Benchmark FTIR Efficiency in Composite Material Evaluation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Spectroscopy Background and Objectives

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century, becoming a cornerstone analytical technique in materials science. The technology leverages the interaction between infrared radiation and matter to identify chemical bonds and molecular structures through their characteristic absorption patterns. Initially developed for chemical analysis, FTIR has progressively expanded its application domains to include advanced material characterization, particularly in composite materials evaluation.

The evolution of FTIR technology has been marked by several key advancements, including improved spectral resolution, enhanced detector sensitivity, and the development of specialized sampling techniques such as Attenuated Total Reflectance (ATR). These innovations have collectively transformed FTIR from a purely qualitative tool to a sophisticated quantitative analytical method capable of providing detailed insights into material composition and structure.

In the context of composite materials, FTIR spectroscopy offers unique capabilities for characterizing both the matrix and reinforcement components, as well as their interfaces. The technique provides valuable information about chemical composition, degree of cure in thermoset matrices, crystallinity in thermoplastics, and detection of contaminants or degradation products. These capabilities are particularly relevant as composite materials continue to replace traditional materials in aerospace, automotive, and construction industries due to their superior strength-to-weight ratios and customizable properties.

The primary objective of benchmarking FTIR efficiency in composite material evaluation is to establish standardized protocols and performance metrics that enable consistent, reliable, and comparable results across different laboratories and instruments. This benchmarking aims to address several critical aspects, including sampling methodology optimization, spectral data processing techniques, quantification accuracy, detection limits, and analysis throughput.

Additionally, this technical research seeks to explore the integration of FTIR with complementary analytical techniques and advanced data processing methods, including machine learning algorithms, to enhance the depth and breadth of information extractable from spectral data. The ultimate goal is to develop a comprehensive framework that maximizes the utility of FTIR spectroscopy in composite material characterization, quality control, and failure analysis applications.

Furthermore, this research aims to identify emerging trends and future directions in FTIR technology specifically tailored for composite materials, including in-situ monitoring during manufacturing processes, non-destructive testing methodologies, and high-throughput screening applications. By establishing clear benchmarks and development pathways, this research will contribute to the advancement of both FTIR technology and composite material science.

The evolution of FTIR technology has been marked by several key advancements, including improved spectral resolution, enhanced detector sensitivity, and the development of specialized sampling techniques such as Attenuated Total Reflectance (ATR). These innovations have collectively transformed FTIR from a purely qualitative tool to a sophisticated quantitative analytical method capable of providing detailed insights into material composition and structure.

In the context of composite materials, FTIR spectroscopy offers unique capabilities for characterizing both the matrix and reinforcement components, as well as their interfaces. The technique provides valuable information about chemical composition, degree of cure in thermoset matrices, crystallinity in thermoplastics, and detection of contaminants or degradation products. These capabilities are particularly relevant as composite materials continue to replace traditional materials in aerospace, automotive, and construction industries due to their superior strength-to-weight ratios and customizable properties.

The primary objective of benchmarking FTIR efficiency in composite material evaluation is to establish standardized protocols and performance metrics that enable consistent, reliable, and comparable results across different laboratories and instruments. This benchmarking aims to address several critical aspects, including sampling methodology optimization, spectral data processing techniques, quantification accuracy, detection limits, and analysis throughput.

Additionally, this technical research seeks to explore the integration of FTIR with complementary analytical techniques and advanced data processing methods, including machine learning algorithms, to enhance the depth and breadth of information extractable from spectral data. The ultimate goal is to develop a comprehensive framework that maximizes the utility of FTIR spectroscopy in composite material characterization, quality control, and failure analysis applications.

Furthermore, this research aims to identify emerging trends and future directions in FTIR technology specifically tailored for composite materials, including in-situ monitoring during manufacturing processes, non-destructive testing methodologies, and high-throughput screening applications. By establishing clear benchmarks and development pathways, this research will contribute to the advancement of both FTIR technology and composite material science.

