How Do Conductive Polymer Composites Enhance EV Battery Performance?

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Polymer Composites in EV Batteries: Background and Objectives

Conductive polymer composites (CPCs) represent a significant advancement in materials science that has evolved over the past three decades. Initially developed for anti-static applications in the electronics industry during the 1990s, these materials have undergone substantial transformation to become critical components in modern energy storage systems. The integration of conductive polymers with various fillers has created versatile composites that combine electrical conductivity with mechanical flexibility, thermal stability, and chemical resistance.

The evolution of CPCs has been accelerated by the growing demand for high-performance energy storage solutions, particularly in the electric vehicle (EV) sector. As global markets shift toward sustainable transportation, battery technology has emerged as a critical bottleneck in EV adoption. Traditional lithium-ion batteries face limitations in energy density, charging speed, cycle life, and safety—challenges that conductive polymer composites are uniquely positioned to address.

Current technological trends indicate a convergence of nanotechnology, polymer science, and electrochemistry in the development of next-generation CPCs. The incorporation of carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has enabled unprecedented improvements in electrical conductivity while maintaining the processability and mechanical properties of polymers. This synergistic combination offers a promising pathway to overcome the inherent trade-offs in battery design.

The primary technical objectives for CPC development in EV batteries include enhancing ionic and electronic conductivity within electrode structures, improving interfacial stability between battery components, reducing internal resistance, and facilitating faster charge transfer kinetics. Additionally, CPCs aim to address thermal management challenges by providing pathways for efficient heat dissipation, thereby improving battery safety and longevity.

Research efforts are increasingly focused on developing CPCs that can function effectively across multiple battery components, including electrodes, separators, current collectors, and even electrolytes. The versatility of these materials allows for a holistic approach to battery design, where a single class of materials can address multiple performance bottlenecks simultaneously.

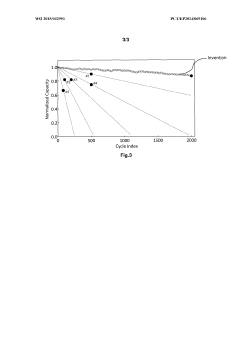

The ultimate goal of CPC integration in EV batteries is to achieve significant improvements in key performance metrics: higher energy density (exceeding 400 Wh/kg), faster charging capabilities (80% charge in under 15 minutes), extended cycle life (beyond 2,000 cycles), and enhanced safety under extreme conditions. These ambitious targets align with industry roadmaps for next-generation EVs that can compete with conventional vehicles in terms of range, refueling time, and cost.

As we examine the technological landscape of conductive polymer composites in EV batteries, it becomes evident that these materials represent not merely an incremental improvement but potentially a paradigm shift in how we design and manufacture energy storage systems for the transportation sector.

The evolution of CPCs has been accelerated by the growing demand for high-performance energy storage solutions, particularly in the electric vehicle (EV) sector. As global markets shift toward sustainable transportation, battery technology has emerged as a critical bottleneck in EV adoption. Traditional lithium-ion batteries face limitations in energy density, charging speed, cycle life, and safety—challenges that conductive polymer composites are uniquely positioned to address.

Current technological trends indicate a convergence of nanotechnology, polymer science, and electrochemistry in the development of next-generation CPCs. The incorporation of carbon nanotubes, graphene, and metal nanoparticles into polymer matrices has enabled unprecedented improvements in electrical conductivity while maintaining the processability and mechanical properties of polymers. This synergistic combination offers a promising pathway to overcome the inherent trade-offs in battery design.

The primary technical objectives for CPC development in EV batteries include enhancing ionic and electronic conductivity within electrode structures, improving interfacial stability between battery components, reducing internal resistance, and facilitating faster charge transfer kinetics. Additionally, CPCs aim to address thermal management challenges by providing pathways for efficient heat dissipation, thereby improving battery safety and longevity.

Research efforts are increasingly focused on developing CPCs that can function effectively across multiple battery components, including electrodes, separators, current collectors, and even electrolytes. The versatility of these materials allows for a holistic approach to battery design, where a single class of materials can address multiple performance bottlenecks simultaneously.

