Autoclave Performance Enhancements through Component Upgrades

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Enhancement Objectives

Autoclaves have evolved significantly since their inception in the early 20th century, transitioning from basic pressure vessels to sophisticated systems integrating advanced materials, precise control mechanisms, and intelligent monitoring capabilities. Initially developed for sterilization in medical settings, autoclaves have expanded their application scope to aerospace, composites manufacturing, and advanced materials processing, driving continuous technological advancement to meet increasingly demanding performance requirements.

The evolution of autoclave technology can be traced through several distinct phases. Early autoclaves (1900s-1950s) featured simple steam pressure vessels with manual controls. The second generation (1960s-1980s) introduced automated control systems and improved safety features. Modern autoclaves (1990s-2010s) incorporated computerized process control, data logging capabilities, and enhanced energy efficiency. The current generation (2010s-present) features smart systems with IoT connectivity, predictive maintenance capabilities, and advanced materials for improved durability and performance.

Component upgrades have been central to this evolution, with significant improvements in heating systems, pressure control mechanisms, door sealing technologies, and monitoring systems. These enhancements have collectively contributed to improved process reliability, reduced cycle times, enhanced energy efficiency, and extended equipment lifespan.

The primary objectives for autoclave performance enhancement through component upgrades include optimizing cure cycles for composite materials, reducing energy consumption, improving temperature uniformity within the chamber, enhancing pressure control precision, and implementing advanced monitoring systems for real-time process optimization. Additionally, there is a growing focus on developing modular component designs that facilitate easier maintenance and future upgrades.

Industry trends indicate a shift toward more sustainable autoclave operations, with emphasis on reducing carbon footprint through improved insulation, heat recovery systems, and more efficient heating elements. The integration of digital technologies for process optimization represents another significant trend, with machine learning algorithms increasingly being employed to predict optimal cure cycles based on material properties and desired outcomes.

Looking forward, autoclave technology enhancement objectives are increasingly focused on developing adaptive control systems capable of real-time process adjustments, implementing advanced composite curing techniques that reduce cycle times while maintaining or improving part quality, and creating more energy-efficient designs that minimize operational costs while maximizing throughput.

The evolution of autoclave technology can be traced through several distinct phases. Early autoclaves (1900s-1950s) featured simple steam pressure vessels with manual controls. The second generation (1960s-1980s) introduced automated control systems and improved safety features. Modern autoclaves (1990s-2010s) incorporated computerized process control, data logging capabilities, and enhanced energy efficiency. The current generation (2010s-present) features smart systems with IoT connectivity, predictive maintenance capabilities, and advanced materials for improved durability and performance.

Component upgrades have been central to this evolution, with significant improvements in heating systems, pressure control mechanisms, door sealing technologies, and monitoring systems. These enhancements have collectively contributed to improved process reliability, reduced cycle times, enhanced energy efficiency, and extended equipment lifespan.

The primary objectives for autoclave performance enhancement through component upgrades include optimizing cure cycles for composite materials, reducing energy consumption, improving temperature uniformity within the chamber, enhancing pressure control precision, and implementing advanced monitoring systems for real-time process optimization. Additionally, there is a growing focus on developing modular component designs that facilitate easier maintenance and future upgrades.

Industry trends indicate a shift toward more sustainable autoclave operations, with emphasis on reducing carbon footprint through improved insulation, heat recovery systems, and more efficient heating elements. The integration of digital technologies for process optimization represents another significant trend, with machine learning algorithms increasingly being employed to predict optimal cure cycles based on material properties and desired outcomes.

Looking forward, autoclave technology enhancement objectives are increasingly focused on developing adaptive control systems capable of real-time process adjustments, implementing advanced composite curing techniques that reduce cycle times while maintaining or improving part quality, and creating more energy-efficient designs that minimize operational costs while maximizing throughput.

Market Demand Analysis for Advanced Sterilization Solutions

The global sterilization equipment market is experiencing robust growth, driven by increasing healthcare expenditures and stringent regulations regarding infection control. Current market valuations place the autoclave segment at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. Healthcare facilities, pharmaceutical manufacturing, and research laboratories constitute the primary demand sources, collectively accounting for over 75% of market consumption.

