Innovations in Conductive Polymer Composites for Renewable Energy

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Evolution and Research Objectives

Conductive polymers have undergone significant evolution since their initial discovery in the 1970s when Alan Heeger, Alan MacDiarmid, and Hideki Shirakawa demonstrated that polyacetylene could conduct electricity when doped with iodine. This groundbreaking work, which earned them the Nobel Prize in Chemistry in 2000, opened a new frontier in materials science that bridges the traditionally separate domains of polymers and electronic conductors.

The development trajectory of conductive polymers has been characterized by several distinct phases. The first generation focused primarily on understanding the fundamental mechanisms of conductivity in organic materials. The second generation, emerging in the 1980s and 1990s, concentrated on improving processability and stability, which were significant limitations of early conductive polymers. The third generation, from the 2000s onward, has emphasized functional applications and integration with other materials to create advanced composites.

Recent advancements have particularly focused on conductive polymer composites (CPCs), which combine conductive polymers with various fillers or matrices to enhance specific properties. These composites have shown remarkable versatility in applications ranging from flexible electronics to energy storage and conversion systems. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles has dramatically improved the electrical, mechanical, and thermal properties of these composites.

In the renewable energy sector, conductive polymer composites have emerged as promising materials for various applications including solar cells, fuel cells, supercapacitors, and thermoelectric generators. Their unique combination of electrical conductivity, flexibility, lightweight nature, and potentially low-cost manufacturing processes makes them particularly attractive for next-generation energy technologies.

The current research objectives in this field are multifaceted. First, there is a strong focus on enhancing the electrical conductivity of these composites while maintaining their mechanical flexibility and processability. Second, researchers are working to improve the long-term stability of these materials under various environmental conditions, addressing issues such as oxidative degradation and thermal instability. Third, there is significant interest in developing scalable and environmentally friendly manufacturing processes that can facilitate the transition from laboratory prototypes to commercial products.

Another critical research objective involves optimizing the interface between the conductive polymer and the filler materials to maximize charge transfer efficiency and minimize resistance. This includes developing novel surface modification techniques and exploring new composite architectures. Additionally, there is growing interest in creating multifunctional composites that can simultaneously serve multiple roles in energy systems, such as combining energy harvesting with storage capabilities.

The ultimate goal of these research efforts is to develop next-generation materials that can significantly enhance the efficiency, durability, and cost-effectiveness of renewable energy technologies, thereby accelerating the global transition toward sustainable energy systems.

The development trajectory of conductive polymers has been characterized by several distinct phases. The first generation focused primarily on understanding the fundamental mechanisms of conductivity in organic materials. The second generation, emerging in the 1980s and 1990s, concentrated on improving processability and stability, which were significant limitations of early conductive polymers. The third generation, from the 2000s onward, has emphasized functional applications and integration with other materials to create advanced composites.

Recent advancements have particularly focused on conductive polymer composites (CPCs), which combine conductive polymers with various fillers or matrices to enhance specific properties. These composites have shown remarkable versatility in applications ranging from flexible electronics to energy storage and conversion systems. The incorporation of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles has dramatically improved the electrical, mechanical, and thermal properties of these composites.

In the renewable energy sector, conductive polymer composites have emerged as promising materials for various applications including solar cells, fuel cells, supercapacitors, and thermoelectric generators. Their unique combination of electrical conductivity, flexibility, lightweight nature, and potentially low-cost manufacturing processes makes them particularly attractive for next-generation energy technologies.

The current research objectives in this field are multifaceted. First, there is a strong focus on enhancing the electrical conductivity of these composites while maintaining their mechanical flexibility and processability. Second, researchers are working to improve the long-term stability of these materials under various environmental conditions, addressing issues such as oxidative degradation and thermal instability. Third, there is significant interest in developing scalable and environmentally friendly manufacturing processes that can facilitate the transition from laboratory prototypes to commercial products.

Another critical research objective involves optimizing the interface between the conductive polymer and the filler materials to maximize charge transfer efficiency and minimize resistance. This includes developing novel surface modification techniques and exploring new composite architectures. Additionally, there is growing interest in creating multifunctional composites that can simultaneously serve multiple roles in energy systems, such as combining energy harvesting with storage capabilities.

The ultimate goal of these research efforts is to develop next-generation materials that can significantly enhance the efficiency, durability, and cost-effectiveness of renewable energy technologies, thereby accelerating the global transition toward sustainable energy systems.