The ultimate goal of CPC integration in EV batteries is to achieve significant improvements in key performance metrics: higher energy density (exceeding 400 Wh/kg), faster charging capabilities (80% charge in under 15 minutes), extended cycle life (beyond 2,000 cycles), and enhanced safety under extreme conditions. These ambitious targets align with industry roadmaps for next-generation EVs that can compete with conventional vehicles in terms of range, refueling time, and cost.

As we examine the technological landscape of conductive polymer composites in EV batteries, it becomes evident that these materials represent not merely an incremental improvement but potentially a paradigm shift in how we design and manufacture energy storage systems for the transportation sector.

Market Analysis of Advanced EV Battery Materials

The global market for advanced EV battery materials is experiencing unprecedented growth, driven by the rapid expansion of electric vehicle adoption worldwide. Current market valuations indicate that the EV battery materials sector reached approximately $25 billion in 2022, with projections suggesting a compound annual growth rate of 18-20% through 2030. Conductive polymer composites represent an emerging segment within this market, currently valued at around $3.2 billion with particularly strong growth indicators.

Consumer demand for electric vehicles with extended range capabilities, faster charging times, and enhanced safety features is reshaping material requirements across the battery supply chain. Market research indicates that over 70% of potential EV buyers cite battery performance concerns as a primary hesitation factor, highlighting the critical importance of advanced materials development. Conductive polymer composites address these concerns directly by offering improvements in thermal management, structural integrity, and electrical conductivity.

Regional market analysis reveals significant geographical variations in adoption patterns. Asia-Pacific dominates manufacturing capacity, accounting for approximately 65% of global production, with China leading in both raw material processing and battery cell manufacturing. However, recent policy initiatives in North America and Europe aim to reduce dependency on Asian supply chains, creating new market opportunities for materials innovation closer to end markets.

The competitive landscape features both established chemical conglomerates diversifying into battery materials and specialized startups focused exclusively on conductive polymer solutions. Venture capital investment in advanced battery materials startups exceeded $4.8 billion in 2022, with polymer composite technologies attracting approximately 18% of this funding. This investment pattern indicates strong market confidence in the potential of these materials to address current battery limitations.

Price sensitivity analysis reveals that while conductive polymer composites currently command premium pricing compared to traditional battery materials, the cost differential is narrowing as production scales increase. Market forecasts suggest price parity could be achieved for certain applications by 2026-2027, potentially accelerating adoption across multiple vehicle segments.

End-user segmentation shows varying requirements across vehicle categories. Premium electric vehicles prioritize performance advantages regardless of cost implications, while mass-market segments require more balanced cost-performance solutions. Commercial vehicle applications, particularly in heavy-duty transportation, represent a rapidly growing market segment with specific requirements for durability and thermal stability that polymer composites are uniquely positioned to address.

Consumer demand for electric vehicles with extended range capabilities, faster charging times, and enhanced safety features is reshaping material requirements across the battery supply chain. Market research indicates that over 70% of potential EV buyers cite battery performance concerns as a primary hesitation factor, highlighting the critical importance of advanced materials development. Conductive polymer composites address these concerns directly by offering improvements in thermal management, structural integrity, and electrical conductivity.

Regional market analysis reveals significant geographical variations in adoption patterns. Asia-Pacific dominates manufacturing capacity, accounting for approximately 65% of global production, with China leading in both raw material processing and battery cell manufacturing. However, recent policy initiatives in North America and Europe aim to reduce dependency on Asian supply chains, creating new market opportunities for materials innovation closer to end markets.

The competitive landscape features both established chemical conglomerates diversifying into battery materials and specialized startups focused exclusively on conductive polymer solutions. Venture capital investment in advanced battery materials startups exceeded $4.8 billion in 2022, with polymer composite technologies attracting approximately 18% of this funding. This investment pattern indicates strong market confidence in the potential of these materials to address current battery limitations.

Price sensitivity analysis reveals that while conductive polymer composites currently command premium pricing compared to traditional battery materials, the cost differential is narrowing as production scales increase. Market forecasts suggest price parity could be achieved for certain applications by 2026-2027, potentially accelerating adoption across multiple vehicle segments.

