Autoclave Stress Testing: Ensuring Durability and Performance

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Testing Background and Objectives

Autoclave testing has evolved significantly since its inception in the early 20th century, originally developed for sterilization purposes in medical and food industries. The adaptation of this technology for materials testing represents a critical advancement in quality assurance methodologies across multiple sectors. Today, autoclave stress testing stands as a cornerstone procedure for evaluating material durability under extreme temperature and pressure conditions, simulating accelerated aging and environmental stress scenarios that products may encounter throughout their lifecycle.

The fundamental principle behind autoclave testing involves subjecting materials or components to controlled environments of elevated temperature, pressure, and humidity simultaneously. This combination creates particularly challenging conditions that can reveal potential failure modes and performance limitations that might otherwise remain undetected through conventional testing methods. The historical progression of autoclave testing technology has seen significant refinements in precision control systems, monitoring capabilities, and test standardization protocols.

Current technological trends in autoclave testing are moving toward more sophisticated computer-controlled systems with enhanced data acquisition capabilities, allowing for real-time monitoring and analysis of material behavior under stress. Additionally, there is growing integration with artificial intelligence and machine learning algorithms to predict long-term material performance based on short-term autoclave test results, representing a paradigm shift in predictive material science.

The primary objectives of modern autoclave stress testing encompass several critical dimensions. First, it aims to validate material integrity and performance under extreme environmental conditions, ensuring products maintain functionality throughout their intended service life. Second, it serves to identify potential failure mechanisms and weak points in material structures or component designs before they reach production stages. Third, it provides comparative data for material selection processes, enabling engineers to make informed decisions regarding material suitability for specific applications.

Furthermore, autoclave testing objectives extend to regulatory compliance, particularly in industries where safety and reliability are paramount concerns, such as aerospace, automotive, and medical device manufacturing. These tests generate essential documentation required by certification bodies and regulatory agencies, demonstrating that materials and components meet established industry standards and safety requirements.

The evolution of autoclave testing methodologies continues to be driven by increasing demands for material performance in extreme environments, the development of advanced composite materials, and the need for accelerated testing protocols that can accurately predict long-term behavior while reducing product development timelines. As industries push the boundaries of material capabilities, autoclave testing remains an indispensable tool in ensuring product reliability, safety, and performance under the most demanding conditions.

The fundamental principle behind autoclave testing involves subjecting materials or components to controlled environments of elevated temperature, pressure, and humidity simultaneously. This combination creates particularly challenging conditions that can reveal potential failure modes and performance limitations that might otherwise remain undetected through conventional testing methods. The historical progression of autoclave testing technology has seen significant refinements in precision control systems, monitoring capabilities, and test standardization protocols.

Current technological trends in autoclave testing are moving toward more sophisticated computer-controlled systems with enhanced data acquisition capabilities, allowing for real-time monitoring and analysis of material behavior under stress. Additionally, there is growing integration with artificial intelligence and machine learning algorithms to predict long-term material performance based on short-term autoclave test results, representing a paradigm shift in predictive material science.

The primary objectives of modern autoclave stress testing encompass several critical dimensions. First, it aims to validate material integrity and performance under extreme environmental conditions, ensuring products maintain functionality throughout their intended service life. Second, it serves to identify potential failure mechanisms and weak points in material structures or component designs before they reach production stages. Third, it provides comparative data for material selection processes, enabling engineers to make informed decisions regarding material suitability for specific applications.

Furthermore, autoclave testing objectives extend to regulatory compliance, particularly in industries where safety and reliability are paramount concerns, such as aerospace, automotive, and medical device manufacturing. These tests generate essential documentation required by certification bodies and regulatory agencies, demonstrating that materials and components meet established industry standards and safety requirements.

The evolution of autoclave testing methodologies continues to be driven by increasing demands for material performance in extreme environments, the development of advanced composite materials, and the need for accelerated testing protocols that can accurately predict long-term behavior while reducing product development timelines. As industries push the boundaries of material capabilities, autoclave testing remains an indispensable tool in ensuring product reliability, safety, and performance under the most demanding conditions.

Market Demand for Autoclave-Resistant Materials

The global market for autoclave-resistant materials has experienced significant growth in recent years, driven primarily by expanding applications in aerospace, healthcare, and industrial manufacturing sectors. Current market valuations indicate that the autoclave-resistant materials market reached approximately $7.2 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028.