Renewable Energy Market Demand Analysis

The global renewable energy market has experienced unprecedented growth over the past decade, creating significant opportunities for advanced materials like conductive polymer composites (CPCs). Current market analysis indicates that the renewable energy sector is projected to reach $1.9 trillion by 2030, with a compound annual growth rate of approximately 8.5% between 2023 and 2030. This robust growth is primarily driven by increasing environmental concerns, government initiatives promoting clean energy, and the declining costs of renewable technologies.

Conductive polymer composites are positioned to address critical needs within this expanding market. Solar energy, which constitutes about 40% of new renewable capacity installations globally, requires materials with enhanced electrical conductivity, thermal management capabilities, and durability. CPCs offer potential solutions for improving solar panel efficiency, which currently averages between 15-22% for commercial panels, with laboratory prototypes achieving up to 47.6% efficiency.

Wind energy, representing approximately 30% of renewable capacity additions, demands materials that can withstand extreme environmental conditions while maintaining electrical functionality. The market for specialized materials in wind turbine manufacturing, including those used in blade design and electrical systems, is growing at 9.8% annually, creating a substantial opportunity for CPC applications.

Energy storage systems, essential for addressing intermittency issues in renewable energy generation, represent another significant market segment. The global battery storage market is expected to grow from $15.6 billion in 2022 to $31.2 billion by 2027. CPCs can potentially enhance battery performance through improved electrode materials and thermal management systems, addressing key industry challenges of energy density, charging speed, and cycle life.

Consumer demand patterns indicate increasing preference for integrated renewable energy solutions in both residential and commercial applications. The building-integrated photovoltaics market, where CPCs could play a crucial role in developing flexible and aesthetically pleasing solar solutions, is growing at 16.2% annually.

Regional analysis reveals varying adoption rates and market potential. Asia-Pacific leads in manufacturing capacity and deployment of renewable technologies, accounting for 45% of global renewable energy investments. Europe follows with strong policy support driving approximately 25% of global investments, while North America contributes about 20% with increasing corporate procurement of renewable energy.

The market demonstrates clear signals for materials innovation, with industry surveys indicating that 78% of renewable energy manufacturers are actively seeking advanced materials to improve product performance and reduce costs. This creates a substantial opportunity for conductive polymer composites that can deliver enhanced electrical properties while maintaining cost-effectiveness and sustainability.

Conductive polymer composites are positioned to address critical needs within this expanding market. Solar energy, which constitutes about 40% of new renewable capacity installations globally, requires materials with enhanced electrical conductivity, thermal management capabilities, and durability. CPCs offer potential solutions for improving solar panel efficiency, which currently averages between 15-22% for commercial panels, with laboratory prototypes achieving up to 47.6% efficiency.

Wind energy, representing approximately 30% of renewable capacity additions, demands materials that can withstand extreme environmental conditions while maintaining electrical functionality. The market for specialized materials in wind turbine manufacturing, including those used in blade design and electrical systems, is growing at 9.8% annually, creating a substantial opportunity for CPC applications.

Energy storage systems, essential for addressing intermittency issues in renewable energy generation, represent another significant market segment. The global battery storage market is expected to grow from $15.6 billion in 2022 to $31.2 billion by 2027. CPCs can potentially enhance battery performance through improved electrode materials and thermal management systems, addressing key industry challenges of energy density, charging speed, and cycle life.

Consumer demand patterns indicate increasing preference for integrated renewable energy solutions in both residential and commercial applications. The building-integrated photovoltaics market, where CPCs could play a crucial role in developing flexible and aesthetically pleasing solar solutions, is growing at 16.2% annually.

Regional analysis reveals varying adoption rates and market potential. Asia-Pacific leads in manufacturing capacity and deployment of renewable technologies, accounting for 45% of global renewable energy investments. Europe follows with strong policy support driving approximately 25% of global investments, while North America contributes about 20% with increasing corporate procurement of renewable energy.

The market demonstrates clear signals for materials innovation, with industry surveys indicating that 78% of renewable energy manufacturers are actively seeking advanced materials to improve product performance and reduce costs. This creates a substantial opportunity for conductive polymer composites that can deliver enhanced electrical properties while maintaining cost-effectiveness and sustainability.

Global Status and Challenges in Polymer Composite Technology

Conductive polymer composites (CPCs) have emerged as a significant technological advancement in renewable energy applications, with research and development efforts spanning across the globe. Currently, the United States, European Union, China, Japan, and South Korea lead in polymer composite technology innovation, with each region focusing on different aspects of development and application.

