Autoclave Pressure Vessel Assessments: Design and Safety Impacts

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Pressure Vessel Technology Evolution and Objectives

Autoclave pressure vessels have evolved significantly since their inception in the early 20th century. Initially designed for basic sterilization processes in medical and food industries, these vessels have transformed into sophisticated engineering systems capable of withstanding extreme pressures and temperatures. The evolution trajectory shows a clear shift from rudimentary pressure containment designs to advanced composite material vessels with integrated monitoring systems.

The 1950s marked a pivotal era when standardized design codes such as ASME Boiler and Pressure Vessel Code were established, providing the first comprehensive framework for pressure vessel design and safety. This standardization catalyzed rapid technological advancement, enabling more precise engineering calculations and material specifications.

By the 1970s and 1980s, computational methods began revolutionizing autoclave design. Finite Element Analysis (FEA) allowed engineers to model stress distributions and predict failure modes with unprecedented accuracy. This computational revolution coincided with material science breakthroughs, particularly in high-strength alloys and later composite materials, dramatically improving pressure-to-weight ratios.

The digital transformation of the 1990s and 2000s introduced real-time monitoring capabilities, with embedded sensors providing continuous data on critical parameters such as temperature gradients, pressure fluctuations, and structural integrity. This shift from periodic inspection to continuous monitoring represents a fundamental change in safety philosophy.

Current technological objectives focus on several key areas. First, enhancing energy efficiency through improved insulation technologies and heat recovery systems to reduce operational costs and environmental impact. Second, developing more sophisticated predictive maintenance algorithms using machine learning to anticipate potential failures before they occur, thereby extending service life and improving safety margins.

Another critical objective involves advancing material science applications, particularly in developing composite materials capable of withstanding higher pressures while maintaining structural integrity over longer operational lifespans. Research into nanomaterials and advanced ceramics shows promising results for next-generation pressure vessels.

Safety enhancement remains a paramount objective, with emphasis on fail-safe mechanisms and redundant safety systems. Modern design approaches increasingly incorporate risk-based methodologies that quantify and mitigate potential failure scenarios throughout the vessel's lifecycle.

The industry is also pursuing greater automation in manufacturing processes to improve consistency and reduce human error in fabrication. Additive manufacturing techniques are being explored for complex components, potentially revolutionizing how pressure vessels are produced and maintained.

The 1950s marked a pivotal era when standardized design codes such as ASME Boiler and Pressure Vessel Code were established, providing the first comprehensive framework for pressure vessel design and safety. This standardization catalyzed rapid technological advancement, enabling more precise engineering calculations and material specifications.

By the 1970s and 1980s, computational methods began revolutionizing autoclave design. Finite Element Analysis (FEA) allowed engineers to model stress distributions and predict failure modes with unprecedented accuracy. This computational revolution coincided with material science breakthroughs, particularly in high-strength alloys and later composite materials, dramatically improving pressure-to-weight ratios.

The digital transformation of the 1990s and 2000s introduced real-time monitoring capabilities, with embedded sensors providing continuous data on critical parameters such as temperature gradients, pressure fluctuations, and structural integrity. This shift from periodic inspection to continuous monitoring represents a fundamental change in safety philosophy.

Current technological objectives focus on several key areas. First, enhancing energy efficiency through improved insulation technologies and heat recovery systems to reduce operational costs and environmental impact. Second, developing more sophisticated predictive maintenance algorithms using machine learning to anticipate potential failures before they occur, thereby extending service life and improving safety margins.

Another critical objective involves advancing material science applications, particularly in developing composite materials capable of withstanding higher pressures while maintaining structural integrity over longer operational lifespans. Research into nanomaterials and advanced ceramics shows promising results for next-generation pressure vessels.

Safety enhancement remains a paramount objective, with emphasis on fail-safe mechanisms and redundant safety systems. Modern design approaches increasingly incorporate risk-based methodologies that quantify and mitigate potential failure scenarios throughout the vessel's lifecycle.

The industry is also pursuing greater automation in manufacturing processes to improve consistency and reduce human error in fabrication. Additive manufacturing techniques are being explored for complex components, potentially revolutionizing how pressure vessels are produced and maintained.