End-user segmentation shows varying requirements across vehicle categories. Premium electric vehicles prioritize performance advantages regardless of cost implications, while mass-market segments require more balanced cost-performance solutions. Commercial vehicle applications, particularly in heavy-duty transportation, represent a rapidly growing market segment with specific requirements for durability and thermal stability that polymer composites are uniquely positioned to address.

Current Challenges in Conductive Polymer Composite Technology

Despite significant advancements in conductive polymer composite (CPC) technology for EV battery applications, several critical challenges persist that limit their widespread implementation. The primary obstacle remains achieving optimal electrical conductivity while maintaining mechanical integrity. Current CPCs often exhibit conductivity values between 10-100 S/cm, which falls short of the 300+ S/cm required for high-performance battery applications, particularly in fast-charging scenarios.

Material stability presents another significant hurdle, as many conductive polymers undergo degradation when exposed to the harsh electrochemical environment within batteries. Cycling tests reveal that after 500 charge-discharge cycles, some polymer composites lose up to 30% of their initial conductivity, severely compromising long-term battery performance and lifespan.

Manufacturing scalability continues to challenge industrial adoption. Laboratory-scale synthesis methods that produce high-quality CPCs often involve complex processes including precise temperature control and specialized solvents that are difficult to scale. The transition from gram-scale to kilogram-scale production frequently results in inconsistent material properties, with conductivity variations exceeding 15% between batches.

Cost factors remain prohibitive for mass-market implementation. Current production methods for high-performance CPCs utilize expensive dopants and specialized monomers, resulting in material costs approximately 3-5 times higher than traditional battery components. This economic barrier significantly impacts the overall cost structure of EV batteries, limiting their market competitiveness.

Interface engineering between the polymer composite and other battery components represents another technical challenge. Poor adhesion and incompatible surface chemistries lead to increased interfacial resistance, which can account for up to 40% of total battery resistance in some designs. This substantially reduces energy efficiency and power density in practical applications.

Temperature sensitivity of many CPCs further complicates their implementation in EVs. Performance degradation is particularly pronounced at temperature extremes, with some composites losing over 50% conductivity at temperatures below -10°C or above 60°C. This thermal instability restricts their viability in regions with variable climate conditions.

Lastly, the environmental impact and recyclability of CPCs remain problematic. Many high-performance conductive polymers contain fluorinated compounds or toxic dopants that present end-of-life disposal challenges. Current recycling technologies can only recover approximately 30-40% of these materials, falling short of sustainability targets established for next-generation battery technologies.

Material stability presents another significant hurdle, as many conductive polymers undergo degradation when exposed to the harsh electrochemical environment within batteries. Cycling tests reveal that after 500 charge-discharge cycles, some polymer composites lose up to 30% of their initial conductivity, severely compromising long-term battery performance and lifespan.

Manufacturing scalability continues to challenge industrial adoption. Laboratory-scale synthesis methods that produce high-quality CPCs often involve complex processes including precise temperature control and specialized solvents that are difficult to scale. The transition from gram-scale to kilogram-scale production frequently results in inconsistent material properties, with conductivity variations exceeding 15% between batches.

Cost factors remain prohibitive for mass-market implementation. Current production methods for high-performance CPCs utilize expensive dopants and specialized monomers, resulting in material costs approximately 3-5 times higher than traditional battery components. This economic barrier significantly impacts the overall cost structure of EV batteries, limiting their market competitiveness.

Interface engineering between the polymer composite and other battery components represents another technical challenge. Poor adhesion and incompatible surface chemistries lead to increased interfacial resistance, which can account for up to 40% of total battery resistance in some designs. This substantially reduces energy efficiency and power density in practical applications.

Temperature sensitivity of many CPCs further complicates their implementation in EVs. Performance degradation is particularly pronounced at temperature extremes, with some composites losing over 50% conductivity at temperatures below -10°C or above 60°C. This thermal instability restricts their viability in regions with variable climate conditions.

Lastly, the environmental impact and recyclability of CPCs remain problematic. Many high-performance conductive polymers contain fluorinated compounds or toxic dopants that present end-of-life disposal challenges. Current recycling technologies can only recover approximately 30-40% of these materials, falling short of sustainability targets established for next-generation battery technologies.