Healthcare-associated infections (HAIs) remain a critical concern worldwide, with the WHO reporting that hundreds of millions of patients are affected annually. This persistent challenge has intensified the demand for more efficient and reliable sterilization technologies, particularly advanced autoclaves with enhanced performance capabilities. Regulatory bodies including the FDA, EU MDR, and various national health authorities have progressively tightened sterilization standards, compelling healthcare providers to upgrade existing equipment.

Component upgrades for autoclaves represent a significant market opportunity, as facilities seek cost-effective alternatives to complete system replacement. The retrofit market segment is growing at 8.3% annually, outpacing the overall autoclave market. Key demand drivers include energy efficiency improvements, which can reduce operational costs by 15-30%, and cycle time optimization, which enhances throughput capacity in high-volume settings.

Market research indicates that healthcare facilities are increasingly prioritizing autoclaves with advanced monitoring capabilities, improved steam distribution systems, and enhanced door sealing mechanisms. These component upgrades directly address pain points related to validation failures, incomplete sterilization, and equipment downtime. Survey data from hospital purchasing departments shows that 68% consider component reliability the most critical factor in sterilization equipment decisions.

Regional analysis reveals varying demand patterns, with mature markets in North America and Europe focusing on automation and efficiency upgrades, while emerging markets in Asia-Pacific and Latin America show stronger demand for basic reliability enhancements and capacity expansion. The dental and outpatient surgical center segments demonstrate particularly strong growth potential, with demand increasing at 9.2% annually as these facilities upgrade from basic to intermediate sterilization capabilities.

Customer feedback consistently highlights three primary requirements driving component upgrade decisions: reduced maintenance frequency, improved energy efficiency, and enhanced process validation capabilities. These market signals align with technological innovation opportunities in materials science, sensor technology, and control systems that can be incorporated into next-generation autoclave components.

Healthcare-associated infections (HAIs) remain a critical concern worldwide, with the WHO reporting that hundreds of millions of patients are affected annually. This persistent challenge has intensified the demand for more efficient and reliable sterilization technologies, particularly advanced autoclaves with enhanced performance capabilities. Regulatory bodies including the FDA, EU MDR, and various national health authorities have progressively tightened sterilization standards, compelling healthcare providers to upgrade existing equipment.

Component upgrades for autoclaves represent a significant market opportunity, as facilities seek cost-effective alternatives to complete system replacement. The retrofit market segment is growing at 8.3% annually, outpacing the overall autoclave market. Key demand drivers include energy efficiency improvements, which can reduce operational costs by 15-30%, and cycle time optimization, which enhances throughput capacity in high-volume settings.

Market research indicates that healthcare facilities are increasingly prioritizing autoclaves with advanced monitoring capabilities, improved steam distribution systems, and enhanced door sealing mechanisms. These component upgrades directly address pain points related to validation failures, incomplete sterilization, and equipment downtime. Survey data from hospital purchasing departments shows that 68% consider component reliability the most critical factor in sterilization equipment decisions.

Regional analysis reveals varying demand patterns, with mature markets in North America and Europe focusing on automation and efficiency upgrades, while emerging markets in Asia-Pacific and Latin America show stronger demand for basic reliability enhancements and capacity expansion. The dental and outpatient surgical center segments demonstrate particularly strong growth potential, with demand increasing at 9.2% annually as these facilities upgrade from basic to intermediate sterilization capabilities.

Customer feedback consistently highlights three primary requirements driving component upgrade decisions: reduced maintenance frequency, improved energy efficiency, and enhanced process validation capabilities. These market signals align with technological innovation opportunities in materials science, sensor technology, and control systems that can be incorporated into next-generation autoclave components.

Current Autoclave Technology Limitations and Challenges

Despite significant advancements in autoclave technology over recent decades, current systems face several critical limitations that impede optimal performance and efficiency. Traditional autoclaves suffer from uneven temperature distribution throughout the chamber, resulting in inconsistent curing processes for composite materials. This thermal gradient issue becomes particularly problematic when processing large or geometrically complex components, where temperature variations can exceed acceptable tolerances of ±5°C, compromising final product quality.

Energy inefficiency represents another major challenge, with conventional systems typically operating at 30-40% thermal efficiency. The substantial heat loss occurs primarily through inadequate insulation, poor door sealing mechanisms, and inefficient heating elements. These inefficiencies translate directly into excessive operational costs, with energy consumption accounting for approximately 60-70% of total autoclave operational expenses in industrial settings.

