Autoclave Structural Materials: Assessing Long-Term Durability

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Materials Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the early 20th century, transforming from simple pressure vessels to sophisticated systems critical in aerospace, medical, and industrial applications. The historical trajectory shows a consistent focus on improving material performance under extreme conditions, with notable advancements occurring during the aerospace boom of the 1960s when composite materials became increasingly important. Recent decades have witnessed accelerated development in autoclave structural materials, driven by demands for higher operating temperatures, pressures, and extended service life in corrosive environments.

The evolution of autoclave materials has been characterized by a transition from basic carbon steels to advanced alloys and composite structures. Early autoclaves utilized primarily carbon steel and basic stainless steel constructions, which provided adequate performance but limited lifespan under harsh conditions. Mid-century developments introduced nickel-based superalloys and specialized stainless steel grades, significantly enhancing corrosion resistance and high-temperature stability. Contemporary autoclave systems increasingly incorporate advanced materials including titanium alloys, specialized ceramics, and composite reinforcements.

Current technological trends indicate a growing emphasis on multi-material solutions that optimize performance across different autoclave components. This approach recognizes that various sections of an autoclave experience different stress profiles, temperature gradients, and exposure to corrosive media. Material selection has consequently become more specialized and targeted to specific functional requirements within the system.

The primary objective of this technical research is to establish comprehensive methodologies for assessing and predicting the long-term durability of autoclave structural materials under various operational conditions. This includes developing accelerated testing protocols that can reliably simulate decades of service in significantly shorter timeframes, creating predictive models that account for material degradation mechanisms, and identifying early indicators of potential structural failures.

Secondary objectives include mapping the relationship between processing parameters and resultant material properties, understanding synergistic effects between different degradation mechanisms, and establishing industry-standard protocols for material qualification. Additionally, this research aims to explore novel material solutions that can extend service life while maintaining or improving performance characteristics such as thermal efficiency, pressure containment, and resistance to cyclic loading.

The ultimate goal is to enable more accurate lifecycle predictions for autoclave systems, reducing unexpected failures, extending maintenance intervals, and providing manufacturers with data-driven approaches to material selection and system design. This will contribute to enhanced safety, reduced operational costs, and improved sustainability through longer service life of critical industrial infrastructure.

The evolution of autoclave materials has been characterized by a transition from basic carbon steels to advanced alloys and composite structures. Early autoclaves utilized primarily carbon steel and basic stainless steel constructions, which provided adequate performance but limited lifespan under harsh conditions. Mid-century developments introduced nickel-based superalloys and specialized stainless steel grades, significantly enhancing corrosion resistance and high-temperature stability. Contemporary autoclave systems increasingly incorporate advanced materials including titanium alloys, specialized ceramics, and composite reinforcements.

Current technological trends indicate a growing emphasis on multi-material solutions that optimize performance across different autoclave components. This approach recognizes that various sections of an autoclave experience different stress profiles, temperature gradients, and exposure to corrosive media. Material selection has consequently become more specialized and targeted to specific functional requirements within the system.

The primary objective of this technical research is to establish comprehensive methodologies for assessing and predicting the long-term durability of autoclave structural materials under various operational conditions. This includes developing accelerated testing protocols that can reliably simulate decades of service in significantly shorter timeframes, creating predictive models that account for material degradation mechanisms, and identifying early indicators of potential structural failures.

Secondary objectives include mapping the relationship between processing parameters and resultant material properties, understanding synergistic effects between different degradation mechanisms, and establishing industry-standard protocols for material qualification. Additionally, this research aims to explore novel material solutions that can extend service life while maintaining or improving performance characteristics such as thermal efficiency, pressure containment, and resistance to cyclic loading.

The ultimate goal is to enable more accurate lifecycle predictions for autoclave systems, reducing unexpected failures, extending maintenance intervals, and providing manufacturers with data-driven approaches to material selection and system design. This will contribute to enhanced safety, reduced operational costs, and improved sustainability through longer service life of critical industrial infrastructure.

Market Demand Analysis for Durable Autoclave Materials

The global market for autoclave structural materials has witnessed significant growth in recent years, driven primarily by expanding applications in aerospace, healthcare, and industrial manufacturing sectors. Current market valuation for high-performance autoclave materials exceeds $12 billion annually, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory reflects the increasing demand for materials capable of withstanding extreme pressure, temperature, and corrosive environments over extended operational lifespans.