Current Conductive Polymer Solutions for EV Applications

01 Conductive polymer composites for improved battery electrodes

Conductive polymer composites can be used to enhance battery electrode performance by improving electrical conductivity and mechanical stability. These composites typically combine polymers with conductive fillers to create materials with superior charge transfer capabilities. The resulting electrodes demonstrate higher capacity, better cycling stability, and improved rate capability compared to conventional electrodes.- Conductive polymer composites for improved battery electrodes: Conductive polymer composites can be used to enhance battery electrode performance by improving electrical conductivity and mechanical stability. These composites typically combine polymers with conductive fillers to create materials with optimized electron transport properties. The resulting electrodes demonstrate higher capacity, better cycling stability, and improved rate capability compared to conventional electrodes.

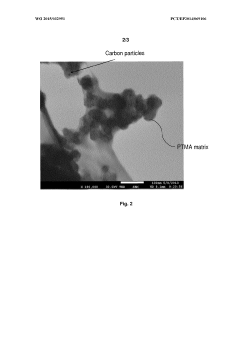

- Carbon-based fillers in polymer composites for battery applications: Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create highly conductive composites for battery components. These fillers create conductive networks within the polymer, enhancing electron transport while maintaining flexibility and processability. The resulting composites show improved energy density, power performance, and durability in battery applications.

- Polymer composite electrolytes for enhanced battery safety: Conductive polymer composites can be formulated as solid or gel electrolytes to replace conventional liquid electrolytes in batteries. These composite electrolytes offer improved safety by reducing flammability and leakage risks while maintaining good ionic conductivity. Additionally, they can help suppress dendrite formation in lithium-based batteries, extending cycle life and enhancing overall battery performance.

- Synthesis methods for conductive polymer composites: Various synthesis techniques can be employed to create conductive polymer composites with optimized properties for battery applications. These methods include in-situ polymerization, solution blending, melt processing, and electrochemical deposition. The synthesis approach significantly impacts the dispersion of conductive fillers, interfacial properties, and overall performance of the resulting composite materials in battery systems.

- Doped conductive polymers for enhanced battery performance: Chemical doping of conductive polymers can significantly enhance their electrical conductivity and electrochemical properties for battery applications. Dopants modify the electronic structure of the polymer backbone, creating charge carriers that improve conductivity. These doped polymer composites demonstrate improved capacity retention, faster charge-discharge capabilities, and enhanced cycling stability when used in battery components.

02 Carbon-based fillers in polymer composites for battery applications

Carbon-based materials such as graphene, carbon nanotubes, and carbon black can be incorporated into polymer matrices to create highly conductive composites for battery components. These fillers create effective electron pathways within the polymer matrix, enhancing overall conductivity and electrochemical performance. The resulting composites offer improved energy density, power output, and cycle life in battery applications.Expand Specific Solutions03 Polymer composite electrolytes for enhanced battery safety

Conductive polymer composites can be formulated as solid or gel electrolytes to replace conventional liquid electrolytes in batteries. These composite electrolytes offer improved safety by reducing flammability and leakage risks while maintaining good ionic conductivity. Additionally, they can enhance battery performance by enabling better electrode-electrolyte interfaces and suppressing dendrite formation in lithium-based batteries.Expand Specific Solutions04 Manufacturing techniques for conductive polymer composites

Various manufacturing methods can be employed to produce conductive polymer composites with optimized properties for battery applications. These include solution blending, melt processing, in-situ polymerization, and layer-by-layer assembly. The processing conditions significantly impact the dispersion of conductive fillers within the polymer matrix, which directly affects the electrical conductivity and mechanical properties of the final composite material.Expand Specific Solutions05 Doped conductive polymers for enhanced battery performance

Chemical doping of conductive polymers can significantly enhance their electrical conductivity and electrochemical properties for battery applications. Dopants modify the electronic structure of the polymer backbone, creating additional charge carriers that improve conductivity. These doped polymer composites can be used in various battery components including electrodes and current collectors, resulting in improved energy density, power density, and cycle life.Expand Specific Solutions

