Minimize Energy Use in Autoclave Sterilization: Techniques Compared

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Sterilization Energy Efficiency Background and Objectives

Autoclave sterilization has been a cornerstone of infection control and sterilization processes since its invention in the late 19th century. The technology has evolved from basic pressure cookers to sophisticated computerized systems, but the fundamental principle remains unchanged: using saturated steam under pressure to eliminate microorganisms through protein denaturation. Over the past decades, the evolution of autoclave technology has been primarily focused on improving safety, reliability, and process control rather than energy efficiency.

Energy consumption in autoclave sterilization represents a significant operational cost for healthcare facilities, laboratories, and manufacturing plants. A standard medical autoclave can consume between 6-20 kWh per cycle, with larger industrial units consuming substantially more. This energy footprint has become increasingly problematic as organizations face rising energy costs and growing pressure to reduce carbon emissions in alignment with global sustainability goals.

The technical evolution trajectory shows three distinct phases: mechanical systems (1880s-1950s), electromechanical systems (1950s-2000s), and digital/smart systems (2000s-present). Each phase brought incremental improvements, but energy efficiency has only recently emerged as a primary design consideration, driven by both economic and environmental imperatives.

Current technical challenges in minimizing energy use include heat loss during operation, inefficient steam generation, suboptimal cycle parameters, and the energy-intensive nature of the drying phase. These challenges are compounded by the strict regulatory requirements that prioritize sterilization efficacy and reliability over energy considerations, creating a complex optimization problem.

The primary objective of this technical research is to comprehensively evaluate and compare various techniques for minimizing energy consumption in autoclave sterilization while maintaining or improving sterilization efficacy. Specific goals include quantifying the energy savings potential of different approaches, identifying the most promising technologies for immediate implementation, and mapping future innovation pathways.

Secondary objectives include developing a standardized methodology for measuring and comparing energy efficiency across different autoclave systems, identifying regulatory barriers to energy optimization, and assessing the total cost of ownership implications of energy-efficient technologies. The research also aims to establish benchmark energy consumption figures for different types and sizes of autoclaves across various applications.

The anticipated outcome is a clear technical roadmap that enables stakeholders to make informed decisions about energy efficiency investments in autoclave technology, with quantifiable metrics for expected returns on investment and environmental impact reduction. This research will serve as a foundation for future technical standards and best practices in sustainable sterilization processes.

Energy consumption in autoclave sterilization represents a significant operational cost for healthcare facilities, laboratories, and manufacturing plants. A standard medical autoclave can consume between 6-20 kWh per cycle, with larger industrial units consuming substantially more. This energy footprint has become increasingly problematic as organizations face rising energy costs and growing pressure to reduce carbon emissions in alignment with global sustainability goals.

The technical evolution trajectory shows three distinct phases: mechanical systems (1880s-1950s), electromechanical systems (1950s-2000s), and digital/smart systems (2000s-present). Each phase brought incremental improvements, but energy efficiency has only recently emerged as a primary design consideration, driven by both economic and environmental imperatives.

Current technical challenges in minimizing energy use include heat loss during operation, inefficient steam generation, suboptimal cycle parameters, and the energy-intensive nature of the drying phase. These challenges are compounded by the strict regulatory requirements that prioritize sterilization efficacy and reliability over energy considerations, creating a complex optimization problem.

The primary objective of this technical research is to comprehensively evaluate and compare various techniques for minimizing energy consumption in autoclave sterilization while maintaining or improving sterilization efficacy. Specific goals include quantifying the energy savings potential of different approaches, identifying the most promising technologies for immediate implementation, and mapping future innovation pathways.

Secondary objectives include developing a standardized methodology for measuring and comparing energy efficiency across different autoclave systems, identifying regulatory barriers to energy optimization, and assessing the total cost of ownership implications of energy-efficient technologies. The research also aims to establish benchmark energy consumption figures for different types and sizes of autoclaves across various applications.

The anticipated outcome is a clear technical roadmap that enables stakeholders to make informed decisions about energy efficiency investments in autoclave technology, with quantifiable metrics for expected returns on investment and environmental impact reduction. This research will serve as a foundation for future technical standards and best practices in sustainable sterilization processes.