In the aerospace sector, which accounts for approximately 38% of the total market share, manufacturers are increasingly seeking autoclave materials that can maintain structural integrity under cyclic loading conditions for 20+ years. The trend toward lightweight composite structures has further intensified the need for autoclave materials that can facilitate proper curing while ensuring long-term durability of critical components.

The healthcare industry represents another significant market segment, contributing roughly 27% to overall demand. Medical device sterilization and pharmaceutical processing require autoclave materials that can withstand thousands of sterilization cycles while maintaining compliance with stringent regulatory standards. Market research indicates that healthcare facilities are willing to pay premium prices for autoclave equipment constructed with materials demonstrating proven longevity, as this reduces total cost of ownership and minimizes operational disruptions.

Industrial manufacturing applications, particularly in chemical processing and energy production, constitute about 22% of market demand. These sectors require autoclave materials capable of withstanding highly corrosive environments while maintaining dimensional stability under fluctuating temperature and pressure conditions. The increasing focus on sustainable manufacturing processes has created additional demand for materials that not only offer durability but also enable energy-efficient autoclave operations.

Regional analysis reveals that North America and Europe currently dominate the market with combined share of 58%, though Asia-Pacific markets are experiencing the fastest growth at 7.3% annually. This geographic shift reflects the expanding manufacturing capabilities in countries like China, India, and South Korea, where investments in advanced materials research have accelerated significantly.

Customer surveys indicate that procurement decisions are increasingly influenced by comprehensive lifecycle performance data rather than initial acquisition costs alone. Approximately 76% of industrial customers identified long-term durability as the primary selection criterion for autoclave structural materials, followed by resistance to specific environmental stressors (68%) and compatibility with existing systems (54%).

The market exhibits clear willingness to adopt novel materials that demonstrate superior durability characteristics, with 82% of surveyed companies expressing interest in materials that can extend maintenance intervals by at least 30% compared to current standards.

In the aerospace sector, which accounts for approximately 38% of the total market share, manufacturers are increasingly seeking autoclave materials that can maintain structural integrity under cyclic loading conditions for 20+ years. The trend toward lightweight composite structures has further intensified the need for autoclave materials that can facilitate proper curing while ensuring long-term durability of critical components.

The healthcare industry represents another significant market segment, contributing roughly 27% to overall demand. Medical device sterilization and pharmaceutical processing require autoclave materials that can withstand thousands of sterilization cycles while maintaining compliance with stringent regulatory standards. Market research indicates that healthcare facilities are willing to pay premium prices for autoclave equipment constructed with materials demonstrating proven longevity, as this reduces total cost of ownership and minimizes operational disruptions.

Industrial manufacturing applications, particularly in chemical processing and energy production, constitute about 22% of market demand. These sectors require autoclave materials capable of withstanding highly corrosive environments while maintaining dimensional stability under fluctuating temperature and pressure conditions. The increasing focus on sustainable manufacturing processes has created additional demand for materials that not only offer durability but also enable energy-efficient autoclave operations.

Regional analysis reveals that North America and Europe currently dominate the market with combined share of 58%, though Asia-Pacific markets are experiencing the fastest growth at 7.3% annually. This geographic shift reflects the expanding manufacturing capabilities in countries like China, India, and South Korea, where investments in advanced materials research have accelerated significantly.

Customer surveys indicate that procurement decisions are increasingly influenced by comprehensive lifecycle performance data rather than initial acquisition costs alone. Approximately 76% of industrial customers identified long-term durability as the primary selection criterion for autoclave structural materials, followed by resistance to specific environmental stressors (68%) and compatibility with existing systems (54%).

The market exhibits clear willingness to adopt novel materials that demonstrate superior durability characteristics, with 82% of surveyed companies expressing interest in materials that can extend maintenance intervals by at least 30% compared to current standards.

Current State and Challenges in Autoclave Structural Materials

Autoclave structural materials have reached a significant level of technological maturity globally, with advanced composites and metal alloys dominating the landscape. Current state-of-the-art materials include carbon fiber reinforced polymers (CFRPs), high-performance metal alloys, and specialized ceramics designed to withstand extreme pressure and temperature conditions. The United States, Japan, Germany, and China lead in research and development, with each country focusing on specific aspects of autoclave material technology.