The global market for polymer composites in renewable energy applications is experiencing robust growth, projected to reach approximately $17.5 billion by 2027, with a compound annual growth rate of 8.3%. This growth is primarily driven by increasing demand for lightweight, durable, and electrically conductive materials in solar panels, wind turbines, and energy storage systems.

Despite significant progress, the field faces several critical challenges. Technical barriers include achieving consistent electrical conductivity across large-scale manufacturing processes, optimizing the interface between polymer matrices and conductive fillers, and enhancing long-term stability under various environmental conditions. The conductivity-mechanical property trade-off remains a persistent issue, as higher filler loadings typically improve conductivity but compromise mechanical integrity.

Manufacturing scalability presents another significant hurdle. Current laboratory-scale production methods often fail to translate effectively to industrial-scale manufacturing, resulting in inconsistent product quality and increased production costs. The complexity of processing techniques for advanced CPCs requires specialized equipment and expertise, limiting widespread adoption.

Environmental considerations also pose challenges. While polymer composites contribute to renewable energy solutions, their production often involves petroleum-based materials and energy-intensive processes. End-of-life management remains problematic, as recycling conductive polymer composites is complicated by the heterogeneous nature of these materials.

Regulatory frameworks vary significantly across regions, creating a fragmented landscape for global manufacturers. Compliance with different standards increases development costs and time-to-market for new products. Additionally, intellectual property protection has created competitive barriers, with major corporations holding extensive patent portfolios that can impede innovation from smaller entities.

Cost factors continue to constrain widespread implementation. High-performance conductive fillers such as carbon nanotubes and graphene remain expensive, while processing techniques for uniform dispersion add further to production expenses. The resulting price premium for advanced CPCs limits their application to high-value sectors, slowing adoption in cost-sensitive renewable energy markets.

Addressing these challenges requires coordinated international research efforts, standardization of testing protocols, and development of sustainable manufacturing processes. Recent collaborative initiatives between academic institutions and industry partners show promise in overcoming these barriers through shared knowledge and resources.

The global market for polymer composites in renewable energy applications is experiencing robust growth, projected to reach approximately $17.5 billion by 2027, with a compound annual growth rate of 8.3%. This growth is primarily driven by increasing demand for lightweight, durable, and electrically conductive materials in solar panels, wind turbines, and energy storage systems.

Despite significant progress, the field faces several critical challenges. Technical barriers include achieving consistent electrical conductivity across large-scale manufacturing processes, optimizing the interface between polymer matrices and conductive fillers, and enhancing long-term stability under various environmental conditions. The conductivity-mechanical property trade-off remains a persistent issue, as higher filler loadings typically improve conductivity but compromise mechanical integrity.

Manufacturing scalability presents another significant hurdle. Current laboratory-scale production methods often fail to translate effectively to industrial-scale manufacturing, resulting in inconsistent product quality and increased production costs. The complexity of processing techniques for advanced CPCs requires specialized equipment and expertise, limiting widespread adoption.

Environmental considerations also pose challenges. While polymer composites contribute to renewable energy solutions, their production often involves petroleum-based materials and energy-intensive processes. End-of-life management remains problematic, as recycling conductive polymer composites is complicated by the heterogeneous nature of these materials.

Regulatory frameworks vary significantly across regions, creating a fragmented landscape for global manufacturers. Compliance with different standards increases development costs and time-to-market for new products. Additionally, intellectual property protection has created competitive barriers, with major corporations holding extensive patent portfolios that can impede innovation from smaller entities.

Cost factors continue to constrain widespread implementation. High-performance conductive fillers such as carbon nanotubes and graphene remain expensive, while processing techniques for uniform dispersion add further to production expenses. The resulting price premium for advanced CPCs limits their application to high-value sectors, slowing adoption in cost-sensitive renewable energy markets.

Addressing these challenges requires coordinated international research efforts, standardization of testing protocols, and development of sustainable manufacturing processes. Recent collaborative initiatives between academic institutions and industry partners show promise in overcoming these barriers through shared knowledge and resources.

Current Polymer Composite Solutions for Energy Applications

01 Conductive polymer composites with carbon-based fillers

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are commonly used as conductive fillers in polymer composites. These materials enhance electrical conductivity while maintaining the mechanical properties of the polymer matrix. The incorporation of these carbon-based fillers creates a conductive network within the polymer, allowing for efficient electron transfer. These composites find applications in electromagnetic shielding, antistatic materials, and flexible electronics.- Carbon-based conductive polymer composites: Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create conductive composites. These materials provide excellent electrical conductivity while maintaining the mechanical properties of the polymer. The resulting composites can be used in various applications including electromagnetic shielding, antistatic materials, and flexible electronics. The dispersion method and concentration of carbon materials significantly affect the conductivity and performance of the final composite.

