properties of electrolyte-enhanced conductive polymer composites, which can improve efficiency and durability while reducing weight and cost.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 40% of global demand, followed by North America and Europe. This distribution reflects the concentration of electronics manufacturing in Asia, particularly in countries like China, Japan, and South Korea, while research and development activities remain strong in Western markets.

Customer requirements are increasingly focused on sustainability, with growing demand for bio-based conductive polymers and environmentally friendly electrolyte systems. This trend aligns with broader industry movements toward green chemistry and circular economy principles, creating new market opportunities for innovative formulations that reduce environmental impact while maintaining or enhancing performance.

The global conductive polymer market was valued at approximately 3.9 billion USD in 2022 and is projected to reach 7.5 billion USD by 2030, growing at a CAGR of around 8.5% during the forecast period. Within this broader market, electrolyte-enhanced CPCs represent an emerging segment with substantial growth potential due to their improved conductivity and performance characteristics.

The automotive industry represents one of the largest application areas for electrolyte-modified CPCs, particularly in electric vehicles where these materials are used in battery components, sensors, and electromagnetic interference (EMI) shielding. The global shift toward vehicle electrification has created a surge in demand for advanced conductive materials that can withstand harsh operating conditions while maintaining consistent electrical properties.

Consumer electronics constitutes another major market segment, with applications in flexible displays, wearable technology, and touch-sensitive interfaces. The miniaturization trend in electronics has intensified the need for conductive materials that can be processed into increasingly complex and compact forms, where electrolyte-modified CPCs offer significant advantages over traditional metallic conductors.

Healthcare applications represent a rapidly growing market for these materials, particularly in biosensors, drug delivery systems, and medical devices. The biocompatibility of certain conductive polymer composites, combined with their electrical properties, makes them ideal for implantable and wearable medical technologies. The global medical wearable market alone is expected to reach 30 billion USD by 2026, creating substantial opportunities for advanced CPCs.

The energy sector, particularly renewable energy systems, has emerged as another significant application area. Solar panels, fuel cells, and energy storage systems all benefit from the unique properties of electrolyte-enhanced conductive polymer composites, which can improve efficiency and durability while reducing weight and cost.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 40% of global demand, followed by North America and Europe. This distribution reflects the concentration of electronics manufacturing in Asia, particularly in countries like China, Japan, and South Korea, while research and development activities remain strong in Western markets.

Customer requirements are increasingly focused on sustainability, with growing demand for bio-based conductive polymers and environmentally friendly electrolyte systems. This trend aligns with broader industry movements toward green chemistry and circular economy principles, creating new market opportunities for innovative formulations that reduce environmental impact while maintaining or enhancing performance.

Current Challenges in Electrolyte-Polymer Interactions

Despite significant advancements in conductive polymer composite (CPC) research, several fundamental challenges persist in understanding and controlling electrolyte-polymer interactions. The primary obstacle remains the complex interfacial phenomena occurring between electrolytes and polymer matrices. These interactions are highly dependent on multiple variables including electrolyte concentration, ionic species, polymer chemistry, and environmental conditions, making systematic characterization extremely difficult.

Researchers face significant hurdles in developing reliable models that can accurately predict how different electrolytes will affect the electrical, mechanical, and chemical properties of polymer composites. Current theoretical frameworks often fail when applied to novel electrolyte-polymer combinations, indicating gaps in our fundamental understanding of the underlying physicochemical processes.

The stability of electrolyte-polymer systems presents another major challenge. Many conductive polymer composites exhibit performance degradation over time due to electrolyte leaching, phase separation, or chemical degradation of the polymer matrix when exposed to certain ionic environments. This instability severely limits the practical applications of these materials, particularly in harsh environments or applications requiring long-term reliability.

Manufacturing scalability remains problematic as laboratory-scale synthesis methods that achieve optimal electrolyte distribution within polymer matrices often cannot be effectively translated to industrial production scales. The processing parameters that govern electrolyte dispersion, polymer crystallinity, and interfacial properties are highly sensitive to production conditions, resulting in batch-to-batch variability.

Characterization techniques for studying electrolyte effects in situ are still limited. Current analytical methods often fail to capture the dynamic nature of electrolyte-polymer interactions under operating conditions, particularly at the nanoscale. This creates a significant knowledge gap between observed macroscopic properties and the underlying molecular mechanisms.

Environmental and safety concerns also pose challenges, as many high-performance electrolytes contain toxic or environmentally harmful components. Developing green alternatives without compromising conductivity and stability has proven difficult, with bio-based electrolytes typically showing inferior performance compared to their synthetic counterparts.