Despite considerable advancements, several critical challenges persist in the field of autoclave structural materials. Long-term durability remains a primary concern, particularly regarding material degradation under cyclic loading and exposure to harsh chemical environments. Research indicates that even advanced composites can experience up to 30% reduction in mechanical properties after extended service in industrial autoclaves, significantly impacting operational safety and maintenance costs.

Thermal stability presents another significant challenge, especially for applications requiring operation at temperatures exceeding 300°C. Current polymer matrix composites often exhibit glass transition temperatures below this threshold, limiting their application in high-temperature autoclave environments. Material scientists are actively exploring novel resin systems with improved thermal resistance, though commercial solutions remain limited.

Corrosion resistance constitutes a persistent obstacle, particularly in medical and chemical processing autoclaves where sterilization chemicals and aggressive reagents accelerate material degradation. Studies have documented corrosion rates in conventional stainless steel components increasing by 15-20% annually in such environments, necessitating frequent replacement and maintenance.

The geographical distribution of autoclave material technology shows concentration in industrialized regions, with North America accounting for approximately 35% of research output, followed by Europe (30%), Asia-Pacific (25%), and other regions (10%). This distribution reflects both technological capabilities and market demand patterns across different regions.

Manufacturing scalability represents another significant challenge, particularly for advanced composite materials requiring precise processing parameters. Current production methods often struggle with consistency across large structural components, resulting in variability in mechanical properties and performance. The industry is actively pursuing automated manufacturing techniques and improved process monitoring to address these limitations.

Regulatory compliance adds complexity to material development, with increasingly stringent safety standards in aerospace, medical, and energy sectors requiring extensive testing and validation. The certification process for new autoclave materials can extend development timelines by 2-3 years, creating barriers to rapid innovation and technology adoption.

Despite considerable advancements, several critical challenges persist in the field of autoclave structural materials. Long-term durability remains a primary concern, particularly regarding material degradation under cyclic loading and exposure to harsh chemical environments. Research indicates that even advanced composites can experience up to 30% reduction in mechanical properties after extended service in industrial autoclaves, significantly impacting operational safety and maintenance costs.

Thermal stability presents another significant challenge, especially for applications requiring operation at temperatures exceeding 300°C. Current polymer matrix composites often exhibit glass transition temperatures below this threshold, limiting their application in high-temperature autoclave environments. Material scientists are actively exploring novel resin systems with improved thermal resistance, though commercial solutions remain limited.

Corrosion resistance constitutes a persistent obstacle, particularly in medical and chemical processing autoclaves where sterilization chemicals and aggressive reagents accelerate material degradation. Studies have documented corrosion rates in conventional stainless steel components increasing by 15-20% annually in such environments, necessitating frequent replacement and maintenance.

The geographical distribution of autoclave material technology shows concentration in industrialized regions, with North America accounting for approximately 35% of research output, followed by Europe (30%), Asia-Pacific (25%), and other regions (10%). This distribution reflects both technological capabilities and market demand patterns across different regions.

Manufacturing scalability represents another significant challenge, particularly for advanced composite materials requiring precise processing parameters. Current production methods often struggle with consistency across large structural components, resulting in variability in mechanical properties and performance. The industry is actively pursuing automated manufacturing techniques and improved process monitoring to address these limitations.

Regulatory compliance adds complexity to material development, with increasingly stringent safety standards in aerospace, medical, and energy sectors requiring extensive testing and validation. The certification process for new autoclave materials can extend development timelines by 2-3 years, creating barriers to rapid innovation and technology adoption.

Current Solutions for Long-Term Durability Enhancement

01 Corrosion-resistant materials for autoclave longevity

Specialized corrosion-resistant materials are crucial for ensuring the long-term durability of autoclave structures. These materials are designed to withstand the harsh conditions inside autoclaves, including high pressure, elevated temperatures, and corrosive environments. By incorporating materials such as specific stainless steel alloys, nickel-based superalloys, or composite materials with enhanced corrosion resistance properties, the structural integrity of autoclaves can be maintained over extended periods, reducing maintenance requirements and extending operational lifespan.- Corrosion-resistant materials for autoclave applications: Materials with enhanced corrosion resistance are crucial for long-term durability in autoclave environments. These materials include specialized alloys and composite structures that can withstand the harsh conditions of high temperature, pressure, and potentially corrosive media inside autoclaves. The development of these materials focuses on preventing degradation mechanisms such as stress corrosion cracking, pitting, and general corrosion that would otherwise compromise structural integrity over extended service periods.

