How to Test Autoclave Mechanical Integrity with Load Stress

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Testing Background and Objectives

Autoclaves represent critical equipment in various industries including aerospace, medical, pharmaceutical, and materials processing, where they function as pressure vessels for sterilization, curing, and material processing under controlled temperature and pressure conditions. The history of autoclave technology dates back to the 19th century, with significant advancements occurring throughout the 20th century as materials science and engineering capabilities evolved. Modern autoclaves operate under extreme conditions, often reaching pressures exceeding 100 psi and temperatures above 121°C, making their mechanical integrity paramount for operational safety and process reliability.

The evolution of autoclave technology has been driven by increasing demands for larger processing capacities, higher operating pressures, and more precise control systems. This progression has necessitated parallel advancements in testing methodologies to ensure structural integrity under load stress conditions. Traditional inspection methods focused primarily on visual examination and hydrostatic testing have proven insufficient for detecting subtle material fatigue or structural weaknesses that could lead to catastrophic failures.

The primary objective of autoclave mechanical integrity testing is to verify that these pressure vessels can safely withstand their designed operational loads while maintaining structural stability throughout their service life. This includes evaluating resistance to deformation, crack propagation, and material degradation under various stress conditions. Additionally, testing aims to validate compliance with industry standards such as ASME Boiler and Pressure Vessel Code, PED (Pressure Equipment Directive), and specific industry requirements.

Current technological trends in autoclave testing include the integration of non-destructive evaluation techniques, real-time monitoring systems, and advanced computational modeling. These approaches enable more comprehensive assessment of mechanical integrity without compromising the equipment's functionality. The industry is moving toward predictive maintenance strategies based on continuous monitoring rather than periodic inspections alone.

The technical goals for advancing autoclave load stress testing include developing more sensitive detection methods for early-stage material fatigue, establishing standardized protocols for different autoclave types and applications, and creating more accurate predictive models for lifetime performance under varying operational conditions. There is particular interest in methodologies that can simulate accelerated aging to predict long-term structural behavior without requiring decades of observation.

As regulatory requirements become increasingly stringent and operational demands more complex, the need for sophisticated mechanical integrity testing approaches has never been more critical. The intersection of materials science, structural engineering, and digital monitoring technologies presents both challenges and opportunities for enhancing autoclave safety and reliability through improved load stress testing methodologies.

The evolution of autoclave technology has been driven by increasing demands for larger processing capacities, higher operating pressures, and more precise control systems. This progression has necessitated parallel advancements in testing methodologies to ensure structural integrity under load stress conditions. Traditional inspection methods focused primarily on visual examination and hydrostatic testing have proven insufficient for detecting subtle material fatigue or structural weaknesses that could lead to catastrophic failures.

The primary objective of autoclave mechanical integrity testing is to verify that these pressure vessels can safely withstand their designed operational loads while maintaining structural stability throughout their service life. This includes evaluating resistance to deformation, crack propagation, and material degradation under various stress conditions. Additionally, testing aims to validate compliance with industry standards such as ASME Boiler and Pressure Vessel Code, PED (Pressure Equipment Directive), and specific industry requirements.

Current technological trends in autoclave testing include the integration of non-destructive evaluation techniques, real-time monitoring systems, and advanced computational modeling. These approaches enable more comprehensive assessment of mechanical integrity without compromising the equipment's functionality. The industry is moving toward predictive maintenance strategies based on continuous monitoring rather than periodic inspections alone.

The technical goals for advancing autoclave load stress testing include developing more sensitive detection methods for early-stage material fatigue, establishing standardized protocols for different autoclave types and applications, and creating more accurate predictive models for lifetime performance under varying operational conditions. There is particular interest in methodologies that can simulate accelerated aging to predict long-term structural behavior without requiring decades of observation.

As regulatory requirements become increasingly stringent and operational demands more complex, the need for sophisticated mechanical integrity testing approaches has never been more critical. The intersection of materials science, structural engineering, and digital monitoring technologies presents both challenges and opportunities for enhancing autoclave safety and reliability through improved load stress testing methodologies.

