Autoclave Performance Enhancements: Innovations in Design

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Technology Evolution and Enhancement Objectives

Autoclaves have evolved significantly since their inception in the early 20th century, transforming from basic pressure vessels to sophisticated systems integrating advanced materials, precise control mechanisms, and intelligent monitoring capabilities. Initially developed for sterilization in medical settings, autoclave technology has expanded into critical manufacturing processes for aerospace, automotive, and renewable energy sectors, particularly in composite material production where precise temperature and pressure control are paramount.

The evolution trajectory of autoclave technology demonstrates a clear shift from manual operation to automated systems. Early autoclaves relied on simple steam generation and mechanical pressure control, while contemporary designs incorporate digital interfaces, programmable logic controllers (PLCs), and real-time monitoring systems. This progression has been driven by increasing demands for process reliability, energy efficiency, and production throughput in high-value manufacturing environments.

Recent technological advancements have focused on enhancing thermal uniformity within the autoclave chamber, a critical factor affecting product quality in composite curing applications. Computational fluid dynamics (CFD) modeling has enabled significant improvements in heat distribution systems, reducing temperature gradients and ensuring consistent material properties throughout large composite structures. Additionally, innovations in insulation materials and heating element design have contributed to substantial energy efficiency improvements, with modern systems consuming up to 30% less energy than designs from a decade ago.

The primary objectives for autoclave performance enhancement center around four key areas: energy efficiency, process reliability, cycle time reduction, and scalability. Energy consumption remains a significant operational cost, driving research into heat recovery systems, advanced insulation materials, and optimized heating cycles. Process reliability improvements focus on developing more sophisticated sensor networks and control algorithms to maintain precise conditions throughout increasingly complex cure cycles.

Cycle time reduction represents perhaps the most economically significant enhancement objective, as autoclave processing often creates production bottlenecks in manufacturing operations. Innovations in rapid heating technologies, optimized pressure application sequences, and advanced cure kinetics modeling aim to reduce processing times while maintaining or improving product quality. Finally, scalability challenges are being addressed through modular design approaches and innovations in large-scale pressure vessel construction techniques.

The convergence of digital technologies with traditional autoclave systems is creating opportunities for predictive maintenance, process optimization through machine learning, and integration with broader manufacturing execution systems. These enhancements collectively aim to transform autoclaves from isolated batch processing equipment into connected, intelligent manufacturing assets capable of adapting to changing production requirements and material specifications.

The evolution trajectory of autoclave technology demonstrates a clear shift from manual operation to automated systems. Early autoclaves relied on simple steam generation and mechanical pressure control, while contemporary designs incorporate digital interfaces, programmable logic controllers (PLCs), and real-time monitoring systems. This progression has been driven by increasing demands for process reliability, energy efficiency, and production throughput in high-value manufacturing environments.

Recent technological advancements have focused on enhancing thermal uniformity within the autoclave chamber, a critical factor affecting product quality in composite curing applications. Computational fluid dynamics (CFD) modeling has enabled significant improvements in heat distribution systems, reducing temperature gradients and ensuring consistent material properties throughout large composite structures. Additionally, innovations in insulation materials and heating element design have contributed to substantial energy efficiency improvements, with modern systems consuming up to 30% less energy than designs from a decade ago.

The primary objectives for autoclave performance enhancement center around four key areas: energy efficiency, process reliability, cycle time reduction, and scalability. Energy consumption remains a significant operational cost, driving research into heat recovery systems, advanced insulation materials, and optimized heating cycles. Process reliability improvements focus on developing more sophisticated sensor networks and control algorithms to maintain precise conditions throughout increasingly complex cure cycles.

Cycle time reduction represents perhaps the most economically significant enhancement objective, as autoclave processing often creates production bottlenecks in manufacturing operations. Innovations in rapid heating technologies, optimized pressure application sequences, and advanced cure kinetics modeling aim to reduce processing times while maintaining or improving product quality. Finally, scalability challenges are being addressed through modular design approaches and innovations in large-scale pressure vessel construction techniques.

