Autoclave Curing Processes in Composite Manufacturing

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Objectives

Autoclave curing technology for composite manufacturing has evolved significantly since its inception in the aerospace industry during the 1950s. Initially developed for military aircraft applications, autoclave processing emerged as a response to the need for high-performance composite structures with consistent quality and minimal void content. The fundamental principle—applying heat and pressure simultaneously in a controlled environment—has remained unchanged, though the sophistication of the process has advanced dramatically.

The 1970s marked a pivotal era when commercial aviation began adopting carbon fiber composites, necessitating larger autoclaves and more refined control systems. During this period, basic temperature and pressure cycles were established, typically featuring single-step cures with limited optimization. The 1980s witnessed significant improvements in process monitoring capabilities, introducing thermocouples and pressure sensors that allowed for real-time adjustments.

By the 1990s, computer modeling of cure kinetics emerged, enabling manufacturers to predict resin behavior during the cure cycle. This advancement reduced the empirical nature of autoclave parameter selection and established more scientific approaches to cure cycle development. The early 2000s brought integrated cure monitoring systems using dielectric analysis and fiber optic sensors, providing unprecedented insight into the actual state of the composite during processing.

Current autoclave technology incorporates sophisticated automation, with adaptive control systems capable of responding to material behavior variations in real-time. Modern autoclaves feature enhanced energy efficiency, reduced cycle times, and improved temperature uniformity—addressing historical limitations of the technology. The integration of Industry 4.0 principles has further transformed autoclave operations, with digital twins and predictive maintenance becoming standard features in advanced manufacturing environments.

The primary objectives of contemporary autoclave technology development center around four key areas: energy efficiency, cycle time reduction, quality consistency, and scalability. Energy consumption remains a significant challenge, with researchers focusing on optimized heating systems, improved insulation, and intelligent power management. Cycle time reduction efforts target both the physical limitations of heat transfer and the chemical kinetics of resin systems, with out-of-autoclave alternatives emerging as complementary technologies.

Quality consistency objectives involve the development of more sophisticated sensing technologies and real-time cure monitoring systems that can detect and correct anomalies during processing. Scalability concerns address the inherent limitations of autoclave size and the associated capital costs, with modular designs and shared facilities emerging as potential solutions for smaller manufacturers.

The 1970s marked a pivotal era when commercial aviation began adopting carbon fiber composites, necessitating larger autoclaves and more refined control systems. During this period, basic temperature and pressure cycles were established, typically featuring single-step cures with limited optimization. The 1980s witnessed significant improvements in process monitoring capabilities, introducing thermocouples and pressure sensors that allowed for real-time adjustments.

By the 1990s, computer modeling of cure kinetics emerged, enabling manufacturers to predict resin behavior during the cure cycle. This advancement reduced the empirical nature of autoclave parameter selection and established more scientific approaches to cure cycle development. The early 2000s brought integrated cure monitoring systems using dielectric analysis and fiber optic sensors, providing unprecedented insight into the actual state of the composite during processing.

Current autoclave technology incorporates sophisticated automation, with adaptive control systems capable of responding to material behavior variations in real-time. Modern autoclaves feature enhanced energy efficiency, reduced cycle times, and improved temperature uniformity—addressing historical limitations of the technology. The integration of Industry 4.0 principles has further transformed autoclave operations, with digital twins and predictive maintenance becoming standard features in advanced manufacturing environments.

The primary objectives of contemporary autoclave technology development center around four key areas: energy efficiency, cycle time reduction, quality consistency, and scalability. Energy consumption remains a significant challenge, with researchers focusing on optimized heating systems, improved insulation, and intelligent power management. Cycle time reduction efforts target both the physical limitations of heat transfer and the chemical kinetics of resin systems, with out-of-autoclave alternatives emerging as complementary technologies.

Quality consistency objectives involve the development of more sophisticated sensing technologies and real-time cure monitoring systems that can detect and correct anomalies during processing. Scalability concerns address the inherent limitations of autoclave size and the associated capital costs, with modular designs and shared facilities emerging as potential solutions for smaller manufacturers.