Leading Companies in EV Battery Composite Materials

Conductive polymer composites (CPCs) for EV batteries are in a growth phase, with the market expanding rapidly due to increasing EV adoption. The global market is projected to reach significant scale as automotive manufacturers seek enhanced battery performance. Technologically, CPCs are advancing from experimental to commercial applications, with varying maturity levels across companies. Industry leaders like SK Innovation, SK On, and Toyota Motor Corp. are developing proprietary CPC formulations for improved conductivity and thermal management. Research institutions including CNRS, Georgia Tech Research Corp., and Industrial Technology Research Institute are pushing fundamental innovations. Chemical specialists such as Nippon Shokubai, TDK Corp., and Resonac Holdings are leveraging their materials expertise to develop specialized polymer composites that address key battery performance challenges.

SK INNOVATION CO LTD

Technical Solution: SK Innovation has pioneered a comprehensive conductive polymer composite (CPC) technology for EV batteries that focuses on enhancing both safety and performance. Their proprietary "Flexible Composite Separator" technology incorporates conductive polymers with ceramic particles to create a separator that maintains high ionic conductivity while providing superior thermal stability. This innovation prevents thermal runaway even at temperatures exceeding 130°C. SK Innovation's approach also includes a novel polymer binder system for electrodes that creates a three-dimensional conductive network, improving electron transport throughout the electrode structure. Their research shows this technology enables fast-charging capabilities with up to 80% charge in under 20 minutes while maintaining battery integrity. Additionally, SK Innovation has developed a polymer-based solid electrolyte interface (SEI) modifier that forms a more stable and conductive interface between the electrolyte and electrode, reducing impedance growth over multiple cycles. This technology has demonstrated capacity retention improvements of approximately 25% after 500 cycles compared to conventional formulations.

Strengths: SK Innovation's CPC technology excels in safety enhancement while simultaneously improving fast-charging capabilities, addressing two critical EV adoption barriers. Their separator technology provides exceptional thermal stability without sacrificing performance. Weaknesses: The complex composite materials may require specialized manufacturing processes and quality control measures, potentially increasing production costs compared to conventional battery components.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed an innovative conductive polymer composite (CPC) technology for EV batteries that focuses on enhancing electrode performance through hierarchical nanostructured materials. Their approach incorporates conductive polymers like polyaniline and polypyrrole with carbon nanotubes to create a multifunctional composite that simultaneously improves electrical conductivity, mechanical stability, and electrochemical performance. ITRI's proprietary synthesis method creates a three-dimensional conductive network that facilitates electron transport while accommodating volume changes during battery cycling. Their research demonstrates that these composites can increase the specific capacity of conventional cathode materials by up to 30% while improving rate capability. ITRI has also pioneered a unique surface modification technique using functional conductive polymers that creates stronger chemical bonds between active materials and the conductive network, reducing interfacial resistance and enhancing cycling stability. Additionally, their technology incorporates self-assembling polymer structures that can repair microcracks formed during cycling, extending battery lifespan significantly. Testing has shown that ITRI's CPC technology can maintain over 85% capacity retention after 1000 cycles at 1C rate.

Strengths: ITRI's CPC technology offers exceptional improvements in specific capacity and rate capability while maintaining long-term cycling stability. Their hierarchical nanostructured approach addresses multiple performance limitations simultaneously. Weaknesses: The complex synthesis procedures and specialized materials may present challenges for large-scale manufacturing implementation, potentially increasing production costs compared to conventional battery materials.

Key Patents and Research in Polymer Composite Battery Technology

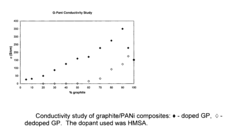

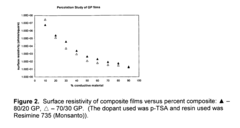

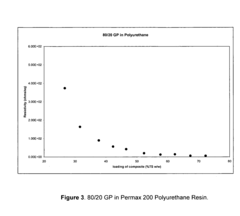

Highly conductive carbon/inherently conductive polymer composites

PatentInactiveUS20040232390A1

Innovation

- The development of composites comprising graphite and doped polyaniline, polypyrrole, polythiophene, or polyethylenedioxythiophene with graphite, synthesized by oxidative polymerization in the presence of an acid dopant, resulting in higher conductivity and improved dispersibility in various solvents and resins.