- Metal-polymer conductive composites: Metal particles or nanowires, particularly silver, copper, and gold, can be dispersed within polymer matrices to create conductive composites. These metal-polymer composites offer high electrical conductivity and can be formulated to maintain flexibility. The size, shape, and distribution of metal particles significantly impact the conductivity threshold and mechanical properties. These composites find applications in printed electronics, sensors, and conductive adhesives where both electrical performance and processability are required.

- Intrinsically conductive polymers in composites: Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be blended with conventional polymers to create conductive composites. These materials offer conductivity without requiring high loadings of conductive fillers, maintaining better mechanical properties. The conductivity can be tuned through doping processes and processing conditions. These composites are particularly useful in applications requiring biocompatibility, such as tissue engineering, bioelectronics, and flexible displays.

- Hybrid conductive polymer composites: Hybrid composites combining multiple types of conductive fillers (such as carbon nanotubes with metal particles or graphene with conductive polymers) can achieve synergistic effects in electrical conductivity. These hybrid systems often reach percolation thresholds at lower filler concentrations than single-filler systems, offering better mechanical properties while maintaining high conductivity. The interaction between different fillers creates multiple conductive pathways, enhancing overall performance and enabling applications in energy storage, electromagnetic interference shielding, and sensors.

- Processing techniques for conductive polymer composites: Various processing techniques including solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly can be used to fabricate conductive polymer composites. The processing method significantly affects the dispersion of conductive fillers and the resulting electrical properties. Surface modification of fillers and the use of compatibilizers can improve dispersion and interfacial adhesion between the conductive fillers and polymer matrix. Advanced techniques like 3D printing and electrospinning enable the fabrication of complex structures with tailored conductivity profiles.

02 Metal-polymer conductive composites

Metal particles or nanoparticles can be incorporated into polymer matrices to create conductive composites. Metals such as silver, copper, and nickel provide excellent electrical conductivity. The size, shape, and distribution of metal particles within the polymer matrix significantly affect the overall conductivity of the composite. These metal-polymer composites are used in applications requiring high conductivity, such as printed electronics, conductive adhesives, and electromagnetic interference shielding materials.Expand Specific Solutions03 Intrinsically conductive polymers in composites

Intrinsically conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be used to create conductive composites. These polymers have conjugated structures that allow for electron movement along the polymer backbone. By blending these conductive polymers with conventional polymers or incorporating them into composite structures, materials with tailored electrical properties can be created. These composites are particularly useful in sensors, actuators, and energy storage devices.Expand Specific Solutions04 Processing techniques for conductive polymer composites

Various processing techniques can be employed to manufacture conductive polymer composites with enhanced properties. These include melt blending, solution mixing, in-situ polymerization, and layer-by-layer assembly. The processing method significantly affects the dispersion of conductive fillers and the resulting electrical properties of the composite. Advanced techniques such as 3D printing and electrospinning can be used to create conductive polymer composites with complex geometries and controlled microstructures.Expand Specific Solutions05 Applications of conductive polymer composites

Conductive polymer composites find applications across various industries. They are used in energy storage devices such as batteries and supercapacitors, where they serve as electrode materials. In electronics, they are employed in flexible circuits, electromagnetic interference shielding, and antistatic packaging. These composites are also utilized in sensors, actuators, and smart materials that respond to external stimuli. Additionally, they have applications in biomedical devices, where biocompatible conductive materials are required for tissue engineering and drug delivery systems.Expand Specific Solutions

Leading Companies and Research Institutions

The conductive polymer composites (CPCs) market for renewable energy applications is currently in a growth phase, characterized by increasing technological maturity and expanding commercial applications. The global market is projected to reach significant scale as renewable energy adoption accelerates worldwide. Leading academic institutions like The Regents of the University of California, Tsinghua University, and Southeast University are driving fundamental research, while established chemical corporations including Sumitomo Chemical, Resonac Holdings, and China Petroleum & Chemical Corp are commercializing advanced materials. Specialized technology companies such as Nanosys and Agentis Air are developing niche applications, with research organizations like the Agency for Science, Technology & Research and Korea Institute of Machinery & Materials bridging the gap between academic innovation and industrial implementation. The technology is approaching commercial viability with ongoing improvements in conductivity, durability, and manufacturing scalability.