Market Analysis for Autoclave-Cured Composites

The global market for autoclave-cured composites continues to demonstrate robust growth, driven primarily by increasing demand from aerospace, defense, and high-performance automotive sectors. Current market valuations indicate that the autoclave-cured composite materials market reached approximately 5.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 6.8% through 2028.

Aerospace remains the dominant application segment, accounting for nearly 65% of the total market share. This dominance stems from the unparalleled quality, consistency, and performance characteristics that autoclave curing provides for critical aerospace components. Commercial aircraft manufacturers like Boeing and Airbus have significantly increased their composite usage in next-generation aircraft, with modern planes containing up to 50% composite materials by weight.

The defense sector represents the second-largest market segment at 18%, where autoclave-cured composites are extensively utilized in military aircraft, naval vessels, and ballistic protection systems. The automotive industry, particularly in Formula 1, supercars, and increasingly in electric vehicles, constitutes approximately 12% of the market as manufacturers seek weight reduction solutions to enhance performance and efficiency.

Regionally, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are emerging as the fastest-growing markets, with annual growth rates exceeding 9%, driven by expanding aerospace manufacturing capabilities and increasing defense spending.

Key market drivers include the ongoing lightweighting trend across transportation industries, stringent fuel efficiency regulations, and the superior mechanical properties offered by autoclave-cured composites compared to alternative manufacturing methods. The aerospace industry's recovery from the COVID-19 pandemic has accelerated demand, with major manufacturers ramping up production rates for commercial aircraft.

Market challenges include high capital equipment costs, with industrial autoclaves requiring investments of 1-5 million USD depending on size and specifications. Energy consumption during the curing process remains substantial, with typical autoclave cycles consuming 250-400 kWh per cure cycle. These factors contribute to higher production costs compared to out-of-autoclave alternatives.

Customer demand is increasingly focused on reduced cycle times and energy consumption, driving innovation in autoclave technology and process optimization. The market is also witnessing growing interest in hybrid manufacturing approaches that combine autoclave curing with alternative methods to optimize cost-performance ratios for specific applications.

Aerospace remains the dominant application segment, accounting for nearly 65% of the total market share. This dominance stems from the unparalleled quality, consistency, and performance characteristics that autoclave curing provides for critical aerospace components. Commercial aircraft manufacturers like Boeing and Airbus have significantly increased their composite usage in next-generation aircraft, with modern planes containing up to 50% composite materials by weight.

The defense sector represents the second-largest market segment at 18%, where autoclave-cured composites are extensively utilized in military aircraft, naval vessels, and ballistic protection systems. The automotive industry, particularly in Formula 1, supercars, and increasingly in electric vehicles, constitutes approximately 12% of the market as manufacturers seek weight reduction solutions to enhance performance and efficiency.

Regionally, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). China and India are emerging as the fastest-growing markets, with annual growth rates exceeding 9%, driven by expanding aerospace manufacturing capabilities and increasing defense spending.

Key market drivers include the ongoing lightweighting trend across transportation industries, stringent fuel efficiency regulations, and the superior mechanical properties offered by autoclave-cured composites compared to alternative manufacturing methods. The aerospace industry's recovery from the COVID-19 pandemic has accelerated demand, with major manufacturers ramping up production rates for commercial aircraft.

Market challenges include high capital equipment costs, with industrial autoclaves requiring investments of 1-5 million USD depending on size and specifications. Energy consumption during the curing process remains substantial, with typical autoclave cycles consuming 250-400 kWh per cure cycle. These factors contribute to higher production costs compared to out-of-autoclave alternatives.

Customer demand is increasingly focused on reduced cycle times and energy consumption, driving innovation in autoclave technology and process optimization. The market is also witnessing growing interest in hybrid manufacturing approaches that combine autoclave curing with alternative methods to optimize cost-performance ratios for specific applications.

Current Challenges in Autoclave Curing Processes

Despite significant advancements in composite manufacturing, autoclave curing processes continue to face several critical challenges that limit production efficiency and material performance. Energy consumption remains a primary concern, with traditional autoclave operations requiring substantial power to maintain high temperatures and pressures for extended periods. This energy-intensive nature not only increases production costs but also contributes significantly to the carbon footprint of composite manufacturing facilities.