Market Demand Analysis for Energy-Efficient Sterilization Solutions

The global market for energy-efficient sterilization solutions is experiencing robust growth, driven by increasing awareness of environmental sustainability and rising energy costs. Healthcare facilities, pharmaceutical companies, and food processing industries are actively seeking technologies that can reduce energy consumption while maintaining effective sterilization standards. Current market analysis indicates that autoclave sterilization accounts for approximately 30% of energy usage in hospital sterile processing departments, creating significant demand for optimization solutions.

Healthcare sector represents the largest market segment, with hospitals and clinics worldwide operating thousands of autoclaves daily. These institutions face mounting pressure to reduce operational costs while meeting stringent infection control standards. Recent industry surveys reveal that healthcare administrators rank energy efficiency among their top five priorities when purchasing new sterilization equipment, a significant shift from previous decades when speed and capacity were the primary considerations.

The pharmaceutical industry constitutes another major market segment, where Good Manufacturing Practices (GMP) requirements necessitate extensive sterilization processes. Companies in this sector are increasingly adopting energy-efficient technologies to align with corporate sustainability goals and reduce production costs. Market research indicates that pharmaceutical manufacturers can achieve 15-20% reduction in operational expenses through implementation of energy-optimized sterilization systems.

Food and beverage processing industries represent a rapidly growing market for energy-efficient sterilization, particularly in regions with stringent food safety regulations. These companies face dual pressures of maintaining product safety while reducing carbon footprints, creating strong demand for innovative sterilization approaches that minimize energy consumption.

Geographically, North America and Europe currently lead market demand due to stringent regulatory frameworks and higher energy costs. However, the Asia-Pacific region is projected to witness the fastest growth rate over the next five years, driven by expanding healthcare infrastructure and increasing adoption of international sterilization standards in developing economies.

Market analysts forecast that the global energy-efficient sterilization equipment market will continue expanding at a compound annual growth rate of 7-9% through 2028. This growth is further supported by government initiatives promoting green healthcare practices and carbon reduction targets across industries. Several countries have implemented financial incentives and tax benefits for healthcare facilities that invest in energy-efficient technologies, creating additional market pull for innovative sterilization solutions.

Consumer awareness regarding environmentally responsible manufacturing processes is also influencing market dynamics, particularly in food and pharmaceutical sectors where end-users increasingly favor products from companies demonstrating environmental stewardship.

Healthcare sector represents the largest market segment, with hospitals and clinics worldwide operating thousands of autoclaves daily. These institutions face mounting pressure to reduce operational costs while meeting stringent infection control standards. Recent industry surveys reveal that healthcare administrators rank energy efficiency among their top five priorities when purchasing new sterilization equipment, a significant shift from previous decades when speed and capacity were the primary considerations.

The pharmaceutical industry constitutes another major market segment, where Good Manufacturing Practices (GMP) requirements necessitate extensive sterilization processes. Companies in this sector are increasingly adopting energy-efficient technologies to align with corporate sustainability goals and reduce production costs. Market research indicates that pharmaceutical manufacturers can achieve 15-20% reduction in operational expenses through implementation of energy-optimized sterilization systems.

Food and beverage processing industries represent a rapidly growing market for energy-efficient sterilization, particularly in regions with stringent food safety regulations. These companies face dual pressures of maintaining product safety while reducing carbon footprints, creating strong demand for innovative sterilization approaches that minimize energy consumption.

Geographically, North America and Europe currently lead market demand due to stringent regulatory frameworks and higher energy costs. However, the Asia-Pacific region is projected to witness the fastest growth rate over the next five years, driven by expanding healthcare infrastructure and increasing adoption of international sterilization standards in developing economies.

Market analysts forecast that the global energy-efficient sterilization equipment market will continue expanding at a compound annual growth rate of 7-9% through 2028. This growth is further supported by government initiatives promoting green healthcare practices and carbon reduction targets across industries. Several countries have implemented financial incentives and tax benefits for healthcare facilities that invest in energy-efficient technologies, creating additional market pull for innovative sterilization solutions.

Consumer awareness regarding environmentally responsible manufacturing processes is also influencing market dynamics, particularly in food and pharmaceutical sectors where end-users increasingly favor products from companies demonstrating environmental stewardship.

Current Energy Challenges in Autoclave Sterilization Technologies

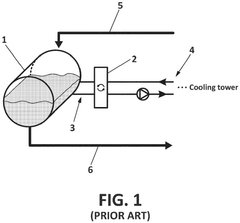

Autoclave sterilization, a cornerstone technology in healthcare, pharmaceutical manufacturing, and food processing industries, faces significant energy efficiency challenges in today's operational landscape. Traditional autoclave systems typically consume substantial amounts of energy, primarily in the form of steam generation and maintenance of high temperatures and pressures over extended periods. These systems often operate at temperatures between 121-134°C and pressures of 15-30 psi, requiring considerable energy input to achieve and maintain these conditions.