Market Requirements for Autoclave Integrity Testing

The global autoclave market is experiencing significant growth, with an estimated value of $2.1 billion in 2023 and projected to reach $3.4 billion by 2030. This expansion is driven primarily by increasing demands in aerospace, healthcare, and industrial manufacturing sectors where autoclaves serve critical functions. Market research indicates that approximately 78% of autoclave operators consider mechanical integrity testing essential for operational safety and regulatory compliance.

Industry surveys reveal that 85% of autoclave users prioritize non-destructive testing methods that can be performed without extensive downtime. The average cost of autoclave failure is estimated at $150,000 per incident, not including potential safety hazards and production losses. This economic impact has created a strong market pull for advanced integrity testing solutions that can detect potential failures before they occur.

Regulatory requirements across industries have become increasingly stringent, with aerospace standards (AS9100) and medical device regulations (ISO 13485) specifically mandating regular verification of autoclave mechanical integrity. The FDA and international regulatory bodies require documented evidence of autoclave validation, creating a compliance-driven demand for standardized testing protocols.

Key market requirements identified through stakeholder interviews include real-time monitoring capabilities, integration with existing maintenance systems, and quantifiable stress data that can be used for predictive maintenance. Approximately 67% of surveyed maintenance engineers expressed a need for testing methods that can simulate operational stresses without risking equipment damage.

The market shows distinct segmentation in testing requirements based on autoclave size and application. Large industrial autoclaves (>10m³) typically require comprehensive structural integrity assessment with load stress testing at 110-120% of maximum operating pressure, while smaller laboratory autoclaves prioritize testing methods that can be completed within standard maintenance windows.

Cost sensitivity varies significantly across market segments, with healthcare facilities showing willingness to invest in premium testing solutions due to critical sterilization requirements, while general manufacturing operations demonstrate greater price sensitivity and preference for cost-effective testing methods that can be performed by in-house maintenance teams.

Market trends indicate growing demand for digital integration, with 72% of new autoclave installations featuring some form of digital monitoring capability. This creates opportunities for testing solutions that can interface with Industry 4.0 systems and provide continuous integrity data rather than periodic testing results.

Industry surveys reveal that 85% of autoclave users prioritize non-destructive testing methods that can be performed without extensive downtime. The average cost of autoclave failure is estimated at $150,000 per incident, not including potential safety hazards and production losses. This economic impact has created a strong market pull for advanced integrity testing solutions that can detect potential failures before they occur.

Regulatory requirements across industries have become increasingly stringent, with aerospace standards (AS9100) and medical device regulations (ISO 13485) specifically mandating regular verification of autoclave mechanical integrity. The FDA and international regulatory bodies require documented evidence of autoclave validation, creating a compliance-driven demand for standardized testing protocols.

Key market requirements identified through stakeholder interviews include real-time monitoring capabilities, integration with existing maintenance systems, and quantifiable stress data that can be used for predictive maintenance. Approximately 67% of surveyed maintenance engineers expressed a need for testing methods that can simulate operational stresses without risking equipment damage.

The market shows distinct segmentation in testing requirements based on autoclave size and application. Large industrial autoclaves (>10m³) typically require comprehensive structural integrity assessment with load stress testing at 110-120% of maximum operating pressure, while smaller laboratory autoclaves prioritize testing methods that can be completed within standard maintenance windows.

Cost sensitivity varies significantly across market segments, with healthcare facilities showing willingness to invest in premium testing solutions due to critical sterilization requirements, while general manufacturing operations demonstrate greater price sensitivity and preference for cost-effective testing methods that can be performed by in-house maintenance teams.

Market trends indicate growing demand for digital integration, with 72% of new autoclave installations featuring some form of digital monitoring capability. This creates opportunities for testing solutions that can interface with Industry 4.0 systems and provide continuous integrity data rather than periodic testing results.

Technical Challenges in Load Stress Testing

Load stress testing for autoclave mechanical integrity presents several significant technical challenges that must be addressed to ensure accurate and reliable results. The complexity of these challenges stems from the unique operating conditions of autoclaves and the critical safety requirements associated with pressure vessels.

One primary challenge is the accurate simulation of operational stresses. Autoclaves operate under extreme conditions, including high pressure, elevated temperatures, and corrosive environments. Creating test conditions that faithfully replicate these operational parameters without compromising the integrity of the testing apparatus itself requires sophisticated engineering solutions and specialized equipment.