Scale-up difficulties present another major obstacle, particularly for large aerospace components. The physical limitations of autoclave chambers restrict the maximum size of producible parts, creating bottlenecks in manufacturing processes for large-scale applications such as aircraft wings or wind turbine blades. This size constraint often necessitates complex joining techniques that can introduce potential weak points in the final structure.

Temperature and pressure uniformity across large composite parts remains problematic. Current autoclave systems struggle to maintain consistent curing conditions throughout the entire volume of complex geometries, resulting in residual stresses, warpage, and potential quality inconsistencies. These variations can compromise the structural integrity and performance characteristics of high-performance composites.

Cycle time optimization continues to challenge manufacturers, with typical autoclave processes requiring several hours to complete. This extended processing duration significantly impacts production throughput and increases manufacturing costs. The industry faces growing pressure to reduce these cycle times without compromising material quality or performance properties.

Process monitoring and control systems present technical limitations that affect quality assurance. Current sensor technologies often cannot provide real-time, comprehensive data on the actual curing state within complex layups. This information gap makes it difficult to implement adaptive control strategies that could optimize curing parameters dynamically during the process.

Material compatibility issues arise when processing advanced composite formulations. Some next-generation resin systems and reinforcement materials exhibit sensitivity to conventional autoclave conditions, requiring careful process modifications that may reduce efficiency or increase complexity.

Automation integration remains challenging due to the batch nature of autoclave processing. Unlike more continuous manufacturing methods, autoclave curing creates inherent production pauses that complicate efforts to implement fully automated composite manufacturing lines. This limitation affects overall production efficiency and increases labor requirements.

Scale-up difficulties present another major obstacle, particularly for large aerospace components. The physical limitations of autoclave chambers restrict the maximum size of producible parts, creating bottlenecks in manufacturing processes for large-scale applications such as aircraft wings or wind turbine blades. This size constraint often necessitates complex joining techniques that can introduce potential weak points in the final structure.

Temperature and pressure uniformity across large composite parts remains problematic. Current autoclave systems struggle to maintain consistent curing conditions throughout the entire volume of complex geometries, resulting in residual stresses, warpage, and potential quality inconsistencies. These variations can compromise the structural integrity and performance characteristics of high-performance composites.

Cycle time optimization continues to challenge manufacturers, with typical autoclave processes requiring several hours to complete. This extended processing duration significantly impacts production throughput and increases manufacturing costs. The industry faces growing pressure to reduce these cycle times without compromising material quality or performance properties.

Process monitoring and control systems present technical limitations that affect quality assurance. Current sensor technologies often cannot provide real-time, comprehensive data on the actual curing state within complex layups. This information gap makes it difficult to implement adaptive control strategies that could optimize curing parameters dynamically during the process.

Material compatibility issues arise when processing advanced composite formulations. Some next-generation resin systems and reinforcement materials exhibit sensitivity to conventional autoclave conditions, requiring careful process modifications that may reduce efficiency or increase complexity.

Automation integration remains challenging due to the batch nature of autoclave processing. Unlike more continuous manufacturing methods, autoclave curing creates inherent production pauses that complicate efforts to implement fully automated composite manufacturing lines. This limitation affects overall production efficiency and increases labor requirements.

State-of-the-Art Autoclave Curing Solutions

01 Autoclave curing for composite materials

Autoclave curing processes are widely used for manufacturing high-performance composite materials. These processes involve placing composite layups in an autoclave where controlled temperature, pressure, and vacuum conditions enable proper consolidation and curing of the resin matrix. This method ensures high-quality parts with minimal voids and optimal mechanical properties, making it particularly valuable for aerospace and automotive applications.- Autoclave curing for composite materials: Autoclave curing processes are widely used for manufacturing high-performance composite materials. These processes involve placing composite layups in an autoclave where controlled temperature, pressure, and vacuum conditions enable proper consolidation and curing of the resin matrix. This method ensures high-quality parts with minimal voids and optimal mechanical properties, making it particularly valuable for aerospace and automotive applications where structural integrity is critical.