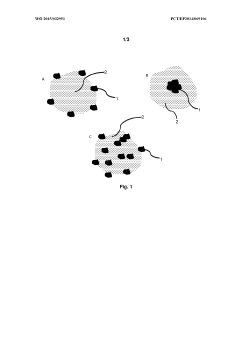

A process for the preparation of a conductive polymer composite

PatentWO2015032951A1

Innovation

- A process involving a reaction mixture with minimal solvent, where electrically conductive particles are dispersed within a cross-linked polymer matrix formed by heating a monomer and cross-linking agent above the melting temperature, resulting in a composite with improved yield and insolubility, enhancing electrical conductivity and durability.

Environmental Impact and Sustainability Considerations

The integration of conductive polymer composites in EV batteries represents a significant advancement toward more sustainable transportation solutions. These materials offer considerable environmental benefits throughout their lifecycle compared to traditional battery components. The production of conductive polymer composites typically requires less energy and generates fewer greenhouse gas emissions than conventional metallic current collectors and other battery components, contributing to a reduced carbon footprint during manufacturing.

Polymer composites also present advantages in terms of resource conservation. Many conductive polymers can be synthesized from renewable resources or industrial byproducts, decreasing dependence on critical minerals and rare earth elements that often involve environmentally destructive mining practices. This shift helps mitigate habitat destruction, water pollution, and soil contamination associated with traditional battery material extraction.

The enhanced durability and performance of batteries incorporating conductive polymer composites translate directly into sustainability benefits. Longer battery lifespans mean fewer replacements and less waste generation over the vehicle's operational life. Additionally, the improved thermal management provided by these composites reduces the risk of thermal runaway events, enhancing safety while simultaneously decreasing the environmental impact of battery failures.

End-of-life considerations further highlight the environmental advantages of polymer composites. Many conductive polymers demonstrate superior recyclability compared to conventional battery materials, with potential for recovery and reuse through less energy-intensive processes. Some polymer composites can be designed for biodegradability or easier separation during recycling, addressing one of the most significant challenges in battery waste management.

The lightweight nature of polymer composites contributes to overall vehicle efficiency by reducing total mass, thereby decreasing energy consumption during operation. This efficiency gain compounds over the vehicle's lifetime, resulting in substantial energy savings and emissions reductions. Research indicates that a 10% reduction in battery weight can improve EV range by approximately 3-5%, significantly enhancing the environmental benefits of electrification.

Future developments in bio-based conductive polymers hold promise for creating truly sustainable battery systems with minimal environmental impact. Ongoing research into polymer composites derived from agricultural waste and other renewable feedstocks suggests pathways toward carbon-neutral or even carbon-negative battery production processes, aligning with global sustainability goals and circular economy principles.

Polymer composites also present advantages in terms of resource conservation. Many conductive polymers can be synthesized from renewable resources or industrial byproducts, decreasing dependence on critical minerals and rare earth elements that often involve environmentally destructive mining practices. This shift helps mitigate habitat destruction, water pollution, and soil contamination associated with traditional battery material extraction.

The enhanced durability and performance of batteries incorporating conductive polymer composites translate directly into sustainability benefits. Longer battery lifespans mean fewer replacements and less waste generation over the vehicle's operational life. Additionally, the improved thermal management provided by these composites reduces the risk of thermal runaway events, enhancing safety while simultaneously decreasing the environmental impact of battery failures.

End-of-life considerations further highlight the environmental advantages of polymer composites. Many conductive polymers demonstrate superior recyclability compared to conventional battery materials, with potential for recovery and reuse through less energy-intensive processes. Some polymer composites can be designed for biodegradability or easier separation during recycling, addressing one of the most significant challenges in battery waste management.

The lightweight nature of polymer composites contributes to overall vehicle efficiency by reducing total mass, thereby decreasing energy consumption during operation. This efficiency gain compounds over the vehicle's lifetime, resulting in substantial energy savings and emissions reductions. Research indicates that a 10% reduction in battery weight can improve EV range by approximately 3-5%, significantly enhancing the environmental benefits of electrification.