Market Analysis for FTIR in Composite Materials Testing

The global market for FTIR (Fourier Transform Infrared Spectroscopy) in composite materials testing has experienced significant growth over the past decade, driven primarily by increasing adoption of composite materials across multiple industries. The market value for FTIR analytical equipment specifically for composite testing reached approximately $520 million in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Aerospace and automotive sectors currently represent the largest market segments, collectively accounting for over 60% of FTIR applications in composite testing. This dominance stems from stringent quality control requirements and the critical nature of material performance in these industries. The aerospace industry, in particular, has established FTIR as a standard evaluation method for detecting contamination and verifying material composition before manufacturing processes.

Regional analysis reveals North America leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.2% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea, particularly in electronics and automotive applications.

Market segmentation by application shows quality control and failure analysis applications represent 45% of the market, followed by research and development (32%), and production monitoring (23%). This distribution highlights the critical role FTIR plays in ensuring composite material integrity throughout the product lifecycle.

Key market drivers include increasingly complex composite formulations requiring sophisticated analysis methods, growing regulatory requirements for material certification, and the push toward automation in testing procedures. The trend toward portable and handheld FTIR devices represents a significant market opportunity, with this segment growing at 9.3% annually as industries seek more flexible testing solutions.

Customer demand analysis indicates growing interest in FTIR systems with enhanced data processing capabilities, particularly those incorporating machine learning algorithms for automated defect identification. End-users increasingly prioritize systems offering comprehensive material characterization rather than single-parameter measurements, driving development of integrated testing platforms.

Market challenges include high equipment costs, with advanced FTIR systems ranging from $50,000 to $150,000, creating barriers for smaller manufacturers. Additionally, the technical expertise required for proper FTIR data interpretation remains a limiting factor in wider adoption, particularly in emerging markets where specialized training resources may be limited.

Aerospace and automotive sectors currently represent the largest market segments, collectively accounting for over 60% of FTIR applications in composite testing. This dominance stems from stringent quality control requirements and the critical nature of material performance in these industries. The aerospace industry, in particular, has established FTIR as a standard evaluation method for detecting contamination and verifying material composition before manufacturing processes.

Regional analysis reveals North America leads the market with approximately 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.2% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea, particularly in electronics and automotive applications.

Market segmentation by application shows quality control and failure analysis applications represent 45% of the market, followed by research and development (32%), and production monitoring (23%). This distribution highlights the critical role FTIR plays in ensuring composite material integrity throughout the product lifecycle.

Key market drivers include increasingly complex composite formulations requiring sophisticated analysis methods, growing regulatory requirements for material certification, and the push toward automation in testing procedures. The trend toward portable and handheld FTIR devices represents a significant market opportunity, with this segment growing at 9.3% annually as industries seek more flexible testing solutions.

Customer demand analysis indicates growing interest in FTIR systems with enhanced data processing capabilities, particularly those incorporating machine learning algorithms for automated defect identification. End-users increasingly prioritize systems offering comprehensive material characterization rather than single-parameter measurements, driving development of integrated testing platforms.

Market challenges include high equipment costs, with advanced FTIR systems ranging from $50,000 to $150,000, creating barriers for smaller manufacturers. Additionally, the technical expertise required for proper FTIR data interpretation remains a limiting factor in wider adoption, particularly in emerging markets where specialized training resources may be limited.

Current FTIR Technology Limitations and Challenges

Despite significant advancements in FTIR technology for composite material evaluation, several critical limitations and challenges persist that hinder its optimal application in industrial settings. The spatial resolution of conventional FTIR systems remains insufficient for detecting microscopic defects and variations within advanced composite materials, particularly those with complex multi-layer structures. This limitation becomes especially problematic when evaluating high-performance composites used in aerospace and automotive applications where defect tolerance is extremely low.

Signal-to-noise ratio challenges continue to plague FTIR analysis of certain composite materials, particularly those with high carbon content or dark colorants that absorb infrared radiation. This absorption significantly reduces the reflected or transmitted signal strength, making accurate spectral interpretation difficult without extensive sample preparation or specialized accessories.

Sample preparation requirements represent another significant hurdle in industrial implementation. Current FTIR techniques often demand careful preparation procedures that are time-consuming and can introduce variability in results. For in-line quality control applications, this preparation requirement creates bottlenecks that reduce throughput and increase production costs.