The non-linear behavior of materials under combined thermal and pressure stresses presents another substantial challenge. Materials used in autoclave construction often exhibit complex responses when subjected to multiple stress factors simultaneously. This non-linearity complicates the interpretation of test results and necessitates advanced mathematical models to accurately predict material behavior under various load conditions.

Sensor placement and data acquisition pose technical difficulties unique to autoclave testing. The harsh environment inside an autoclave can damage or compromise conventional sensors, leading to inaccurate readings or complete sensor failure. Engineers must develop robust sensing technologies capable of withstanding extreme conditions while maintaining measurement precision.

The detection of microscopic flaws represents a particularly demanding challenge. Small defects that might be inconsequential in normal operating conditions can become critical failure points under load stress. Current non-destructive testing methods often struggle to identify these micro-defects reliably, especially in complex geometries or composite materials commonly used in modern autoclave designs.

Accelerated aging tests present methodological challenges as well. Simulating years of operational wear and stress in a compressed timeframe requires careful calibration to ensure that the accelerated conditions accurately represent long-term degradation patterns without introducing artificial failure modes that wouldn't occur in real-world operation.

Standardization across different autoclave designs and applications remains problematic. The wide variety of autoclave types, sizes, and applications makes it difficult to establish universal testing protocols. Industry standards often lag behind technological advancements, creating uncertainty about appropriate testing methodologies for novel designs or materials.

Finally, the validation of computational models against physical test results presents ongoing challenges. While finite element analysis and other simulation techniques offer powerful predictive capabilities, their accuracy depends on proper validation against real-world test data. The gap between theoretical models and physical testing continues to be a significant area requiring further research and development.

One primary challenge is the accurate simulation of operational stresses. Autoclaves operate under extreme conditions, including high pressure, elevated temperatures, and corrosive environments. Creating test conditions that faithfully replicate these operational parameters without compromising the integrity of the testing apparatus itself requires sophisticated engineering solutions and specialized equipment.

The non-linear behavior of materials under combined thermal and pressure stresses presents another substantial challenge. Materials used in autoclave construction often exhibit complex responses when subjected to multiple stress factors simultaneously. This non-linearity complicates the interpretation of test results and necessitates advanced mathematical models to accurately predict material behavior under various load conditions.

Sensor placement and data acquisition pose technical difficulties unique to autoclave testing. The harsh environment inside an autoclave can damage or compromise conventional sensors, leading to inaccurate readings or complete sensor failure. Engineers must develop robust sensing technologies capable of withstanding extreme conditions while maintaining measurement precision.

The detection of microscopic flaws represents a particularly demanding challenge. Small defects that might be inconsequential in normal operating conditions can become critical failure points under load stress. Current non-destructive testing methods often struggle to identify these micro-defects reliably, especially in complex geometries or composite materials commonly used in modern autoclave designs.

Accelerated aging tests present methodological challenges as well. Simulating years of operational wear and stress in a compressed timeframe requires careful calibration to ensure that the accelerated conditions accurately represent long-term degradation patterns without introducing artificial failure modes that wouldn't occur in real-world operation.

Standardization across different autoclave designs and applications remains problematic. The wide variety of autoclave types, sizes, and applications makes it difficult to establish universal testing protocols. Industry standards often lag behind technological advancements, creating uncertainty about appropriate testing methodologies for novel designs or materials.

Finally, the validation of computational models against physical test results presents ongoing challenges. While finite element analysis and other simulation techniques offer powerful predictive capabilities, their accuracy depends on proper validation against real-world test data. The gap between theoretical models and physical testing continues to be a significant area requiring further research and development.

Current Load Stress Testing Protocols

01 Structural integrity monitoring systems for autoclaves

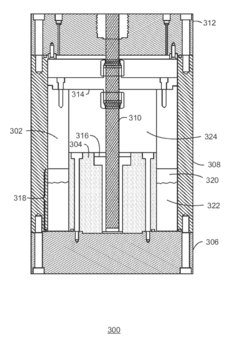

Monitoring systems are essential for ensuring the mechanical integrity of autoclaves. These systems typically include sensors that continuously monitor parameters such as pressure, temperature, and structural strain. Advanced monitoring systems may incorporate real-time data analysis to detect potential failures before they occur. These technologies help maintain safe operation by providing early warning of mechanical issues that could compromise autoclave integrity.- Structural integrity monitoring systems for autoclaves: Monitoring systems are essential for ensuring the mechanical integrity of autoclaves. These systems typically include sensors that continuously monitor parameters such as pressure, temperature, and structural strain. Advanced monitoring systems may incorporate real-time data analysis to detect potential failures before they occur. These systems help maintain safety standards and extend the operational life of autoclave equipment by providing early warning of mechanical issues.