Healthcare applications represent the largest market segment, accounting for nearly 38% of total demand. This is largely attributed to the increasing need for sterilization-resistant materials in medical devices, surgical instruments, and implantable components. The COVID-19 pandemic further accelerated this demand, as healthcare facilities worldwide intensified sterilization protocols, creating additional stress on materials and equipment.

The aerospace industry follows as the second-largest consumer of autoclave-resistant materials, representing approximately 27% of market share. With aircraft manufacturers increasingly adopting composite materials that require autoclave curing processes, the demand for materials capable of withstanding extreme pressure and temperature conditions has surged. Boeing and Airbus have both reported increased procurement of specialized autoclave-resistant materials for their next-generation aircraft programs.

Regional analysis reveals that North America currently leads the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 24%. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.3% annually, driven by rapid industrialization in China and India, along with expanding healthcare infrastructure.

Consumer preferences are increasingly shifting toward materials that not only withstand autoclave conditions but also demonstrate enhanced longevity through multiple sterilization cycles. Market research indicates that end-users are willing to pay premium prices for materials that can maintain structural integrity and performance characteristics beyond 500 autoclave cycles, representing a 30% increase in cycle expectations compared to five years ago.

Sustainability considerations are also reshaping market demands, with 62% of procurement professionals reporting that they now prioritize autoclave-resistant materials that are recyclable or have reduced environmental impact. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly mandate life-cycle assessments for industrial materials.

Supply chain challenges, particularly raw material shortages and production bottlenecks, have created market tensions since 2021. These constraints have resulted in price increases averaging 12-15% for specialized high-performance polymers and composite materials, forcing manufacturers to explore alternative formulations and material science innovations to meet market demands while managing cost pressures.

Healthcare applications represent the largest market segment, accounting for nearly 38% of total demand. This is largely attributed to the increasing need for sterilization-resistant materials in medical devices, surgical instruments, and implantable components. The COVID-19 pandemic further accelerated this demand, as healthcare facilities worldwide intensified sterilization protocols, creating additional stress on materials and equipment.

The aerospace industry follows as the second-largest consumer of autoclave-resistant materials, representing approximately 27% of market share. With aircraft manufacturers increasingly adopting composite materials that require autoclave curing processes, the demand for materials capable of withstanding extreme pressure and temperature conditions has surged. Boeing and Airbus have both reported increased procurement of specialized autoclave-resistant materials for their next-generation aircraft programs.

Regional analysis reveals that North America currently leads the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 24%. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.3% annually, driven by rapid industrialization in China and India, along with expanding healthcare infrastructure.

Consumer preferences are increasingly shifting toward materials that not only withstand autoclave conditions but also demonstrate enhanced longevity through multiple sterilization cycles. Market research indicates that end-users are willing to pay premium prices for materials that can maintain structural integrity and performance characteristics beyond 500 autoclave cycles, representing a 30% increase in cycle expectations compared to five years ago.

Sustainability considerations are also reshaping market demands, with 62% of procurement professionals reporting that they now prioritize autoclave-resistant materials that are recyclable or have reduced environmental impact. This trend is particularly pronounced in European markets, where regulatory frameworks increasingly mandate life-cycle assessments for industrial materials.

Supply chain challenges, particularly raw material shortages and production bottlenecks, have created market tensions since 2021. These constraints have resulted in price increases averaging 12-15% for specialized high-performance polymers and composite materials, forcing manufacturers to explore alternative formulations and material science innovations to meet market demands while managing cost pressures.

Current Challenges in Autoclave Stress Testing

Despite significant advancements in autoclave stress testing methodologies, the field continues to face several critical challenges that impede accurate performance assessment and reliability prediction. One of the primary obstacles is the inherent difficulty in replicating real-world operational conditions within controlled laboratory environments. Autoclaves typically operate under extreme pressure and temperature combinations that vary dynamically during actual industrial processes, making standardized testing protocols insufficient for comprehensive evaluation.

The accelerated aging tests commonly employed in autoclave stress testing often fail to account for the complex interaction of multiple stressors simultaneously affecting materials and components. This simplification can lead to inaccurate durability predictions, as the synergistic effects of combined stressors may produce failure modes not observed when testing against individual stress factors.

Data interpretation presents another significant challenge, particularly in correlating accelerated test results with actual service life expectations. The non-linear relationship between stress intensity and material degradation complicates the development of reliable mathematical models for lifetime prediction. Industry experts report discrepancies of up to 30% between predicted and actual performance lifespans based on current testing methodologies.