The interpretation of FTIR spectra for complex composite materials presents substantial challenges due to overlapping absorption bands from multiple components. Modern composites often contain numerous additives, fillers, and modifiers that create complex spectral patterns requiring sophisticated deconvolution algorithms and reference libraries. These interpretation challenges are exacerbated when analyzing aged or environmentally exposed composites where chemical changes may be subtle yet critically important.

Quantitative analysis limitations represent another significant challenge. While FTIR excels at qualitative identification, achieving reliable quantitative measurements of component concentrations in heterogeneous composite materials remains difficult. Variations in sample thickness, surface roughness, and material density all contribute to quantitative inaccuracies that require complex calibration procedures to address.

Depth profiling capabilities of standard FTIR systems are limited, making it difficult to characterize composition changes throughout the thickness of composite materials. This limitation is particularly problematic when evaluating interfacial properties in laminated composites or when assessing degradation that progresses from the surface inward.

Finally, current FTIR benchmarking protocols lack standardization across the industry, resulting in inconsistent evaluation metrics and difficulty in comparing results between different laboratories or manufacturing facilities. This absence of universally accepted benchmarking standards impedes the broader adoption of FTIR as a primary quality control tool in composite manufacturing environments.

Signal-to-noise ratio challenges continue to plague FTIR analysis of certain composite materials, particularly those with high carbon content or dark colorants that absorb infrared radiation. This absorption significantly reduces the reflected or transmitted signal strength, making accurate spectral interpretation difficult without extensive sample preparation or specialized accessories.

Sample preparation requirements represent another significant hurdle in industrial implementation. Current FTIR techniques often demand careful preparation procedures that are time-consuming and can introduce variability in results. For in-line quality control applications, this preparation requirement creates bottlenecks that reduce throughput and increase production costs.

The interpretation of FTIR spectra for complex composite materials presents substantial challenges due to overlapping absorption bands from multiple components. Modern composites often contain numerous additives, fillers, and modifiers that create complex spectral patterns requiring sophisticated deconvolution algorithms and reference libraries. These interpretation challenges are exacerbated when analyzing aged or environmentally exposed composites where chemical changes may be subtle yet critically important.

Quantitative analysis limitations represent another significant challenge. While FTIR excels at qualitative identification, achieving reliable quantitative measurements of component concentrations in heterogeneous composite materials remains difficult. Variations in sample thickness, surface roughness, and material density all contribute to quantitative inaccuracies that require complex calibration procedures to address.

Depth profiling capabilities of standard FTIR systems are limited, making it difficult to characterize composition changes throughout the thickness of composite materials. This limitation is particularly problematic when evaluating interfacial properties in laminated composites or when assessing degradation that progresses from the surface inward.

Finally, current FTIR benchmarking protocols lack standardization across the industry, resulting in inconsistent evaluation metrics and difficulty in comparing results between different laboratories or manufacturing facilities. This absence of universally accepted benchmarking standards impedes the broader adoption of FTIR as a primary quality control tool in composite manufacturing environments.

Benchmark Methodologies for FTIR Composite Evaluation

01 Advanced FTIR system designs for improved efficiency

Modern FTIR spectroscopy systems incorporate innovative designs to enhance measurement efficiency. These include optimized optical configurations, improved interferometer designs, and integrated data processing capabilities. Such advancements allow for faster scan rates, higher resolution, and better signal-to-noise ratios, ultimately improving the efficiency of spectral data collection and analysis.- Advanced FTIR system designs for improved efficiency: Modern FTIR spectroscopy systems incorporate innovative designs to enhance measurement efficiency. These include optimized optical configurations, improved interferometer designs, and integrated data processing capabilities. Advanced systems feature enhanced signal-to-noise ratios, faster scanning capabilities, and reduced measurement times while maintaining high spectral resolution. These design improvements enable more efficient analysis across various applications.

- Sample preparation and handling techniques for FTIR efficiency: Efficient sample preparation and handling methods significantly impact FTIR analysis quality and throughput. Specialized sample holders, automated sample introduction systems, and standardized preparation protocols enhance measurement consistency and reduce analysis time. Techniques for minimizing sample quantity requirements while maximizing signal quality contribute to overall system efficiency. These approaches are particularly valuable for high-throughput applications and when analyzing challenging sample types.