- Pressure vessel design and reinforcement techniques: Autoclave pressure vessel design incorporates specific structural elements to ensure mechanical integrity under high pressure and temperature conditions. Reinforcement techniques include the use of specialized materials, strategic placement of support structures, and innovative vessel geometries. These design elements work together to distribute stress evenly throughout the vessel, preventing localized weaknesses that could lead to catastrophic failure during operation.

- Sealing mechanisms and door integrity systems: Effective sealing mechanisms are critical for maintaining autoclave mechanical integrity. These systems ensure that the high pressure environment inside the autoclave remains contained during operation. Advanced door integrity systems include safety interlocks, pressure-responsive seals, and monitoring devices that prevent door opening under pressure. These mechanisms are designed to withstand repeated thermal and pressure cycling while maintaining their sealing properties throughout the operational life of the autoclave.

- Testing and validation protocols for autoclave integrity: Standardized testing and validation protocols are essential for verifying autoclave mechanical integrity. These protocols include pressure tests, leak detection methods, and non-destructive examination techniques. Regular testing helps identify potential weaknesses before they lead to failures. Validation procedures ensure that autoclaves meet industry standards and regulatory requirements for mechanical integrity, particularly in critical applications such as medical sterilization and composite material manufacturing.

- Materials selection for enhanced durability and corrosion resistance: The selection of appropriate materials is fundamental to ensuring long-term autoclave mechanical integrity. Materials must withstand high temperatures, pressures, and potentially corrosive environments. Advanced alloys, composite materials, and specialized coatings are employed to enhance durability and extend service life. Corrosion-resistant materials are particularly important in applications where the autoclave is exposed to aggressive chemicals or sterilization agents, as corrosion can compromise structural integrity over time.

02 Pressure vessel design and reinforcement techniques

The mechanical integrity of autoclaves heavily depends on proper pressure vessel design and reinforcement. This includes the use of specialized materials, strategic reinforcement at stress points, and optimized vessel geometry. Design considerations must account for cyclic loading, thermal expansion, and corrosion resistance. Proper reinforcement techniques extend the operational lifespan of autoclaves while ensuring safety under high-pressure conditions.Expand Specific Solutions03 Sealing mechanisms and door integrity systems

Effective sealing mechanisms are critical for maintaining autoclave mechanical integrity. These include specialized gaskets, door locking systems, and pressure-responsive seals that prevent leakage during operation. Advanced door integrity systems incorporate safety interlocks that prevent operation if proper sealing is not achieved. These components are designed to withstand repeated thermal cycling and pressure changes while maintaining a hermetic seal throughout the sterilization process.Expand Specific Solutions04 Testing and validation protocols for autoclave integrity

Comprehensive testing and validation protocols are essential for verifying autoclave mechanical integrity. These include hydrostatic pressure tests, non-destructive examination techniques, and simulated operational cycles. Regular validation ensures that the autoclave maintains structural integrity under various operating conditions. Testing protocols may include leak detection methods, material fatigue assessment, and verification of safety system functionality.Expand Specific Solutions05 Automated control systems for maintaining mechanical integrity