The energy consumption profile of conventional autoclaves reveals several critical inefficiencies. Steam generation alone accounts for approximately 50-70% of total energy usage, with additional energy losses occurring through poor insulation, suboptimal load configurations, and inefficient heating and cooling cycles. Industry data indicates that a standard 250-liter autoclave can consume between 15-25 kWh per cycle, translating to substantial operational costs and environmental impact.

Regulatory requirements further complicate energy optimization efforts. Sterilization protocols mandated by organizations such as the FDA, WHO, and ISO establish minimum temperature, pressure, and exposure time parameters that cannot be compromised regardless of energy considerations. This creates a challenging balance between regulatory compliance and energy efficiency goals.

Infrastructure limitations present additional obstacles. Many facilities operate with aging autoclave equipment that lacks modern energy-efficient features. Retrofitting these systems requires significant capital investment, creating financial barriers to improvement. Furthermore, facilities often face spatial constraints that limit options for equipment replacement or supplementary energy recovery systems.

The economic implications of these energy challenges are substantial. Energy costs typically represent 15-25% of operational expenses for autoclave-dependent facilities. With rising energy prices globally, this percentage continues to increase, placing pressure on operational budgets and sustainability targets. Healthcare facilities alone spend an estimated $6.5 billion annually on energy in the United States, with sterilization processes contributing significantly to this figure.

Environmental considerations add another dimension to the challenge. The carbon footprint associated with autoclave energy consumption is considerable, with each sterilization cycle potentially generating 5-15 kg of CO2 equivalent emissions. As organizations face increasing pressure to reduce their environmental impact and meet sustainability goals, addressing autoclave energy efficiency becomes increasingly urgent.

Recent technological innovations offer promising pathways to address these challenges, including advanced insulation materials, precise digital controls, heat recovery systems, and alternative sterilization methods. However, adoption remains limited due to implementation costs, validation requirements, and resistance to changing established protocols in highly regulated environments.

The energy consumption profile of conventional autoclaves reveals several critical inefficiencies. Steam generation alone accounts for approximately 50-70% of total energy usage, with additional energy losses occurring through poor insulation, suboptimal load configurations, and inefficient heating and cooling cycles. Industry data indicates that a standard 250-liter autoclave can consume between 15-25 kWh per cycle, translating to substantial operational costs and environmental impact.

Regulatory requirements further complicate energy optimization efforts. Sterilization protocols mandated by organizations such as the FDA, WHO, and ISO establish minimum temperature, pressure, and exposure time parameters that cannot be compromised regardless of energy considerations. This creates a challenging balance between regulatory compliance and energy efficiency goals.

Infrastructure limitations present additional obstacles. Many facilities operate with aging autoclave equipment that lacks modern energy-efficient features. Retrofitting these systems requires significant capital investment, creating financial barriers to improvement. Furthermore, facilities often face spatial constraints that limit options for equipment replacement or supplementary energy recovery systems.

The economic implications of these energy challenges are substantial. Energy costs typically represent 15-25% of operational expenses for autoclave-dependent facilities. With rising energy prices globally, this percentage continues to increase, placing pressure on operational budgets and sustainability targets. Healthcare facilities alone spend an estimated $6.5 billion annually on energy in the United States, with sterilization processes contributing significantly to this figure.

Environmental considerations add another dimension to the challenge. The carbon footprint associated with autoclave energy consumption is considerable, with each sterilization cycle potentially generating 5-15 kg of CO2 equivalent emissions. As organizations face increasing pressure to reduce their environmental impact and meet sustainability goals, addressing autoclave energy efficiency becomes increasingly urgent.

Recent technological innovations offer promising pathways to address these challenges, including advanced insulation materials, precise digital controls, heat recovery systems, and alternative sterilization methods. However, adoption remains limited due to implementation costs, validation requirements, and resistance to changing established protocols in highly regulated environments.