Market Analysis for Autoclave Pressure Vessel Applications

The global autoclave pressure vessel market is experiencing robust growth, driven primarily by expanding applications across aerospace, healthcare, composite manufacturing, and industrial processing sectors. Current market valuation stands at approximately 2.3 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by increasing demand for advanced materials processing capabilities and stringent safety requirements across industries.

The aerospace sector represents the largest market segment, accounting for nearly 32% of total demand. This dominance stems from the critical role autoclaves play in manufacturing composite components for aircraft structures, where precise pressure and temperature control are essential for producing high-performance parts. The healthcare sector follows closely, with sterilization applications driving consistent demand growth as healthcare facilities worldwide expand their capacities.

Regional analysis reveals North America as the leading market, holding approximately 38% market share due to its advanced aerospace and medical industries. Asia-Pacific demonstrates the fastest growth rate at 7.2% annually, fueled by rapid industrialization in China and India, alongside expanding manufacturing capabilities in composite materials and medical equipment.

Market dynamics are significantly influenced by regulatory frameworks governing pressure vessel safety standards. The ASME Boiler and Pressure Vessel Code in North America and the Pressure Equipment Directive in Europe have established stringent design and operational requirements that directly impact product development and market entry barriers. These regulations continue to evolve toward more rigorous safety protocols, creating both challenges and opportunities for manufacturers.

Customer requirements are increasingly focused on energy efficiency, automation capabilities, and enhanced safety features. The trend toward larger capacity vessels with improved monitoring systems represents a key market driver, particularly in industrial processing applications where operational efficiency directly impacts production economics.

Pricing trends indicate moderate increases of 3-4% annually, primarily attributed to rising material costs and the integration of advanced control systems. However, competitive pressures are intensifying as new market entrants from emerging economies introduce more cost-effective solutions, particularly in standard-sized vessels for less demanding applications.

The aftermarket service segment presents substantial growth potential, with maintenance, recertification, and retrofitting services accounting for approximately 22% of total market revenue. This segment is expected to expand as the installed base grows and aging equipment requires updates to meet evolving safety standards and operational requirements.

The aerospace sector represents the largest market segment, accounting for nearly 32% of total demand. This dominance stems from the critical role autoclaves play in manufacturing composite components for aircraft structures, where precise pressure and temperature control are essential for producing high-performance parts. The healthcare sector follows closely, with sterilization applications driving consistent demand growth as healthcare facilities worldwide expand their capacities.

Regional analysis reveals North America as the leading market, holding approximately 38% market share due to its advanced aerospace and medical industries. Asia-Pacific demonstrates the fastest growth rate at 7.2% annually, fueled by rapid industrialization in China and India, alongside expanding manufacturing capabilities in composite materials and medical equipment.

Market dynamics are significantly influenced by regulatory frameworks governing pressure vessel safety standards. The ASME Boiler and Pressure Vessel Code in North America and the Pressure Equipment Directive in Europe have established stringent design and operational requirements that directly impact product development and market entry barriers. These regulations continue to evolve toward more rigorous safety protocols, creating both challenges and opportunities for manufacturers.

Customer requirements are increasingly focused on energy efficiency, automation capabilities, and enhanced safety features. The trend toward larger capacity vessels with improved monitoring systems represents a key market driver, particularly in industrial processing applications where operational efficiency directly impacts production economics.

Pricing trends indicate moderate increases of 3-4% annually, primarily attributed to rising material costs and the integration of advanced control systems. However, competitive pressures are intensifying as new market entrants from emerging economies introduce more cost-effective solutions, particularly in standard-sized vessels for less demanding applications.

The aftermarket service segment presents substantial growth potential, with maintenance, recertification, and retrofitting services accounting for approximately 22% of total market revenue. This segment is expected to expand as the installed base grows and aging equipment requires updates to meet evolving safety standards and operational requirements.

Current Challenges in Pressure Vessel Assessment Methodologies

Despite significant advancements in pressure vessel assessment methodologies, the industry continues to face several critical challenges that impact design integrity and safety assurance. Traditional assessment approaches often rely on simplified analytical models that fail to fully capture the complex stress distributions and material behaviors under extreme operating conditions. This limitation becomes particularly evident when evaluating autoclave vessels subjected to cyclic loading, high-temperature gradients, and corrosive environments simultaneously.