Pressure control systems in current autoclaves frequently exhibit response lag during critical cure cycle transitions. This limitation becomes particularly evident during rapid pressure ramp-up or cool-down phases, where pressure fluctuations can deviate by up to 0.2 bar from programmed values. Such deviations can induce residual stresses in composite materials, potentially leading to microstructural defects and reduced mechanical properties.

Monitoring and control technologies represent another significant limitation area. Many operational autoclaves still rely on outdated control systems with limited sensor integration capabilities. The inability to implement comprehensive real-time monitoring creates blind spots in process verification, necessitating conservative processing parameters that extend cycle times unnecessarily. Industry data suggests that optimized monitoring could reduce cycle times by 15-25% without compromising quality.

Component durability presents ongoing challenges, particularly for heating elements, circulation fans, and sealing mechanisms that operate under extreme conditions. Current materials often demonstrate accelerated degradation, requiring frequent maintenance interventions that increase downtime and operational costs. Maintenance records indicate that heating element failures account for approximately 40% of unplanned autoclave downtime events.

Automation limitations further constrain autoclave performance, with many systems lacking advanced adaptive control algorithms capable of responding to real-time process variations. This deficiency necessitates constant operator supervision and manual adjustments, increasing labor costs and introducing potential human error factors into critical manufacturing processes.

Environmental considerations also pose challenges, as traditional autoclave systems consume substantial water resources for cooling processes and may utilize environmentally problematic heat transfer fluids. Regulatory pressures increasingly demand more sustainable solutions that reduce resource consumption while maintaining processing capabilities.

Energy inefficiency represents another major challenge, with conventional systems typically operating at 30-40% thermal efficiency. The substantial heat loss occurs primarily through inadequate insulation, poor door sealing mechanisms, and inefficient heating elements. These inefficiencies translate directly into excessive operational costs, with energy consumption accounting for approximately 60-70% of total autoclave operational expenses in industrial settings.

Pressure control systems in current autoclaves frequently exhibit response lag during critical cure cycle transitions. This limitation becomes particularly evident during rapid pressure ramp-up or cool-down phases, where pressure fluctuations can deviate by up to 0.2 bar from programmed values. Such deviations can induce residual stresses in composite materials, potentially leading to microstructural defects and reduced mechanical properties.

Monitoring and control technologies represent another significant limitation area. Many operational autoclaves still rely on outdated control systems with limited sensor integration capabilities. The inability to implement comprehensive real-time monitoring creates blind spots in process verification, necessitating conservative processing parameters that extend cycle times unnecessarily. Industry data suggests that optimized monitoring could reduce cycle times by 15-25% without compromising quality.

Component durability presents ongoing challenges, particularly for heating elements, circulation fans, and sealing mechanisms that operate under extreme conditions. Current materials often demonstrate accelerated degradation, requiring frequent maintenance interventions that increase downtime and operational costs. Maintenance records indicate that heating element failures account for approximately 40% of unplanned autoclave downtime events.

Automation limitations further constrain autoclave performance, with many systems lacking advanced adaptive control algorithms capable of responding to real-time process variations. This deficiency necessitates constant operator supervision and manual adjustments, increasing labor costs and introducing potential human error factors into critical manufacturing processes.

Environmental considerations also pose challenges, as traditional autoclave systems consume substantial water resources for cooling processes and may utilize environmentally problematic heat transfer fluids. Regulatory pressures increasingly demand more sustainable solutions that reduce resource consumption while maintaining processing capabilities.

Current Component Upgrade Solutions and Implementations

01 Autoclave sterilization process optimization

Optimization of autoclave sterilization processes involves controlling parameters such as temperature, pressure, and cycle time to ensure effective sterilization while maintaining the integrity of sterilized items. Advanced monitoring systems can track these parameters in real-time, allowing for precise control and validation of the sterilization process. Innovations in this area focus on improving efficiency, reducing cycle times, and ensuring consistent sterilization results across different load types.- Autoclave sterilization efficiency and monitoring: Autoclave performance can be enhanced through improved sterilization efficiency and monitoring systems. This includes advanced temperature and pressure control mechanisms, real-time monitoring of sterilization parameters, and validation systems that ensure complete sterilization cycles. These technologies help maintain consistent performance and provide documentation of sterilization effectiveness for regulatory compliance.

