Measure Autoclave Steam Purity for Pharmaceutical Sterilization

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pharmaceutical Autoclave Steam Purity Background and Objectives

Steam sterilization via autoclaves has been a cornerstone of pharmaceutical manufacturing and healthcare facilities for over a century. The evolution of this technology began in the late 19th century with the development of the first pressure steam sterilizers, progressing significantly through the 20th century with advancements in automation, control systems, and validation methodologies. The fundamental principle—utilizing saturated steam under pressure to eliminate microbial contaminants—remains unchanged, though the precision and reliability of the process have dramatically improved.

In recent decades, regulatory bodies including the FDA, EMA, and WHO have established increasingly stringent requirements for steam quality in pharmaceutical sterilization processes. This regulatory evolution reflects growing understanding of how steam impurities can compromise sterilization efficacy and potentially introduce contaminants into sterile products or equipment.

The technical objective of measuring autoclave steam purity centers on ensuring that steam used in pharmaceutical sterilization processes meets or exceeds established purity standards, particularly those outlined in HTM 2031, EN 285, and ANSI/AAMI ST79. These standards specify maximum allowable levels of non-condensable gases, particulates, and chemical contaminants in steam used for sterilization.

Current industry trends indicate a shift toward continuous monitoring systems rather than periodic testing, driven by the pharmaceutical industry's adoption of Quality by Design (QbD) principles and Process Analytical Technology (PAT) frameworks. This evolution aims to enhance process understanding and control through real-time data acquisition and analysis.

The measurement of steam purity presents unique technical challenges due to the high-temperature, high-pressure environment of autoclaves, requiring specialized instrumentation capable of withstanding these conditions while delivering accurate, reproducible results. Traditional methods often involve condensate sampling and analysis, but these provide only retrospective data rather than real-time monitoring.

Emerging technologies in this field include advanced sensor systems capable of in-situ measurements, spectroscopic techniques for chemical contaminant detection, and integrated monitoring platforms that combine multiple measurement parameters. These innovations aim to provide more comprehensive, real-time assessment of steam quality parameters.

The ultimate goal of steam purity measurement technology development is to establish reliable, continuous monitoring systems that can detect deviations from specified parameters in real-time, allowing for immediate corrective action and ensuring consistent sterilization efficacy across pharmaceutical manufacturing operations.

In recent decades, regulatory bodies including the FDA, EMA, and WHO have established increasingly stringent requirements for steam quality in pharmaceutical sterilization processes. This regulatory evolution reflects growing understanding of how steam impurities can compromise sterilization efficacy and potentially introduce contaminants into sterile products or equipment.

The technical objective of measuring autoclave steam purity centers on ensuring that steam used in pharmaceutical sterilization processes meets or exceeds established purity standards, particularly those outlined in HTM 2031, EN 285, and ANSI/AAMI ST79. These standards specify maximum allowable levels of non-condensable gases, particulates, and chemical contaminants in steam used for sterilization.

Current industry trends indicate a shift toward continuous monitoring systems rather than periodic testing, driven by the pharmaceutical industry's adoption of Quality by Design (QbD) principles and Process Analytical Technology (PAT) frameworks. This evolution aims to enhance process understanding and control through real-time data acquisition and analysis.

The measurement of steam purity presents unique technical challenges due to the high-temperature, high-pressure environment of autoclaves, requiring specialized instrumentation capable of withstanding these conditions while delivering accurate, reproducible results. Traditional methods often involve condensate sampling and analysis, but these provide only retrospective data rather than real-time monitoring.

Emerging technologies in this field include advanced sensor systems capable of in-situ measurements, spectroscopic techniques for chemical contaminant detection, and integrated monitoring platforms that combine multiple measurement parameters. These innovations aim to provide more comprehensive, real-time assessment of steam quality parameters.

The ultimate goal of steam purity measurement technology development is to establish reliable, continuous monitoring systems that can detect deviations from specified parameters in real-time, allowing for immediate corrective action and ensuring consistent sterilization efficacy across pharmaceutical manufacturing operations.

