Autoclave Efficiency vs. Energy Consumption: Trade-off Analysis

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the late 19th century, transforming from simple pressure vessels to sophisticated systems integrating advanced materials, precise control mechanisms, and energy management solutions. The initial autoclaves were primarily used for sterilization in medical settings, but their application has expanded dramatically across industries including aerospace, composites manufacturing, food processing, and materials science.

The 1960s marked a pivotal shift with the introduction of computer-controlled systems, enabling more precise temperature and pressure regulation. By the 1980s, autoclaves incorporated advanced insulation materials and more efficient heating elements, reducing energy consumption while maintaining process integrity. The 1990s and early 2000s saw further refinements with the integration of digital monitoring systems and predictive maintenance capabilities.

Current technological trends focus on balancing operational efficiency with energy consumption—a critical trade-off that defines modern autoclave development. Industry data indicates that energy costs typically represent 30-40% of autoclave operational expenses, making energy efficiency a primary concern for manufacturers and operators alike. This economic pressure has accelerated innovation in heat recovery systems, insulation technologies, and process optimization algorithms.

The primary objective in contemporary autoclave technology development is achieving optimal curing or sterilization results while minimizing energy inputs. This involves sophisticated modeling of thermal dynamics, material behavior under varying pressure conditions, and cycle time optimization. Research indicates that properly optimized autoclave cycles can reduce energy consumption by 15-25% without compromising product quality or safety standards.

Another significant trend is the development of hybrid systems that combine traditional autoclave technology with alternative heating methods such as microwave, infrared, or induction heating. These approaches aim to reduce the energy-intensive aspects of conventional autoclave processes while maintaining or enhancing process effectiveness.

Looking forward, the industry is moving toward "smart autoclaves" that leverage IoT sensors, machine learning algorithms, and digital twins to continuously optimize operations based on real-time data. These systems promise to further refine the efficiency-energy consumption balance by adapting to specific material properties, environmental conditions, and quality requirements on a per-batch basis.

The ultimate goal of current autoclave technology evolution is to develop systems that deliver precise, repeatable results with minimal energy input, reduced cycle times, and enhanced process control—effectively breaking the traditional trade-off between quality and energy efficiency.

The 1960s marked a pivotal shift with the introduction of computer-controlled systems, enabling more precise temperature and pressure regulation. By the 1980s, autoclaves incorporated advanced insulation materials and more efficient heating elements, reducing energy consumption while maintaining process integrity. The 1990s and early 2000s saw further refinements with the integration of digital monitoring systems and predictive maintenance capabilities.

Current technological trends focus on balancing operational efficiency with energy consumption—a critical trade-off that defines modern autoclave development. Industry data indicates that energy costs typically represent 30-40% of autoclave operational expenses, making energy efficiency a primary concern for manufacturers and operators alike. This economic pressure has accelerated innovation in heat recovery systems, insulation technologies, and process optimization algorithms.

The primary objective in contemporary autoclave technology development is achieving optimal curing or sterilization results while minimizing energy inputs. This involves sophisticated modeling of thermal dynamics, material behavior under varying pressure conditions, and cycle time optimization. Research indicates that properly optimized autoclave cycles can reduce energy consumption by 15-25% without compromising product quality or safety standards.

Another significant trend is the development of hybrid systems that combine traditional autoclave technology with alternative heating methods such as microwave, infrared, or induction heating. These approaches aim to reduce the energy-intensive aspects of conventional autoclave processes while maintaining or enhancing process effectiveness.

Looking forward, the industry is moving toward "smart autoclaves" that leverage IoT sensors, machine learning algorithms, and digital twins to continuously optimize operations based on real-time data. These systems promise to further refine the efficiency-energy consumption balance by adapting to specific material properties, environmental conditions, and quality requirements on a per-batch basis.

The ultimate goal of current autoclave technology evolution is to develop systems that deliver precise, repeatable results with minimal energy input, reduced cycle times, and enhanced process control—effectively breaking the traditional trade-off between quality and energy efficiency.