Material heterogeneity and manufacturing variability further complicate testing procedures. Even minor inconsistencies in material composition or processing can significantly alter stress resistance properties, necessitating larger sample sizes and more sophisticated statistical analysis than currently practiced in many testing facilities. This variability is especially problematic for composite materials and advanced alloys used in high-performance applications.

The energy consumption and environmental impact of traditional autoclave testing represent growing concerns in the industry. Conventional testing equipment requires substantial power input and often utilizes environmentally problematic heat transfer fluids. As sustainability becomes increasingly important across industries, developing more energy-efficient and environmentally friendly testing methods has become an urgent priority.

Instrumentation limitations also pose significant challenges. Current sensor technologies struggle to maintain accuracy and reliability under extreme autoclave conditions, particularly for extended test durations. The development of more robust monitoring systems capable of providing real-time, high-precision data throughout the entire testing cycle remains an active area of research with considerable technical hurdles.

Finally, the lack of standardization across different industries and regions creates difficulties in comparing test results and establishing universal quality benchmarks. While organizations such as ASTM International and ISO have developed guidelines, their implementation varies significantly, leading to inconsistent testing practices and results interpretation across the global manufacturing landscape.

The accelerated aging tests commonly employed in autoclave stress testing often fail to account for the complex interaction of multiple stressors simultaneously affecting materials and components. This simplification can lead to inaccurate durability predictions, as the synergistic effects of combined stressors may produce failure modes not observed when testing against individual stress factors.

Data interpretation presents another significant challenge, particularly in correlating accelerated test results with actual service life expectations. The non-linear relationship between stress intensity and material degradation complicates the development of reliable mathematical models for lifetime prediction. Industry experts report discrepancies of up to 30% between predicted and actual performance lifespans based on current testing methodologies.

Material heterogeneity and manufacturing variability further complicate testing procedures. Even minor inconsistencies in material composition or processing can significantly alter stress resistance properties, necessitating larger sample sizes and more sophisticated statistical analysis than currently practiced in many testing facilities. This variability is especially problematic for composite materials and advanced alloys used in high-performance applications.

The energy consumption and environmental impact of traditional autoclave testing represent growing concerns in the industry. Conventional testing equipment requires substantial power input and often utilizes environmentally problematic heat transfer fluids. As sustainability becomes increasingly important across industries, developing more energy-efficient and environmentally friendly testing methods has become an urgent priority.

Instrumentation limitations also pose significant challenges. Current sensor technologies struggle to maintain accuracy and reliability under extreme autoclave conditions, particularly for extended test durations. The development of more robust monitoring systems capable of providing real-time, high-precision data throughout the entire testing cycle remains an active area of research with considerable technical hurdles.

Finally, the lack of standardization across different industries and regions creates difficulties in comparing test results and establishing universal quality benchmarks. While organizations such as ASTM International and ISO have developed guidelines, their implementation varies significantly, leading to inconsistent testing practices and results interpretation across the global manufacturing landscape.

Current Autoclave Stress Testing Protocols

01 Autoclave testing methods for material durability

Various methods are employed to test material durability under autoclave conditions. These methods involve subjecting materials to high pressure, temperature, and steam environments to evaluate their resistance to degradation. The testing protocols typically include multiple cycles of exposure to simulate long-term use conditions. These methods help in determining the structural integrity and longevity of materials used in applications requiring sterilization.- Autoclave testing methods for material durability: Various methods are employed to test material durability under autoclave conditions. These methods involve subjecting materials to high temperature, pressure, and steam environments to evaluate their performance and longevity. The testing protocols typically include monitoring physical properties before and after exposure to autoclave conditions, measuring degradation rates, and assessing structural integrity changes. These methods help in determining whether materials can withstand sterilization processes repeatedly without significant deterioration.

- Monitoring systems for autoclave performance: Advanced monitoring systems are developed to evaluate autoclave performance during stress testing. These systems incorporate sensors, data acquisition equipment, and analytical software to track parameters such as temperature distribution, pressure consistency, and steam quality. Real-time monitoring allows for immediate detection of performance anomalies and helps in validating sterilization processes. The monitoring systems can be integrated with automated control mechanisms to maintain optimal conditions throughout the testing cycle.