Market Demand Analysis for Steam Quality Monitoring

The global market for steam quality monitoring in pharmaceutical sterilization processes has experienced significant growth in recent years, driven primarily by increasingly stringent regulatory requirements and the critical importance of contamination prevention in pharmaceutical manufacturing. According to industry reports, the pharmaceutical sterilization equipment market, which includes steam quality monitoring systems, is projected to reach $12.5 billion by 2027, growing at a CAGR of 6.8% from 2022.

Steam quality monitoring represents a crucial segment within this market, as autoclave sterilization remains the most widely used method for terminal sterilization in pharmaceutical manufacturing. The demand is particularly strong in regions with established pharmaceutical manufacturing bases, including North America, Europe, and increasingly in Asia-Pacific countries such as China, India, and Singapore.

Key market drivers include the implementation of more rigorous Good Manufacturing Practice (GMP) standards by regulatory bodies worldwide, including the FDA, EMA, and various national regulatory authorities. These regulations specifically address steam quality parameters such as non-condensable gases, superheat, and dryness fraction, creating substantial demand for advanced monitoring solutions that can provide real-time, accurate measurements.

The COVID-19 pandemic has further accelerated market growth, as pharmaceutical companies have expanded production capacities and upgraded existing facilities to meet unprecedented demand for vaccines and other sterile products. This expansion has directly translated into increased demand for steam quality monitoring systems that can ensure process validation and product safety.

End-user segments showing the strongest demand include large pharmaceutical manufacturers, contract manufacturing organizations (CMOs), and hospital pharmacies that prepare sterile products in-house. Among these, CMOs represent the fastest-growing segment, with a projected growth rate of 8.2% annually through 2027, reflecting the ongoing trend toward outsourced pharmaceutical manufacturing.

From a technological perspective, the market is witnessing a shift from traditional offline testing methods toward continuous monitoring systems that integrate with facility management software and provide real-time alerts. This transition is driven by the need for more reliable documentation for regulatory compliance and the push toward Industry 4.0 principles in pharmaceutical manufacturing.

Cost considerations remain significant, with pharmaceutical companies seeking solutions that balance initial investment with long-term operational benefits. The average return on investment period for advanced steam quality monitoring systems is approximately 18-24 months, primarily through reduced batch rejection rates and minimized production downtime.

Steam quality monitoring represents a crucial segment within this market, as autoclave sterilization remains the most widely used method for terminal sterilization in pharmaceutical manufacturing. The demand is particularly strong in regions with established pharmaceutical manufacturing bases, including North America, Europe, and increasingly in Asia-Pacific countries such as China, India, and Singapore.

Key market drivers include the implementation of more rigorous Good Manufacturing Practice (GMP) standards by regulatory bodies worldwide, including the FDA, EMA, and various national regulatory authorities. These regulations specifically address steam quality parameters such as non-condensable gases, superheat, and dryness fraction, creating substantial demand for advanced monitoring solutions that can provide real-time, accurate measurements.

The COVID-19 pandemic has further accelerated market growth, as pharmaceutical companies have expanded production capacities and upgraded existing facilities to meet unprecedented demand for vaccines and other sterile products. This expansion has directly translated into increased demand for steam quality monitoring systems that can ensure process validation and product safety.

End-user segments showing the strongest demand include large pharmaceutical manufacturers, contract manufacturing organizations (CMOs), and hospital pharmacies that prepare sterile products in-house. Among these, CMOs represent the fastest-growing segment, with a projected growth rate of 8.2% annually through 2027, reflecting the ongoing trend toward outsourced pharmaceutical manufacturing.

From a technological perspective, the market is witnessing a shift from traditional offline testing methods toward continuous monitoring systems that integrate with facility management software and provide real-time alerts. This transition is driven by the need for more reliable documentation for regulatory compliance and the push toward Industry 4.0 principles in pharmaceutical manufacturing.

Cost considerations remain significant, with pharmaceutical companies seeking solutions that balance initial investment with long-term operational benefits. The average return on investment period for advanced steam quality monitoring systems is approximately 18-24 months, primarily through reduced batch rejection rates and minimized production downtime.

Current Steam Purity Measurement Technologies and Challenges

Steam purity measurement in pharmaceutical autoclaves presents significant technical challenges due to the demanding requirements of sterilization processes. Current technologies primarily fall into three categories: traditional sampling methods, real-time monitoring systems, and laboratory analytical techniques.