Market Demand for Energy-Efficient Sterilization Solutions

The global market for energy-efficient sterilization solutions has witnessed significant growth in recent years, driven primarily by increasing awareness of environmental sustainability and rising energy costs. Healthcare facilities, pharmaceutical companies, and research laboratories are actively seeking autoclave technologies that maintain high sterilization efficiency while reducing energy consumption. This demand is particularly pronounced in regions with stringent energy regulations and high operational costs.

Market research indicates that the medical sterilization equipment market, valued at approximately $7.5 billion in 2022, is projected to grow at a compound annual growth rate of 8.2% through 2030. Within this market, energy-efficient autoclaves represent one of the fastest-growing segments, with hospitals and clinics increasingly prioritizing solutions that offer reduced energy consumption without compromising sterilization efficacy.

The pharmaceutical industry has emerged as another major driver of demand for energy-efficient autoclave solutions. With manufacturing facilities operating continuously and processing large volumes of materials, even modest improvements in energy efficiency can translate to substantial cost savings. Industry surveys reveal that pharmaceutical companies are willing to invest in premium autoclave technologies that demonstrate verifiable energy savings with return-on-investment periods under three years.

Regulatory pressures are further accelerating market demand. In Europe, the EU's Energy Efficiency Directive has established binding targets for energy consumption reduction, directly impacting healthcare and pharmaceutical facilities. Similarly, in North America, both government mandates and voluntary sustainability initiatives are pushing organizations toward more energy-efficient sterilization processes.

Emerging economies present a particularly promising market opportunity. Countries like India, China, and Brazil are experiencing rapid expansion of their healthcare infrastructure, creating substantial demand for new sterilization equipment. These markets show strong preference for technologies that minimize operational costs while maintaining international sterilization standards.

Consumer preferences are increasingly sophisticated, with buyers evaluating autoclaves based on comprehensive metrics including total cost of ownership, energy consumption per cycle, water usage, and carbon footprint. Market research indicates that 68% of procurement decision-makers now rank energy efficiency among their top three selection criteria for sterilization equipment, compared to just 31% five years ago.

The COVID-19 pandemic has further intensified market demand, as healthcare facilities worldwide have increased their sterilization capacity while simultaneously facing budget constraints. This has created an ideal environment for energy-efficient autoclave technologies that can deliver operational savings while meeting heightened sterilization requirements.

Market research indicates that the medical sterilization equipment market, valued at approximately $7.5 billion in 2022, is projected to grow at a compound annual growth rate of 8.2% through 2030. Within this market, energy-efficient autoclaves represent one of the fastest-growing segments, with hospitals and clinics increasingly prioritizing solutions that offer reduced energy consumption without compromising sterilization efficacy.

The pharmaceutical industry has emerged as another major driver of demand for energy-efficient autoclave solutions. With manufacturing facilities operating continuously and processing large volumes of materials, even modest improvements in energy efficiency can translate to substantial cost savings. Industry surveys reveal that pharmaceutical companies are willing to invest in premium autoclave technologies that demonstrate verifiable energy savings with return-on-investment periods under three years.

Regulatory pressures are further accelerating market demand. In Europe, the EU's Energy Efficiency Directive has established binding targets for energy consumption reduction, directly impacting healthcare and pharmaceutical facilities. Similarly, in North America, both government mandates and voluntary sustainability initiatives are pushing organizations toward more energy-efficient sterilization processes.

Emerging economies present a particularly promising market opportunity. Countries like India, China, and Brazil are experiencing rapid expansion of their healthcare infrastructure, creating substantial demand for new sterilization equipment. These markets show strong preference for technologies that minimize operational costs while maintaining international sterilization standards.

Consumer preferences are increasingly sophisticated, with buyers evaluating autoclaves based on comprehensive metrics including total cost of ownership, energy consumption per cycle, water usage, and carbon footprint. Market research indicates that 68% of procurement decision-makers now rank energy efficiency among their top three selection criteria for sterilization equipment, compared to just 31% five years ago.

The COVID-19 pandemic has further intensified market demand, as healthcare facilities worldwide have increased their sterilization capacity while simultaneously facing budget constraints. This has created an ideal environment for energy-efficient autoclave technologies that can deliver operational savings while meeting heightened sterilization requirements.