One persistent challenge is the accurate prediction of creep-fatigue interaction in pressure vessel materials during long-term operation. Current methodologies struggle to integrate time-dependent material degradation with cyclic stress effects, leading to potential underestimation of damage accumulation. This gap becomes more pronounced for modern high-performance alloys whose behavior under combined loading mechanisms remains incompletely characterized in industry standards.

The assessment of weld integrity presents another significant hurdle. Welds represent critical discontinuities in pressure vessel structures, yet current evaluation methods often apply simplified approaches that inadequately address residual stress distributions, microstructural variations, and localized property changes in heat-affected zones. This simplification can lead to either overly conservative designs or, more concerning, unidentified vulnerability points.

Computational limitations continue to constrain comprehensive assessment capabilities. While finite element analysis (FEA) has become more sophisticated, the computational demands for fully-coupled multiphysics simulations—incorporating thermal, mechanical, and chemical interactions—remain prohibitive for routine industrial applications. This forces practitioners to make simplifying assumptions that may compromise assessment accuracy.

Risk-based inspection (RBI) methodologies, though increasingly adopted, face implementation challenges due to insufficient historical failure data for newer vessel designs and materials. The statistical foundations for probability of failure calculations often rely on limited datasets, introducing uncertainty into remaining life predictions and inspection interval determinations.

Emerging manufacturing techniques, particularly additive manufacturing for pressure vessel components, have outpaced the development of corresponding assessment protocols. Current methodologies inadequately address the unique microstructural characteristics, property anisotropy, and defect distributions inherent to additively manufactured parts, creating significant uncertainty in fitness-for-service evaluations.

Regulatory fragmentation across global markets further complicates assessment standardization. Divergent requirements between ASME, PED, JIS, and other international codes create compliance challenges for globally distributed equipment, sometimes leading to conflicting assessment outcomes for identical technical scenarios.

One persistent challenge is the accurate prediction of creep-fatigue interaction in pressure vessel materials during long-term operation. Current methodologies struggle to integrate time-dependent material degradation with cyclic stress effects, leading to potential underestimation of damage accumulation. This gap becomes more pronounced for modern high-performance alloys whose behavior under combined loading mechanisms remains incompletely characterized in industry standards.

The assessment of weld integrity presents another significant hurdle. Welds represent critical discontinuities in pressure vessel structures, yet current evaluation methods often apply simplified approaches that inadequately address residual stress distributions, microstructural variations, and localized property changes in heat-affected zones. This simplification can lead to either overly conservative designs or, more concerning, unidentified vulnerability points.

Computational limitations continue to constrain comprehensive assessment capabilities. While finite element analysis (FEA) has become more sophisticated, the computational demands for fully-coupled multiphysics simulations—incorporating thermal, mechanical, and chemical interactions—remain prohibitive for routine industrial applications. This forces practitioners to make simplifying assumptions that may compromise assessment accuracy.

Risk-based inspection (RBI) methodologies, though increasingly adopted, face implementation challenges due to insufficient historical failure data for newer vessel designs and materials. The statistical foundations for probability of failure calculations often rely on limited datasets, introducing uncertainty into remaining life predictions and inspection interval determinations.

Emerging manufacturing techniques, particularly additive manufacturing for pressure vessel components, have outpaced the development of corresponding assessment protocols. Current methodologies inadequately address the unique microstructural characteristics, property anisotropy, and defect distributions inherent to additively manufactured parts, creating significant uncertainty in fitness-for-service evaluations.

Regulatory fragmentation across global markets further complicates assessment standardization. Divergent requirements between ASME, PED, JIS, and other international codes create compliance challenges for globally distributed equipment, sometimes leading to conflicting assessment outcomes for identical technical scenarios.