The convergence of digital technologies with traditional autoclave systems is creating opportunities for predictive maintenance, process optimization through machine learning, and integration with broader manufacturing execution systems. These enhancements collectively aim to transform autoclaves from isolated batch processing equipment into connected, intelligent manufacturing assets capable of adapting to changing production requirements and material specifications.

Market Demand Analysis for Advanced Sterilization Solutions

The global sterilization market is experiencing robust growth, driven by increasing healthcare expenditures, rising surgical procedures, and heightened awareness of infection control protocols. Current market valuations place the medical sterilization equipment sector at approximately 7.5 billion USD, with projections indicating a compound annual growth rate of 8.4% through 2028. Autoclave technology, as a cornerstone of sterilization methods, represents nearly 40% of this market share, highlighting significant commercial opportunities for design innovations.

Healthcare facilities worldwide are facing mounting pressure to improve operational efficiency while maintaining stringent sterilization standards. A recent survey of 500 hospitals across North America, Europe, and Asia revealed that 78% of facilities consider energy efficiency a critical factor when purchasing new autoclave equipment. Additionally, 65% expressed interest in solutions that reduce water consumption, while 82% prioritized reduced cycle times to improve throughput in central sterilization departments.

The pharmaceutical and biotechnology sectors present particularly promising growth segments, with increasing demand for advanced sterilization solutions that can accommodate sensitive materials and complex instruments. Market research indicates these industries are willing to invest 15-20% premium pricing for autoclave systems that offer enhanced performance metrics, particularly regarding temperature uniformity and validation capabilities.

Emerging economies represent a significant untapped market potential, with healthcare infrastructure development creating demand for both entry-level and sophisticated sterilization equipment. Countries in Southeast Asia and Latin America are experiencing healthcare spending growth rates exceeding 10% annually, with sterilization equipment procurement increasing proportionally.

Consumer preferences are evolving toward more sustainable solutions, with 73% of procurement specialists indicating environmental impact as a "very important" or "critical" consideration. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly incentivize reduced resource consumption in medical equipment.

The COVID-19 pandemic has fundamentally altered market dynamics, accelerating demand for sterilization equipment across traditional and non-traditional settings. Healthcare facilities have increased sterilization capacity by an average of 35%, while non-healthcare sectors including food production, laboratory sciences, and educational institutions have expanded their sterilization capabilities to meet heightened safety protocols.

Market segmentation analysis reveals distinct needs across different user groups: large hospitals prioritize throughput and integration with tracking systems; outpatient facilities value compact footprints and rapid cycles; while research laboratories emphasize precision temperature control and specialized cycle parameters. These diverse requirements underscore the need for customizable autoclave design innovations that can address specific market segment demands.

Healthcare facilities worldwide are facing mounting pressure to improve operational efficiency while maintaining stringent sterilization standards. A recent survey of 500 hospitals across North America, Europe, and Asia revealed that 78% of facilities consider energy efficiency a critical factor when purchasing new autoclave equipment. Additionally, 65% expressed interest in solutions that reduce water consumption, while 82% prioritized reduced cycle times to improve throughput in central sterilization departments.

The pharmaceutical and biotechnology sectors present particularly promising growth segments, with increasing demand for advanced sterilization solutions that can accommodate sensitive materials and complex instruments. Market research indicates these industries are willing to invest 15-20% premium pricing for autoclave systems that offer enhanced performance metrics, particularly regarding temperature uniformity and validation capabilities.

Emerging economies represent a significant untapped market potential, with healthcare infrastructure development creating demand for both entry-level and sophisticated sterilization equipment. Countries in Southeast Asia and Latin America are experiencing healthcare spending growth rates exceeding 10% annually, with sterilization equipment procurement increasing proportionally.