- Software and algorithm enhancements for FTIR data processing: Advanced software solutions and computational algorithms significantly improve FTIR data processing efficiency. These include specialized algorithms for spectral correction, baseline adjustment, and noise reduction. Machine learning and artificial intelligence approaches enable automated spectral interpretation and pattern recognition. Real-time data processing capabilities allow for immediate analysis results, while advanced chemometric methods extract more information from spectral data, enhancing overall analytical efficiency.

- Miniaturized and portable FTIR systems: Compact and portable FTIR systems offer significant efficiency advantages for field applications and point-of-use testing. These systems feature miniaturized components, optimized power consumption, and ruggedized designs for operation outside laboratory environments. Despite their reduced size, these systems maintain acceptable analytical performance through innovative optical designs and specialized components. Portable systems enable immediate on-site analysis, eliminating sample transport requirements and reducing overall analysis time.

- Application-specific FTIR optimization techniques: FTIR systems can be optimized for specific applications to maximize efficiency in particular analytical contexts. These optimizations include specialized accessories for particular sample types, application-specific calibration methods, and customized measurement protocols. Industry-specific configurations enhance performance for applications in pharmaceuticals, environmental monitoring, material science, and chemical manufacturing. These targeted optimizations improve analytical efficiency by focusing system capabilities on the specific requirements of each application area.

02 Sample preparation and handling techniques

Efficient sample preparation and handling methods significantly impact FTIR spectroscopy performance. Specialized sample holders, automated sample introduction systems, and techniques for minimizing contamination or interference contribute to more reliable and reproducible results. These approaches reduce analysis time and improve the quality of spectral data obtained from various sample types.Expand Specific Solutions03 Real-time monitoring and process control applications

FTIR spectroscopy systems designed for real-time monitoring offer enhanced efficiency in industrial and research settings. These systems enable continuous analysis of chemical processes, quality control, and environmental monitoring without interruption. Integration with automated control systems allows for immediate response to spectral changes, optimizing process efficiency and reducing the need for offline analysis.Expand Specific Solutions04 Miniaturization and portable FTIR solutions

Compact and portable FTIR systems address efficiency challenges in field applications and space-constrained laboratories. These miniaturized designs maintain analytical performance while reducing power consumption and physical footprint. Portable FTIR devices enable on-site analysis, eliminating sample transport delays and allowing for immediate decision-making based on spectral data collected in diverse environments.Expand Specific Solutions05 Data processing and analysis algorithms

Advanced computational methods enhance FTIR spectroscopy efficiency through improved data processing. Machine learning algorithms, automated spectral interpretation, and enhanced signal processing techniques allow for faster analysis of complex spectral data. These computational approaches reduce analysis time, improve accuracy in identifying chemical components, and enable more efficient handling of large datasets generated during high-throughput screening applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The FTIR efficiency benchmarking in composite material evaluation market is currently in a growth phase, with increasing adoption across aerospace and manufacturing sectors. The market size is expanding steadily as composite materials become more prevalent in high-performance applications. Technology maturity varies significantly among key players, with aerospace giants like Boeing and Rolls-Royce demonstrating advanced implementation in their manufacturing processes. Specialized instrumentation companies such as Spectra Analysis Instruments and Horiba Ltd. offer sophisticated FTIR solutions with high sensitivity for composite analysis. Academic institutions including Beihang University and Zhejiang University of Technology are advancing fundamental research, while industrial players like TPI Composites and Schaeffler Technologies are focusing on practical applications for quality control and failure analysis in composite structures.

The Boeing Co.

Technical Solution: Boeing has developed advanced FTIR (Fourier Transform Infrared) spectroscopy techniques specifically optimized for aerospace composite material evaluation. Their approach integrates attenuated total reflectance (ATR) FTIR with machine learning algorithms to rapidly identify chemical composition changes and detect contamination in carbon fiber reinforced polymers (CFRP). Boeing's system employs a portable FTIR device capable of on-site analysis during manufacturing and maintenance operations, with specialized software that compares spectral data against an extensive materials database. This allows for real-time quality control and defect identification without destructive testing. Boeing has also pioneered the use of micro-FTIR imaging to map resin distribution and cure gradients across composite structures, enabling more precise evaluation of material integrity and performance characteristics.