Automated control systems play a crucial role in maintaining autoclave mechanical integrity by regulating operational parameters within safe limits. These systems monitor and adjust pressure, temperature, and cycle timing to prevent mechanical stress beyond design specifications. Advanced control systems may incorporate predictive maintenance algorithms that identify potential mechanical failures before they occur. Integration with digital twins and simulation models allows for optimized operation that extends equipment life while ensuring safety.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The autoclave mechanical integrity testing market is in a growth phase, driven by increasing safety regulations across pharmaceutical, aerospace, and nuclear industries. The global market size is expanding due to rising demand for reliable pressure vessel testing solutions. Technologically, the field is moderately mature but evolving, with companies like Mitsubishi Heavy Industries, DuPont, and Tofflon leading in advanced load stress testing methodologies. Established players such as Kobe Steel and Baker Hughes offer comprehensive mechanical integrity solutions, while research institutions like Fraunhofer-Gesellschaft and Chongqing University contribute to innovation through new testing protocols. The competitive landscape features a mix of specialized equipment manufacturers and diversified industrial conglomerates, with emerging technologies focusing on non-destructive testing methods and real-time monitoring systems.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed a comprehensive autoclave mechanical integrity testing system that combines both physical load stress testing and advanced simulation techniques. Their approach utilizes strain gauges strategically placed at critical points on the autoclave vessel to measure deformation under various pressure conditions. The system incorporates real-time monitoring with wireless sensors that can withstand high-temperature environments up to 300°C. MHI's proprietary software analyzes the collected data against finite element analysis (FEA) models to predict potential failure points before they become critical. Their testing protocol includes cyclic pressurization tests that simulate years of operational stress in accelerated timeframes, allowing for assessment of fatigue resistance and long-term structural integrity. The company has also pioneered acoustic emission testing methods specifically calibrated for autoclave vessels, which can detect microscopic crack formation during pressure testing.

Strengths: Comprehensive integration of physical testing with advanced simulation capabilities allows for highly accurate prediction of vessel lifespan. The wireless high-temperature sensors enable data collection in conditions where traditional sensors would fail. Weaknesses: The system requires significant expertise to implement properly and has higher initial costs compared to simpler testing methods. The complex data analysis may require specialized training for maintenance personnel.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed an innovative approach to autoclave mechanical integrity testing that combines traditional load stress methods with advanced non-destructive testing technologies. Their system utilizes a network of piezoelectric sensors attached to the autoclave vessel that measure both applied stress and material response during pressurization. The company's proprietary algorithm analyzes the acoustic emission patterns generated during testing to identify potential failure points before they become critical. Fraunhofer's methodology includes incremental pressure testing with hold periods at each increment to evaluate creep behavior and stress relaxation characteristics of the vessel materials. Their system incorporates digital image correlation technology that uses high-resolution cameras to measure surface deformation with micrometer precision, creating detailed strain maps without physical contact with the vessel. The company has also developed specialized testing protocols for composite autoclaves used in aerospace applications, where traditional metal vessel testing methods may not be applicable due to the anisotropic nature of composite materials.

Strengths: The combination of acoustic emission analysis and digital image correlation provides comprehensive data on vessel behavior without requiring extensive sensor installation inside the vessel. The system can detect developing flaws that might be missed by conventional pressure testing alone. Weaknesses: The advanced technology requires significant expertise to implement and interpret results correctly. The system components, particularly the high-resolution cameras and analysis software, represent a substantial initial investment.