Traditional sampling methods involve collecting steam condensate samples for subsequent laboratory analysis. The most widely used approach is the condensate collection method, where steam is condensed in a controlled environment and collected in sterile containers. While this method provides reliable data, it suffers from significant time delays between sampling and results, making real-time process control impossible. Additionally, the sampling process itself may introduce contaminants, potentially skewing results.

Real-time monitoring systems have emerged as a response to the limitations of traditional methods. Conductivity meters represent the most common real-time approach, measuring the electrical conductivity of steam condensate to detect ionic impurities. These systems offer continuous monitoring capabilities but lack specificity in identifying particular contaminants. More advanced systems incorporate multiple sensors for parameters such as total organic carbon (TOC), pH, and specific ion detection, providing a more comprehensive purity profile.

Spectroscopic techniques have gained traction in recent years, with Near-Infrared (NIR) and Raman spectroscopy showing promise for non-invasive steam quality assessment. These methods can detect both particulate and chemical contaminants without sample extraction, though their implementation in high-pressure, high-temperature autoclave environments remains technically challenging.

The pharmaceutical industry faces several critical challenges in steam purity measurement. First, regulatory requirements from agencies like FDA and EMA demand increasingly stringent documentation of sterilization parameters, including steam quality. Current technologies often struggle to provide the level of detail and certainty required by these regulations.

Second, measurement accuracy and precision at high temperatures (121-134°C) and pressures (1-3 bar) present significant engineering challenges. Sensor durability in these harsh conditions often compromises long-term reliability and measurement consistency.

Third, the detection of non-condensable gases (NCGs) such as air and carbon dioxide remains problematic. These gases can form insulating pockets within the autoclave, preventing steam contact with surfaces and compromising sterilization efficacy. Current technologies often fail to detect these gases at the low concentrations that can still impact sterilization.

Finally, there exists a significant gap between laboratory analytical capabilities and practical in-situ monitoring solutions. While laboratory methods can detect contaminants at parts-per-billion levels, translating this sensitivity to online monitoring systems within operational autoclaves remains an unresolved technical challenge for the industry.

Traditional sampling methods involve collecting steam condensate samples for subsequent laboratory analysis. The most widely used approach is the condensate collection method, where steam is condensed in a controlled environment and collected in sterile containers. While this method provides reliable data, it suffers from significant time delays between sampling and results, making real-time process control impossible. Additionally, the sampling process itself may introduce contaminants, potentially skewing results.

Real-time monitoring systems have emerged as a response to the limitations of traditional methods. Conductivity meters represent the most common real-time approach, measuring the electrical conductivity of steam condensate to detect ionic impurities. These systems offer continuous monitoring capabilities but lack specificity in identifying particular contaminants. More advanced systems incorporate multiple sensors for parameters such as total organic carbon (TOC), pH, and specific ion detection, providing a more comprehensive purity profile.

Spectroscopic techniques have gained traction in recent years, with Near-Infrared (NIR) and Raman spectroscopy showing promise for non-invasive steam quality assessment. These methods can detect both particulate and chemical contaminants without sample extraction, though their implementation in high-pressure, high-temperature autoclave environments remains technically challenging.

The pharmaceutical industry faces several critical challenges in steam purity measurement. First, regulatory requirements from agencies like FDA and EMA demand increasingly stringent documentation of sterilization parameters, including steam quality. Current technologies often struggle to provide the level of detail and certainty required by these regulations.

Second, measurement accuracy and precision at high temperatures (121-134°C) and pressures (1-3 bar) present significant engineering challenges. Sensor durability in these harsh conditions often compromises long-term reliability and measurement consistency.

Third, the detection of non-condensable gases (NCGs) such as air and carbon dioxide remains problematic. These gases can form insulating pockets within the autoclave, preventing steam contact with surfaces and compromising sterilization efficacy. Current technologies often fail to detect these gases at the low concentrations that can still impact sterilization.

Finally, there exists a significant gap between laboratory analytical capabilities and practical in-situ monitoring solutions. While laboratory methods can detect contaminants at parts-per-billion levels, translating this sensitivity to online monitoring systems within operational autoclaves remains an unresolved technical challenge for the industry.