Consumer preferences are evolving toward more sustainable solutions, with 73% of procurement specialists indicating environmental impact as a "very important" or "critical" consideration. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly incentivize reduced resource consumption in medical equipment.

The COVID-19 pandemic has fundamentally altered market dynamics, accelerating demand for sterilization equipment across traditional and non-traditional settings. Healthcare facilities have increased sterilization capacity by an average of 35%, while non-healthcare sectors including food production, laboratory sciences, and educational institutions have expanded their sterilization capabilities to meet heightened safety protocols.

Market segmentation analysis reveals distinct needs across different user groups: large hospitals prioritize throughput and integration with tracking systems; outpatient facilities value compact footprints and rapid cycles; while research laboratories emphasize precision temperature control and specialized cycle parameters. These diverse requirements underscore the need for customizable autoclave design innovations that can address specific market segment demands.

Current Autoclave Technology Landscape and Limitations

Autoclaves represent a cornerstone technology in various industries including aerospace, medical, and composite manufacturing. The current landscape of autoclave technology is characterized by large, energy-intensive systems that operate under high pressure and temperature conditions to facilitate curing processes. Traditional autoclaves typically consist of a pressure vessel, heating elements, vacuum systems, and control mechanisms that work in concert to create optimal curing environments for materials.

Despite their widespread adoption, conventional autoclave systems face significant limitations. Energy efficiency remains a primary concern, with standard autoclaves consuming substantial amounts of electricity during operation cycles that can last several hours. This inefficiency translates to high operational costs and considerable carbon footprints, increasingly problematic in an era of heightened environmental consciousness and rising energy prices.

Size constraints represent another critical limitation. Industrial autoclaves often require dedicated facilities due to their massive footprint, limiting their application in space-constrained environments. The capital investment required for installation, including reinforced foundations and specialized infrastructure, creates significant barriers to entry for smaller manufacturers and research institutions.

Process control capabilities in traditional systems frequently lack precision, resulting in inconsistent quality outcomes. Many existing autoclaves employ rudimentary control systems that cannot adequately respond to dynamic process requirements or material-specific curing profiles. This limitation becomes particularly problematic when processing advanced composites that demand precise temperature ramps and pressure cycles.

Maintenance requirements constitute another significant drawback. Conventional autoclaves necessitate regular servicing of seals, heating elements, and pressure systems, leading to substantial downtime and reduced operational efficiency. The complexity of these systems often requires specialized technicians, further increasing the total cost of ownership.

From a geographical perspective, advanced autoclave technology remains concentrated in industrialized nations, particularly in North America, Western Europe, and parts of Asia. This uneven distribution creates technological disparities and limits access to state-of-the-art curing capabilities in developing regions.

Recent technological developments have begun addressing these limitations through innovations in heating technology, pressure management systems, and digital control interfaces. However, fundamental challenges persist regarding scalability, energy consumption, and process optimization. The industry stands at a critical juncture where incremental improvements to existing designs compete with potentially disruptive technologies that could fundamentally transform autoclave operations.

Despite their widespread adoption, conventional autoclave systems face significant limitations. Energy efficiency remains a primary concern, with standard autoclaves consuming substantial amounts of electricity during operation cycles that can last several hours. This inefficiency translates to high operational costs and considerable carbon footprints, increasingly problematic in an era of heightened environmental consciousness and rising energy prices.

Size constraints represent another critical limitation. Industrial autoclaves often require dedicated facilities due to their massive footprint, limiting their application in space-constrained environments. The capital investment required for installation, including reinforced foundations and specialized infrastructure, creates significant barriers to entry for smaller manufacturers and research institutions.

Process control capabilities in traditional systems frequently lack precision, resulting in inconsistent quality outcomes. Many existing autoclaves employ rudimentary control systems that cannot adequately respond to dynamic process requirements or material-specific curing profiles. This limitation becomes particularly problematic when processing advanced composites that demand precise temperature ramps and pressure cycles.