- High-temperature resistant structural components: Structural components designed for autoclave applications require exceptional resistance to high temperatures to maintain their mechanical properties during prolonged exposure. These components incorporate materials and designs that minimize thermal expansion issues, prevent creep deformation, and resist thermal fatigue. Advanced ceramics, specialized metal alloys, and composite materials are engineered to maintain structural integrity and dimensional stability under the cyclic thermal conditions typical in autoclave operations.

- Pressure-resistant sealing and joining technologies: Long-term durability of autoclave structures depends significantly on the integrity of seals and joints that must withstand repeated pressure cycles. Advanced sealing technologies incorporate elastomeric compounds, metal-to-metal seals, and composite gaskets designed to maintain their properties despite repeated compression and decompression. Joining methods such as specialized welding techniques, diffusion bonding, and mechanical fastening systems are developed to ensure that connections between structural components remain leak-tight and structurally sound throughout the autoclave's operational life.

- Monitoring and predictive maintenance systems: Systems for monitoring the structural integrity of autoclave components enable predictive maintenance approaches that enhance long-term durability. These systems incorporate sensors that detect early signs of material degradation, structural fatigue, or seal failure. Advanced algorithms analyze operational data to predict potential failures before they occur, allowing for timely maintenance interventions. Implementation of these monitoring systems extends the service life of autoclave structural materials by preventing catastrophic failures and optimizing maintenance schedules.

- Composite and hybrid material structures: Composite and hybrid material structures offer superior long-term durability in autoclave environments by combining the beneficial properties of multiple materials. These structures may incorporate fiber-reinforced polymers, metal matrix composites, or ceramic-metal hybrids designed to resist specific degradation mechanisms. The strategic combination of materials creates structures with enhanced resistance to corrosion, thermal cycling, and mechanical stress, while potentially reducing weight and improving thermal efficiency. These advanced material systems are engineered to maintain their properties throughout the extended service life required for autoclave applications.

02 Advanced coating technologies for autoclave protection

Protective coatings play a significant role in enhancing the durability of autoclave structural materials. These specialized coatings create barriers against corrosion, oxidation, and other degradation mechanisms that occur in high-temperature and high-pressure environments. Advanced coating technologies include ceramic-based coatings, polymer composites, and multi-layer protective systems that can be applied to critical structural components. These coatings not only extend the service life of autoclave materials but also improve their performance under extreme operating conditions.Expand Specific Solutions03 Structural design innovations for improved durability

Innovative structural designs can significantly enhance the long-term durability of autoclave systems. These design approaches focus on stress distribution, thermal management, and material optimization to minimize wear and fatigue. Key innovations include modular construction techniques, reinforced junction points, and strategic placement of expansion joints to accommodate thermal cycling. By implementing these design principles, autoclave structures can better withstand repeated sterilization cycles and maintain their integrity over extended operational periods.Expand Specific Solutions04 Monitoring and predictive maintenance systems

Advanced monitoring systems and predictive maintenance technologies are essential for ensuring the long-term durability of autoclave structural materials. These systems utilize sensors, data analytics, and machine learning algorithms to detect early signs of material degradation, stress accumulation, or potential failure points. By continuously monitoring critical parameters such as temperature distribution, pressure fluctuations, and material integrity, operators can implement timely maintenance interventions before catastrophic failures occur, thereby extending the operational lifespan of autoclave structures.Expand Specific Solutions05 Composite and hybrid materials for extreme conditions

The development of composite and hybrid materials has revolutionized autoclave structural durability for long-term applications. These materials combine the beneficial properties of multiple components to create structures that can withstand extreme temperature variations, pressure cycles, and chemical exposure. Advanced composites may incorporate ceramic reinforcements, metal matrices, or polymer-based components that work synergistically to resist degradation mechanisms. The strategic use of these materials in critical autoclave components significantly extends service life while maintaining operational efficiency under demanding conditions.Expand Specific Solutions

Key Industry Players in Autoclave Materials Development

The autoclave structural materials market is currently in a growth phase, with increasing demand driven by aerospace, petrochemical, and energy sectors. Major players like Boeing, Airbus, and Lockheed Martin dominate the aerospace segment, focusing on developing lightweight, high-temperature resistant composites for long-term durability. In the industrial sector, companies such as Saudi Aramco, China Petroleum & Chemical Corp, and JFE Steel are advancing corrosion-resistant alloys for extreme environments. Research institutions like Southwest Petroleum University and Xi'an Thermal Power Research Institute collaborate with industry leaders to enhance material performance. The market is characterized by continuous innovation in material science, with companies like 3M and PPG Industries developing specialized coatings and treatments to extend service life under high-pressure, high-temperature conditions.