- Autoclave design innovations for performance optimization: Innovations in autoclave design significantly impact performance. These include improved chamber configurations, advanced door sealing mechanisms, and optimized steam distribution systems. Design enhancements focus on uniform heat distribution, reduced cycle times, and energy efficiency while maintaining sterilization efficacy. Specialized designs also address specific industry needs such as medical, laboratory, or industrial applications.

- Performance testing and validation methods: Reliable performance testing and validation methods are essential for autoclave operation. These include biological indicators, chemical indicators, and physical parameter monitoring to verify sterilization effectiveness. Advanced testing protocols help identify performance issues before they affect sterilization results. Regular validation procedures ensure consistent performance and compliance with industry standards and regulatory requirements.

- Automation and control systems for enhanced performance: Modern autoclaves incorporate sophisticated automation and control systems to optimize performance. These include programmable logic controllers, touchscreen interfaces, and remote monitoring capabilities. Automated systems manage critical parameters such as temperature, pressure, and cycle duration with precision, reducing human error and improving consistency. Advanced control systems also enable customized cycles for different load types and materials.

- Energy efficiency and sustainability improvements: Energy efficiency innovations significantly improve autoclave performance while reducing operational costs and environmental impact. These include heat recovery systems, improved insulation, water recycling mechanisms, and optimized steam generation. Sustainable designs minimize resource consumption without compromising sterilization effectiveness. Energy-efficient autoclaves maintain performance standards while addressing growing concerns about environmental sustainability in laboratory and medical settings.

02 Autoclave design and structural improvements

Structural improvements in autoclave design focus on enhancing performance through better chamber construction, door sealing mechanisms, and overall equipment durability. Modern autoclaves incorporate features such as improved insulation, corrosion-resistant materials, and ergonomic designs that facilitate loading and unloading. These design enhancements contribute to more efficient heat distribution, reduced energy consumption, and extended equipment lifespan.Expand Specific Solutions03 Monitoring and validation systems for autoclave performance

Advanced monitoring and validation systems are crucial for ensuring autoclave performance meets required standards. These systems include sensors for temperature, pressure, and steam quality measurement, as well as data logging capabilities for process verification. Modern validation technologies incorporate digital interfaces, remote monitoring capabilities, and automated documentation to ensure compliance with regulatory requirements and provide comprehensive sterilization cycle records.Expand Specific Solutions04 Energy efficiency and sustainability in autoclave operation

Innovations in energy-efficient autoclave design focus on reducing resource consumption while maintaining sterilization effectiveness. These improvements include better insulation, heat recovery systems, optimized steam generation, and water recycling mechanisms. Energy-efficient autoclaves incorporate smart controls that adjust resource usage based on load size and type, resulting in reduced operational costs and environmental impact without compromising sterilization performance.Expand Specific Solutions05 Specialized autoclave systems for specific applications

Specialized autoclave systems are designed to meet the unique requirements of specific industries and applications. These include autoclaves for medical waste treatment, pharmaceutical production, laboratory research, and food processing. These specialized systems feature customized chambers, loading mechanisms, and cycle parameters optimized for particular materials and sterilization needs, ensuring effective performance while addressing industry-specific challenges and regulatory requirements.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The autoclave performance enhancement market is currently in a growth phase, with increasing demand driven by aerospace, automotive, and medical sectors. The market size is estimated to be expanding at a CAGR of 5-7%, fueled by technological advancements in component upgrades. Leading players like Boeing, Airbus Operations, and Mitsubishi Heavy Industries are investing heavily in autoclave technology maturity, focusing on energy efficiency and process optimization. General Electric and Pratt & Whitney are advancing control systems integration, while ThyssenKrupp Presta and Sony Semiconductor Solutions are developing specialized components for high-pressure applications. The competitive landscape shows a mix of established aerospace giants and specialized technology providers competing to deliver enhanced autoclave performance through innovative component solutions.

The Boeing Co.