Strengths: Highly specialized for aerospace applications with extensive composite materials database; portable systems enable in-situ testing during manufacturing and maintenance. Weaknesses: Proprietary systems may have limited compatibility with third-party equipment; requires significant expertise to interpret complex spectral data from multi-layer composites.

Spectra Analysis Instruments, Inc.

Technical Solution: Spectra Analysis Instruments has developed the DiscovIR-LC™ system, which combines FTIR spectroscopy with liquid chromatography specifically for composite material analysis. Their technology employs a unique solid-phase deposition interface that allows for direct FTIR analysis of separated components from composite materials. The system features a cryogenically-cooled mercury cadmium telluride (MCT) detector that significantly enhances sensitivity for detecting trace components and contaminants in composite matrices. Their proprietary software includes chemometric analysis tools that can identify subtle changes in polymer composition, degree of cure, and degradation products. Spectra Analysis has also developed specialized sampling accessories for different composite geometries, including diamond ATR for surface analysis and transmission cells for thin film evaluation, maximizing FTIR efficiency across various composite material types.

Strengths: Specialized integration of chromatography with FTIR provides superior component separation and identification; high sensitivity detection system can identify trace contaminants. Weaknesses: Complex system requires significant training and expertise; higher cost compared to standard FTIR systems; primarily laboratory-based rather than field-deployable.

Key FTIR Spectral Analysis Techniques and Patents

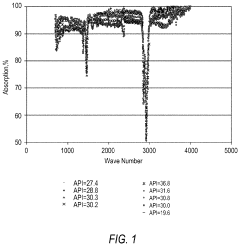

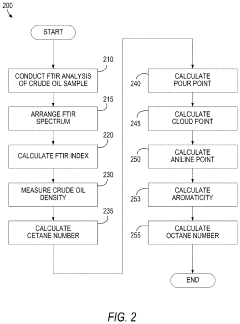

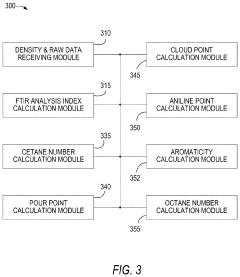

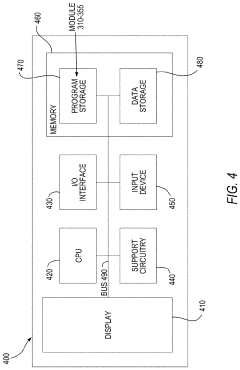

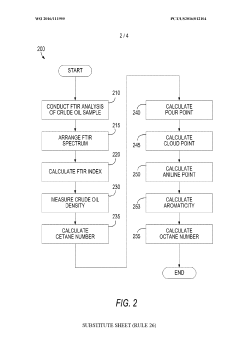

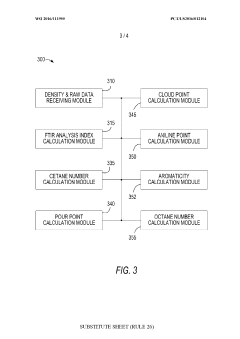

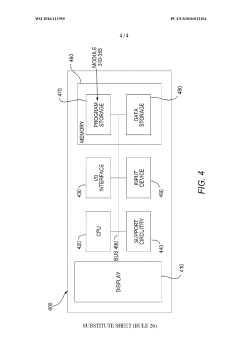

Characterization of crude oil and its fractions by fourier transform infrared (FTIR) spectroscopy analysis

PatentActiveUS10942160B2

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess the indicative properties of crude oil fractions without fractionation, using a system that calculates these properties based on density and FTIR measurements, enabling rapid evaluation of crude oil quality.

Characterization of crude oil and its fractions by fourier transform infrared spectroscopy (FTIR) analysis

PatentWO2016111955A1

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess properties like cetane number, pour point, cloud point, aniline point, and aromaticity of crude oil fractions without fractionation, using a system that calculates these properties based on density and FTIR measurements.