Maintenance requirements constitute another significant drawback. Conventional autoclaves necessitate regular servicing of seals, heating elements, and pressure systems, leading to substantial downtime and reduced operational efficiency. The complexity of these systems often requires specialized technicians, further increasing the total cost of ownership.

From a geographical perspective, advanced autoclave technology remains concentrated in industrialized nations, particularly in North America, Western Europe, and parts of Asia. This uneven distribution creates technological disparities and limits access to state-of-the-art curing capabilities in developing regions.

Recent technological developments have begun addressing these limitations through innovations in heating technology, pressure management systems, and digital control interfaces. However, fundamental challenges persist regarding scalability, energy consumption, and process optimization. The industry stands at a critical juncture where incremental improvements to existing designs compete with potentially disruptive technologies that could fundamentally transform autoclave operations.

Contemporary Design Solutions for Performance Optimization

01 Autoclave sterilization efficiency and monitoring

Autoclave performance can be enhanced through improved sterilization efficiency and monitoring systems. Modern autoclaves incorporate advanced sensors and control mechanisms to ensure optimal sterilization conditions are maintained throughout the cycle. These systems monitor critical parameters such as temperature, pressure, and time to validate sterilization effectiveness. Real-time monitoring allows for immediate detection of any deviations from the required parameters, ensuring consistent performance and compliance with sterilization standards.- Autoclave monitoring and control systems: Advanced monitoring and control systems are essential for optimizing autoclave performance. These systems include sensors for tracking temperature, pressure, and cycle time to ensure sterilization efficacy. Modern autoclaves incorporate digital interfaces, automated validation processes, and data logging capabilities that help maintain consistent performance and provide documentation for regulatory compliance. Real-time monitoring allows for immediate adjustments to parameters during operation.

- Steam quality and distribution improvements: The quality and distribution of steam significantly impacts autoclave performance. Innovations focus on steam generation systems, distribution networks, and chamber design to ensure uniform steam penetration throughout the load. Enhanced steam quality with minimal non-condensable gases improves heat transfer efficiency. Some designs incorporate pulsed vacuum phases to remove air pockets and ensure steam reaches all surfaces, while others use specialized nozzles or baffles to direct steam flow for optimal coverage.

- Energy efficiency and sustainability features: Modern autoclaves incorporate energy-saving technologies to reduce operational costs and environmental impact. These include improved insulation materials, heat recovery systems that capture and reuse waste heat, water recycling mechanisms, and smart power management. Some designs feature rapid heating and cooling capabilities to shorten cycle times while maintaining sterilization efficacy. Vacuum-assisted drying systems reduce moisture retention and energy consumption during the final phase of operation.

- Load configuration and capacity optimization: Autoclave performance depends significantly on proper load configuration and capacity management. Innovations in this area include specialized racks, containers, and loading systems designed to maximize steam penetration while optimizing chamber space. Some designs feature adjustable shelving, modular loading carts, or specialized holders for specific instruments. Advanced load sensing technologies can detect improper loading conditions and adjust cycle parameters accordingly to ensure sterilization efficacy regardless of load density or composition.

- Validation and testing methodologies: Reliable validation and testing protocols are crucial for verifying autoclave performance. These include biological indicators, chemical indicators, parametric monitoring, and physical measurements to confirm sterilization efficacy. Advanced testing methods incorporate real-time monitoring of critical parameters throughout the sterilization cycle. Some systems feature automated documentation of test results for regulatory compliance. Regular performance qualification testing ensures continued effectiveness of the autoclave under various operating conditions and load configurations.