Technical Solution: Boeing has developed a comprehensive autoclave enhancement program called AutoclavePrecision+ that focuses on component upgrades for large-scale aerospace manufacturing. Their heating system upgrades incorporate multi-zone control with predictive algorithms that reduce temperature variations to less than 2°C across chambers up to 15 meters in length. Boeing's pressure management components feature rapid response capabilities that achieve pressure change rates 40% faster than industry standards while maintaining precise tolerances. The company has engineered specialized thermal barriers that reduce heat loss by approximately 32%, significantly improving energy efficiency for large autoclaves. Their component upgrades also include advanced circulation systems with computational fluid dynamics-optimized fan designs that ensure uniform heat distribution even around complex geometries. Boeing's monitoring package incorporates over 100 sensors per autoclave that feed into a machine learning system for continuous process improvement.

Strengths: Exceptional performance for very large autoclave systems; advanced predictive control capabilities; excellent uniformity around complex aerospace structures. Weaknesses: Significant capital investment required; complex implementation process; specialized technical support needs for software maintenance.

General Electric Company

Technical Solution: GE has pioneered autoclave component upgrades through their SmartClave technology platform, which focuses on energy efficiency and process reliability. Their heating system upgrades incorporate ceramic heating elements that achieve 30% faster heat-up rates while consuming 25% less energy than traditional systems. GE's pressure management components feature adaptive control algorithms that automatically adjust to material-specific requirements, reducing cycle times by up to 20% for certain composite materials. The company has developed specialized thermal insulation packages that reduce heat loss by approximately 35%, significantly improving energy efficiency during long cure cycles. Their component upgrades also include advanced circulation fans with variable frequency drives that optimize air flow patterns based on part geometry, reducing temperature variations to less than 3°C throughout the autoclave chamber.

Strengths: Exceptional energy efficiency improvements; reduced operational costs; advanced control systems with material-specific optimization capabilities. Weaknesses: Retrofit complexity for older autoclave systems; higher upfront investment compared to standard components; requires specialized technical support for software updates.

Key Innovations in Autoclave Component Engineering

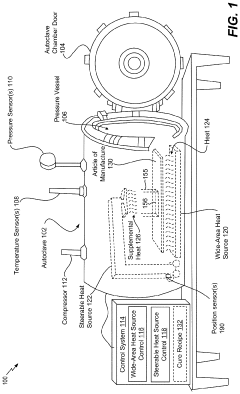

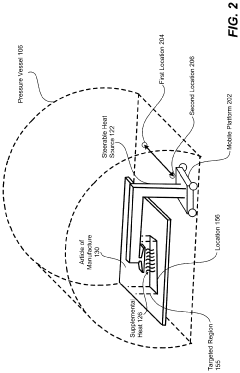

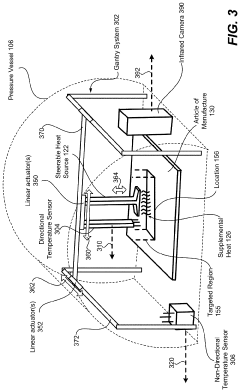

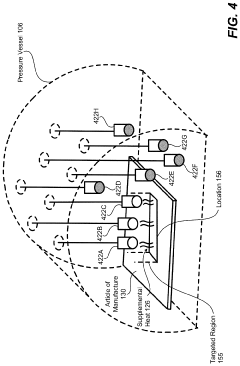

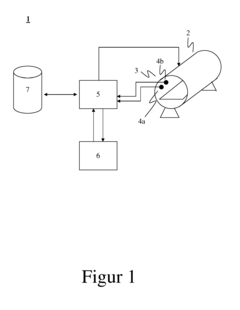

Steerable heat source

PatentActiveUS20200307035A1

Innovation

- A steerable heat source is integrated within the autoclave, coupled with a control system that directs supplemental heat to targeted regions using temperature sensors and a compressor to regulate pressure, ensuring precise temperature control and uniform heating.

Control of an autoclave production process

PatentActiveEP2572853A2

Innovation

- A method involving a sensor system to continuously record process and component parameters, with a control unit determining the component status and dynamically controlling the autoclave process based on this data, allowing for real-time adjustments of temperature, pressure, and cycle time to ensure quality and optimize productivity.