Existing Steam Purity Measurement Methodologies

01 Methods for measuring steam purity in autoclaves

Various methods are employed to measure steam purity in autoclave systems, including conductivity measurements, spectroscopic analysis, and chemical indicators. These techniques help monitor the quality of steam by detecting impurities such as particulates, non-condensable gases, and chemical contaminants that could compromise sterilization efficacy. Accurate measurement of steam purity is essential for ensuring proper sterilization in medical, pharmaceutical, and laboratory settings.- Steam quality measurement techniques: Various techniques are employed to measure steam purity in autoclaves, including conductivity measurements, spectroscopic analysis, and chemical indicators. These methods help determine the presence of impurities such as particulates, chemicals, and microorganisms in the steam. Accurate measurement of steam quality is essential for ensuring effective sterilization in medical, pharmaceutical, and laboratory settings.

- Monitoring systems for autoclave steam purity: Automated monitoring systems are designed to continuously assess steam purity in autoclaves. These systems typically incorporate sensors, data loggers, and control interfaces that provide real-time feedback on steam quality parameters. Advanced monitoring solutions may include alarm functions that alert operators when steam purity falls below acceptable thresholds, ensuring sterilization processes remain compliant with industry standards.

- Steam purification methods for autoclaves: Various methods are employed to purify steam before it enters the autoclave chamber. These include filtration systems, demineralizers, steam separators, and condensate traps that remove contaminants from the steam. Purification processes help eliminate non-condensable gases, particulates, and chemical impurities that could compromise sterilization efficacy or damage sensitive instruments during the autoclave cycle.

- Temperature and pressure control for steam quality: Precise control of temperature and pressure parameters is crucial for maintaining steam purity in autoclaves. Systems that regulate these variables help ensure that steam remains in the proper saturated state required for effective sterilization. Advanced control mechanisms may include pressure sensors, temperature probes, and automated valves that work together to maintain optimal steam conditions throughout the sterilization cycle.

- Standards and validation for steam purity: Regulatory standards and validation protocols exist to ensure autoclave steam meets specific purity requirements. These standards define acceptable limits for contaminants and provide guidelines for testing and certification. Validation procedures typically involve periodic testing of steam quality using standardized methods, documentation of results, and calibration of measurement instruments to ensure ongoing compliance with industry requirements for sterile processing.

02 Steam quality monitoring systems and sensors

Specialized monitoring systems and sensors are designed to continuously evaluate steam quality parameters in autoclaves. These systems typically incorporate temperature sensors, pressure transducers, and conductivity probes that work together to provide real-time data on steam purity. Advanced systems may include automated sampling mechanisms and digital interfaces that alert operators when steam quality falls below acceptable standards for sterilization processes.Expand Specific Solutions03 Steam purity standards and compliance testing

Regulatory standards establish specific requirements for steam purity in sterilization processes. Compliance testing protocols involve sampling steam at critical points in the autoclave system and analyzing for contaminants according to established thresholds. These standards typically specify acceptable levels of dryness, superheat, non-condensable gases, and particulate matter. Regular validation testing ensures that autoclave systems consistently produce steam of sufficient purity for effective sterilization.Expand Specific Solutions04 Steam generation and purification technologies

Technologies for generating and purifying steam for autoclave applications focus on removing impurities that could compromise sterilization efficacy. These include water pretreatment systems, steam separators, filters, and demineralizers that remove minerals, organic compounds, and particulates. Some advanced systems incorporate multiple purification stages to achieve ultra-pure steam suitable for critical applications in pharmaceutical manufacturing and medical device sterilization.Expand Specific Solutions05 Automated steam quality control systems

Automated control systems maintain optimal steam purity by continuously monitoring key parameters and making real-time adjustments. These systems integrate sensors, controllers, and feedback mechanisms to regulate steam generation, purification, and delivery processes. When deviations in steam quality are detected, the systems can automatically adjust operating parameters or alert operators. Advanced systems may incorporate predictive analytics to anticipate potential steam quality issues before they affect sterilization performance.Expand Specific Solutions

Key Industry Players in Autoclave Monitoring Solutions

The pharmaceutical sterilization steam purity measurement market is currently in a growth phase, driven by increasing regulatory requirements and quality control standards in pharmaceutical manufacturing. The global market size for sterilization equipment and validation technologies is estimated at $6-8 billion, with steady annual growth of 5-7%. From a technological maturity perspective, established players like STERIS (American Sterilizer Co.) and Fedegari Autoclavi lead with comprehensive validation solutions, while companies such as 3M Innovative Properties and Olympus Medical Systems contribute specialized sensing technologies. Emerging players including Turbett Surgical and Arann Healthcare are introducing innovative approaches to steam quality monitoring. The competitive landscape shows a mix of large medical device manufacturers and specialized sterilization technology providers, with increasing focus on automated, real-time monitoring systems that ensure compliance with stringent pharmaceutical manufacturing standards.