Cross-disciplinary knowledge integration represents another obstacle, as expertise from polymer science, electrochemistry, materials engineering, and computational modeling must be effectively combined to address these complex systems. The lack of standardized terminology and testing protocols across these fields further complicates collaborative research efforts and technology transfer.

Researchers face significant hurdles in developing reliable models that can accurately predict how different electrolytes will affect the electrical, mechanical, and chemical properties of polymer composites. Current theoretical frameworks often fail when applied to novel electrolyte-polymer combinations, indicating gaps in our fundamental understanding of the underlying physicochemical processes.

The stability of electrolyte-polymer systems presents another major challenge. Many conductive polymer composites exhibit performance degradation over time due to electrolyte leaching, phase separation, or chemical degradation of the polymer matrix when exposed to certain ionic environments. This instability severely limits the practical applications of these materials, particularly in harsh environments or applications requiring long-term reliability.

Manufacturing scalability remains problematic as laboratory-scale synthesis methods that achieve optimal electrolyte distribution within polymer matrices often cannot be effectively translated to industrial production scales. The processing parameters that govern electrolyte dispersion, polymer crystallinity, and interfacial properties are highly sensitive to production conditions, resulting in batch-to-batch variability.

Characterization techniques for studying electrolyte effects in situ are still limited. Current analytical methods often fail to capture the dynamic nature of electrolyte-polymer interactions under operating conditions, particularly at the nanoscale. This creates a significant knowledge gap between observed macroscopic properties and the underlying molecular mechanisms.

Environmental and safety concerns also pose challenges, as many high-performance electrolytes contain toxic or environmentally harmful components. Developing green alternatives without compromising conductivity and stability has proven difficult, with bio-based electrolytes typically showing inferior performance compared to their synthetic counterparts.

Cross-disciplinary knowledge integration represents another obstacle, as expertise from polymer science, electrochemistry, materials engineering, and computational modeling must be effectively combined to address these complex systems. The lack of standardized terminology and testing protocols across these fields further complicates collaborative research efforts and technology transfer.

Current Methodologies for Electrolyte Integration

01 Carbon-based fillers for enhancing polymer conductivity

Carbon-based materials such as carbon nanotubes, graphene, carbon black, and carbon fibers can be incorporated into polymer matrices to enhance electrical conductivity. These fillers create conductive pathways within the polymer matrix, allowing for electron transfer. The concentration and dispersion of these carbon-based fillers significantly impact the overall conductivity of the polymer composite.- Carbon-based fillers for enhancing polymer conductivity: Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create conductive composites. These fillers form conductive networks within the polymer, significantly enhancing electrical conductivity while maintaining the processability of the polymer. The concentration and dispersion of these carbon-based fillers are critical factors that determine the final conductivity of the composite.

- Metal particle incorporation in polymer composites: Metal particles, including nanoparticles of silver, copper, and gold, can be dispersed within polymer matrices to create highly conductive composites. These metal-polymer composites offer excellent electrical conductivity while maintaining flexibility and processability. The size, shape, and distribution of metal particles significantly impact the conductivity and mechanical properties of the resulting composite materials.

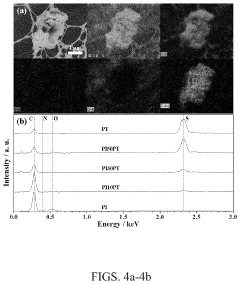

- Intrinsically conductive polymers and their applications: Intrinsically conductive polymers such as polyaniline, polypyrrole, and polythiophene can be used either alone or as components in composite materials to achieve electrical conductivity. These polymers contain conjugated double bonds that allow electron movement along the polymer chain. Doping these polymers with appropriate substances can significantly enhance their conductivity, making them suitable for various electronic applications.

- Processing techniques for conductive polymer composites: Various processing techniques can be employed to optimize the conductivity of polymer composites, including solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. These methods affect the dispersion of conductive fillers and the interfacial interactions between the filler and polymer matrix, which directly impact the electrical properties of the final composite. Advanced processing techniques can achieve higher conductivity at lower filler loadings.

- Novel hybrid conductive composites and synergistic effects: Hybrid conductive composites incorporating multiple types of conductive fillers (such as combinations of carbon nanotubes with metal particles or graphene with conductive polymers) can exhibit synergistic effects, resulting in conductivity values higher than would be expected from the individual components alone. These hybrid systems often allow for lower overall filler content while achieving superior electrical properties and maintaining good mechanical characteristics.