- Temperature and pressure control systems for autoclave curing: Advanced control systems are essential for managing the temperature and pressure parameters during autoclave curing processes. These systems include sensors, monitoring equipment, and feedback mechanisms that ensure precise adherence to curing cycles. Proper control prevents thermal overshoots, maintains uniform heating throughout the part, and applies appropriate pressure at specific stages of the cure cycle, resulting in consistent quality and reduced processing defects.

- Resin formulations optimized for autoclave curing: Specialized resin formulations have been developed specifically for autoclave curing processes. These formulations feature controlled viscosity profiles, optimized cure kinetics, and enhanced thermal stability to withstand the high temperatures and pressures of autoclave environments. Some formulations incorporate toughening agents, while others focus on reducing cure times or improving the glass transition temperature of the final product.

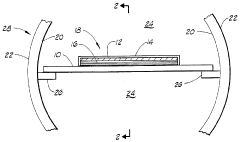

- Vacuum bagging techniques for autoclave curing: Vacuum bagging is a critical preparatory step for autoclave curing processes. This technique involves sealing the composite layup within specialized bagging materials and applying vacuum to remove air and volatiles before and during the cure cycle. Proper vacuum bagging techniques include strategic placement of breather materials, release films, and vacuum ports to ensure uniform pressure distribution and efficient removal of entrapped air and excess resin, resulting in higher quality finished parts.

- Monitoring and quality control in autoclave curing: Advanced monitoring and quality control methods are implemented in autoclave curing processes to ensure consistent results. These include in-situ cure monitoring sensors, dielectric analysis systems, and acoustic monitoring techniques that provide real-time data on the curing state of the material. Post-cure inspection methods such as ultrasonic testing and thermography help verify the integrity of the cured parts and detect any internal defects or inconsistencies that may have occurred during the curing process.

02 Temperature and pressure control systems for autoclave curing

Advanced control systems are essential for managing the temperature and pressure parameters during autoclave curing cycles. These systems monitor and adjust conditions in real-time to ensure optimal curing profiles are maintained throughout the process. Sophisticated sensors, feedback mechanisms, and computerized controls help prevent defects and ensure consistent quality in the final products by maintaining precise environmental conditions within the autoclave chamber.Expand Specific Solutions03 Specialized autoclave curing for thermosetting resins

Thermosetting resins require specific autoclave curing protocols to achieve complete cross-linking and optimal mechanical properties. The process typically involves carefully controlled heating rates, dwell times at specific temperatures, and cooling phases. Different resin systems (such as epoxies, bismaleimides, and phenolics) require tailored curing cycles to ensure complete polymerization while preventing issues like thermal degradation or residual stresses.Expand Specific Solutions04 Vacuum-assisted autoclave curing techniques

Vacuum-assisted autoclave curing combines vacuum bagging with autoclave pressure to enhance the quality of composite parts. The vacuum removes air and volatiles from the laminate while the autoclave pressure ensures proper consolidation. This dual-pressure approach minimizes void content, improves fiber-to-resin ratio, and enhances interlaminar properties. The technique is particularly valuable for thick or complex composite structures where conventional methods might result in porosity or delamination.Expand Specific Solutions05 Monitoring and quality control in autoclave curing

Advanced monitoring systems and quality control methods are implemented during autoclave curing to ensure process reliability and product consistency. These include in-situ sensors that track temperature distribution, pressure, degree of cure, and resin flow. Data acquisition systems collect and analyze this information in real-time, allowing for process optimization and documentation for regulatory compliance. Post-cure inspection techniques help verify that the cured components meet required specifications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The autoclave curing process in composite manufacturing is currently in a mature growth phase, with a global market valued at approximately $4-5 billion and projected to expand at 6-8% CAGR through 2028. Major aerospace manufacturers like Boeing, Airbus Defence & Space, and Mitsubishi Heavy Industries dominate the landscape, leveraging decades of expertise in high-performance composite curing. Academic institutions such as Central South University and Nanjing University of Aeronautics & Astronautics are advancing fundamental research, while specialized companies like Hexcel, Premium Aerotec, and Vistex Composites are driving innovation in materials and process optimization. The technology shows varying maturity levels across sectors, with aerospace applications being most advanced while automotive and renewable energy implementations are still evolving with significant growth potential.