- Specialized equipment for autoclave stress testing: Specialized equipment has been developed specifically for conducting autoclave stress tests on various materials and products. This equipment includes custom test chambers, specimen holders, and fixtures designed to simulate real-world sterilization conditions while allowing for precise control of test parameters. The equipment often features capabilities for cyclic testing, accelerated aging, and comparative analysis between different materials or components. These specialized tools enable more accurate prediction of product performance in actual use conditions.

- Data analysis and prediction models for durability assessment: Advanced data analysis techniques and prediction models are employed to assess the durability of materials subjected to autoclave stress testing. These models utilize statistical methods, machine learning algorithms, and historical performance data to predict long-term behavior and failure points. The analysis considers multiple factors including material composition, structural design, and environmental conditions to generate comprehensive durability assessments. These predictive capabilities help manufacturers optimize product designs and select appropriate materials for autoclave-compatible applications.

- Standardized protocols for autoclave performance validation: Standardized testing protocols have been established to validate autoclave performance and material durability. These protocols define specific parameters such as temperature ranges, pressure levels, exposure times, and cycle counts to ensure consistent and comparable test results across different facilities. The standardized approaches include procedures for sample preparation, placement within the autoclave, post-test evaluation, and documentation requirements. Adherence to these protocols enables reliable quality assurance and regulatory compliance for products that must withstand autoclave sterilization.

02 Performance monitoring systems for autoclaves

Advanced monitoring systems are designed to evaluate autoclave performance during stress testing. These systems incorporate sensors and data acquisition tools to measure parameters such as temperature distribution, pressure consistency, and steam penetration. Real-time monitoring allows for immediate detection of performance issues and ensures that sterilization processes meet required standards. The collected data can be analyzed to identify potential failure points and optimize autoclave operation.Expand Specific Solutions03 Specialized fixtures and apparatus for autoclave testing

Specialized fixtures and apparatus are developed to facilitate autoclave stress testing of various components and materials. These fixtures are designed to hold test specimens in specific orientations and conditions during the autoclave process. They enable consistent and reproducible testing conditions, allowing for accurate assessment of material performance under sterilization stress. Some fixtures include additional features for applying mechanical stress simultaneously with thermal and pressure stress.Expand Specific Solutions04 Accelerated aging protocols using autoclave conditions

Accelerated aging protocols utilize autoclave conditions to predict long-term durability of materials and products. These protocols subject test specimens to intensified stress conditions to simulate extended use in a compressed timeframe. The approach helps in estimating product lifespan and identifying potential failure modes that might occur after prolonged use. Various parameters such as temperature, pressure, and cycle duration can be adjusted to correlate with different real-world aging scenarios.Expand Specific Solutions05 Quality control and validation techniques for autoclave processes

Quality control and validation techniques ensure the reliability of autoclave processes and the durability of sterilized items. These techniques include standardized testing procedures, performance qualification protocols, and statistical analysis of test results. Validation methods verify that autoclave cycles consistently achieve required sterilization parameters while maintaining product integrity. Regular performance testing helps identify equipment deterioration before it affects sterilization efficacy or damages processed items.Expand Specific Solutions

Key Industry Players in Autoclave Testing

Autoclave stress testing technology is currently in a mature development phase, with a growing market driven by increasing demands for material durability verification across aerospace, energy, and automotive sectors. The competitive landscape features a diverse mix of players including academic institutions (Southwest Petroleum University, Xi'an Jiaotong University), major energy corporations (China Petroleum & Chemical Corp., CNOOC), research organizations (Fraunhofer-Gesellschaft, Shanghai Nuclear Engineering Research & Design Institute), and industrial manufacturers (Steriflow SAS, Robert Bosch GmbH). Technical maturity varies by application area, with petroleum and nuclear industries demonstrating advanced capabilities, while automotive and materials science sectors continue to innovate with new testing methodologies. The collaboration between academic institutions and industry leaders is accelerating standardization efforts and technological advancement in this critical quality assurance field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced Autoclave Stress Testing system specifically designed for oil and gas equipment validation. Their approach integrates multi-parameter stress testing with real-time monitoring capabilities, allowing simultaneous evaluation of pressure, temperature, and corrosive media effects on materials and components. The system employs proprietary sensor arrays that can withstand extreme conditions (up to 200 MPa and 350°C) while maintaining measurement accuracy. Sinopec's methodology incorporates cyclic loading patterns that simulate actual field conditions experienced in deep-well operations, providing more realistic performance predictions than conventional static tests. Their data acquisition system features adaptive sampling rates that increase during critical transition periods, capturing transient stress behaviors that might be missed in standard testing protocols.