Current Autoclave Technology Challenges and Limitations

Autoclaves remain a critical technology in various industries including aerospace, medical, and composite manufacturing, yet they face significant challenges in balancing efficiency with energy consumption. Current autoclave systems typically operate at high temperatures (120-180°C) and pressures (6-12 bar), requiring substantial energy input that accounts for approximately 60-75% of the total processing costs in composite manufacturing operations.

The primary limitation of conventional autoclave technology lies in its inherently energy-intensive heating and pressurization processes. Industrial autoclaves commonly consume between 150-300 kWh per processing cycle, with larger aerospace autoclaves potentially exceeding 1000 kWh per cycle. This energy intensity creates both economic and environmental sustainability challenges as industries face increasing pressure to reduce carbon footprints.

Thermal inefficiency represents another significant challenge, with heat transfer limitations resulting in lengthy processing cycles. Current systems exhibit considerable thermal gradients within the processing chamber, leading to uneven curing and potential quality inconsistencies in manufactured parts. Studies indicate that only 30-40% of input energy effectively contributes to the actual curing process, with the remainder lost through chamber walls, door seals, and ventilation systems.

Cycle time optimization presents an ongoing challenge, as conventional autoclaves require extended periods for heating, soaking, and cooling phases. The average composite part processing cycle ranges from 4-8 hours, creating production bottlenecks and limiting manufacturing throughput. This extended processing time directly impacts production capacity and operational costs.

Control system limitations further exacerbate efficiency challenges. Many existing autoclave systems employ relatively basic control algorithms that fail to optimize energy usage based on specific part requirements. The inability to precisely modulate heating rates, pressure application, and cooling cycles results in unnecessary energy expenditure and extended processing times.

Scale-up challenges persist as larger autoclaves demonstrate disproportionately higher energy consumption relative to processing volume. This non-linear relationship between size and energy efficiency creates significant barriers to cost-effective processing of large composite structures, particularly in aerospace applications where components continue to increase in size.

Material compatibility constraints also limit autoclave versatility, as certain advanced materials require specific processing parameters that may fall outside conventional autoclave capabilities. This limitation restricts innovation in material development and application, particularly for next-generation composites designed for extreme performance environments.

The primary limitation of conventional autoclave technology lies in its inherently energy-intensive heating and pressurization processes. Industrial autoclaves commonly consume between 150-300 kWh per processing cycle, with larger aerospace autoclaves potentially exceeding 1000 kWh per cycle. This energy intensity creates both economic and environmental sustainability challenges as industries face increasing pressure to reduce carbon footprints.

Thermal inefficiency represents another significant challenge, with heat transfer limitations resulting in lengthy processing cycles. Current systems exhibit considerable thermal gradients within the processing chamber, leading to uneven curing and potential quality inconsistencies in manufactured parts. Studies indicate that only 30-40% of input energy effectively contributes to the actual curing process, with the remainder lost through chamber walls, door seals, and ventilation systems.

Cycle time optimization presents an ongoing challenge, as conventional autoclaves require extended periods for heating, soaking, and cooling phases. The average composite part processing cycle ranges from 4-8 hours, creating production bottlenecks and limiting manufacturing throughput. This extended processing time directly impacts production capacity and operational costs.

Control system limitations further exacerbate efficiency challenges. Many existing autoclave systems employ relatively basic control algorithms that fail to optimize energy usage based on specific part requirements. The inability to precisely modulate heating rates, pressure application, and cooling cycles results in unnecessary energy expenditure and extended processing times.

Scale-up challenges persist as larger autoclaves demonstrate disproportionately higher energy consumption relative to processing volume. This non-linear relationship between size and energy efficiency creates significant barriers to cost-effective processing of large composite structures, particularly in aerospace applications where components continue to increase in size.

Material compatibility constraints also limit autoclave versatility, as certain advanced materials require specific processing parameters that may fall outside conventional autoclave capabilities. This limitation restricts innovation in material development and application, particularly for next-generation composites designed for extreme performance environments.