The Boeing Co.

Technical Solution: Boeing has developed advanced autoclave curing processes for large-scale composite structures used in commercial aircraft like the 787 Dreamliner. Their approach incorporates precise temperature and pressure control systems that maintain uniform heating rates across massive composite parts. Boeing's autoclave technology features multi-zone heating control with real-time monitoring through embedded sensors that track cure progression. They've implemented adaptive cure cycle optimization that adjusts parameters based on material feedback, reducing cure times by up to 20% while maintaining structural integrity. Boeing has also pioneered vacuum-assisted processing techniques that minimize void content to below 1% in critical aerospace components, ensuring superior mechanical properties and longevity.

Strengths: Exceptional capability for curing very large composite structures with uniform properties; sophisticated real-time monitoring systems; proven track record in aerospace applications. Weaknesses: High capital investment requirements; energy-intensive processes; limited flexibility for rapid production changes.

Airbus Defence & Space GmbH

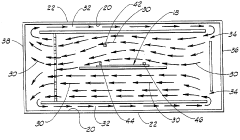

Technical Solution: Airbus Defence & Space has developed sophisticated autoclave curing processes for manufacturing high-performance composite structures used in aerospace applications. Their technology incorporates multi-zone temperature control systems that maintain precise thermal gradients across large and complex composite parts. Airbus has implemented advanced computational fluid dynamics modeling to optimize autoclave airflow patterns, ensuring uniform heat distribution and minimizing cure cycle times. Their process includes proprietary vacuum bagging techniques that enhance consolidation quality while reducing the risk of wrinkles and voids. Airbus has also developed specialized tooling systems with integrated thermal monitoring that provides real-time feedback during the cure cycle, allowing for adaptive process control that responds to actual part conditions rather than predetermined parameters.

Strengths: Exceptional capability for curing complex geometries with consistent quality; advanced simulation-driven process optimization; integration with broader digital manufacturing systems. Weaknesses: High operational costs; significant energy consumption; limited production throughput compared to out-of-autoclave alternatives.

Critical Patents and Research in Composite Curing

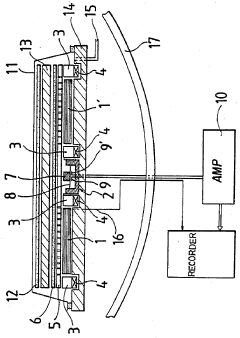

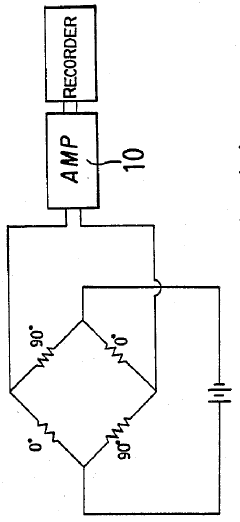

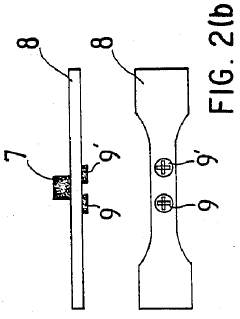

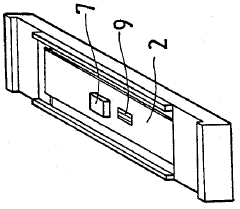

Continuous monitering system for compaction behavior of composite laminates in autoclave curing

PatentInactiveUS4831881A

Innovation

- A thickness measuring sensor system that uses a 3-point bending mechanism with strain gauges to continuously monitor thickness changes of composite laminates, featuring a linear displacement-strain relationship and minimal thermal-induced errors, allowing for real-time data collection and feedback to the autoclave control system.