02 Autoclave design innovations for performance optimization

Innovations in autoclave design significantly impact performance capabilities. These include improved chamber configurations, enhanced heating systems, and optimized steam distribution mechanisms. Some designs incorporate pulsed vacuum technology to ensure better steam penetration and air removal from the sterilization chamber. Advanced door sealing mechanisms and pressure control systems contribute to maintaining stable conditions during sterilization cycles. These design improvements result in more efficient operation, reduced cycle times, and improved overall performance.Expand Specific Solutions03 Energy efficiency and sustainability in autoclave operation

Modern autoclaves incorporate features to improve energy efficiency and sustainability. These include advanced insulation materials, heat recovery systems, and optimized water consumption mechanisms. Some autoclaves utilize intelligent power management systems that adjust energy usage based on load size and sterilization requirements. Water recycling systems reduce resource consumption while maintaining performance standards. These improvements not only enhance environmental sustainability but also reduce operational costs while maintaining or improving sterilization effectiveness.Expand Specific Solutions04 Validation and testing methods for autoclave performance

Ensuring consistent autoclave performance requires rigorous validation and testing protocols. Various methods are employed to verify sterilization effectiveness, including biological indicators, chemical indicators, and physical parameter monitoring. Standardized testing procedures help identify potential issues before they affect sterilization outcomes. Regular performance qualification testing ensures that autoclaves maintain their effectiveness over time. These validation methods are critical for applications in healthcare, laboratory, and industrial settings where sterilization reliability directly impacts safety and quality.Expand Specific Solutions05 Specialized autoclave systems for specific applications

Different applications require specialized autoclave systems with performance characteristics tailored to specific needs. Medical autoclaves feature rapid cycle times and validation systems designed for healthcare environments. Laboratory autoclaves may emphasize precision and reproducibility for research applications. Industrial autoclaves often focus on large capacity and robust performance for manufacturing processes. Specialized features such as cooling systems, load sensing technology, and customized cycle parameters enhance performance for particular applications. These purpose-built systems ensure optimal sterilization results for their intended use cases.Expand Specific Solutions

Leading Manufacturers and Competitive Positioning

The autoclave performance enhancement market is currently in a growth phase, characterized by increasing demand for advanced autoclave technologies across aerospace, medical, and industrial sectors. The global market size is estimated to exceed $2 billion, driven by requirements for higher efficiency, reduced cycle times, and energy optimization. From a technological maturity perspective, established players like Boeing, Airbus, and GE lead with sophisticated innovations in design and control systems, while specialized manufacturers such as ProTec Polymer Processing and Linde GmbH focus on niche applications. Academic institutions including Tsinghua University and China Agricultural University are contributing fundamental research, creating a competitive landscape where collaboration between industry leaders and research organizations is accelerating innovation in materials processing, digital monitoring, and sustainability-focused autoclave technologies.

The Boeing Co.

Technical Solution: Boeing has developed next-generation autoclave technology focused on process optimization and energy efficiency. Their "Accelerated Cure System" incorporates advanced thermal management with multiple heating elements strategically positioned to create uniform temperature distribution, reducing cure time by up to 25% for large composite structures. Boeing's autoclaves feature adaptive pressure control systems that automatically adjust based on material feedback, maintaining optimal consolidation pressure throughout the cure cycle. Their proprietary monitoring system uses embedded sensors to track the actual degree of cure in real-time, allowing for dynamic cycle adjustments. Boeing has also implemented advanced door sealing mechanisms that reduce preparation time and improve safety, with automated locking systems that can withstand extreme pressures while maintaining perfect seals.

Strengths: Significant reduction in cure cycle times, excellent process monitoring capabilities, and enhanced safety features. Weaknesses: High implementation costs and requires specialized operator training to fully utilize the advanced monitoring systems.

General Electric Company

Technical Solution: GE has developed advanced autoclave systems featuring digital twin technology that creates virtual replicas of physical autoclaves to monitor performance in real-time. Their design innovations include adaptive heating systems with multiple independently controlled zones that optimize temperature distribution and reduce cycle times by up to 30%. GE's autoclaves incorporate smart sensors and IoT connectivity for predictive maintenance, detecting potential failures before they occur. Their proprietary composite curing algorithms dynamically adjust pressure and temperature parameters based on real-time material response data, ensuring optimal curing while minimizing energy consumption. GE has also implemented vacuum integrity monitoring systems that automatically detect and compensate for leaks during the curing process.