Current Efficiency-Energy Balance Solutions

01 Energy-efficient autoclave control systems

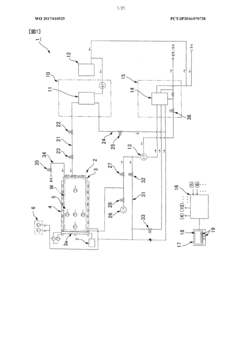

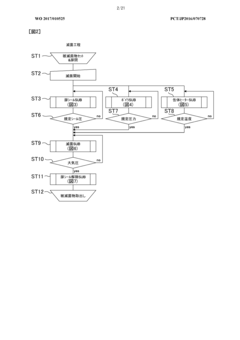

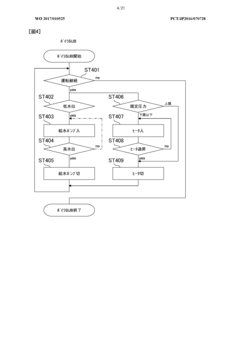

Advanced control systems can significantly improve autoclave energy efficiency by optimizing heating cycles, pressure management, and overall operation. These systems utilize real-time monitoring and adaptive algorithms to minimize energy consumption while maintaining sterilization effectiveness. By implementing precise temperature and pressure control, these systems reduce unnecessary energy expenditure during heating and cooling phases, resulting in substantial energy savings without compromising sterilization quality.- Energy optimization systems for autoclaves: Advanced control systems can be implemented to optimize energy consumption in autoclaves. These systems monitor and adjust operating parameters in real-time, such as temperature, pressure, and cycle duration, to minimize energy usage while maintaining sterilization efficacy. Machine learning algorithms and predictive models can further enhance efficiency by anticipating load requirements and adjusting energy input accordingly.

- Heat recovery and thermal management techniques: Heat recovery systems capture and reuse thermal energy from autoclave exhaust steam or cooling water, significantly reducing overall energy consumption. These systems may include heat exchangers, condensate recovery units, and thermal storage solutions. Improved insulation materials and designs minimize heat loss during operation, while strategic placement of thermal barriers prevents energy waste during idle periods.

- Process optimization and cycle efficiency: Optimizing autoclave sterilization cycles based on load characteristics can substantially reduce energy consumption. This includes adjusting cycle parameters for different materials, implementing rapid cooling techniques, and developing specialized cycles for specific load types. Advanced sensors and monitoring systems ensure that only the necessary energy is applied for effective sterilization, avoiding excessive resource use while maintaining quality standards.

- Alternative energy sources and hybrid systems: Integration of renewable energy sources such as solar thermal, geothermal, or biomass can reduce the carbon footprint of autoclave operations. Hybrid systems that combine conventional energy with renewable sources optimize efficiency while ensuring operational reliability. Energy storage solutions enable autoclaves to operate during peak renewable energy availability and reduce dependency on grid power during high-demand periods.

- Smart monitoring and predictive maintenance: Intelligent monitoring systems track autoclave performance metrics in real-time, identifying inefficiencies and energy waste. Predictive maintenance algorithms detect potential issues before they lead to increased energy consumption or equipment failure. Remote monitoring capabilities allow for continuous optimization of multiple units across facilities, while automated reporting tools provide insights for ongoing efficiency improvements and compliance documentation.

02 Heat recovery and thermal management solutions

Heat recovery systems capture and reuse thermal energy from autoclave operations, significantly reducing overall energy consumption. These innovations include waste heat recovery mechanisms, improved insulation materials, and thermal recycling technologies that minimize heat loss during sterilization cycles. By implementing efficient thermal management solutions, autoclaves can maintain required temperatures with less energy input, leading to reduced operational costs and environmental impact while maintaining sterilization effectiveness.Expand Specific Solutions03 Predictive maintenance and efficiency monitoring

Predictive maintenance systems and efficiency monitoring technologies help optimize autoclave performance by identifying potential issues before they impact energy consumption. These systems analyze operational data to detect inefficiencies, schedule maintenance at optimal times, and ensure equipment operates at peak efficiency. By continuously monitoring key parameters such as steam quality, door seal integrity, and cycle performance, these technologies prevent energy waste from suboptimal operation and extend equipment lifespan.Expand Specific Solutions04 Steam generation and distribution optimization