Standardization and Quality Control Protocols

To establish reliable benchmarking of FTIR efficiency in composite material evaluation, comprehensive standardization and quality control protocols are essential. These protocols must address sample preparation, instrument calibration, data acquisition, and analysis methodologies to ensure consistent and comparable results across different laboratories and testing environments.

Sample preparation standardization represents the foundation of reliable FTIR analysis. This includes specific guidelines for sample dimensions, surface preparation techniques, and environmental conditioning parameters. For composite materials, protocols must account for heterogeneity by specifying minimum sampling areas and multiple measurement points. Additionally, standardized cleaning procedures using appropriate solvents that won't interfere with spectral analysis must be established to prevent contamination-related artifacts.

Instrument calibration protocols ensure measurement accuracy and reproducibility across different FTIR systems. This encompasses regular verification using certified reference materials with known spectral characteristics, particularly those resembling the composite materials being evaluated. Calibration schedules should be clearly defined, with documentation requirements for calibration history and verification results. Performance validation using standard samples should be conducted before each analytical session to confirm instrument stability.

Data acquisition standardization is critical for meaningful comparisons between measurements. Protocols must specify resolution settings, scan numbers, spectral ranges, and background collection frequencies appropriate for composite material analysis. Additionally, environmental conditions such as temperature and humidity must be controlled and documented, as these factors can significantly impact FTIR measurements of moisture-sensitive composite materials.

Analysis methodology standardization ensures consistent interpretation of spectral data. This includes defining baseline correction techniques, peak identification criteria, and quantification methods specific to composite material components. Statistical analysis protocols should establish minimum requirements for replicate measurements and acceptable variance thresholds. Furthermore, data reporting formats must be standardized to facilitate interlaboratory comparisons and database development.

Quality assurance procedures must include regular proficiency testing through interlaboratory comparison studies specific to composite materials. These studies help identify systematic errors and improve measurement consistency across the industry. Implementation of internal quality control measures, such as the regular analysis of control samples with known compositions, provides ongoing verification of method performance and early detection of analytical drift.

Documentation requirements form the final component of these protocols, mandating detailed records of all procedural steps, from sample preparation through data analysis. This documentation ensures traceability and facilitates troubleshooting when unexpected results occur, ultimately supporting the continuous improvement of FTIR benchmarking methodologies for composite material evaluation.

Sample preparation standardization represents the foundation of reliable FTIR analysis. This includes specific guidelines for sample dimensions, surface preparation techniques, and environmental conditioning parameters. For composite materials, protocols must account for heterogeneity by specifying minimum sampling areas and multiple measurement points. Additionally, standardized cleaning procedures using appropriate solvents that won't interfere with spectral analysis must be established to prevent contamination-related artifacts.

Instrument calibration protocols ensure measurement accuracy and reproducibility across different FTIR systems. This encompasses regular verification using certified reference materials with known spectral characteristics, particularly those resembling the composite materials being evaluated. Calibration schedules should be clearly defined, with documentation requirements for calibration history and verification results. Performance validation using standard samples should be conducted before each analytical session to confirm instrument stability.

Data acquisition standardization is critical for meaningful comparisons between measurements. Protocols must specify resolution settings, scan numbers, spectral ranges, and background collection frequencies appropriate for composite material analysis. Additionally, environmental conditions such as temperature and humidity must be controlled and documented, as these factors can significantly impact FTIR measurements of moisture-sensitive composite materials.

Analysis methodology standardization ensures consistent interpretation of spectral data. This includes defining baseline correction techniques, peak identification criteria, and quantification methods specific to composite material components. Statistical analysis protocols should establish minimum requirements for replicate measurements and acceptable variance thresholds. Furthermore, data reporting formats must be standardized to facilitate interlaboratory comparisons and database development.

Quality assurance procedures must include regular proficiency testing through interlaboratory comparison studies specific to composite materials. These studies help identify systematic errors and improve measurement consistency across the industry. Implementation of internal quality control measures, such as the regular analysis of control samples with known compositions, provides ongoing verification of method performance and early detection of analytical drift.