Contemporary Design and Assessment Techniques for Pressure Vessels

01 Structural design considerations for pressure vessels

The structural design of autoclave pressure vessels is critical for ensuring safety and operational efficiency. Key considerations include material selection, wall thickness calculations, and reinforcement methods to withstand high internal pressures. Design elements such as cylindrical or spherical shapes help distribute pressure evenly, while proper flange and closure designs prevent leakage. Advanced computational methods like finite element analysis are employed to optimize structural integrity while minimizing material usage.- Structural Design and Materials for Pressure Vessels: The structural design of autoclave pressure vessels involves specific considerations for materials and construction to ensure safety under high pressure conditions. Key aspects include the use of high-strength alloys, reinforced walls, and specialized geometries that distribute pressure evenly. The design must account for thermal expansion, corrosion resistance, and fatigue strength to maintain integrity during repeated pressurization cycles. Proper material selection is critical, with many designs incorporating stainless steel, carbon fiber composites, or other materials specifically engineered for pressure containment.

- Safety Mechanisms and Pressure Relief Systems: Autoclave pressure vessels incorporate various safety mechanisms to prevent catastrophic failures. These include pressure relief valves, rupture discs, and emergency venting systems that activate when pressure exceeds safe thresholds. Redundant safety systems are often implemented to ensure fail-safe operation. Modern designs feature electronic monitoring systems that continuously track pressure, temperature, and structural integrity, with automatic shutdown capabilities when abnormal conditions are detected. These safety features are essential for preventing accidents and ensuring operator safety during autoclave operation.

- Sealing and Closure Mechanisms: Effective sealing and closure mechanisms are crucial for autoclave pressure vessel safety. Advanced designs incorporate specialized gaskets, O-rings, and sealing surfaces that maintain integrity under high pressure and temperature conditions. Locking mechanisms ensure that the vessel cannot be opened while under pressure, preventing accidental exposure. Some designs feature quick-release systems that allow for safe depressurization before opening. The interface between the vessel body and closure components requires precise engineering to prevent leaks while allowing for repeated use without degradation of sealing surfaces.

- Heating and Temperature Control Systems: Autoclave pressure vessels often incorporate sophisticated heating and temperature control systems to maintain precise conditions required for sterilization or processing. These systems may include external heating jackets, internal heating elements, or circulation systems that distribute heat evenly throughout the vessel. Temperature sensors placed at strategic locations provide feedback to control systems, ensuring uniform heating and preventing localized hotspots that could compromise vessel integrity. Advanced designs feature programmable temperature profiles and cooling systems for controlled process completion.

- Monitoring and Control Automation: Modern autoclave pressure vessels incorporate advanced monitoring and control automation to enhance safety and operational efficiency. These systems include pressure sensors, temperature probes, and structural monitoring devices that provide real-time data on vessel conditions. Computerized control systems manage operation parameters, record process data, and alert operators to potential issues before they become critical. Remote monitoring capabilities allow for operation supervision without direct exposure to potential hazards. Integration with facility safety systems ensures coordinated emergency response in case of equipment malfunction.

02 Safety mechanisms and monitoring systems

Modern autoclave pressure vessels incorporate multiple safety mechanisms to prevent accidents and ensure safe operation. These include pressure relief valves, rupture discs, and emergency venting systems that activate when pressure exceeds safe limits. Advanced monitoring systems with sensors track critical parameters like temperature, pressure, and structural integrity in real-time. Automated control systems can initiate emergency protocols when abnormal conditions are detected, while redundant safety features provide multiple layers of protection.Expand Specific Solutions03 Heating and cooling systems integration

Effective temperature control is essential for autoclave pressure vessel operation. Integrated heating systems using steam jackets, electrical elements, or direct steam injection provide precise temperature regulation. Cooling systems utilizing water circulation, heat exchangers, or forced air help control exothermic reactions and enable rapid temperature reduction when needed. Advanced designs feature zoned heating and cooling for temperature uniformity throughout the vessel, with thermal insulation to improve energy efficiency and operator safety.Expand Specific Solutions04 Sealing and closure mechanisms

Reliable sealing systems are critical for preventing leaks in autoclave pressure vessels. Advanced designs incorporate specialized gaskets, O-rings, and metal-to-metal seals that maintain integrity under high pressure and temperature conditions. Quick-opening closure mechanisms enable efficient loading and unloading while maintaining safety, with interlocks preventing opening under pressure. Innovations include self-energizing seals that increase sealing force as internal pressure rises, and specialized materials resistant to chemical degradation and thermal cycling.Expand Specific Solutions05 Compliance with international standards and testing protocols