Strengths: Superior process control through digital integration, reduced cycle times, and energy efficiency improvements of up to 25% compared to conventional systems. Weaknesses: Higher initial capital investment required, and the complex control systems necessitate specialized training for operators.

Critical Patents and Technical Innovations in Autoclave Design

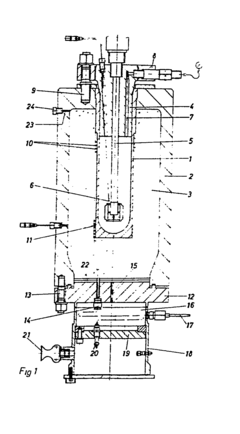

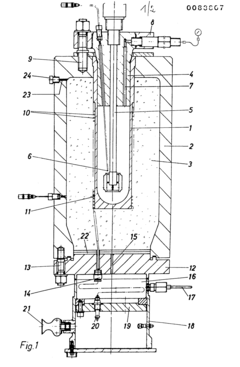

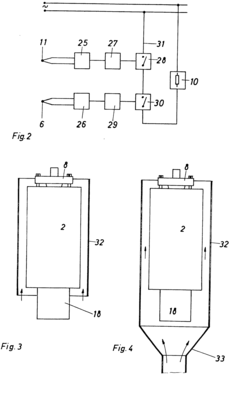

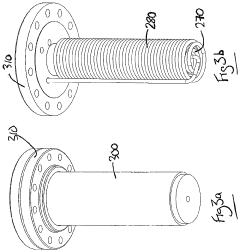

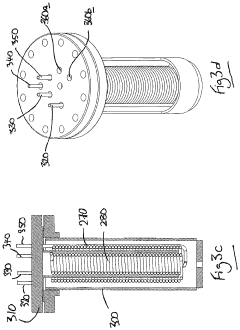

Heatable high-pressure autoclave

PatentInactiveEP0083807A1

Innovation

- A high-pressure autoclave design with a thin-walled reaction vessel and a thick-walled pressure vessel separated by a refractory concrete insulating compound, equipped with a temperature sensor and controller to limit the surface temperature of the heating coil, and an explosion-proof junction box for the heating coil connections, along with optional external cooling using a chimney jacket and cooling fan.

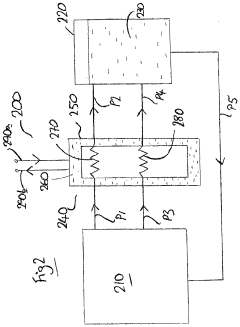

Autoclave system and method

PatentActiveUS20200147568A1

Innovation

- A heat exchanger is interposed between the autoclave vessel and the external support system, utilizing thermal exchange conduits and a medium to cool and manage both leaching and venting fluids, reducing their temperature and pressure before reintroduction, while also pre-heating the leaching fluid for efficient operation.

Energy Efficiency and Sustainability Considerations

Energy efficiency has become a critical consideration in modern autoclave design, driven by both economic pressures and environmental regulations. Traditional autoclaves are notorious for their high energy consumption, with thermal inefficiencies accounting for up to 40% of operational costs in some industrial applications. Recent innovations have focused on reducing this energy footprint through advanced insulation materials, such as aerogel-based composites that can reduce heat loss by up to 30% compared to conventional materials. These developments not only decrease operational expenses but also significantly reduce carbon emissions associated with autoclave operations.

Heat recovery systems represent another frontier in autoclave sustainability. Waste heat recapture technologies, including regenerative heat exchangers and thermal storage systems, can repurpose up to 25% of energy that would otherwise be lost. Some cutting-edge facilities have implemented closed-loop systems where steam condensate is collected, treated, and reused, reducing both water consumption and the energy required for heating fresh water supplies.