American Sterilizer Co.

Technical Solution: American Sterilizer Co. has developed a comprehensive steam quality monitoring system specifically for pharmaceutical applications. Their technology employs a multi-sensor approach that simultaneously measures conductivity, particulate content, and non-condensable gas concentration in steam used for sterilization. The system features a specialized sampling chamber that can be installed at various points in the steam path, from the generator to the sterilization chamber. Their proprietary algorithms analyze real-time data against established pharmacopeial standards to ensure compliance. The technology includes automated documentation features that generate batch-specific steam quality certificates for regulatory submissions. American Sterilizer's system can detect contaminants at concentrations below 0.1 ppm and provides continuous monitoring throughout the sterilization cycle, with particular attention to the critical exposure phase.

Strengths: Comprehensive multi-parameter monitoring; automated compliance documentation; high sensitivity to low-level contaminants. Weaknesses: Complex installation requirements; higher maintenance needs compared to simpler monitoring systems.

Fedegari Autoclavi SpA

Technical Solution: Fedegari has developed advanced steam quality monitoring systems that integrate directly with their pharmaceutical autoclaves. Their technology employs real-time conductivity sensors and specialized steam samplers positioned at critical points within the sterilization chamber. The system continuously monitors non-condensable gases, superheat levels, and dryness fraction through a network of temperature and pressure sensors. Fedegari's solution includes their proprietary Thema4 process controller that analyzes multiple parameters simultaneously to ensure compliance with EN 285 and HTM 2010 standards. Their technology can detect contaminants down to parts per billion levels and automatically adjusts sterilization parameters when deviations occur, ensuring process validation integrity throughout the sterilization cycle.

Strengths: Integrated approach combining hardware sensors with sophisticated software analytics; real-time monitoring capabilities; automatic adjustment of sterilization parameters. Weaknesses: Proprietary system architecture may limit compatibility with third-party equipment; relatively high implementation cost compared to standalone monitoring solutions.

Critical Technologies for Pharmaceutical Steam Quality Assessment

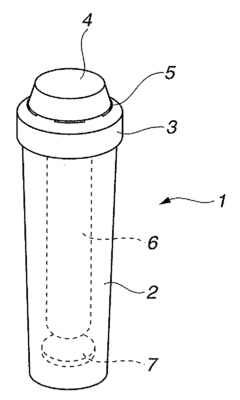

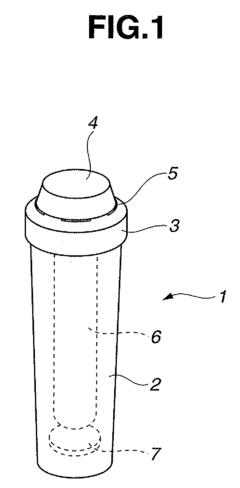

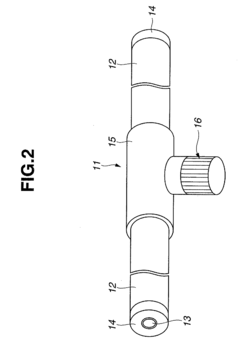

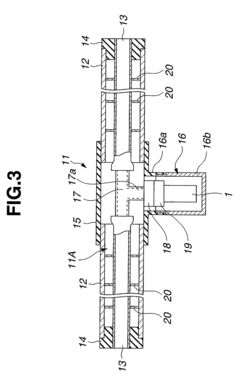

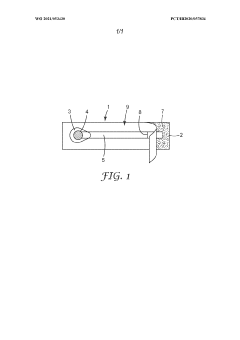

Endoscope sterilization evaluation device

PatentInactiveUS20090081767A1

Innovation

- An endoscope sterilization evaluation device with an elongated hollow body simulating the tubular passage, housing a biological indicator and culture solution, allows for easy attachment and removal from the endoscope, enabling sterilization effect determination without a germ-free environment or skilled operation by using a communication passage for sterilizing gas penetration and culture solution immersion.