Autoclave pressure vessel design and manufacturing must adhere to strict international standards and regulations. These include ASME Boiler and Pressure Vessel Code, European Pressure Equipment Directive, and various national standards that specify material requirements, design methodologies, and safety factors. Rigorous testing protocols involve hydrostatic pressure tests, non-destructive examinations, and material certifications. Regular inspection and maintenance schedules are mandated to ensure continued safe operation, with documentation requirements for design calculations, material traceability, and test results.Expand Specific Solutions

Leading Manufacturers and Certification Bodies in Autoclave Industry

The autoclave pressure vessel assessment market is in a growth phase, characterized by increasing demand for safety and reliability in aerospace, automotive, and industrial sectors. The market size is expanding due to stringent safety regulations and growing applications in manufacturing processes. Technologically, the field shows varying maturity levels across industries, with aerospace leaders like Boeing and Airbus demonstrating advanced capabilities through extensive R&D. Automotive manufacturers including Mercedes-Benz, BMW, and Hyundai are integrating sophisticated assessment methodologies, while specialized firms such as Priorclave, Aerothermal Technology Group, and Feelit Technologies are driving innovation with sensor-based monitoring solutions. Research institutions like East China University of Science & Technology and Hefei Institutes contribute significantly to theoretical advancements in pressure vessel integrity assessment.

The Boeing Co.

Technical Solution: Boeing has developed advanced autoclave pressure vessel assessment methodologies specifically for aerospace composite manufacturing. Their approach integrates computational fluid dynamics (CFD) with finite element analysis (FEA) to simulate and optimize autoclave curing cycles. Boeing's AGATE (Advanced General Aviation Transport Experiments) program established industry standards for composite pressure vessel design. Their proprietary BVID (Barely Visible Impact Damage) assessment protocol evaluates pressure vessel integrity after minor impacts that might compromise structural integrity. Boeing implements digital twin technology for real-time monitoring of autoclave operations, allowing predictive maintenance and safety interventions before critical failures occur.

Strengths: Extensive aerospace experience provides superior understanding of high-performance requirements; integrated simulation capabilities reduce physical testing costs. Weaknesses: Solutions are primarily optimized for aerospace applications and may require significant adaptation for other industries; high implementation costs limit accessibility for smaller operations.

Priorclave Ltd.

Technical Solution: Priorclave has pioneered specialized autoclave pressure vessel assessment technologies focused on laboratory and medical applications. Their QuickSeal single-action door closure system incorporates advanced pressure vessel safety features with automatic gasket compression and thermal protection systems. The company's Tactrol control system continuously monitors pressure vessel parameters through multiple independent sensors, implementing redundant safety systems that exceed international standards. Priorclave's pressure vessels undergo rigorous hydrostatic testing at 1.5 times working pressure, followed by proprietary non-destructive testing protocols including ultrasonic thickness measurement and acoustic emission analysis. Their vessels incorporate unique thermal protection systems that prevent door opening until chamber pressure reaches atmospheric levels and temperature falls below 80°C.

Strengths: Specialized expertise in laboratory autoclaves with exceptional safety record; innovative door sealing mechanisms reduce operational risks. Weaknesses: Limited to smaller-scale pressure vessels; solutions primarily focused on sterilization applications rather than industrial manufacturing processes.

Critical Patents and Research in Pressure Vessel Safety Engineering

High pressure autoclave

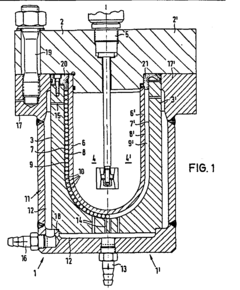

PatentInactiveEP0099443A3

Innovation

- The pressure vessel is equipped with a spaced skirt and spacer elements, such as spherical steel balls, between its inner and outer walls, allowing for optimized material selection and reducing the wall thickness needed to withstand internal pressure, while the outer shell absorbs tensile forces and chemical influences, and a heat transfer medium is used to manage temperature exposure through a connected passage space.