Strengths: Exceptional capability to simulate extreme downhole conditions specific to oil and gas applications; comprehensive multi-parameter testing in a single setup reduces overall testing time. Weaknesses: System is highly specialized for petroleum applications and may require significant modifications for other industries; high operational costs due to sophisticated monitoring equipment.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed a comprehensive Autoclave Stress Testing platform that integrates multiple analytical techniques for real-time material characterization during stress exposure. Their system incorporates acoustic emission monitoring, in-situ microscopy, and spectroscopic analysis capabilities within specialized pressure vessels, enabling direct observation of microstructural changes during testing. The institute has pioneered multi-axial stress testing methodologies that can simultaneously apply pressure, temperature, and mechanical loading in controlled orientations to evaluate anisotropic material properties. Their testing framework includes advanced data fusion algorithms that correlate multiple sensor inputs to identify precursors to material failure before catastrophic events occur. Fraunhofer's approach incorporates modular test chamber designs that can be rapidly reconfigured for different test environments, including hydrogen embrittlement studies, supercritical fluid exposure, and cryogenic applications. The institute has also developed specialized non-destructive evaluation protocols that can be applied during test interruptions to track progressive damage accumulation.

Strengths: Exceptional analytical capabilities for fundamental understanding of failure mechanisms; highly versatile system applicable across multiple industries and research domains. Weaknesses: Complex system requires significant expertise to operate effectively; higher cost compared to more specialized testing platforms; requires more extensive calibration and maintenance.

Critical Technologies in Autoclave Resistance

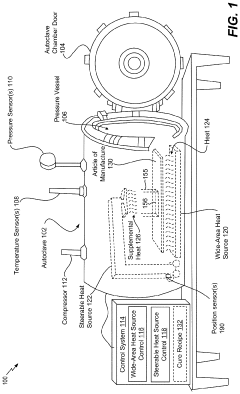

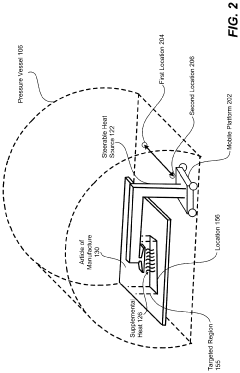

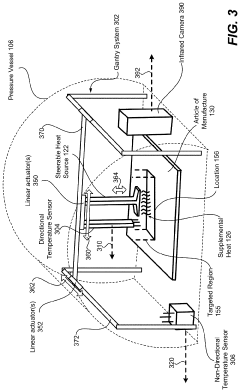

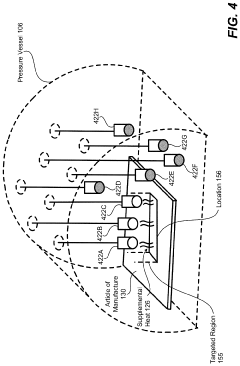

Steerable heat source

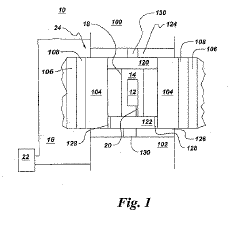

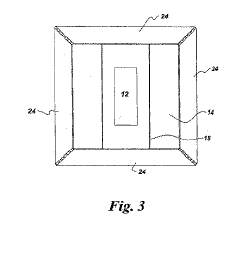

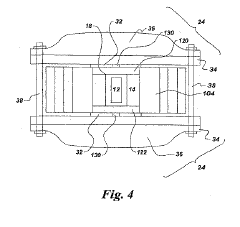

PatentActiveUS20200307035A1

Innovation

- A steerable heat source is integrated within the autoclave, coupled with a control system that directs supplemental heat to targeted regions using temperature sensors and a compressor to regulate pressure, ensuring precise temperature control and uniform heating.

Improved pressure vessel

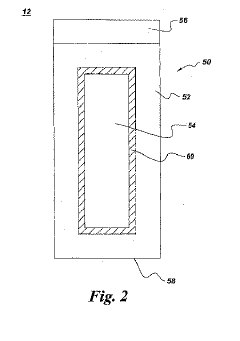

PatentInactiveJP2005515884A

Innovation

- A self-pressurizing pressure vessel that maintains a substantially air-free environment, using a self-pressurizing capsule surrounded by a pressure-transmitting medium, with heating elements and a power control system to manage temperature and pressure, and restraints to prevent leakage, allowing processing in supercritical fluids.