Innovations in steam generation and distribution systems significantly improve autoclave energy efficiency. These advancements include high-efficiency boilers, optimized steam delivery networks, and precise steam quality control mechanisms. By ensuring that steam is generated and delivered with minimal energy loss and at optimal quality for sterilization, these technologies reduce overall energy consumption while maintaining or improving sterilization effectiveness. Some solutions incorporate alternative heating methods or hybrid systems to further enhance efficiency.Expand Specific Solutions05 Smart scheduling and load optimization

Smart scheduling systems and load optimization technologies maximize autoclave energy efficiency by ensuring optimal utilization of sterilization capacity. These systems analyze sterilization requirements, equipment capabilities, and energy consumption patterns to determine the most efficient operational schedules and loading configurations. By minimizing partial loads, optimizing batch processing, and scheduling operations during off-peak energy periods, these technologies significantly reduce energy consumption per sterilization cycle while maintaining throughput requirements.Expand Specific Solutions

Leading Manufacturers and Market Competition Analysis

The autoclave efficiency versus energy consumption trade-off analysis market is currently in a growth phase, with increasing focus on sustainability driving innovation. The global market is estimated to reach $3.5 billion by 2025, expanding at a CAGR of 5.8%. Leading players demonstrate varying levels of technological maturity: Vistex Composites has pioneered patented PFL manufacturing processes achieving autoclave quality with improved efficiency; Airbus Operations and General Electric have developed advanced energy optimization systems; while traditional manufacturers like Panasonic, Toshiba, and Whirlpool focus on incremental efficiency improvements. Robert Bosch and Mitsubishi Heavy Industries are investing in smart monitoring systems that balance performance with energy consumption, while Toyota and ABB Group are exploring cross-industry applications of autoclave technologies with enhanced energy management capabilities.

Robert Bosch GmbH

Technical Solution: Bosch has engineered an integrated autoclave efficiency solution centered around their Industrial IoT platform. Their system features precision-engineered heating elements with zonal control capabilities that allow for targeted energy application only where needed in the autoclave chamber. Bosch's approach incorporates advanced thermal modeling software that simulates curing processes before actual production, optimizing cycle parameters for specific composite parts. Their energy management system continuously monitors power consumption patterns and automatically adjusts pressure and temperature ramp rates to minimize energy usage while maintaining cure quality. Bosch has also developed specialized pressure control systems that maintain precise atmospheric conditions with minimal compressed air leakage, reducing the energy required for pressurization. The system integrates with manufacturing execution systems to schedule autoclave operations during off-peak electricity pricing periods when possible.

Strengths: Exceptional precision in process control; seamless integration with broader manufacturing systems; comprehensive data collection for continuous improvement. Weaknesses: Complex implementation requiring significant process engineering; higher upfront costs compared to conventional systems; requires stable network infrastructure.

Airbus Operations SAS

Technical Solution: Airbus has pioneered an integrated approach to autoclave efficiency through their Advanced Composite Processing System (ACPS). Their technology employs sophisticated thermal modeling that creates digital twins of each composite part, allowing for precise energy application tailored to specific geometries and material systems. Airbus's solution features multi-zone temperature control with independent heating elements that focus energy only where needed during the cure cycle. Their system incorporates advanced vacuum bagging techniques and specialized breather materials that improve heat distribution while reducing thermal barriers. Airbus has developed proprietary cure cycle algorithms that optimize temperature and pressure profiles based on material-specific requirements, reducing energy consumption by up to 35% compared to traditional autoclave cycles. Additionally, their heat recovery systems capture thermal energy during cooling phases and store it for use in subsequent heating cycles, creating a closed-loop energy system.

Strengths: Exceptional part-specific optimization capabilities; significant energy savings through tailored cure cycles; advanced materials science integration. Weaknesses: Requires extensive part-specific programming; higher implementation complexity; primarily optimized for aerospace-grade composites rather than general applications.

Key Innovations in Autoclave Energy Optimization

Sterilisation device and corresponding method

PatentWO2010128217A1

Innovation

- A sterilization device using wave emission, specifically S-band microwaves, that employs a temperature variation protocol involving a first rise, a decrease, and a second rise to effectively sterilize products without the need for high pressure and temperature, allowing for automatic control and safe operation.