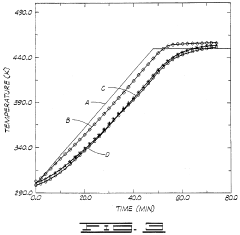

Curing of composite materials using extended heat transfer models

PatentInactiveUS5453226A

Innovation

- A computer-controlled method that integrates predictive analytic models for selecting optimal cure cycles based on real-time measurements of temperature, pressure, degree of cure, and viscosity, using a thermo-chemical model extended to account for convective heat transfer, allowing for continuous adjustment of the curing process.

Energy Efficiency and Sustainability Considerations

Autoclave curing processes in composite manufacturing are energy-intensive operations that significantly impact both production costs and environmental footprint. Current autoclave systems typically consume substantial electrical power, with energy requirements ranging from 100-500 kWh per curing cycle depending on part size and process parameters. This high energy consumption stems primarily from the need to maintain elevated temperatures (often 120-180°C) and pressures (up to 7 bar) for extended periods, sometimes exceeding 8 hours for complex aerospace components.

Recent advancements in energy efficiency have focused on optimizing heating and cooling cycles through improved insulation materials and intelligent control systems. Thermal analysis modeling has enabled manufacturers to reduce energy waste by up to 30% through precise temperature ramping and dwell time optimization. Additionally, heat recovery systems that capture and repurpose thermal energy from exhaust gases have demonstrated potential energy savings of 15-25% in industrial applications.

The carbon footprint of autoclave operations presents significant sustainability challenges. A typical aerospace-grade autoclave curing cycle can generate 50-200 kg CO2 equivalent emissions per composite part produced. This environmental impact has prompted regulatory pressure and corporate sustainability initiatives across the composites industry, with major manufacturers committing to carbon reduction targets between 30-50% by 2030.

Alternative curing technologies such as out-of-autoclave (OOA) processes offer promising sustainability advantages, potentially reducing energy consumption by 40-70% compared to traditional autoclave methods. However, these alternatives often face challenges in achieving equivalent mechanical properties and surface finish quality for high-performance applications.

Water consumption represents another critical sustainability consideration, particularly in cooling systems. Modern autoclave facilities have implemented closed-loop water recycling systems that reduce freshwater requirements by up to 80% compared to older open-loop designs. Additionally, the transition to water-based release agents from solvent-based alternatives has significantly reduced volatile organic compound (VOC) emissions during the curing process.

Life cycle assessment (LCA) studies indicate that while the production phase dominates the environmental impact of composite manufacturing, optimized autoclave curing can reduce overall product lifetime emissions by improving part quality and extending service life. This highlights the importance of balancing immediate process efficiency with long-term sustainability considerations in technology development roadmaps.

Recent advancements in energy efficiency have focused on optimizing heating and cooling cycles through improved insulation materials and intelligent control systems. Thermal analysis modeling has enabled manufacturers to reduce energy waste by up to 30% through precise temperature ramping and dwell time optimization. Additionally, heat recovery systems that capture and repurpose thermal energy from exhaust gases have demonstrated potential energy savings of 15-25% in industrial applications.

The carbon footprint of autoclave operations presents significant sustainability challenges. A typical aerospace-grade autoclave curing cycle can generate 50-200 kg CO2 equivalent emissions per composite part produced. This environmental impact has prompted regulatory pressure and corporate sustainability initiatives across the composites industry, with major manufacturers committing to carbon reduction targets between 30-50% by 2030.

Alternative curing technologies such as out-of-autoclave (OOA) processes offer promising sustainability advantages, potentially reducing energy consumption by 40-70% compared to traditional autoclave methods. However, these alternatives often face challenges in achieving equivalent mechanical properties and surface finish quality for high-performance applications.

Water consumption represents another critical sustainability consideration, particularly in cooling systems. Modern autoclave facilities have implemented closed-loop water recycling systems that reduce freshwater requirements by up to 80% compared to older open-loop designs. Additionally, the transition to water-based release agents from solvent-based alternatives has significantly reduced volatile organic compound (VOC) emissions during the curing process.