Comparative Analysis of Current Energy Reduction Techniques

01 Energy-efficient autoclave designs

Various innovations in autoclave design focus on reducing energy consumption during sterilization processes. These designs incorporate improved insulation materials, optimized chamber configurations, and advanced heating systems that minimize heat loss and energy waste. Some designs utilize heat recovery systems that capture and reuse thermal energy from the sterilization cycle, significantly reducing the overall energy footprint of the autoclave operation.- Energy-efficient autoclave designs: Modern autoclave designs incorporate energy-saving features such as improved insulation, heat recovery systems, and optimized heating elements. These designs minimize heat loss during the sterilization process, reduce warm-up times, and improve overall energy efficiency. Advanced thermal management systems help maintain precise temperature control while consuming less power, making the sterilization process more environmentally friendly and cost-effective.

- Monitoring and control systems for energy optimization: Sophisticated monitoring and control systems are implemented in autoclaves to optimize energy usage. These systems include sensors that track temperature, pressure, and energy consumption in real-time, allowing for precise control of the sterilization process. Automated systems can adjust operational parameters to minimize energy waste while maintaining sterilization efficacy. Some advanced systems incorporate predictive algorithms to anticipate energy needs and adjust accordingly.

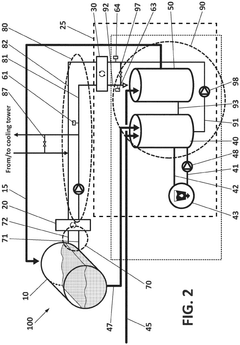

- Steam generation and management techniques: Efficient steam generation and management is crucial for energy conservation in autoclave sterilization. Innovations include on-demand steam generation, steam recycling systems, and improved steam distribution within the chamber. These techniques ensure that steam is produced only when needed and is effectively utilized throughout the sterilization cycle. Some systems incorporate condensate recovery to recapture heat energy that would otherwise be lost.

- Alternative energy sources and hybrid systems: To reduce reliance on conventional energy sources, autoclaves are being developed that utilize alternative or renewable energy. These include solar-powered autoclaves, systems that harness waste heat from other processes, and hybrid designs that combine multiple energy sources. Such approaches significantly reduce the carbon footprint of sterilization processes while maintaining effectiveness. Some designs incorporate energy storage capabilities to ensure consistent operation even when renewable sources are intermittent.

- Load optimization and cycle customization: Energy efficiency in autoclave sterilization can be improved through load optimization and cycle customization. This involves adjusting sterilization parameters based on the specific requirements of different loads, avoiding unnecessary energy expenditure. Advanced systems can automatically detect load characteristics and select the most energy-efficient cycle. Proper loading techniques and standardized procedures also contribute to reduced energy consumption while maintaining sterilization quality.

02 Monitoring and control systems for energy optimization

Advanced monitoring and control systems are implemented in autoclaves to optimize energy usage during sterilization cycles. These systems include sensors and controllers that precisely regulate temperature, pressure, and cycle duration based on the specific load requirements. Real-time monitoring capabilities allow for dynamic adjustments to minimize energy consumption while maintaining sterilization efficacy. Some systems incorporate predictive algorithms that can further reduce energy use by optimizing cycle parameters based on historical performance data.Expand Specific Solutions03 Alternative energy sources for autoclave operation

Innovations in autoclave technology include the use of alternative energy sources to power sterilization processes. These developments incorporate renewable energy systems such as solar thermal collectors, biomass heating, and geothermal energy to reduce reliance on conventional electricity or fossil fuels. Some designs integrate hybrid energy systems that can switch between different power sources depending on availability and efficiency considerations, further reducing the environmental impact of autoclave operations.Expand Specific Solutions04 Steam generation and management techniques

Efficient steam generation and management is critical for reducing energy consumption in autoclave sterilization. Innovations in this area include improved boiler designs, steam distribution systems, and condensate recovery mechanisms that maximize the thermal efficiency of the sterilization process. Some technologies incorporate pulse steam injection methods that reduce the total amount of steam required while maintaining effective sterilization. Advanced steam quality monitoring ensures optimal performance with minimal energy input.Expand Specific Solutions05 Load optimization and cycle customization

Energy efficiency in autoclave sterilization can be significantly improved through load optimization and cycle customization techniques. These approaches involve adjusting sterilization parameters based on the specific characteristics of the load, including size, density, and material composition. Some systems incorporate pre-programmed cycles for common load types, while others use adaptive algorithms to determine the most energy-efficient sterilization protocol. Proper loading configurations and the use of specialized containers or wrapping materials can also reduce cycle times and energy consumption.Expand Specific Solutions