Material Science Advancements for Autoclave Applications

The evolution of material science has significantly impacted autoclave technology, particularly in stress testing applications. Advanced composite materials, including carbon fiber reinforced polymers (CFRP) and high-performance ceramics, have revolutionized autoclave design by offering superior strength-to-weight ratios and enhanced thermal stability. These materials can withstand extreme pressure and temperature conditions, making them ideal for modern autoclave environments where testing parameters continue to become more demanding.

Recent developments in nanomaterials have introduced new possibilities for autoclave components. Nanocomposites incorporating graphene, carbon nanotubes, and ceramic nanoparticles demonstrate remarkable improvements in mechanical properties, thermal conductivity, and chemical resistance. These characteristics are particularly valuable in autoclave stress testing, where materials must maintain structural integrity under cyclical loading and aggressive environmental conditions.

Smart materials represent another frontier in autoclave technology. Shape memory alloys and piezoelectric materials enable real-time monitoring of stress conditions within the autoclave chamber. These materials can respond to environmental changes, providing valuable data on material behavior during testing cycles while potentially extending equipment lifespan through adaptive responses to stress conditions.

Corrosion-resistant alloys have addressed one of the most persistent challenges in autoclave environments. Advanced stainless steels, nickel-based superalloys, and titanium alloys offer exceptional resistance to high-temperature oxidation, stress corrosion cracking, and hydrogen embrittlement. These properties are essential for maintaining the integrity of autoclave chambers and test specimens during extended exposure to harsh testing conditions.

Thermal barrier coatings (TBCs) have emerged as critical components for protecting autoclave surfaces. Ceramic-based TBCs, often incorporating yttria-stabilized zirconia or alumina, provide insulation against extreme temperatures while minimizing thermal gradient damage. These coatings extend component lifespans and improve energy efficiency during autoclave operation.

Biomimetic materials, inspired by natural structures, are beginning to influence autoclave design. Materials that mimic the hierarchical structures found in natural systems like nacre or bone demonstrate exceptional combinations of strength, toughness, and damage tolerance. These characteristics are particularly valuable for components subjected to the complex stress states typical in autoclave testing environments.

The integration of computational materials science with experimental approaches has accelerated material development for autoclave applications. Machine learning algorithms now predict material behavior under specific autoclave conditions, while digital twins simulate component performance throughout their lifecycle, enabling more efficient material selection and testing protocols.

Recent developments in nanomaterials have introduced new possibilities for autoclave components. Nanocomposites incorporating graphene, carbon nanotubes, and ceramic nanoparticles demonstrate remarkable improvements in mechanical properties, thermal conductivity, and chemical resistance. These characteristics are particularly valuable in autoclave stress testing, where materials must maintain structural integrity under cyclical loading and aggressive environmental conditions.

Smart materials represent another frontier in autoclave technology. Shape memory alloys and piezoelectric materials enable real-time monitoring of stress conditions within the autoclave chamber. These materials can respond to environmental changes, providing valuable data on material behavior during testing cycles while potentially extending equipment lifespan through adaptive responses to stress conditions.

Corrosion-resistant alloys have addressed one of the most persistent challenges in autoclave environments. Advanced stainless steels, nickel-based superalloys, and titanium alloys offer exceptional resistance to high-temperature oxidation, stress corrosion cracking, and hydrogen embrittlement. These properties are essential for maintaining the integrity of autoclave chambers and test specimens during extended exposure to harsh testing conditions.

Thermal barrier coatings (TBCs) have emerged as critical components for protecting autoclave surfaces. Ceramic-based TBCs, often incorporating yttria-stabilized zirconia or alumina, provide insulation against extreme temperatures while minimizing thermal gradient damage. These coatings extend component lifespans and improve energy efficiency during autoclave operation.

Biomimetic materials, inspired by natural structures, are beginning to influence autoclave design. Materials that mimic the hierarchical structures found in natural systems like nacre or bone demonstrate exceptional combinations of strength, toughness, and damage tolerance. These characteristics are particularly valuable for components subjected to the complex stress states typical in autoclave testing environments.