02 Metal particles and nanowires as conductive fillers

Metal particles, particularly silver, copper, and gold nanowires or nanoparticles, can be incorporated into polymer matrices to create highly conductive composites. These metal fillers provide excellent electrical conductivity while maintaining the processability of the polymer. The size, shape, and distribution of metal particles within the polymer matrix affect the percolation threshold and overall conductivity of the composite.Expand Specific Solutions03 Intrinsically conductive polymers and their blends

Intrinsically conductive polymers such as polyaniline, polypyrrole, and polythiophene derivatives can be used either as the primary matrix or blended with conventional polymers to create conductive composites. These polymers contain conjugated double bonds that allow for electron movement along the polymer backbone. Doping these polymers with appropriate agents can significantly enhance their conductivity properties.Expand Specific Solutions04 Processing techniques for optimizing conductivity

Various processing techniques can be employed to optimize the conductivity of polymer composites. These include solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly. The processing method affects the dispersion of conductive fillers and the formation of conductive networks within the polymer matrix, which directly impacts the electrical conductivity of the final composite.Expand Specific Solutions05 Surface modification and interface engineering

Surface modification of conductive fillers and interface engineering between the filler and polymer matrix can significantly enhance the electrical conductivity of polymer composites. Techniques such as functionalization of fillers, use of coupling agents, and controlled aggregation can improve filler dispersion and create more efficient conductive networks, resulting in enhanced electrical conductivity at lower filler loadings.Expand Specific Solutions

Leading Researchers and Industry Players

The electrolyte effects on conductive polymer composites market is currently in a growth phase, with increasing applications across electronics, energy storage, and sensing technologies. The global market size is estimated to reach significant value due to rising demand for advanced materials with tailored electrical properties. Technologically, this field shows moderate maturity with ongoing innovations. Leading academic institutions like Nanjing University, Zhejiang University, and Sichuan University are conducting fundamental research, while companies including Kaneka Corp., Tayca Corp., and BASF Corp. focus on commercial applications. Industrial players such as LG Energy Solution and Panasonic Holdings are leveraging these materials for battery technologies, while specialized firms like CYG Wayon and KEMET Electronics are developing circuit protection applications, indicating diverse market participation across the value chain.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced conductive polymer composite technologies focusing on electrolyte interactions for next-generation energy storage applications. Their approach centers on creating polymer-based solid electrolytes with enhanced ionic conductivity and electrochemical stability. LG's proprietary technology utilizes modified polyethylene oxide (PEO) matrices incorporating lithium salts and ceramic fillers to create composite systems with optimized ion transport properties. Their research has demonstrated that controlling the polymer-ceramic-electrolyte interfaces through surface functionalization techniques can significantly enhance ionic conductivity while maintaining mechanical integrity. LG Energy Solution has also pioneered composite systems that incorporate ionic liquids as plasticizers to lower the glass transition temperature of the polymer matrix, thereby improving room-temperature conductivity while maintaining the safety advantages of solid-state systems. Their materials achieve ionic conductivities approaching 10^-3 S/cm at operating temperatures, with excellent electrochemical stability windows exceeding 4.5V vs. Li/Li+.

Strengths: Extensive battery manufacturing expertise enables practical implementation in commercial products; strong vertical integration from materials to finished cells. Weaknesses: Some formulations show performance limitations at low temperatures; higher production complexity compared to conventional liquid electrolyte systems.

BASF Corp.

Technical Solution: BASF has developed advanced conductive polymer composites (CPCs) with tailored electrolyte interactions for enhanced performance. Their proprietary technology focuses on polymer matrices (including polyethylene oxide and polyvinylidene fluoride) modified with ionic liquid electrolytes to create stable interfaces. BASF's approach involves precise control of the polymer-electrolyte interface through surface functionalization techniques that optimize ion transport while maintaining mechanical integrity. Their research demonstrates that incorporating specific ionic liquids with low volatility can significantly improve the conductivity of polymer composites while reducing degradation issues common with traditional liquid electrolytes. BASF has also pioneered composite systems that combine conductive polymers with ceramic fillers to create hybrid electrolytes with superior thermal stability and electrochemical performance for energy storage applications.

Strengths: Industry-leading expertise in chemical formulation allows for precise control of polymer-electrolyte interfaces; extensive manufacturing capabilities enable scalable production. Weaknesses: Higher production costs compared to conventional materials; some formulations may have limited temperature operating windows.

Key Mechanisms of Electrolyte-Enhanced Conductivity

High-ionic conductivity electrolyte compositions comprising semi-interpenetrating polymer networks and their composites

PatentWO2014147648A1

Innovation

- Development of high-ionic conductivity electrolyte compositions using semi-interpenetrating polymer networks (semi-IPNs) and their nanocomposites, incorporating a polyether backbone, low molecular weight polymers, electrolyte salts, and surface-functionalized nanoparticles to enhance ionic conductivity, thermal stability, and film-forming capabilities.