The Boeing Co.

Technical Solution: Boeing has developed advanced composite autoclave processing technologies for aerospace applications, focusing on carbon fiber reinforced polymers (CFRP) with enhanced durability properties. Their approach includes specialized resin systems with improved thermal oxidative stability and moisture resistance specifically designed for long-term aerospace service environments. Boeing implements a multi-scale testing methodology that combines accelerated aging protocols with real-time exposure testing to validate material performance over projected service lifetimes of 20+ years[1]. Their proprietary cure cycle optimization reduces residual stresses in large composite structures, minimizing microcracking that could lead to premature degradation. Boeing's materials qualification program incorporates environmental conditioning that simulates combined effects of temperature cycling, moisture absorption, and mechanical loading to predict long-term structural integrity[3].

Strengths: Extensive aerospace qualification data and experience with large-scale composite structures; sophisticated multi-parameter aging models calibrated with decades of in-service data. Weaknesses: Technologies primarily optimized for aerospace applications with less focus on cost-effectiveness for other industries; proprietary nature limits broader implementation.

Airbus Operations GmbH

Technical Solution: Airbus has pioneered autoclave material durability assessment through their Integrated Technology Validation (ITV) program, which combines physical testing with advanced computational modeling. Their approach focuses on thermosetting composite systems with specialized toughening agents that maintain mechanical properties after thousands of thermal cycles. Airbus employs a hierarchical testing methodology starting at coupon level and progressing to full-scale components, with particular emphasis on interface durability between composite layers and between composites and metallic components[2]. Their material qualification includes exposure to simulated service environments including UV radiation, hydraulic fluid contamination, and lightning strike effects. Airbus has developed proprietary non-destructive evaluation techniques specifically calibrated for detecting early-stage degradation mechanisms in autoclave-cured materials, allowing for predictive maintenance before structural integrity is compromised[4]. Their material systems incorporate self-sensing capabilities through embedded fiber optic sensors that monitor strain and temperature history throughout the service life.

Strengths: Comprehensive integration of material durability considerations into design process; extensive database of in-service performance validation; advanced non-destructive evaluation capabilities. Weaknesses: High development costs; technologies primarily optimized for commercial aviation applications with specific loading profiles.

Critical Materials Science Innovations for Autoclaves

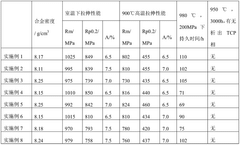

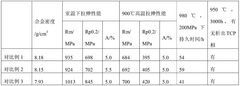

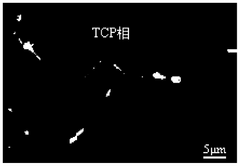

High-temperature alloy having good long-term stability and preparation method therefor

PatentWO2022233283A1

Innovation

- The strengthening element design scheme of high Al, low Ti and high Ta is adopted to form a Ni3 (Al, Ti, Ta) strengthening phase containing higher Al and Ta at the same time. Combined with the specific element ratio and preparation method, the alloy is ensured to perform at 950℃ No TCP phase precipitates after 3000 hours of treatment, meeting the design and use requirements of advanced aero engines and gas turbines.