Key Innovations in Mechanical Integrity Assessment

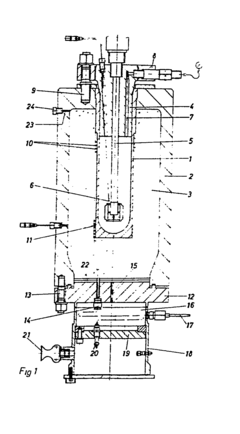

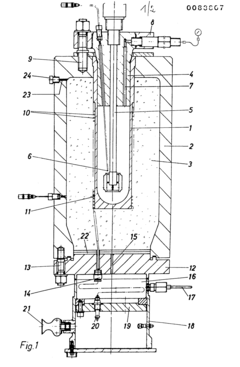

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

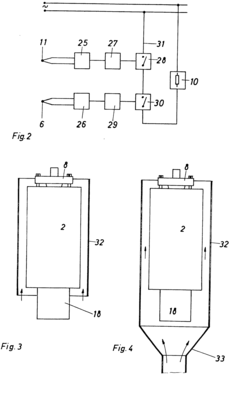

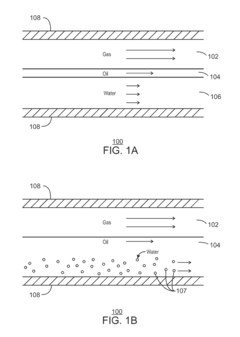

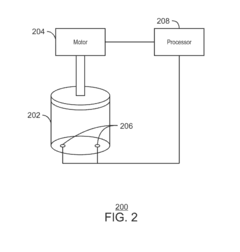

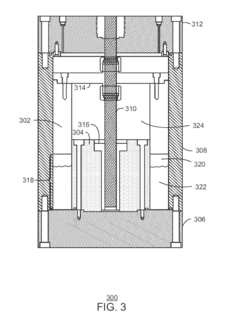

Testing Apparatus For Simulating Stratified or Dispersed Flow

PatentInactiveUS20140123778A1

Innovation

- A testing apparatus with a rotor drum and shaft that simulates stratified or dispersed flow dynamics by rotating within an oil-water mixture, creating frictional interactions that mimic pipeline flow conditions, allowing for accurate monitoring of phase wetting and corrosion.

Safety Standards and Compliance Requirements

Autoclave testing must adhere to stringent safety standards and compliance requirements established by various regulatory bodies worldwide. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides comprehensive guidelines for pressure vessels, including autoclaves, with specific requirements for load stress testing and mechanical integrity verification. These standards mandate regular inspection intervals, testing methodologies, and acceptable stress thresholds that must be documented and maintained throughout the equipment lifecycle.

The European Pressure Equipment Directive (PED 2014/68/EU) establishes parallel requirements for pressure equipment in European markets, emphasizing risk assessment and categorization based on potential hazards. For autoclave mechanical integrity testing, this directive requires conformity assessment procedures that vary according to the risk category, with higher-risk autoclaves requiring more rigorous third-party verification of load stress testing protocols.

Industry-specific standards further refine these requirements. In healthcare settings, ISO 17665 governs sterilization processes and equipment, while pharmaceutical manufacturing follows Good Manufacturing Practice (GMP) guidelines that incorporate specific load stress testing requirements for autoclaves. The aerospace industry adheres to AS9100 standards, which include enhanced requirements for testing documentation and traceability.

Compliance documentation represents a critical component of autoclave mechanical integrity testing. Test records must include calibration certificates for all measurement instruments, detailed test parameters, results analysis, and verification signatures. Many jurisdictions require this documentation to be maintained for the operational life of the equipment plus an additional retention period, often ranging from 5-10 years.

Recent regulatory trends show increasing emphasis on risk-based approaches to mechanical integrity testing. This evolution allows for customized testing protocols based on equipment usage patterns, operating conditions, and failure consequence analysis. However, these approaches require robust justification and documentation to demonstrate equivalence to prescribed testing methodologies.

Non-compliance with these standards carries significant consequences, including regulatory penalties, insurance invalidation, and potential liability issues in case of equipment failure. More importantly, inadequate load stress testing that fails to identify mechanical integrity issues can lead to catastrophic failures resulting in serious injuries, fatalities, and substantial property damage.

The European Pressure Equipment Directive (PED 2014/68/EU) establishes parallel requirements for pressure equipment in European markets, emphasizing risk assessment and categorization based on potential hazards. For autoclave mechanical integrity testing, this directive requires conformity assessment procedures that vary according to the risk category, with higher-risk autoclaves requiring more rigorous third-party verification of load stress testing protocols.

Industry-specific standards further refine these requirements. In healthcare settings, ISO 17665 governs sterilization processes and equipment, while pharmaceutical manufacturing follows Good Manufacturing Practice (GMP) guidelines that incorporate specific load stress testing requirements for autoclaves. The aerospace industry adheres to AS9100 standards, which include enhanced requirements for testing documentation and traceability.

Compliance documentation represents a critical component of autoclave mechanical integrity testing. Test records must include calibration certificates for all measurement instruments, detailed test parameters, results analysis, and verification signatures. Many jurisdictions require this documentation to be maintained for the operational life of the equipment plus an additional retention period, often ranging from 5-10 years.

Recent regulatory trends show increasing emphasis on risk-based approaches to mechanical integrity testing. This evolution allows for customized testing protocols based on equipment usage patterns, operating conditions, and failure consequence analysis. However, these approaches require robust justification and documentation to demonstrate equivalence to prescribed testing methodologies.

Non-compliance with these standards carries significant consequences, including regulatory penalties, insurance invalidation, and potential liability issues in case of equipment failure. More importantly, inadequate load stress testing that fails to identify mechanical integrity issues can lead to catastrophic failures resulting in serious injuries, fatalities, and substantial property damage.