Electron conductive polymer composites and their use as electrode materials

PatentInactiveUS20200176762A1

Innovation

- A composite material is developed comprising an ion-permeable, non-electron conductive organic polymer core coated with an electron conductive polymer, specifically aromatic polyimide coated with conductive polythiophene (PI@PT), which enhances electronic conductivity and stability, enabling high reversible capacity and cycling stability in lithium-ion batteries.

Environmental Impact Assessment

The production and disposal of conductive polymer composites (CPCs) containing electrolytes present significant environmental considerations that must be evaluated comprehensively. These materials, while offering technological advantages, introduce potential ecological challenges throughout their lifecycle. The manufacturing processes of electrolyte-enhanced CPCs often involve solvents, chemical additives, and energy-intensive procedures that generate greenhouse gas emissions and chemical waste streams requiring proper management.

Water consumption represents another critical environmental factor, as electrolyte preparation and polymer processing typically demand substantial quantities of purified water. This usage pattern raises concerns in regions experiencing water scarcity or where industrial water competition exists with agricultural or residential needs. Additionally, the chemical stability of electrolytes within these composites determines their long-term environmental persistence, with more stable formulations potentially creating lasting ecological impacts.

Toxicity profiles of electrolytes vary significantly based on their chemical composition. Ionic liquid electrolytes, while offering performance benefits, may contain components harmful to aquatic ecosystems if released untreated. Traditional salt-based electrolytes present different environmental challenges, particularly regarding their biodegradability and bioaccumulation potential. Recent research indicates that certain electrolyte formulations can leach from CPCs during use or disposal, potentially contaminating soil and water systems.

End-of-life considerations reveal further environmental implications. The recyclability of electrolyte-containing CPCs remains technically challenging due to the intimate mixing of polymers, conductive fillers, and electrolyte components. Current recycling technologies struggle to efficiently separate these constituents, often resulting in downcycling rather than true material recovery. Incineration of these materials may release harmful compounds depending on the specific electrolyte chemistry employed.

Emerging research points toward more environmentally benign alternatives, including bio-derived electrolytes and green synthesis methods that reduce ecological footprints. Several studies demonstrate promising results using plant-derived ionic compounds and water-based processing techniques that minimize hazardous waste generation. Life cycle assessment (LCA) data suggests that these alternative approaches can reduce environmental impact by 30-45% compared to conventional methods, though scale-up challenges remain.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials like electrolyte-enhanced CPCs. The European Union's REACH regulations and similar initiatives in other regions now require more rigorous environmental testing and documentation for these composite materials, driving industry innovation toward greener formulations and manufacturing processes.

Water consumption represents another critical environmental factor, as electrolyte preparation and polymer processing typically demand substantial quantities of purified water. This usage pattern raises concerns in regions experiencing water scarcity or where industrial water competition exists with agricultural or residential needs. Additionally, the chemical stability of electrolytes within these composites determines their long-term environmental persistence, with more stable formulations potentially creating lasting ecological impacts.

Toxicity profiles of electrolytes vary significantly based on their chemical composition. Ionic liquid electrolytes, while offering performance benefits, may contain components harmful to aquatic ecosystems if released untreated. Traditional salt-based electrolytes present different environmental challenges, particularly regarding their biodegradability and bioaccumulation potential. Recent research indicates that certain electrolyte formulations can leach from CPCs during use or disposal, potentially contaminating soil and water systems.

End-of-life considerations reveal further environmental implications. The recyclability of electrolyte-containing CPCs remains technically challenging due to the intimate mixing of polymers, conductive fillers, and electrolyte components. Current recycling technologies struggle to efficiently separate these constituents, often resulting in downcycling rather than true material recovery. Incineration of these materials may release harmful compounds depending on the specific electrolyte chemistry employed.

Emerging research points toward more environmentally benign alternatives, including bio-derived electrolytes and green synthesis methods that reduce ecological footprints. Several studies demonstrate promising results using plant-derived ionic compounds and water-based processing techniques that minimize hazardous waste generation. Life cycle assessment (LCA) data suggests that these alternative approaches can reduce environmental impact by 30-45% compared to conventional methods, though scale-up challenges remain.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials like electrolyte-enhanced CPCs. The European Union's REACH regulations and similar initiatives in other regions now require more rigorous environmental testing and documentation for these composite materials, driving industry innovation toward greener formulations and manufacturing processes.