Documentation requirements form the final component of these protocols, mandating detailed records of all procedural steps, from sample preparation through data analysis. This documentation ensures traceability and facilitates troubleshooting when unexpected results occur, ultimately supporting the continuous improvement of FTIR benchmarking methodologies for composite material evaluation.

Environmental Impact of FTIR Testing Methods

The environmental impact of FTIR testing methods in composite material evaluation represents a critical consideration for sustainable industrial practices. Traditional FTIR spectroscopy systems consume significant electrical power during operation, with high-resolution instruments requiring continuous energy input for precise measurements. This energy consumption contributes to carbon emissions, particularly when powered by non-renewable energy sources.

Sample preparation for FTIR analysis often involves chemical solvents for extraction and cleaning processes. Many of these solvents, including acetone, methanol, and dichloromethane, are classified as volatile organic compounds (VOCs) that contribute to air pollution and pose potential health risks to laboratory personnel. The disposal of these chemical waste products requires specialized handling to prevent environmental contamination.

FTIR accessories and components present additional environmental concerns. ATR crystals often contain hazardous materials such as zinc selenide or germanium, which require proper disposal protocols at end-of-life. Similarly, liquid nitrogen used for cooling detectors in high-sensitivity FTIR systems has a significant carbon footprint associated with its production and transportation.

Recent advancements have focused on developing more environmentally friendly FTIR methodologies. Portable FTIR devices with lower power requirements reduce energy consumption while maintaining acceptable measurement accuracy for field applications. These systems often utilize rechargeable batteries and energy-efficient components, significantly reducing their operational carbon footprint compared to laboratory-based instruments.

Solvent-free sample preparation techniques represent another important environmental improvement. Direct analysis methods such as ATR-FTIR eliminate or substantially reduce solvent requirements, minimizing chemical waste generation. Additionally, microextraction techniques have emerged that use minimal solvent quantities while maintaining analytical sensitivity.

The lifecycle assessment of FTIR equipment reveals opportunities for environmental optimization. Manufacturers are increasingly designing instruments with longer operational lifespans, modular components for easier repair and upgrade, and recyclable materials. Some companies have implemented take-back programs for proper disposal and recycling of electronic components and hazardous materials.

Regulatory frameworks worldwide are driving improvements in the environmental profile of analytical testing. Standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives influence the design and disposal practices for FTIR instruments, pushing manufacturers toward greener technologies and materials.

Sample preparation for FTIR analysis often involves chemical solvents for extraction and cleaning processes. Many of these solvents, including acetone, methanol, and dichloromethane, are classified as volatile organic compounds (VOCs) that contribute to air pollution and pose potential health risks to laboratory personnel. The disposal of these chemical waste products requires specialized handling to prevent environmental contamination.

FTIR accessories and components present additional environmental concerns. ATR crystals often contain hazardous materials such as zinc selenide or germanium, which require proper disposal protocols at end-of-life. Similarly, liquid nitrogen used for cooling detectors in high-sensitivity FTIR systems has a significant carbon footprint associated with its production and transportation.

Recent advancements have focused on developing more environmentally friendly FTIR methodologies. Portable FTIR devices with lower power requirements reduce energy consumption while maintaining acceptable measurement accuracy for field applications. These systems often utilize rechargeable batteries and energy-efficient components, significantly reducing their operational carbon footprint compared to laboratory-based instruments.

Solvent-free sample preparation techniques represent another important environmental improvement. Direct analysis methods such as ATR-FTIR eliminate or substantially reduce solvent requirements, minimizing chemical waste generation. Additionally, microextraction techniques have emerged that use minimal solvent quantities while maintaining analytical sensitivity.

The lifecycle assessment of FTIR equipment reveals opportunities for environmental optimization. Manufacturers are increasingly designing instruments with longer operational lifespans, modular components for easier repair and upgrade, and recyclable materials. Some companies have implemented take-back programs for proper disposal and recycling of electronic components and hazardous materials.

Regulatory frameworks worldwide are driving improvements in the environmental profile of analytical testing. Standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives influence the design and disposal practices for FTIR instruments, pushing manufacturers toward greener technologies and materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!