Leading Manufacturers and Competitors in Sterilization Equipment

The autoclave sterilization energy efficiency market is currently in a growth phase, with increasing focus on sustainability driving innovation. The global medical sterilization equipment market is projected to reach approximately $12 billion by 2027, with autoclave technology representing a significant segment. Technologically, the field is moderately mature but evolving rapidly toward energy-efficient solutions. Key players include established medical equipment manufacturers like Stryker Corp. and Siemens AG, who leverage their extensive healthcare infrastructure, alongside specialized sterilization experts such as LTE Scientific and CISA SpA. Academic institutions including China Agricultural University and Zhejiang University of Technology are contributing research advancements, while companies like W&H Sterilization and Turbett Surgical focus on innovative energy-efficient autoclave designs. The competitive landscape features both multinational corporations and specialized regional players competing through technological differentiation and energy performance metrics.

Cefla SC

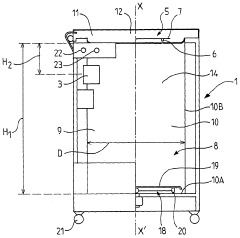

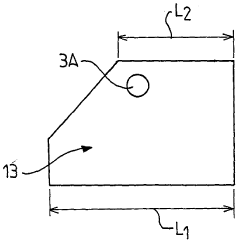

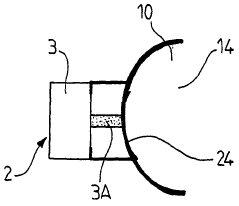

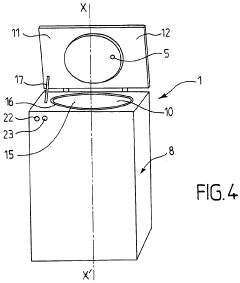

Technical Solution: Cefla SC has developed advanced energy optimization systems for autoclave sterilization through their SterilEnergy platform. This technology incorporates multiple energy-saving techniques including dynamic pressure control systems that optimize steam generation based on load requirements rather than maintaining constant maximum pressure. Their autoclaves feature intelligent heat recovery systems that capture and reuse waste heat from the sterilization process to preheat incoming water, reducing energy consumption by up to 35% compared to conventional systems[1]. Cefla's approach also includes vacuum pump optimization with variable frequency drives that adjust power consumption based on real-time requirements. Their proprietary insulation technology uses multi-layer ceramic composite materials that reduce heat loss by approximately 40% compared to standard insulation[2]. Additionally, Cefla has implemented predictive load sensing technology that automatically adjusts cycle parameters based on the specific thermal mass of each load, further reducing unnecessary energy expenditure.

Strengths: Comprehensive energy recovery systems that capture waste heat from multiple process points; advanced insulation technology that significantly reduces standby energy consumption; intelligent cycle optimization that adapts to specific load requirements. Weaknesses: Higher initial investment costs compared to conventional systems; requires more sophisticated maintenance protocols; optimal energy savings depend on proper staff training and adherence to recommended loading patterns.

LTE Scientific Ltd.

Technical Solution: LTE Scientific has developed the EcoTech autoclave platform specifically designed to minimize energy consumption in sterilization processes. Their technology incorporates a vacuum-assisted steam penetration system that achieves sterilization conditions more rapidly than conventional methods, reducing cycle times by approximately 25% and corresponding energy usage[1]. The system features proprietary thermal insulation composed of multi-layer vacuum panels that reduce heat loss by up to 60% compared to standard insulation materials. LTE's autoclaves employ intelligent water management systems that recycle cooling water, reducing both water consumption and the energy required for water heating by approximately 40%[2]. Their technology includes adaptive power management that automatically adjusts energy input based on load thermal mass, preventing energy waste during lighter loads. Additionally, LTE has implemented advanced standby management systems that reduce power consumption by up to 85% during idle periods while maintaining temperature at an optimal level for quick restart. The company's latest models also incorporate heat recovery systems that capture waste heat from exhaust steam and condensate to preheat incoming water and chamber walls[3].

Strengths: Exceptional thermal insulation that significantly reduces heat loss during operation; intelligent water recycling system that simultaneously conserves water and energy; adaptive power management that prevents energy waste during partial loads. Weaknesses: More complex technology requires specialized maintenance; optimal energy savings depend on proper cycle selection and loading practices; higher initial investment compared to standard autoclave systems.