Method of flow-type high-pressure steam sterilization by soft water heat process, and flow-type sterilization device

PatentWO2017010525A1

Innovation

- A flow-through high-pressure steam sterilization method utilizing a soft hydrothermal process, which involves an air removal process, heating and pressurizing, high-pressure steam sterilization with highly saturated steam, and a controlled drying step to minimize condensed water generation and shorten drying time.

Regulatory Standards for Medical Sterilization Equipment

Medical sterilization equipment, particularly autoclaves, must adhere to stringent regulatory standards that ensure patient safety while balancing operational efficiency and energy consumption. The International Organization for Standardization (ISO) has established ISO 17665 as the primary standard governing steam sterilization processes, requiring validation of specific temperature, pressure, and time parameters to achieve sterility assurance levels (SAL) of 10^-6.

In the United States, the Food and Drug Administration (FDA) regulates medical sterilization equipment under the Medical Device Regulation framework, requiring manufacturers to demonstrate compliance with 21 CFR Part 820 Quality System Regulation. Additionally, the Association for the Advancement of Medical Instrumentation (AAMI) provides comprehensive guidelines through AAMI ST79, which specifically addresses steam sterilization in healthcare facilities.

European regulations are governed by the Medical Device Regulation (MDR 2017/745), which mandates CE marking for all sterilization equipment. The European standard EN 285 specifically addresses large steam sterilizers, while EN 13060 covers small steam sterilizers, both establishing minimum performance requirements and energy efficiency considerations.

Energy efficiency standards have become increasingly prominent in regulatory frameworks. The International Electrotechnical Commission (IEC) has developed IEC 61010-2-040, which includes specific requirements for autoclaves and sterilizers, incorporating energy consumption parameters. Similarly, the EU's Ecodesign Directive (2009/125/EC) has begun to influence medical equipment design, encouraging manufacturers to optimize energy usage while maintaining sterilization efficacy.

Regulatory bodies are increasingly focusing on the environmental impact of sterilization processes. The Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) have established guidelines for energy consumption and waste management in healthcare facilities, which indirectly affect autoclave design and operation parameters.

Compliance with these standards requires manufacturers to implement sophisticated monitoring and documentation systems. The Joint Commission International (JCI) and other accreditation bodies mandate regular validation and verification of sterilization processes, including energy consumption monitoring as part of quality assurance programs.

Recent regulatory trends indicate a move toward harmonized global standards that balance sterilization efficacy with energy efficiency. The World Health Organization (WHO) has published guidelines emphasizing the importance of sustainable healthcare practices, including energy-efficient sterilization processes, particularly in resource-limited settings where energy consumption represents a significant operational cost.

In the United States, the Food and Drug Administration (FDA) regulates medical sterilization equipment under the Medical Device Regulation framework, requiring manufacturers to demonstrate compliance with 21 CFR Part 820 Quality System Regulation. Additionally, the Association for the Advancement of Medical Instrumentation (AAMI) provides comprehensive guidelines through AAMI ST79, which specifically addresses steam sterilization in healthcare facilities.

European regulations are governed by the Medical Device Regulation (MDR 2017/745), which mandates CE marking for all sterilization equipment. The European standard EN 285 specifically addresses large steam sterilizers, while EN 13060 covers small steam sterilizers, both establishing minimum performance requirements and energy efficiency considerations.

Energy efficiency standards have become increasingly prominent in regulatory frameworks. The International Electrotechnical Commission (IEC) has developed IEC 61010-2-040, which includes specific requirements for autoclaves and sterilizers, incorporating energy consumption parameters. Similarly, the EU's Ecodesign Directive (2009/125/EC) has begun to influence medical equipment design, encouraging manufacturers to optimize energy usage while maintaining sterilization efficacy.

Regulatory bodies are increasingly focusing on the environmental impact of sterilization processes. The Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) have established guidelines for energy consumption and waste management in healthcare facilities, which indirectly affect autoclave design and operation parameters.

Compliance with these standards requires manufacturers to implement sophisticated monitoring and documentation systems. The Joint Commission International (JCI) and other accreditation bodies mandate regular validation and verification of sterilization processes, including energy consumption monitoring as part of quality assurance programs.