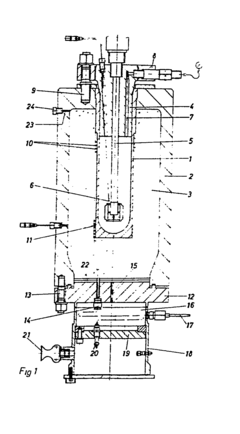

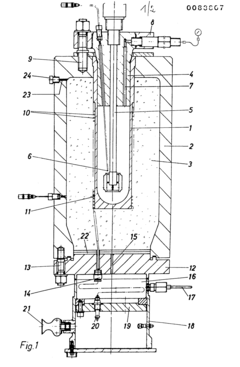

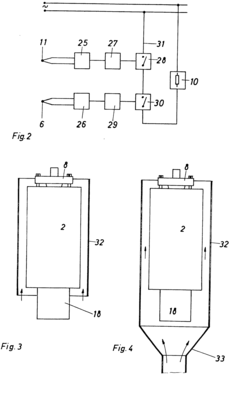

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

Corrosion Resistance Strategies for Extreme Environments

In extreme environments such as autoclaves, where materials face high temperatures, pressures, and potentially corrosive media, specialized corrosion resistance strategies are essential for ensuring long-term structural integrity. The primary approach involves the selection of advanced alloys specifically engineered for these conditions, including nickel-based superalloys (Inconel 625, Hastelloy C-276), high-performance stainless steels (316L, 254SMO), and titanium alloys (Grade 5, Grade 7), each offering distinct advantages in specific corrosive environments.

Surface modification techniques represent another critical strategy, with thermal spray coatings providing protective barriers against corrosive agents. These include ceramic coatings (Al2O3, Cr2O3) that offer excellent chemical stability and thermal resistance. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) techniques enable the application of ultra-thin, highly adherent protective layers with precisely controlled composition and microstructure.

Passive protection systems utilize sacrificial anodes and impressed current cathodic protection (ICCP) to redirect corrosion processes away from critical structural components. These systems require careful design and regular monitoring to maintain effectiveness throughout the service life of autoclave equipment.

Advanced composite materials offer promising alternatives to traditional metal alloys in extreme environments. Fiber-reinforced polymers (FRPs) with specialized resin systems demonstrate exceptional corrosion resistance while maintaining structural integrity. Ceramic matrix composites (CMCs) provide superior performance at elevated temperatures where conventional materials would rapidly degrade.

Electrochemical inhibition strategies involve the introduction of specific chemical compounds that interfere with corrosion reactions at the molecular level. Vapor phase inhibitors create protective molecular films on metal surfaces, while solution-phase inhibitors modify the electrochemical behavior of the material-environment interface to suppress corrosion processes.

Microstructural engineering focuses on optimizing material grain boundaries and phase distributions to enhance corrosion resistance. Techniques such as grain refinement, precipitation hardening, and controlled alloying can significantly improve a material's resistance to localized corrosion mechanisms like pitting and stress corrosion cracking.

Predictive maintenance protocols incorporating real-time corrosion monitoring systems enable early detection of material degradation. Advanced sensors utilizing electrochemical impedance spectroscopy, electrical resistance techniques, and acoustic emission monitoring provide continuous data on material condition, allowing for timely intervention before critical failure occurs.

Surface modification techniques represent another critical strategy, with thermal spray coatings providing protective barriers against corrosive agents. These include ceramic coatings (Al2O3, Cr2O3) that offer excellent chemical stability and thermal resistance. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) techniques enable the application of ultra-thin, highly adherent protective layers with precisely controlled composition and microstructure.

Passive protection systems utilize sacrificial anodes and impressed current cathodic protection (ICCP) to redirect corrosion processes away from critical structural components. These systems require careful design and regular monitoring to maintain effectiveness throughout the service life of autoclave equipment.

Advanced composite materials offer promising alternatives to traditional metal alloys in extreme environments. Fiber-reinforced polymers (FRPs) with specialized resin systems demonstrate exceptional corrosion resistance while maintaining structural integrity. Ceramic matrix composites (CMCs) provide superior performance at elevated temperatures where conventional materials would rapidly degrade.

Electrochemical inhibition strategies involve the introduction of specific chemical compounds that interfere with corrosion reactions at the molecular level. Vapor phase inhibitors create protective molecular films on metal surfaces, while solution-phase inhibitors modify the electrochemical behavior of the material-environment interface to suppress corrosion processes.

Microstructural engineering focuses on optimizing material grain boundaries and phase distributions to enhance corrosion resistance. Techniques such as grain refinement, precipitation hardening, and controlled alloying can significantly improve a material's resistance to localized corrosion mechanisms like pitting and stress corrosion cracking.

Predictive maintenance protocols incorporating real-time corrosion monitoring systems enable early detection of material degradation. Advanced sensors utilizing electrochemical impedance spectroscopy, electrical resistance techniques, and acoustic emission monitoring provide continuous data on material condition, allowing for timely intervention before critical failure occurs.