Key Innovations in Low-Energy Sterilization Methods

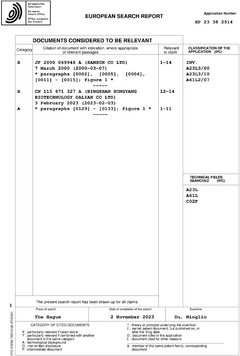

Circular resources system and method

PatentPendingEP4470390A1

Innovation

- A recovery system that reuses water and energy by storing cooled-down water in a warm water tank and transferring heat from this tank to a hot water tank for subsequent sterilization cycles, reducing the need for fresh water and energy consumption.

Sterilisation device and corresponding method

PatentWO2010128217A1

Innovation

- A sterilization device using wave emission, specifically S-band microwaves, that employs a temperature variation protocol involving a first rise, a decrease, and a second rise to effectively sterilize products without the need for high pressure and temperature, allowing for automatic control and safe operation.

Environmental Impact and Sustainability Considerations

Autoclave sterilization processes, while essential for healthcare and industrial applications, carry significant environmental implications that warrant careful consideration. The energy-intensive nature of traditional autoclave operations contributes substantially to carbon emissions, with a standard hospital autoclave consuming between 120-150 kWh per cycle. This translates to approximately 60-75 kg of CO2 emissions per cycle in regions reliant on fossil fuel energy sources. Water consumption presents another environmental concern, with conventional systems using 50-100 gallons per cycle, often discharged as heated wastewater containing chemical residues.

Material lifecycle considerations extend beyond operational impacts. Single-use sterilization wraps and packaging contribute an estimated 255 million pounds of waste annually in U.S. healthcare facilities alone. The manufacturing and disposal of these materials represent significant upstream and downstream environmental burdens that must be factored into comprehensive sustainability assessments of autoclave technologies.

Recent innovations demonstrate promising pathways toward reduced environmental footprints. Pulse vacuum technology has shown potential to reduce energy consumption by 20-30% compared to gravity displacement methods, while advanced insulation materials can decrease heat loss by up to 15%. Water recycling systems implemented in newer autoclave models have demonstrated water use reductions of 80-90%, significantly lowering resource demands and wastewater generation.

Renewable energy integration represents a transformative opportunity for autoclave sustainability. Solar thermal systems can provide supplementary heating, reducing fossil fuel dependence by 30-50% in suitable climates. Several healthcare facilities have successfully implemented combined heat and power systems that capture waste heat from other operations to support sterilization processes, achieving overall facility energy efficiency improvements of 15-25%.

Regulatory frameworks increasingly recognize these environmental dimensions. The EU Medical Device Regulation now includes sustainability considerations, while the U.S. EPA's Environmentally Preferable Purchasing program provides guidelines for healthcare facilities seeking greener sterilization options. Industry certification programs like LEED for Healthcare and Practice Greenhealth offer frameworks for evaluating and recognizing sustainable sterilization practices.

Economic analyses indicate that while sustainable autoclave technologies often require higher initial investments, operational savings typically yield positive returns within 3-5 years. A comprehensive life cycle assessment comparing traditional and energy-efficient autoclaves found that advanced models can reduce lifetime carbon footprints by 40-60%, demonstrating that environmental and economic benefits can align through thoughtful technology selection and implementation.

Material lifecycle considerations extend beyond operational impacts. Single-use sterilization wraps and packaging contribute an estimated 255 million pounds of waste annually in U.S. healthcare facilities alone. The manufacturing and disposal of these materials represent significant upstream and downstream environmental burdens that must be factored into comprehensive sustainability assessments of autoclave technologies.

Recent innovations demonstrate promising pathways toward reduced environmental footprints. Pulse vacuum technology has shown potential to reduce energy consumption by 20-30% compared to gravity displacement methods, while advanced insulation materials can decrease heat loss by up to 15%. Water recycling systems implemented in newer autoclave models have demonstrated water use reductions of 80-90%, significantly lowering resource demands and wastewater generation.

Renewable energy integration represents a transformative opportunity for autoclave sustainability. Solar thermal systems can provide supplementary heating, reducing fossil fuel dependence by 30-50% in suitable climates. Several healthcare facilities have successfully implemented combined heat and power systems that capture waste heat from other operations to support sterilization processes, achieving overall facility energy efficiency improvements of 15-25%.