The integration of computational materials science with experimental approaches has accelerated material development for autoclave applications. Machine learning algorithms now predict material behavior under specific autoclave conditions, while digital twins simulate component performance throughout their lifecycle, enabling more efficient material selection and testing protocols.

Regulatory Standards for Autoclave-Processed Products

Regulatory standards for autoclave-processed products are critical frameworks that ensure the safety, reliability, and performance of items subjected to autoclave sterilization across various industries. These standards are established by international, regional, and national regulatory bodies to provide consistent guidelines for manufacturers, testing laboratories, and end-users.

The International Organization for Standardization (ISO) has developed several key standards specifically addressing autoclave processing, including ISO 17665 for moist heat sterilization validation and routine control, and ISO 11134 which outlines requirements for validation and routine control of industrial moist heat sterilization. These standards define the parameters for effective sterilization cycles, including temperature ranges, pressure levels, and exposure times.

In the medical device industry, regulatory bodies such as the FDA in the United States and the European Medicines Agency (EMA) enforce stringent requirements through regulations like 21 CFR Part 820 and the Medical Device Regulation (MDR) 2017/745, respectively. These regulations mandate that autoclave-processed medical products undergo thorough validation to demonstrate that sterilization processes consistently deliver the required sterility assurance level (SAL) of 10^-6.

For food processing applications, the Food Safety Modernization Act (FSMA) in the US and similar regulations worldwide establish requirements for thermal processing equipment, including autoclaves. These standards focus on preventing pathogen survival and ensuring food safety through validated thermal processes.

The aerospace industry follows standards such as SAE AMS 2750 for pyrometry and ASTM F1980 for accelerated aging tests, which include specific protocols for autoclave stress testing of composite materials and components. These standards ensure that materials can withstand the extreme conditions encountered during service life.

Material-specific standards also exist, such as ASTM D6484 for open-hole compression strength of polymer matrix composite laminates and ASTM D3039 for tensile properties of polymer matrix composite materials, which include provisions for testing after autoclave exposure.

Compliance with these regulatory standards typically requires comprehensive documentation of validation studies, routine monitoring data, and periodic requalification of autoclave equipment. Many standards mandate specific test methods for evaluating material properties before and after autoclave processing, including mechanical strength, dimensional stability, and chemical resistance.

As technology advances, regulatory standards continue to evolve, with increasing emphasis on process analytical technology (PAT) for real-time monitoring and control of autoclave processes, as well as risk-based approaches to validation and quality assurance.

The International Organization for Standardization (ISO) has developed several key standards specifically addressing autoclave processing, including ISO 17665 for moist heat sterilization validation and routine control, and ISO 11134 which outlines requirements for validation and routine control of industrial moist heat sterilization. These standards define the parameters for effective sterilization cycles, including temperature ranges, pressure levels, and exposure times.

In the medical device industry, regulatory bodies such as the FDA in the United States and the European Medicines Agency (EMA) enforce stringent requirements through regulations like 21 CFR Part 820 and the Medical Device Regulation (MDR) 2017/745, respectively. These regulations mandate that autoclave-processed medical products undergo thorough validation to demonstrate that sterilization processes consistently deliver the required sterility assurance level (SAL) of 10^-6.

For food processing applications, the Food Safety Modernization Act (FSMA) in the US and similar regulations worldwide establish requirements for thermal processing equipment, including autoclaves. These standards focus on preventing pathogen survival and ensuring food safety through validated thermal processes.

The aerospace industry follows standards such as SAE AMS 2750 for pyrometry and ASTM F1980 for accelerated aging tests, which include specific protocols for autoclave stress testing of composite materials and components. These standards ensure that materials can withstand the extreme conditions encountered during service life.

Material-specific standards also exist, such as ASTM D6484 for open-hole compression strength of polymer matrix composite laminates and ASTM D3039 for tensile properties of polymer matrix composite materials, which include provisions for testing after autoclave exposure.

Compliance with these regulatory standards typically requires comprehensive documentation of validation studies, routine monitoring data, and periodic requalification of autoclave equipment. Many standards mandate specific test methods for evaluating material properties before and after autoclave processing, including mechanical strength, dimensional stability, and chemical resistance.

As technology advances, regulatory standards continue to evolve, with increasing emphasis on process analytical technology (PAT) for real-time monitoring and control of autoclave processes, as well as risk-based approaches to validation and quality assurance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!