Smart control systems have revolutionized energy management in autoclave operations. Machine learning algorithms can optimize heating cycles based on load characteristics, reducing unnecessary energy expenditure during partial-load operations. Studies indicate that predictive control systems can achieve energy savings of 15-20% compared to traditional time-based control methods, while maintaining or even improving process quality and consistency.

The integration of renewable energy sources presents promising opportunities for sustainable autoclave operations. Solar thermal systems can provide supplementary heating for low and medium-temperature applications, while biomass-derived steam generation offers carbon-neutral alternatives for high-temperature processes. Several manufacturing facilities have successfully implemented hybrid energy systems that reduce fossil fuel dependency by 30-50% without compromising performance reliability.

Life cycle assessment (LCA) methodologies are increasingly being applied to autoclave design and operation. These comprehensive evaluations consider environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. Recent LCA studies have identified that operational energy consumption typically accounts for 70-80% of lifetime environmental impact, highlighting the importance of efficiency improvements. This holistic approach has led to design innovations such as modular construction that facilitates component replacement and upgrades rather than complete system replacement.

Water conservation represents another dimension of autoclave sustainability. Closed-loop cooling systems and advanced water treatment technologies can reduce freshwater consumption by up to 60% compared to conventional designs. Additionally, the integration of rainwater harvesting and greywater recycling systems in newer facilities demonstrates the potential for near-zero external water requirements in some applications.

Heat recovery systems represent another frontier in autoclave sustainability. Waste heat recapture technologies, including regenerative heat exchangers and thermal storage systems, can repurpose up to 25% of energy that would otherwise be lost. Some cutting-edge facilities have implemented closed-loop systems where steam condensate is collected, treated, and reused, reducing both water consumption and the energy required for heating fresh water supplies.

Smart control systems have revolutionized energy management in autoclave operations. Machine learning algorithms can optimize heating cycles based on load characteristics, reducing unnecessary energy expenditure during partial-load operations. Studies indicate that predictive control systems can achieve energy savings of 15-20% compared to traditional time-based control methods, while maintaining or even improving process quality and consistency.

The integration of renewable energy sources presents promising opportunities for sustainable autoclave operations. Solar thermal systems can provide supplementary heating for low and medium-temperature applications, while biomass-derived steam generation offers carbon-neutral alternatives for high-temperature processes. Several manufacturing facilities have successfully implemented hybrid energy systems that reduce fossil fuel dependency by 30-50% without compromising performance reliability.

Life cycle assessment (LCA) methodologies are increasingly being applied to autoclave design and operation. These comprehensive evaluations consider environmental impacts from raw material extraction through manufacturing, operation, and end-of-life disposal. Recent LCA studies have identified that operational energy consumption typically accounts for 70-80% of lifetime environmental impact, highlighting the importance of efficiency improvements. This holistic approach has led to design innovations such as modular construction that facilitates component replacement and upgrades rather than complete system replacement.

Water conservation represents another dimension of autoclave sustainability. Closed-loop cooling systems and advanced water treatment technologies can reduce freshwater consumption by up to 60% compared to conventional designs. Additionally, the integration of rainwater harvesting and greywater recycling systems in newer facilities demonstrates the potential for near-zero external water requirements in some applications.

Regulatory Compliance and Safety Standards

Autoclave operations are subject to stringent regulatory frameworks that govern safety standards, operational protocols, and quality assurance measures. The primary regulatory bodies overseeing autoclave design and operation include the American Society of Mechanical Engineers (ASME), which establishes the Boiler and Pressure Vessel Code (BPVC), and the International Organization for Standardization (ISO), particularly ISO 17665 for sterilization of health care products.

ASME BPVC Section VIII specifically addresses pressure vessels, mandating design requirements, material specifications, fabrication methods, inspection procedures, and testing protocols. Compliance with these standards is non-negotiable for autoclave manufacturers, as they establish minimum safety thresholds for pressure-bearing equipment.