Regulatory frameworks increasingly recognize these environmental dimensions. The EU Medical Device Regulation now includes sustainability considerations, while the U.S. EPA's Environmentally Preferable Purchasing program provides guidelines for healthcare facilities seeking greener sterilization options. Industry certification programs like LEED for Healthcare and Practice Greenhealth offer frameworks for evaluating and recognizing sustainable sterilization practices.

Economic analyses indicate that while sustainable autoclave technologies often require higher initial investments, operational savings typically yield positive returns within 3-5 years. A comprehensive life cycle assessment comparing traditional and energy-efficient autoclaves found that advanced models can reduce lifetime carbon footprints by 40-60%, demonstrating that environmental and economic benefits can align through thoughtful technology selection and implementation.

Cost-Benefit Analysis of Energy-Efficient Sterilization Investments

Investing in energy-efficient autoclave sterilization technologies requires thorough financial analysis to justify capital expenditures. Initial investment costs for advanced energy-efficient autoclaves typically range from $50,000 to $200,000, depending on capacity and technological sophistication. While this represents a significant upfront expense, operational savings can offset these costs over time.

Energy consumption analysis reveals that traditional autoclaves consume approximately 120-150 kWh per cycle, while energy-efficient models reduce this to 70-90 kWh—representing potential energy savings of 30-50%. When calculated annually for facilities running multiple cycles daily, this translates to $10,000-$30,000 in reduced energy costs per year per unit.

Water usage presents another significant cost factor. Conventional systems use 300-500 gallons per cycle, while efficient systems reduce consumption by up to 60%. At industrial water rates, this represents additional annual savings of $5,000-$15,000, with greater impact in water-scarce regions where rates are higher.

Return on investment calculations indicate payback periods ranging from 2-5 years for most healthcare facilities and industrial applications. Hospitals operating autoclaves continuously may see ROI periods closer to 2 years, while facilities with intermittent usage may approach the 5-year mark. These calculations improve further when factoring in available government incentives and rebates for energy efficiency upgrades.

Lifecycle cost analysis demonstrates that energy-efficient autoclaves typically reduce total ownership costs by 25-40% over a 10-year operational period. This includes not only energy and water savings but also reduced maintenance requirements and extended equipment lifespan due to improved engineering and materials.

Risk assessment indicates minimal financial downside, with technology reliability comparable to conventional systems. The primary risk factor involves potential underutilization of capacity, which can extend payback periods. Sensitivity analysis shows that even with 30% lower utilization than projected, most facilities still achieve positive ROI within acceptable timeframes.

Financing options further enhance investment attractiveness. Many manufacturers offer leasing arrangements with monthly payments lower than projected energy savings, creating immediate positive cash flow. Additionally, energy service companies (ESCOs) increasingly offer performance contracts for sterilization equipment, guaranteeing energy savings and reducing financial risk.

Energy consumption analysis reveals that traditional autoclaves consume approximately 120-150 kWh per cycle, while energy-efficient models reduce this to 70-90 kWh—representing potential energy savings of 30-50%. When calculated annually for facilities running multiple cycles daily, this translates to $10,000-$30,000 in reduced energy costs per year per unit.

Water usage presents another significant cost factor. Conventional systems use 300-500 gallons per cycle, while efficient systems reduce consumption by up to 60%. At industrial water rates, this represents additional annual savings of $5,000-$15,000, with greater impact in water-scarce regions where rates are higher.

Return on investment calculations indicate payback periods ranging from 2-5 years for most healthcare facilities and industrial applications. Hospitals operating autoclaves continuously may see ROI periods closer to 2 years, while facilities with intermittent usage may approach the 5-year mark. These calculations improve further when factoring in available government incentives and rebates for energy efficiency upgrades.

Lifecycle cost analysis demonstrates that energy-efficient autoclaves typically reduce total ownership costs by 25-40% over a 10-year operational period. This includes not only energy and water savings but also reduced maintenance requirements and extended equipment lifespan due to improved engineering and materials.

Risk assessment indicates minimal financial downside, with technology reliability comparable to conventional systems. The primary risk factor involves potential underutilization of capacity, which can extend payback periods. Sensitivity analysis shows that even with 30% lower utilization than projected, most facilities still achieve positive ROI within acceptable timeframes.

Financing options further enhance investment attractiveness. Many manufacturers offer leasing arrangements with monthly payments lower than projected energy savings, creating immediate positive cash flow. Additionally, energy service companies (ESCOs) increasingly offer performance contracts for sterilization equipment, guaranteeing energy savings and reducing financial risk.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!