The Regents of the University of California

Technical Solution: The University of California has developed innovative nanostructured conductive polymer composites that enhance charge transport in solar cells. Their approach involves creating hierarchical structures with controlled morphology at the nanoscale, incorporating carbon nanotubes and graphene into polymer matrices to form efficient electron pathways. Their PEDOT:PSS-based composites with optimized morphology have demonstrated power conversion efficiencies exceeding 15% in organic photovoltaics, representing a significant improvement over conventional systems. The university's research also extends to self-healing conductive polymers that can restore electrical conductivity after mechanical damage, crucial for extending the operational lifetime of flexible solar panels and energy storage devices.

Strengths: Superior charge transport properties through nanoscale engineering; self-healing capabilities that enhance durability in real-world applications; strong fundamental research foundation. Weaknesses: Higher production costs compared to traditional materials; challenges in scaling laboratory innovations to industrial production; potential long-term stability issues in extreme environmental conditions.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed high-performance conductive polymer composites based on polythiophene derivatives with engineered interfaces for solar energy harvesting. Their technology employs a proprietary molecular design approach that incorporates specific functional groups to enhance compatibility between the polymer matrix and conductive fillers. This results in exceptional charge transfer efficiency at material interfaces. Their composites feature self-organizing properties that create optimal morphology during processing, eliminating the need for post-treatment steps. Sumitomo's materials demonstrate remarkable thermal stability up to 200°C while maintaining conductivity, addressing a key limitation in many polymer-based systems. The company has successfully implemented these materials in commercial organic photovoltaic modules, achieving power conversion efficiencies of 14% with significantly improved operational lifetimes compared to previous generations.

Strengths: Excellent thermal stability for harsh operating environments; optimized interfacial properties enhancing charge transfer; established commercial production capabilities. Weaknesses: Complex synthesis procedures increasing production costs; limited flexibility compared to some competing materials; performance degradation in high humidity environments.

Key Patents and Breakthroughs in Conductive Polymers

Conductive polymers, the organic photovoltaic cell comprising the same, and the synthesis thereof

PatentActiveUS20180006228A1

Innovation

- A novel conductive polymer with a symmetrical structure is synthesized by modifying the orientation of quaterthiophene and benzothiadiazole derivatives using palladium catalysts, enhancing its optical characteristics and photoelectric conversion efficiency.