In the European Union, the Pressure Equipment Directive (PED) 2014/68/EU regulates the design and fabrication of pressure equipment, including autoclaves. This directive requires CE marking for compliant equipment and emphasizes risk assessment throughout the design process. Similarly, in Asia, countries like Japan and China have established their own regulatory frameworks, such as Japan's High Pressure Gas Safety Act and China's Special Equipment Safety Law.

Recent innovations in autoclave design must navigate these complex regulatory landscapes while implementing performance enhancements. Advanced monitoring systems that provide real-time data on critical parameters (temperature, pressure, time) have become essential for regulatory compliance, enabling automated documentation for audit trails and validation processes.

Safety standards have evolved to address emerging risks associated with newer autoclave technologies. For instance, the integration of digital controls and remote operation capabilities has prompted updated cybersecurity requirements to prevent unauthorized access or tampering with critical safety systems. The IEC 61508 standard for functional safety of electrical/electronic/programmable electronic safety-related systems has become increasingly relevant for modern autoclave designs.

Material innovations must undergo rigorous testing and certification processes before implementation in autoclave construction. New composite materials or alloys must demonstrate compliance with mechanical strength requirements, corrosion resistance standards, and thermal stability parameters across the operational temperature range of autoclaves.

Environmental regulations have also influenced autoclave design innovations, particularly regarding energy efficiency and water consumption. The EU's Ecodesign Directive and similar regulations worldwide have pushed manufacturers to develop autoclaves with reduced environmental footprints while maintaining or enhancing performance capabilities.

Regulatory harmonization efforts are underway to streamline compliance across international markets, with initiatives like the Medical Device Single Audit Program (MDSAP) allowing for single regulatory audits acceptable across multiple jurisdictions. This trend toward global standardization presents both challenges and opportunities for innovative autoclave designs seeking multi-market approval.

ASME BPVC Section VIII specifically addresses pressure vessels, mandating design requirements, material specifications, fabrication methods, inspection procedures, and testing protocols. Compliance with these standards is non-negotiable for autoclave manufacturers, as they establish minimum safety thresholds for pressure-bearing equipment.

In the European Union, the Pressure Equipment Directive (PED) 2014/68/EU regulates the design and fabrication of pressure equipment, including autoclaves. This directive requires CE marking for compliant equipment and emphasizes risk assessment throughout the design process. Similarly, in Asia, countries like Japan and China have established their own regulatory frameworks, such as Japan's High Pressure Gas Safety Act and China's Special Equipment Safety Law.

Recent innovations in autoclave design must navigate these complex regulatory landscapes while implementing performance enhancements. Advanced monitoring systems that provide real-time data on critical parameters (temperature, pressure, time) have become essential for regulatory compliance, enabling automated documentation for audit trails and validation processes.

Safety standards have evolved to address emerging risks associated with newer autoclave technologies. For instance, the integration of digital controls and remote operation capabilities has prompted updated cybersecurity requirements to prevent unauthorized access or tampering with critical safety systems. The IEC 61508 standard for functional safety of electrical/electronic/programmable electronic safety-related systems has become increasingly relevant for modern autoclave designs.

Material innovations must undergo rigorous testing and certification processes before implementation in autoclave construction. New composite materials or alloys must demonstrate compliance with mechanical strength requirements, corrosion resistance standards, and thermal stability parameters across the operational temperature range of autoclaves.

Environmental regulations have also influenced autoclave design innovations, particularly regarding energy efficiency and water consumption. The EU's Ecodesign Directive and similar regulations worldwide have pushed manufacturers to develop autoclaves with reduced environmental footprints while maintaining or enhancing performance capabilities.

Regulatory harmonization efforts are underway to streamline compliance across international markets, with initiatives like the Medical Device Single Audit Program (MDSAP) allowing for single regulatory audits acceptable across multiple jurisdictions. This trend toward global standardization presents both challenges and opportunities for innovative autoclave designs seeking multi-market approval.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!