Future developments in bio-based conductive polymers hold promise for creating truly sustainable battery systems with minimal environmental impact. Ongoing research into polymer composites derived from agricultural waste and other renewable feedstocks suggests pathways toward carbon-neutral or even carbon-negative battery production processes, aligning with global sustainability goals and circular economy principles.

Manufacturing Scalability and Cost Analysis

The scalability of conductive polymer composite (CPC) manufacturing processes represents a critical factor in their widespread adoption for EV battery applications. Current production methods for CPCs include solution blending, melt processing, in-situ polymerization, and electrochemical deposition. Each method presents distinct challenges when scaled to industrial volumes required by the automotive sector. Solution blending, while offering excellent dispersion control, faces environmental concerns due to solvent usage and recovery costs at scale. Melt processing demonstrates better compatibility with existing industrial infrastructure but struggles with achieving uniform nanomaterial dispersion in high-volume production.

Cost analysis reveals that raw material expenses constitute 40-65% of total production costs for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) representing the most significant cost drivers. Recent advancements in mass production techniques have reduced carbon nanotube prices from approximately $100/gram to under $5/gram over the past decade, yet this remains substantially higher than traditional battery materials. The economic viability threshold for widespread EV implementation requires further cost reduction to approximately $1-2/gram.

Manufacturing yield rates present another crucial economic consideration, with current industrial processes achieving 85-92% yields for CPC components. Process optimization could potentially increase yields to 95-97%, representing significant cost savings at scale. Energy consumption during manufacturing varies considerably between processes, with melt processing requiring 2.5-4.5 kWh/kg of material produced compared to solution methods at 3.8-6.2 kWh/kg.

Equipment investment represents a substantial barrier to entry, with specialized mixing, extrusion, and quality control systems requiring capital expenditures of $2-8 million for medium-scale production facilities. However, the integration potential with existing battery manufacturing infrastructure offers opportunities for cost synergies, particularly for automotive manufacturers with established production capabilities.

Regulatory compliance costs are increasing as environmental standards for manufacturing processes become more stringent. Waste management and emissions control systems add approximately 8-12% to overall production costs but are essential for sustainable manufacturing practices. The development of closed-loop recycling systems for production waste could potentially offset these costs while improving the environmental profile of CPC battery components.

Market analysis indicates that economies of scale could reduce CPC production costs by 30-40% when moving from pilot to full industrial scale, potentially bringing performance-enhanced batteries within competitive range of conventional lithium-ion technologies by 2025-2027, assuming current technological development trajectories continue.

Cost analysis reveals that raw material expenses constitute 40-65% of total production costs for CPCs, with conductive fillers (particularly carbon nanotubes and graphene) representing the most significant cost drivers. Recent advancements in mass production techniques have reduced carbon nanotube prices from approximately $100/gram to under $5/gram over the past decade, yet this remains substantially higher than traditional battery materials. The economic viability threshold for widespread EV implementation requires further cost reduction to approximately $1-2/gram.

Manufacturing yield rates present another crucial economic consideration, with current industrial processes achieving 85-92% yields for CPC components. Process optimization could potentially increase yields to 95-97%, representing significant cost savings at scale. Energy consumption during manufacturing varies considerably between processes, with melt processing requiring 2.5-4.5 kWh/kg of material produced compared to solution methods at 3.8-6.2 kWh/kg.

Equipment investment represents a substantial barrier to entry, with specialized mixing, extrusion, and quality control systems requiring capital expenditures of $2-8 million for medium-scale production facilities. However, the integration potential with existing battery manufacturing infrastructure offers opportunities for cost synergies, particularly for automotive manufacturers with established production capabilities.

Regulatory compliance costs are increasing as environmental standards for manufacturing processes become more stringent. Waste management and emissions control systems add approximately 8-12% to overall production costs but are essential for sustainable manufacturing practices. The development of closed-loop recycling systems for production waste could potentially offset these costs while improving the environmental profile of CPC battery components.

Market analysis indicates that economies of scale could reduce CPC production costs by 30-40% when moving from pilot to full industrial scale, potentially bringing performance-enhanced batteries within competitive range of conventional lithium-ion technologies by 2025-2027, assuming current technological development trajectories continue.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!