Energy Efficiency and Sustainability Considerations

Autoclave systems represent significant energy consumers in industrial settings, with traditional models often operating at suboptimal efficiency levels. Energy consumption in autoclaves primarily stems from heating elements, pressurization systems, and auxiliary components that maintain operational parameters. Recent advancements in component technology offer substantial opportunities for reducing energy footprints while maintaining or enhancing performance standards.

Thermal insulation upgrades present one of the most immediate paths to energy efficiency improvement. Advanced ceramic-based insulation materials can reduce heat loss by up to 30% compared to conventional fiberglass or mineral wool insulations. These materials, including aerogels and multi-layer ceramic composites, maintain their insulative properties even under extreme temperature and pressure conditions typical in autoclave operations.

Heat recovery systems represent another critical enhancement area. Implementation of waste heat recovery units can capture thermal energy from exhaust steam and condensate, redirecting it to preheat incoming water or support auxiliary heating requirements. Studies indicate that properly designed heat recovery systems can recapture 15-25% of energy that would otherwise be lost, significantly reducing the overall energy demand per operational cycle.

Control system upgrades offer both energy efficiency and operational benefits. Modern PLC-based systems with adaptive algorithms can optimize heating cycles based on load characteristics, minimizing energy waste from overheating or extended cycle times. Integration of IoT-enabled sensors allows for real-time monitoring and adjustment of operational parameters, potentially reducing energy consumption by 10-18% through precision control.

Renewable energy integration represents an emerging trend in autoclave sustainability. Solar thermal systems can supplement conventional heating methods, particularly in preheating applications. Some manufacturing facilities have successfully implemented hybrid systems where renewable sources provide baseline heating requirements while conventional systems handle peak demands and specialized cycle requirements.

Water conservation technologies complement energy efficiency measures in creating sustainable autoclave operations. Closed-loop water systems with advanced filtration can reduce water consumption by up to 80% compared to traditional once-through systems. Additionally, condensate recovery systems not only conserve water but also retain thermal energy that would otherwise be lost.

Carbon footprint reduction extends beyond direct energy consumption to include considerations of component lifecycle and materials selection. Components manufactured using sustainable practices and materials with lower embodied carbon offer additional environmental benefits. Manufacturers increasingly provide environmental product declarations (EPDs) that quantify the lifecycle environmental impact of components, enabling informed decision-making in upgrade planning.

Return on investment calculations for energy efficiency upgrades typically show payback periods of 12-36 months, depending on operational intensity and local energy costs. These calculations increasingly incorporate carbon pricing mechanisms and regulatory compliance costs, strengthening the business case for sustainability-focused upgrades.

Thermal insulation upgrades present one of the most immediate paths to energy efficiency improvement. Advanced ceramic-based insulation materials can reduce heat loss by up to 30% compared to conventional fiberglass or mineral wool insulations. These materials, including aerogels and multi-layer ceramic composites, maintain their insulative properties even under extreme temperature and pressure conditions typical in autoclave operations.

Heat recovery systems represent another critical enhancement area. Implementation of waste heat recovery units can capture thermal energy from exhaust steam and condensate, redirecting it to preheat incoming water or support auxiliary heating requirements. Studies indicate that properly designed heat recovery systems can recapture 15-25% of energy that would otherwise be lost, significantly reducing the overall energy demand per operational cycle.

Control system upgrades offer both energy efficiency and operational benefits. Modern PLC-based systems with adaptive algorithms can optimize heating cycles based on load characteristics, minimizing energy waste from overheating or extended cycle times. Integration of IoT-enabled sensors allows for real-time monitoring and adjustment of operational parameters, potentially reducing energy consumption by 10-18% through precision control.

Renewable energy integration represents an emerging trend in autoclave sustainability. Solar thermal systems can supplement conventional heating methods, particularly in preheating applications. Some manufacturing facilities have successfully implemented hybrid systems where renewable sources provide baseline heating requirements while conventional systems handle peak demands and specialized cycle requirements.

Water conservation technologies complement energy efficiency measures in creating sustainable autoclave operations. Closed-loop water systems with advanced filtration can reduce water consumption by up to 80% compared to traditional once-through systems. Additionally, condensate recovery systems not only conserve water but also retain thermal energy that would otherwise be lost.