Life cycle assessment (LCA) studies indicate that while the production phase dominates the environmental impact of composite manufacturing, optimized autoclave curing can reduce overall product lifetime emissions by improving part quality and extending service life. This highlights the importance of balancing immediate process efficiency with long-term sustainability considerations in technology development roadmaps.

Quality Control and Process Monitoring Advancements

Quality control and process monitoring in autoclave curing processes have undergone significant advancements in recent years, transforming the composite manufacturing landscape. Traditional methods relied heavily on post-process inspection, resulting in high scrap rates and inconsistent quality. Modern approaches now emphasize real-time monitoring and adaptive control systems that can detect and respond to process variations during the curing cycle.

The integration of sensor technologies represents a major breakthrough in this domain. Dielectric sensors embedded within composite layups provide continuous monitoring of resin flow and cure state, enabling manufacturers to track the degree of cure in real-time. Similarly, fiber optic sensors offer distributed temperature and strain measurements throughout the part, detecting potential anomalies that might lead to defects.

Acoustic emission monitoring systems have emerged as powerful tools for detecting micro-failures during the curing process. These systems can identify delamination, matrix cracking, and fiber breakage events before they propagate into catastrophic failures, allowing for immediate intervention or process adjustment.

Advanced thermal imaging technologies now provide comprehensive temperature mapping across complex geometries. This capability ensures uniform heat distribution and identifies potential cold or hot spots that could compromise part quality. The latest systems incorporate artificial intelligence algorithms that can predict thermal behavior and recommend parameter adjustments to optimize cure cycles.

Process simulation and digital twin technology represent another frontier in quality control. These systems create virtual representations of the physical autoclave and part, running parallel to the actual process. By comparing real-time data with predicted values, manufacturers can detect deviations early and implement corrective actions before defects occur.

Vacuum integrity monitoring systems have also evolved significantly. Modern systems utilize ultrasonic and pressure decay techniques to detect even microscopic leaks in vacuum bags, preventing void formation and ensuring proper consolidation. These systems can be integrated with autoclave controls to automatically adjust pressure parameters when integrity issues are detected.

The emergence of Industry 4.0 principles has led to interconnected monitoring systems that aggregate data across multiple autoclaves and production runs. This approach enables statistical process control at unprecedented scales, identifying subtle trends and correlations that impact part quality. Machine learning algorithms continuously refine process parameters based on historical data, gradually optimizing cure cycles for specific part geometries and material systems.

The integration of sensor technologies represents a major breakthrough in this domain. Dielectric sensors embedded within composite layups provide continuous monitoring of resin flow and cure state, enabling manufacturers to track the degree of cure in real-time. Similarly, fiber optic sensors offer distributed temperature and strain measurements throughout the part, detecting potential anomalies that might lead to defects.

Acoustic emission monitoring systems have emerged as powerful tools for detecting micro-failures during the curing process. These systems can identify delamination, matrix cracking, and fiber breakage events before they propagate into catastrophic failures, allowing for immediate intervention or process adjustment.

Advanced thermal imaging technologies now provide comprehensive temperature mapping across complex geometries. This capability ensures uniform heat distribution and identifies potential cold or hot spots that could compromise part quality. The latest systems incorporate artificial intelligence algorithms that can predict thermal behavior and recommend parameter adjustments to optimize cure cycles.

Process simulation and digital twin technology represent another frontier in quality control. These systems create virtual representations of the physical autoclave and part, running parallel to the actual process. By comparing real-time data with predicted values, manufacturers can detect deviations early and implement corrective actions before defects occur.

Vacuum integrity monitoring systems have also evolved significantly. Modern systems utilize ultrasonic and pressure decay techniques to detect even microscopic leaks in vacuum bags, preventing void formation and ensuring proper consolidation. These systems can be integrated with autoclave controls to automatically adjust pressure parameters when integrity issues are detected.

The emergence of Industry 4.0 principles has led to interconnected monitoring systems that aggregate data across multiple autoclaves and production runs. This approach enables statistical process control at unprecedented scales, identifying subtle trends and correlations that impact part quality. Machine learning algorithms continuously refine process parameters based on historical data, gradually optimizing cure cycles for specific part geometries and material systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!