Scalability and Manufacturing Considerations

The scalability of conductive polymer composite (CPC) manufacturing processes represents a critical factor in their commercial viability. Current laboratory-scale production methods often face significant challenges when transitioning to industrial-scale manufacturing. The interaction between electrolytes and polymer matrices introduces additional complexity to scaling operations, requiring careful consideration of mixing uniformity, curing conditions, and quality control parameters.

Mass production of electrolyte-enhanced CPCs demands specialized equipment capable of handling potentially reactive materials while maintaining precise control over composition ratios. Conventional polymer processing equipment may require modifications to accommodate electrolyte incorporation without degradation or uneven distribution. High-shear mixing technologies have demonstrated promising results for ensuring homogeneous electrolyte distribution throughout the polymer matrix, though optimization remains necessary for specific formulations.

Processing parameters such as temperature, pressure, and residence time significantly impact the final properties of electrolyte-containing CPCs. These parameters must be carefully calibrated to prevent electrolyte degradation while ensuring complete integration with the polymer matrix. Continuous manufacturing approaches, including extrusion and roll-to-roll processing, offer potential advantages for large-scale production but require precise control systems to maintain consistency across production runs.

Cost considerations represent another crucial aspect of manufacturing scalability. While electrolytes can enhance conductivity performance, they may significantly increase raw material costs. Economic viability depends on achieving an optimal balance between performance enhancement and production expenses. Alternative electrolyte sources and recycling strategies are being explored to address cost concerns while maintaining performance standards.

Quality control protocols for electrolyte-enhanced CPCs require specialized testing methodologies beyond traditional polymer composite inspection techniques. In-line monitoring of electrical properties, electrolyte distribution, and structural integrity presents technical challenges that must be addressed for reliable mass production. Advanced characterization techniques such as impedance spectroscopy and thermal analysis are being adapted for production environments to ensure consistent product quality.

Environmental and safety considerations also impact manufacturing scalability. Some electrolytes present handling challenges due to reactivity or toxicity concerns, necessitating additional containment measures and worker protection protocols. Sustainable manufacturing approaches are increasingly prioritized, focusing on reducing waste streams and minimizing environmental impact through closed-loop processing systems and benign electrolyte alternatives.

Future manufacturing innovations may leverage emerging technologies such as additive manufacturing and microfluidic mixing systems to enable more precise control over electrolyte distribution within polymer matrices. These approaches could potentially reduce material waste while improving performance consistency, though significant development work remains before industrial implementation becomes feasible.

Mass production of electrolyte-enhanced CPCs demands specialized equipment capable of handling potentially reactive materials while maintaining precise control over composition ratios. Conventional polymer processing equipment may require modifications to accommodate electrolyte incorporation without degradation or uneven distribution. High-shear mixing technologies have demonstrated promising results for ensuring homogeneous electrolyte distribution throughout the polymer matrix, though optimization remains necessary for specific formulations.

Processing parameters such as temperature, pressure, and residence time significantly impact the final properties of electrolyte-containing CPCs. These parameters must be carefully calibrated to prevent electrolyte degradation while ensuring complete integration with the polymer matrix. Continuous manufacturing approaches, including extrusion and roll-to-roll processing, offer potential advantages for large-scale production but require precise control systems to maintain consistency across production runs.

Cost considerations represent another crucial aspect of manufacturing scalability. While electrolytes can enhance conductivity performance, they may significantly increase raw material costs. Economic viability depends on achieving an optimal balance between performance enhancement and production expenses. Alternative electrolyte sources and recycling strategies are being explored to address cost concerns while maintaining performance standards.

Quality control protocols for electrolyte-enhanced CPCs require specialized testing methodologies beyond traditional polymer composite inspection techniques. In-line monitoring of electrical properties, electrolyte distribution, and structural integrity presents technical challenges that must be addressed for reliable mass production. Advanced characterization techniques such as impedance spectroscopy and thermal analysis are being adapted for production environments to ensure consistent product quality.

Environmental and safety considerations also impact manufacturing scalability. Some electrolytes present handling challenges due to reactivity or toxicity concerns, necessitating additional containment measures and worker protection protocols. Sustainable manufacturing approaches are increasingly prioritized, focusing on reducing waste streams and minimizing environmental impact through closed-loop processing systems and benign electrolyte alternatives.

Future manufacturing innovations may leverage emerging technologies such as additive manufacturing and microfluidic mixing systems to enable more precise control over electrolyte distribution within polymer matrices. These approaches could potentially reduce material waste while improving performance consistency, though significant development work remains before industrial implementation becomes feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!