Sustainability Considerations in Advanced Autoclave Materials

The environmental impact of autoclave materials and processes has become increasingly significant as industries strive for greater sustainability. Advanced autoclave structural materials must not only deliver exceptional durability but also align with modern sustainability imperatives. This requires a holistic approach that considers the entire lifecycle of these materials from production through disposal.

Material sourcing represents a critical sustainability consideration. Traditional autoclave materials often rely on non-renewable resources and energy-intensive extraction processes. Recent innovations have focused on incorporating recycled content and renewable resources into high-performance composites without compromising structural integrity. For instance, bio-based resins derived from agricultural waste have shown promising results in reducing the carbon footprint of certain autoclave applications.

Energy consumption during manufacturing presents another significant sustainability challenge. Autoclave curing typically requires substantial energy inputs to maintain high temperatures and pressures. Research into low-temperature curing alternatives and more efficient heating systems has demonstrated potential energy savings of 15-30% without sacrificing material performance. Additionally, the development of rapid-cure resins has reduced processing times, further decreasing the energy demands of autoclave operations.

Toxicity and emissions concerns extend throughout the material lifecycle. Traditional autoclave materials often contain volatile organic compounds (VOCs) and other potentially harmful substances that can impact worker health and environmental quality. Next-generation materials are being engineered with reduced toxicity profiles while maintaining necessary performance characteristics. Water-based systems and solvent-free formulations represent promising advances in this area.

End-of-life considerations have historically been neglected in autoclave material development, resulting in difficult-to-recycle composite waste. Recent research has focused on designing materials with improved recyclability and biodegradability. Thermoplastic composites that can be melted and reformed represent one approach, while chemically recyclable thermosets offer another pathway to reducing landfill waste from decommissioned autoclave structures.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the true environmental impact of autoclave materials. These comprehensive analyses consider everything from raw material extraction to disposal, providing valuable insights for material selection and process optimization. Several studies have demonstrated that higher initial material costs for sustainable alternatives can be offset by reduced environmental impacts and extended service life.

Regulatory frameworks worldwide are evolving to encourage more sustainable practices in industrial materials. Companies developing advanced autoclave materials must navigate these changing requirements while maintaining competitive performance characteristics. Those that successfully integrate sustainability considerations into their material development processes stand to gain significant market advantages as environmental concerns continue to shape purchasing decisions.

Material sourcing represents a critical sustainability consideration. Traditional autoclave materials often rely on non-renewable resources and energy-intensive extraction processes. Recent innovations have focused on incorporating recycled content and renewable resources into high-performance composites without compromising structural integrity. For instance, bio-based resins derived from agricultural waste have shown promising results in reducing the carbon footprint of certain autoclave applications.

Energy consumption during manufacturing presents another significant sustainability challenge. Autoclave curing typically requires substantial energy inputs to maintain high temperatures and pressures. Research into low-temperature curing alternatives and more efficient heating systems has demonstrated potential energy savings of 15-30% without sacrificing material performance. Additionally, the development of rapid-cure resins has reduced processing times, further decreasing the energy demands of autoclave operations.

Toxicity and emissions concerns extend throughout the material lifecycle. Traditional autoclave materials often contain volatile organic compounds (VOCs) and other potentially harmful substances that can impact worker health and environmental quality. Next-generation materials are being engineered with reduced toxicity profiles while maintaining necessary performance characteristics. Water-based systems and solvent-free formulations represent promising advances in this area.

End-of-life considerations have historically been neglected in autoclave material development, resulting in difficult-to-recycle composite waste. Recent research has focused on designing materials with improved recyclability and biodegradability. Thermoplastic composites that can be melted and reformed represent one approach, while chemically recyclable thermosets offer another pathway to reducing landfill waste from decommissioned autoclave structures.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the true environmental impact of autoclave materials. These comprehensive analyses consider everything from raw material extraction to disposal, providing valuable insights for material selection and process optimization. Several studies have demonstrated that higher initial material costs for sustainable alternatives can be offset by reduced environmental impacts and extended service life.

Regulatory frameworks worldwide are evolving to encourage more sustainable practices in industrial materials. Companies developing advanced autoclave materials must navigate these changing requirements while maintaining competitive performance characteristics. Those that successfully integrate sustainability considerations into their material development processes stand to gain significant market advantages as environmental concerns continue to shape purchasing decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!