Conductive polymer composites

PatentInactiveUS20080272344A1

Innovation

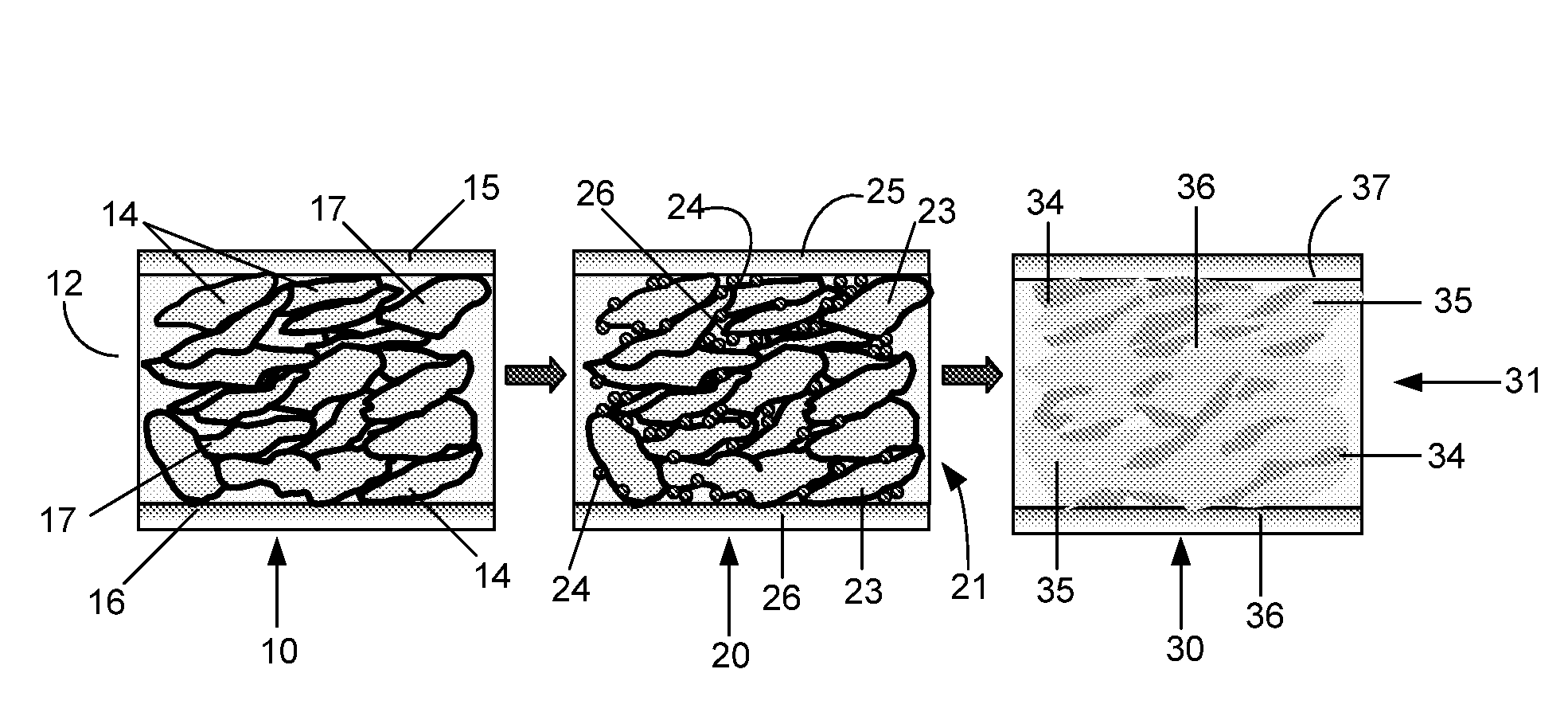

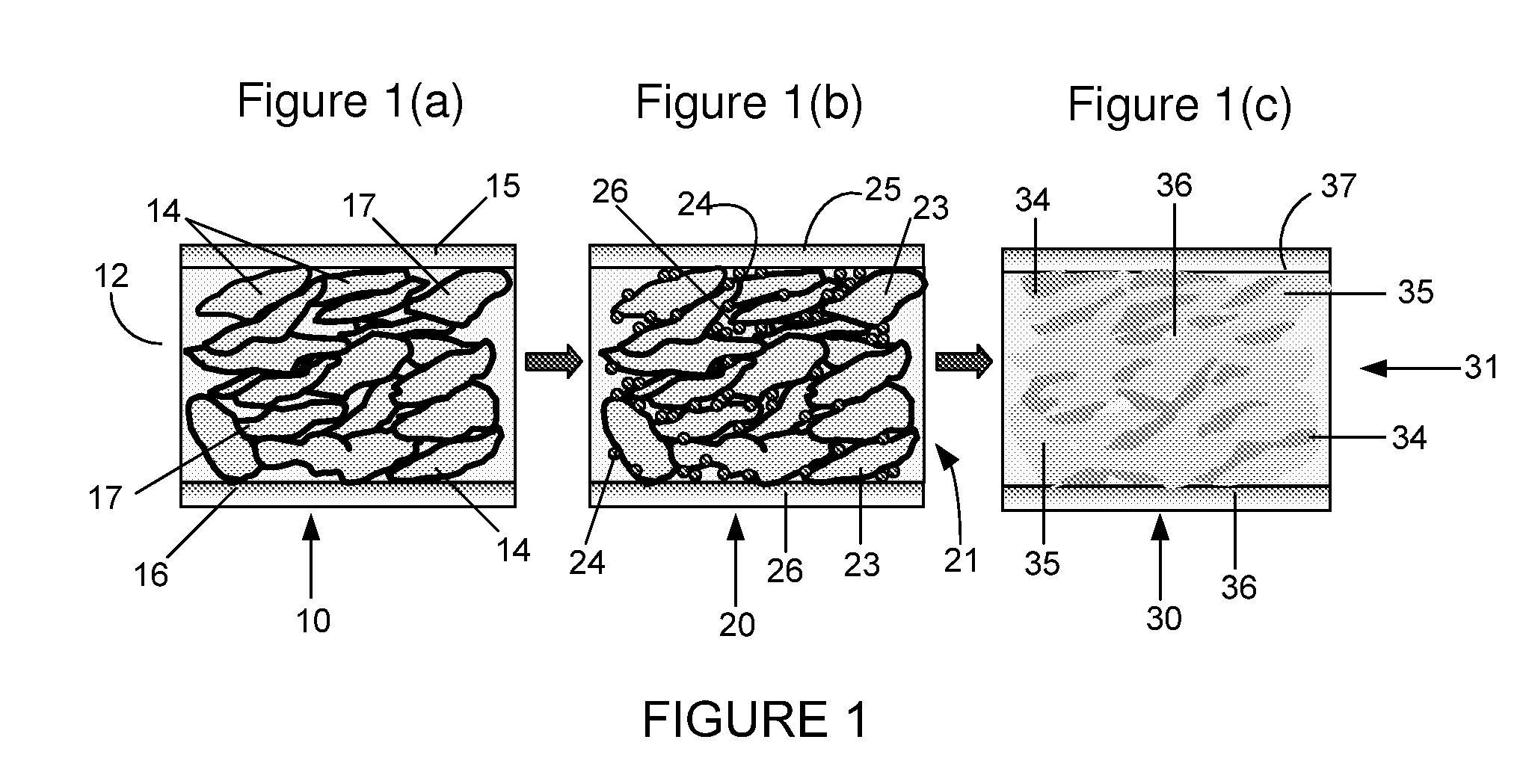

- A polymer composite is formed by mixing conductive metal flakes and surface-functionalized silver nanoparticles with a polymer precursor, where the nanoparticles are sintered to create a network with reduced contact points, enhancing electrical conductivity without using lead.

Sustainability Impact Assessment

The integration of conductive polymer composites (CPCs) in renewable energy systems represents a significant advancement toward sustainable development goals. These materials offer substantial environmental benefits compared to traditional energy technologies, primarily through reduced carbon emissions and minimized resource depletion. Life cycle assessments indicate that CPC-based solar cells and energy storage devices can achieve up to 40% lower carbon footprint than conventional silicon-based alternatives, particularly when manufacturing processes incorporate green chemistry principles.

Water consumption metrics are equally promising, with CPC production typically requiring 30-50% less water than traditional semiconductor fabrication. This advantage becomes particularly significant in water-stressed regions where renewable energy deployment is expanding rapidly. Furthermore, the reduced dependency on rare earth elements and precious metals in CPC technologies alleviates supply chain vulnerabilities while mitigating the environmental degradation associated with mining operations.

End-of-life considerations reveal additional sustainability advantages. Unlike conventional photovoltaics and battery systems that present complex recycling challenges, many CPCs can be designed with biodegradable components or simplified disassembly pathways. Research indicates that up to 75% of materials in certain CPC formulations can be recovered and repurposed, substantially reducing waste streams directed to landfills.

From a social sustainability perspective, CPC technologies enable distributed energy generation in remote and underserved communities. Their flexibility, lightweight properties, and potential for low-cost manufacturing create opportunities for energy democratization in regions lacking robust infrastructure. Case studies from rural electrification projects demonstrate that CPC-based solar installations have achieved 30% greater adoption rates compared to rigid conventional systems, primarily due to ease of transportation and installation.