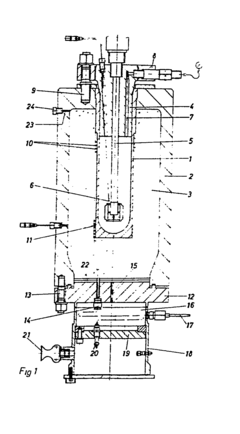

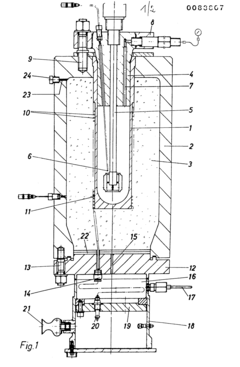

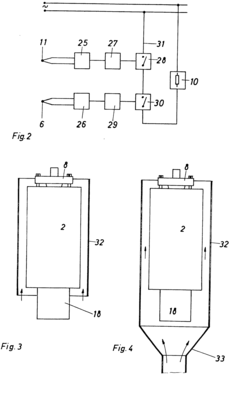

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

Regulatory Compliance and International Safety Standards

Regulatory compliance for autoclave pressure vessels is governed by a complex framework of international, regional, and national standards that establish minimum safety requirements. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII is widely recognized as the gold standard, providing comprehensive guidelines for design, fabrication, inspection, and testing of pressure vessels. In Europe, the Pressure Equipment Directive (PED 2014/68/EU) establishes essential safety requirements for pressure equipment exceeding 0.5 bar.

These regulatory frameworks typically mandate rigorous design verification through calculations, material certifications, and non-destructive testing protocols. For autoclave pressure vessels specifically, additional standards such as EN 13445 (European Standard for Unfired Pressure Vessels) and ISO 16528 (Boilers and Pressure Vessels) provide supplementary requirements addressing the unique operational conditions of autoclaves.

Safety certification processes vary by jurisdiction but generally involve third-party inspection by authorized bodies. In the United States, the National Board of Boiler and Pressure Vessel Inspectors oversees compliance, while in Europe, Notified Bodies perform conformity assessments. These organizations verify that vessels meet all applicable safety standards before commissioning.

Recent regulatory trends show increasing harmonization of international standards, with particular emphasis on risk-based approaches to pressure vessel assessment. The International Organization for Standardization (ISO) has been instrumental in developing globally recognized standards that facilitate international trade while maintaining stringent safety requirements.

Industry-specific regulations impose additional requirements for specialized applications. For instance, autoclaves used in aerospace manufacturing must comply with Nadcap (National Aerospace and Defense Contractors Accreditation Program) requirements, while those in pharmaceutical production must meet Good Manufacturing Practice (GMP) standards and FDA regulations in the United States.

Periodic inspection requirements constitute another critical aspect of regulatory compliance. Most jurisdictions mandate regular in-service inspections at intervals determined by vessel classification, operating conditions, and risk assessment. These inspections typically include visual examination, thickness measurements, and pressure testing to verify continued safe operation.

Compliance documentation requirements have become increasingly stringent, with regulatory bodies requiring comprehensive technical files including design calculations, material certifications, manufacturing procedures, test reports, and risk assessments. This documentation must be maintained throughout the vessel's operational life and updated following any modifications or repairs.

These regulatory frameworks typically mandate rigorous design verification through calculations, material certifications, and non-destructive testing protocols. For autoclave pressure vessels specifically, additional standards such as EN 13445 (European Standard for Unfired Pressure Vessels) and ISO 16528 (Boilers and Pressure Vessels) provide supplementary requirements addressing the unique operational conditions of autoclaves.

Safety certification processes vary by jurisdiction but generally involve third-party inspection by authorized bodies. In the United States, the National Board of Boiler and Pressure Vessel Inspectors oversees compliance, while in Europe, Notified Bodies perform conformity assessments. These organizations verify that vessels meet all applicable safety standards before commissioning.

Recent regulatory trends show increasing harmonization of international standards, with particular emphasis on risk-based approaches to pressure vessel assessment. The International Organization for Standardization (ISO) has been instrumental in developing globally recognized standards that facilitate international trade while maintaining stringent safety requirements.

Industry-specific regulations impose additional requirements for specialized applications. For instance, autoclaves used in aerospace manufacturing must comply with Nadcap (National Aerospace and Defense Contractors Accreditation Program) requirements, while those in pharmaceutical production must meet Good Manufacturing Practice (GMP) standards and FDA regulations in the United States.