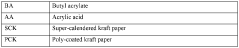

High temperature sterilizable adhesive articles

PatentWO2021053430A1

Innovation

- Incorporating a high temperature sealing agent into the (meth)acrylate-based pressure-sensitive adhesive matrix, which remains unreactive at ambient temperatures but forms a heat-sealed adhesive bond with increased adhesion at temperatures above 100°C, enhancing the adhesive's cohesive strength and preventing viscous flow.

Regulatory Compliance Requirements for Pharmaceutical Sterilization

Pharmaceutical sterilization processes are subject to stringent regulatory frameworks established by various international and national authorities. The FDA's Current Good Manufacturing Practice (cGMP) regulations, specifically 21 CFR Parts 210 and 211, mandate that steam used in sterilization processes must meet specific purity requirements to ensure product safety and efficacy. These regulations require pharmaceutical manufacturers to validate their sterilization processes and continuously monitor steam quality parameters.

The European Medicines Agency (EMA) has established similar requirements through EU GMP Annex 1, which specifically addresses sterile medicinal products. This regulation emphasizes the need for regular monitoring of steam quality and purity, with particular attention to non-condensable gases and superheating conditions that could compromise sterilization efficacy.

ISO 17665-1:2006 provides comprehensive guidelines for the development, validation, and routine control of moist heat sterilization processes. This standard explicitly requires monitoring of steam quality parameters, including dryness value, superheat, and non-condensable gas content, establishing specific acceptable ranges for each parameter.

The United States Pharmacopeia (USP) Chapter <1229.4> on Steam Sterilization further elaborates on steam quality requirements, specifying that steam must be free from contaminants that could affect product quality or patient safety. It establishes limits for particulates, endotoxins, and chemical impurities in pharmaceutical-grade steam.

Japanese Pharmacopoeia and Chinese Pharmacopoeia also contain specific requirements for steam purity in pharmaceutical applications, though these may vary slightly from Western standards. These variations necessitate careful consideration when designing global manufacturing facilities.

Regulatory bodies increasingly require real-time monitoring and documentation of steam purity parameters throughout the sterilization cycle. This trend has driven the development of advanced monitoring technologies capable of continuous measurement and automatic documentation to satisfy regulatory expectations for data integrity.

Compliance with these regulations requires pharmaceutical manufacturers to implement comprehensive validation protocols that include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) of steam generation and distribution systems. These protocols must demonstrate that steam purity consistently meets established specifications under all operating conditions.

Risk-based approaches to regulatory compliance, as outlined in ICH Q9 Quality Risk Management, are becoming increasingly important. Manufacturers must identify potential failure modes in steam generation systems and implement appropriate control strategies to mitigate risks to product quality and patient safety.

The European Medicines Agency (EMA) has established similar requirements through EU GMP Annex 1, which specifically addresses sterile medicinal products. This regulation emphasizes the need for regular monitoring of steam quality and purity, with particular attention to non-condensable gases and superheating conditions that could compromise sterilization efficacy.

ISO 17665-1:2006 provides comprehensive guidelines for the development, validation, and routine control of moist heat sterilization processes. This standard explicitly requires monitoring of steam quality parameters, including dryness value, superheat, and non-condensable gas content, establishing specific acceptable ranges for each parameter.

The United States Pharmacopeia (USP) Chapter <1229.4> on Steam Sterilization further elaborates on steam quality requirements, specifying that steam must be free from contaminants that could affect product quality or patient safety. It establishes limits for particulates, endotoxins, and chemical impurities in pharmaceutical-grade steam.

Japanese Pharmacopoeia and Chinese Pharmacopoeia also contain specific requirements for steam purity in pharmaceutical applications, though these may vary slightly from Western standards. These variations necessitate careful consideration when designing global manufacturing facilities.

Regulatory bodies increasingly require real-time monitoring and documentation of steam purity parameters throughout the sterilization cycle. This trend has driven the development of advanced monitoring technologies capable of continuous measurement and automatic documentation to satisfy regulatory expectations for data integrity.