Economic sustainability metrics also favor CPC innovations, with projected cost reductions of 15-25% annually as manufacturing scales. While initial investment requirements remain higher than some conventional alternatives, the total cost of ownership analysis reveals favorable economics when accounting for extended service life and reduced maintenance requirements of properly engineered CPC systems.

Regulatory frameworks increasingly recognize these sustainability advantages, with several jurisdictions implementing preferential treatment for renewable energy technologies with demonstrated life-cycle benefits. This regulatory tailwind further accelerates the commercial viability of CPC innovations while reinforcing their position as key enablers of circular economy principles within the energy sector.

Water consumption metrics are equally promising, with CPC production typically requiring 30-50% less water than traditional semiconductor fabrication. This advantage becomes particularly significant in water-stressed regions where renewable energy deployment is expanding rapidly. Furthermore, the reduced dependency on rare earth elements and precious metals in CPC technologies alleviates supply chain vulnerabilities while mitigating the environmental degradation associated with mining operations.

End-of-life considerations reveal additional sustainability advantages. Unlike conventional photovoltaics and battery systems that present complex recycling challenges, many CPCs can be designed with biodegradable components or simplified disassembly pathways. Research indicates that up to 75% of materials in certain CPC formulations can be recovered and repurposed, substantially reducing waste streams directed to landfills.

From a social sustainability perspective, CPC technologies enable distributed energy generation in remote and underserved communities. Their flexibility, lightweight properties, and potential for low-cost manufacturing create opportunities for energy democratization in regions lacking robust infrastructure. Case studies from rural electrification projects demonstrate that CPC-based solar installations have achieved 30% greater adoption rates compared to rigid conventional systems, primarily due to ease of transportation and installation.