Periodic inspection requirements constitute another critical aspect of regulatory compliance. Most jurisdictions mandate regular in-service inspections at intervals determined by vessel classification, operating conditions, and risk assessment. These inspections typically include visual examination, thickness measurements, and pressure testing to verify continued safe operation.

Compliance documentation requirements have become increasingly stringent, with regulatory bodies requiring comprehensive technical files including design calculations, material certifications, manufacturing procedures, test reports, and risk assessments. This documentation must be maintained throughout the vessel's operational life and updated following any modifications or repairs.

Failure Mode Analysis and Risk Mitigation Strategies

Comprehensive failure mode analysis is essential for autoclave pressure vessel safety and reliability. The primary failure modes include material fatigue, stress corrosion cracking, brittle fracture, and creep deformation. Material fatigue typically occurs due to cyclic loading during pressurization and depressurization cycles, with crack initiation at stress concentration points such as welds, corners, or surface defects. Stress corrosion cracking presents a significant risk, particularly in environments with corrosive media combined with tensile stress.

Brittle fracture remains a critical concern, especially for vessels operating below their ductile-to-brittle transition temperature. This failure mode can lead to catastrophic vessel rupture with minimal warning signs. Creep deformation becomes relevant for autoclaves operating at elevated temperatures for extended periods, gradually reducing vessel wall thickness and structural integrity.

Risk mitigation strategies must be implemented systematically across the vessel lifecycle. During design phases, appropriate material selection considering service conditions is paramount, with preference for materials exhibiting high fracture toughness and corrosion resistance. Computational methods including Finite Element Analysis (FEA) should be employed to identify stress concentration areas and optimize geometric features accordingly.

Manufacturing quality control represents another critical mitigation strategy, encompassing stringent welding procedures, comprehensive non-destructive testing, and post-weld heat treatment to relieve residual stresses. Operational safeguards must include conservative pressure ratings with adequate safety factors, controlled heating and cooling rates to minimize thermal stress, and installation of reliable pressure relief devices.

In-service inspection programs constitute the cornerstone of ongoing risk management. These should incorporate regular thickness measurements, acoustic emission testing during hydrostatic tests, and advanced techniques such as phased array ultrasonic testing for early detection of developing flaws. Inspection frequency should be risk-based, considering vessel age, operating conditions, and previous inspection findings.

Documentation and training form the final layer of defense, requiring detailed maintenance records, clear operating procedures, and comprehensive training for personnel. Emergency response protocols must be established and regularly practiced to minimize consequences should a failure occur despite preventive measures. Implementation of these strategies significantly reduces failure probability while enhancing overall pressure vessel safety and operational reliability.

Brittle fracture remains a critical concern, especially for vessels operating below their ductile-to-brittle transition temperature. This failure mode can lead to catastrophic vessel rupture with minimal warning signs. Creep deformation becomes relevant for autoclaves operating at elevated temperatures for extended periods, gradually reducing vessel wall thickness and structural integrity.

Risk mitigation strategies must be implemented systematically across the vessel lifecycle. During design phases, appropriate material selection considering service conditions is paramount, with preference for materials exhibiting high fracture toughness and corrosion resistance. Computational methods including Finite Element Analysis (FEA) should be employed to identify stress concentration areas and optimize geometric features accordingly.

Manufacturing quality control represents another critical mitigation strategy, encompassing stringent welding procedures, comprehensive non-destructive testing, and post-weld heat treatment to relieve residual stresses. Operational safeguards must include conservative pressure ratings with adequate safety factors, controlled heating and cooling rates to minimize thermal stress, and installation of reliable pressure relief devices.

In-service inspection programs constitute the cornerstone of ongoing risk management. These should incorporate regular thickness measurements, acoustic emission testing during hydrostatic tests, and advanced techniques such as phased array ultrasonic testing for early detection of developing flaws. Inspection frequency should be risk-based, considering vessel age, operating conditions, and previous inspection findings.

Documentation and training form the final layer of defense, requiring detailed maintenance records, clear operating procedures, and comprehensive training for personnel. Emergency response protocols must be established and regularly practiced to minimize consequences should a failure occur despite preventive measures. Implementation of these strategies significantly reduces failure probability while enhancing overall pressure vessel safety and operational reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!