Carbon footprint reduction extends beyond direct energy consumption to include considerations of component lifecycle and materials selection. Components manufactured using sustainable practices and materials with lower embodied carbon offer additional environmental benefits. Manufacturers increasingly provide environmental product declarations (EPDs) that quantify the lifecycle environmental impact of components, enabling informed decision-making in upgrade planning.

Return on investment calculations for energy efficiency upgrades typically show payback periods of 12-36 months, depending on operational intensity and local energy costs. These calculations increasingly incorporate carbon pricing mechanisms and regulatory compliance costs, strengthening the business case for sustainability-focused upgrades.

Safety Standards and Regulatory Compliance

Autoclave safety standards and regulatory compliance represent a critical framework governing the design, operation, and maintenance of these pressure vessels across various industries. The International Organization for Standardization (ISO) has established ISO 17665 specifically for sterilization of health care products, while the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code provides comprehensive guidelines for pressure vessel construction and operation. These standards are complemented by regional regulations such as the European Pressure Equipment Directive (PED) 2014/68/EU and the FDA's Quality System Regulation in the United States.

Component upgrades to autoclaves must adhere to these established safety protocols, with particular attention to pressure management systems, temperature control mechanisms, and door safety interlocks. Recent regulatory trends have emphasized the implementation of redundant safety systems and advanced monitoring capabilities to prevent catastrophic failures. For instance, modern pressure relief valves now incorporate dual-activation mechanisms that respond to both excessive pressure and temperature anomalies.

Documentation and certification requirements have become increasingly stringent, with regulatory bodies requiring detailed validation protocols for any significant component modifications. This includes comprehensive risk assessments that evaluate potential failure modes and their consequences, particularly for autoclaves used in critical applications such as medical device sterilization or aerospace composite curing.

The integration of digital monitoring systems has introduced new compliance considerations related to data integrity and cybersecurity. Regulatory frameworks now address the validation of software-controlled safety features and the protection of critical operational parameters from unauthorized manipulation. This has led to the development of specialized validation protocols for electronic recording systems that document sterilization cycles and safety-critical operations.

Material selection for component upgrades faces rigorous scrutiny under current regulations, with particular emphasis on corrosion resistance, thermal stability, and mechanical durability. Manufacturers must provide extensive documentation demonstrating material compatibility with process conditions and sterilants. This includes accelerated aging tests and chemical resistance evaluations that predict long-term performance under operational conditions.

Compliance with occupational safety regulations represents another crucial dimension, with standards addressing operator exposure to heat, pressure hazards, and potentially harmful sterilants. Component upgrades must incorporate ergonomic considerations and user interface improvements that minimize operational risks while enhancing usability. This human-centered approach to safety design has become increasingly prominent in recent regulatory updates.

Component upgrades to autoclaves must adhere to these established safety protocols, with particular attention to pressure management systems, temperature control mechanisms, and door safety interlocks. Recent regulatory trends have emphasized the implementation of redundant safety systems and advanced monitoring capabilities to prevent catastrophic failures. For instance, modern pressure relief valves now incorporate dual-activation mechanisms that respond to both excessive pressure and temperature anomalies.

Documentation and certification requirements have become increasingly stringent, with regulatory bodies requiring detailed validation protocols for any significant component modifications. This includes comprehensive risk assessments that evaluate potential failure modes and their consequences, particularly for autoclaves used in critical applications such as medical device sterilization or aerospace composite curing.

The integration of digital monitoring systems has introduced new compliance considerations related to data integrity and cybersecurity. Regulatory frameworks now address the validation of software-controlled safety features and the protection of critical operational parameters from unauthorized manipulation. This has led to the development of specialized validation protocols for electronic recording systems that document sterilization cycles and safety-critical operations.

Material selection for component upgrades faces rigorous scrutiny under current regulations, with particular emphasis on corrosion resistance, thermal stability, and mechanical durability. Manufacturers must provide extensive documentation demonstrating material compatibility with process conditions and sterilants. This includes accelerated aging tests and chemical resistance evaluations that predict long-term performance under operational conditions.

Compliance with occupational safety regulations represents another crucial dimension, with standards addressing operator exposure to heat, pressure hazards, and potentially harmful sterilants. Component upgrades must incorporate ergonomic considerations and user interface improvements that minimize operational risks while enhancing usability. This human-centered approach to safety design has become increasingly prominent in recent regulatory updates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!