Economic sustainability metrics also favor CPC innovations, with projected cost reductions of 15-25% annually as manufacturing scales. While initial investment requirements remain higher than some conventional alternatives, the total cost of ownership analysis reveals favorable economics when accounting for extended service life and reduced maintenance requirements of properly engineered CPC systems.

Regulatory frameworks increasingly recognize these sustainability advantages, with several jurisdictions implementing preferential treatment for renewable energy technologies with demonstrated life-cycle benefits. This regulatory tailwind further accelerates the commercial viability of CPC innovations while reinforcing their position as key enablers of circular economy principles within the energy sector.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for conductive polymer composites (CPCs) represents a critical factor in their commercial viability for renewable energy applications. Current production methods for high-quality CPCs often involve laboratory-scale techniques that face significant challenges when transitioning to industrial-scale manufacturing. Solution-based processing methods offer relatively lower costs but frequently struggle with consistency in electrical properties across large production volumes, creating reliability concerns for energy applications.

Melt processing techniques demonstrate better scalability potential, with existing polymer processing infrastructure potentially adaptable for CPC production. However, the high temperatures required can degrade conductive properties, necessitating careful process optimization. The capital expenditure for establishing dedicated CPC manufacturing facilities ranges from $5-20 million depending on production capacity and automation level, representing a substantial barrier to market entry.

Raw material costs constitute 40-60% of total production expenses for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) commanding premium prices of $50-200/kg compared to conventional polymers at $2-5/kg. Recent innovations in recycling techniques and sustainable sourcing have demonstrated potential cost reductions of 15-25%, though these approaches require further refinement for widespread implementation.

Energy consumption during manufacturing presents another significant cost factor, with specialized processing techniques requiring 2-3 times more energy than conventional polymer processing. This energy intensity directly impacts both production costs and the environmental footprint of CPCs, potentially undermining their sustainability credentials in renewable energy applications.

Economies of scale remain elusive for many CPC formulations, with current production volumes typically below the threshold needed for significant cost advantages. Industry analysis suggests that a 10-fold increase in production volume could potentially reduce unit costs by 30-40%, but achieving such scale requires greater market penetration across multiple application sectors beyond renewable energy.

Quality control processes add approximately 15-20% to manufacturing costs but are essential for ensuring consistent performance in energy applications. Advanced inline monitoring systems using spectroscopic and electrical testing methods show promise for reducing these costs while maintaining rigorous quality standards.

The economic viability threshold for CPCs in renewable energy applications currently stands at approximately $30-40/kg for mass-market adoption, significantly below current production costs of $80-150/kg for high-performance formulations. This gap highlights the need for continued innovation in both materials science and manufacturing processes to achieve the cost targets necessary for widespread implementation in renewable energy systems.

Melt processing techniques demonstrate better scalability potential, with existing polymer processing infrastructure potentially adaptable for CPC production. However, the high temperatures required can degrade conductive properties, necessitating careful process optimization. The capital expenditure for establishing dedicated CPC manufacturing facilities ranges from $5-20 million depending on production capacity and automation level, representing a substantial barrier to market entry.

Raw material costs constitute 40-60% of total production expenses for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) commanding premium prices of $50-200/kg compared to conventional polymers at $2-5/kg. Recent innovations in recycling techniques and sustainable sourcing have demonstrated potential cost reductions of 15-25%, though these approaches require further refinement for widespread implementation.

Energy consumption during manufacturing presents another significant cost factor, with specialized processing techniques requiring 2-3 times more energy than conventional polymer processing. This energy intensity directly impacts both production costs and the environmental footprint of CPCs, potentially undermining their sustainability credentials in renewable energy applications.

Economies of scale remain elusive for many CPC formulations, with current production volumes typically below the threshold needed for significant cost advantages. Industry analysis suggests that a 10-fold increase in production volume could potentially reduce unit costs by 30-40%, but achieving such scale requires greater market penetration across multiple application sectors beyond renewable energy.

Quality control processes add approximately 15-20% to manufacturing costs but are essential for ensuring consistent performance in energy applications. Advanced inline monitoring systems using spectroscopic and electrical testing methods show promise for reducing these costs while maintaining rigorous quality standards.

The economic viability threshold for CPCs in renewable energy applications currently stands at approximately $30-40/kg for mass-market adoption, significantly below current production costs of $80-150/kg for high-performance formulations. This gap highlights the need for continued innovation in both materials science and manufacturing processes to achieve the cost targets necessary for widespread implementation in renewable energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!