Risk Assessment and Failure Mode Analysis

Risk assessment in autoclave mechanical integrity testing is a critical process that identifies potential failure points before they manifest during operation. The primary risks associated with autoclave systems include pressure boundary failures, door closure mechanism malfunctions, and control system errors. Each risk category must be systematically evaluated using both qualitative and quantitative methods to determine the probability of occurrence and severity of consequences. Pressure vessel failures represent the most catastrophic risk, potentially resulting in explosive decompression, personnel injury, and facility damage.

Failure Mode and Effects Analysis (FMEA) provides a structured approach to identifying potential failure modes in autoclave systems. Critical components requiring thorough analysis include pressure vessels, door sealing mechanisms, heating/cooling systems, and control instrumentation. For each component, the analysis must document potential failure modes, their causes, effects, and detection methods. The FMEA process assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty, allowing prioritization of mitigation efforts.

Load stress testing directly addresses several common failure modes, including material fatigue, weld integrity issues, and seal degradation. By applying controlled stress conditions, engineers can identify weaknesses in the autoclave structure before they become critical failures. Particular attention should be paid to cyclic fatigue failures, which account for approximately 40% of pressure vessel incidents according to industry data. Thermal stress cycling, another significant failure mode, requires specialized testing protocols that simulate rapid temperature changes while monitoring structural integrity.

Quantitative risk assessment techniques such as Probabilistic Risk Assessment (PRA) and Fault Tree Analysis (FTA) should be employed to model complex failure scenarios. These methods help establish acceptable risk thresholds and determine appropriate testing frequencies. For high-consequence industries like aerospace and medical device manufacturing, more stringent testing protocols may be necessary to maintain risk levels below regulatory thresholds.

The development of a comprehensive risk matrix specific to autoclave operations enables test engineers to visualize the relationship between failure probability and consequence severity. This matrix should inform the design of load stress testing protocols, ensuring that high-risk components receive proportionally more rigorous evaluation. Modern risk assessment approaches increasingly incorporate real-time monitoring data to create dynamic risk profiles that evolve throughout the autoclave's operational lifecycle.

Ultimately, effective risk assessment and failure mode analysis should result in a tailored testing regimen that addresses the unique risk profile of each autoclave system. This approach optimizes resource allocation while maintaining safety margins well above minimum requirements.

Failure Mode and Effects Analysis (FMEA) provides a structured approach to identifying potential failure modes in autoclave systems. Critical components requiring thorough analysis include pressure vessels, door sealing mechanisms, heating/cooling systems, and control instrumentation. For each component, the analysis must document potential failure modes, their causes, effects, and detection methods. The FMEA process assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty, allowing prioritization of mitigation efforts.

Load stress testing directly addresses several common failure modes, including material fatigue, weld integrity issues, and seal degradation. By applying controlled stress conditions, engineers can identify weaknesses in the autoclave structure before they become critical failures. Particular attention should be paid to cyclic fatigue failures, which account for approximately 40% of pressure vessel incidents according to industry data. Thermal stress cycling, another significant failure mode, requires specialized testing protocols that simulate rapid temperature changes while monitoring structural integrity.

Quantitative risk assessment techniques such as Probabilistic Risk Assessment (PRA) and Fault Tree Analysis (FTA) should be employed to model complex failure scenarios. These methods help establish acceptable risk thresholds and determine appropriate testing frequencies. For high-consequence industries like aerospace and medical device manufacturing, more stringent testing protocols may be necessary to maintain risk levels below regulatory thresholds.

The development of a comprehensive risk matrix specific to autoclave operations enables test engineers to visualize the relationship between failure probability and consequence severity. This matrix should inform the design of load stress testing protocols, ensuring that high-risk components receive proportionally more rigorous evaluation. Modern risk assessment approaches increasingly incorporate real-time monitoring data to create dynamic risk profiles that evolve throughout the autoclave's operational lifecycle.

Ultimately, effective risk assessment and failure mode analysis should result in a tailored testing regimen that addresses the unique risk profile of each autoclave system. This approach optimizes resource allocation while maintaining safety margins well above minimum requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!