Compliance with these regulations requires pharmaceutical manufacturers to implement comprehensive validation protocols that include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) of steam generation and distribution systems. These protocols must demonstrate that steam purity consistently meets established specifications under all operating conditions.

Risk-based approaches to regulatory compliance, as outlined in ICH Q9 Quality Risk Management, are becoming increasingly important. Manufacturers must identify potential failure modes in steam generation systems and implement appropriate control strategies to mitigate risks to product quality and patient safety.

Validation Protocols for Steam Quality Measurement Systems

Validation protocols for steam quality measurement systems in pharmaceutical sterilization processes must adhere to rigorous standards to ensure patient safety and product integrity. These protocols typically follow a three-phase approach: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), each serving distinct validation purposes.

Installation Qualification protocols verify that measurement instruments are properly installed according to manufacturer specifications and regulatory requirements. This includes documentation of calibration certificates, material certificates for components in contact with steam, and verification of proper connections to sampling points. The protocol must specify acceptance criteria for installation parameters and include detailed checklists for visual inspections.

Operational Qualification protocols focus on demonstrating that the steam quality measurement system functions as intended under controlled conditions. This phase includes testing the system's ability to detect non-condensable gases, measure dryness value, and identify superheating conditions. Challenge tests with known contaminant levels should be incorporated to verify detection capabilities and alarm functions when parameters exceed acceptable limits.

Performance Qualification protocols evaluate the measurement system's reliability during actual sterilization cycles. This involves multiple test runs under various operating conditions to ensure consistent performance. The protocol should specify sampling frequency, locations, and statistical methods for data analysis. Correlation studies between different measurement methods (e.g., conductivity vs. direct sampling) are essential to validate measurement accuracy.

Change control procedures must be integrated into validation protocols, detailing how modifications to the measurement system will be evaluated and revalidated. This includes risk assessments for any proposed changes and determination of the extent of revalidation required based on the change impact analysis.

Periodic revalidation requirements should be clearly defined, including frequency intervals based on risk assessment, critical parameters to be reassessed, and acceptance criteria that may evolve with updated regulatory guidance. The protocol should establish a documented review process for evaluating historical data to identify drift or deterioration in measurement accuracy.

Documentation requirements constitute a critical component of validation protocols, specifying formats for recording raw data, calculation methodologies, and reporting templates. Electronic data management systems must comply with 21 CFR Part 11 requirements if utilized for data storage and analysis, with appropriate audit trails and data integrity safeguards.

Installation Qualification protocols verify that measurement instruments are properly installed according to manufacturer specifications and regulatory requirements. This includes documentation of calibration certificates, material certificates for components in contact with steam, and verification of proper connections to sampling points. The protocol must specify acceptance criteria for installation parameters and include detailed checklists for visual inspections.

Operational Qualification protocols focus on demonstrating that the steam quality measurement system functions as intended under controlled conditions. This phase includes testing the system's ability to detect non-condensable gases, measure dryness value, and identify superheating conditions. Challenge tests with known contaminant levels should be incorporated to verify detection capabilities and alarm functions when parameters exceed acceptable limits.

Performance Qualification protocols evaluate the measurement system's reliability during actual sterilization cycles. This involves multiple test runs under various operating conditions to ensure consistent performance. The protocol should specify sampling frequency, locations, and statistical methods for data analysis. Correlation studies between different measurement methods (e.g., conductivity vs. direct sampling) are essential to validate measurement accuracy.

Change control procedures must be integrated into validation protocols, detailing how modifications to the measurement system will be evaluated and revalidated. This includes risk assessments for any proposed changes and determination of the extent of revalidation required based on the change impact analysis.

Periodic revalidation requirements should be clearly defined, including frequency intervals based on risk assessment, critical parameters to be reassessed, and acceptance criteria that may evolve with updated regulatory guidance. The protocol should establish a documented review process for evaluating historical data to identify drift or deterioration in measurement accuracy.

Documentation requirements constitute a critical component of validation protocols, specifying formats for recording raw data, calculation methodologies, and reporting templates. Electronic data management systems must comply with 21 CFR Part 11 requirements if utilized for data storage and analysis, with appropriate audit trails and data integrity safeguards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!