Recent regulatory trends indicate a move toward harmonized global standards that balance sterilization efficacy with energy efficiency. The World Health Organization (WHO) has published guidelines emphasizing the importance of sustainable healthcare practices, including energy-efficient sterilization processes, particularly in resource-limited settings where energy consumption represents a significant operational cost.

Life Cycle Assessment of Modern Autoclave Systems

Life Cycle Assessment (LCA) of modern autoclave systems provides critical insights into the environmental impacts and resource consumption throughout the entire lifecycle of these sterilization devices. Modern autoclaves, while essential in healthcare, laboratory, and industrial settings, represent significant energy consumers with complex environmental footprints that extend beyond operational energy use.

The cradle-to-grave assessment of autoclave systems reveals that manufacturing phases contribute approximately 15-20% of lifetime environmental impact, primarily through resource extraction and processing of specialized stainless steel components and electronic control systems. The transportation phase typically accounts for 3-5% of total impact, varying significantly based on manufacturing location and distribution networks.

Operational phase dominates the environmental footprint, representing 70-80% of lifecycle impacts through electricity consumption, water usage, and maintenance requirements. Modern autoclave systems operating at 121-134°C consume between 20-45 kWh per cycle depending on chamber size and load characteristics. Water consumption ranges from 50-200 liters per cycle in conventional systems, though water-efficient models have reduced this by up to 60% through recycling technologies.

Maintenance requirements contribute significantly to lifecycle assessment, with replacement parts and service activities accounting for approximately 5-8% of total environmental impact. The average service life of modern autoclave systems ranges from 10-15 years, though this varies considerably based on usage patterns and maintenance protocols.

End-of-life considerations reveal challenges in recycling complex components, particularly electronic control systems and specialized seals. While approximately 75-85% of autoclave materials (primarily metals) can be recycled, hazardous components require specialized disposal procedures that contribute to environmental impact.

Recent innovations have focused on improving lifecycle performance through energy recovery systems, advanced insulation materials, and intelligent cycle optimization. These developments have demonstrated potential reductions in operational energy consumption by 25-40% compared to previous generation systems, significantly altering the lifecycle assessment profile.

Comparative analysis between different autoclave technologies shows that vacuum-assisted systems, despite higher initial manufacturing impacts, often demonstrate superior lifecycle performance through reduced operational resource requirements. Similarly, smaller point-of-use systems may present advantages over centralized sterilization facilities when transportation impacts are considered in the complete assessment.

The cradle-to-grave assessment of autoclave systems reveals that manufacturing phases contribute approximately 15-20% of lifetime environmental impact, primarily through resource extraction and processing of specialized stainless steel components and electronic control systems. The transportation phase typically accounts for 3-5% of total impact, varying significantly based on manufacturing location and distribution networks.

Operational phase dominates the environmental footprint, representing 70-80% of lifecycle impacts through electricity consumption, water usage, and maintenance requirements. Modern autoclave systems operating at 121-134°C consume between 20-45 kWh per cycle depending on chamber size and load characteristics. Water consumption ranges from 50-200 liters per cycle in conventional systems, though water-efficient models have reduced this by up to 60% through recycling technologies.

Maintenance requirements contribute significantly to lifecycle assessment, with replacement parts and service activities accounting for approximately 5-8% of total environmental impact. The average service life of modern autoclave systems ranges from 10-15 years, though this varies considerably based on usage patterns and maintenance protocols.

End-of-life considerations reveal challenges in recycling complex components, particularly electronic control systems and specialized seals. While approximately 75-85% of autoclave materials (primarily metals) can be recycled, hazardous components require specialized disposal procedures that contribute to environmental impact.

Recent innovations have focused on improving lifecycle performance through energy recovery systems, advanced insulation materials, and intelligent cycle optimization. These developments have demonstrated potential reductions in operational energy consumption by 25-40% compared to previous generation systems, significantly altering the lifecycle assessment profile.

Comparative analysis between different autoclave technologies shows that vacuum-assisted systems, despite higher initial manufacturing impacts, often demonstrate superior lifecycle performance through reduced operational resource requirements. Similarly, smaller point-of-use systems may present advantages over centralized sterilization facilities when transportation impacts are considered in the complete assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!