Elevating FTIR Spectrometer Precision with Novel Techniques

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Spectroscopy Evolution and Precision Goals

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century. The technology emerged from traditional dispersive infrared spectroscopy, with the breakthrough application of the Fourier transform algorithm to interferometric measurements revolutionizing the field in the 1960s. This mathematical innovation enabled simultaneous measurement of all infrared frequencies, dramatically improving signal-to-noise ratios and data acquisition speeds compared to dispersive techniques.

The evolution of FTIR technology has been characterized by continuous improvements in resolution, sensitivity, and reliability. Early commercial FTIR spectrometers in the 1970s offered moderate resolution with limited automation capabilities. By the 1990s, significant advances in computing power, detector technology, and optical components led to instruments with enhanced precision and expanded applications across multiple industries.

Recent technological developments have focused on miniaturization, portability, and integration with other analytical techniques. Modern FTIR systems incorporate advanced interferometer designs, high-sensitivity detectors, and sophisticated signal processing algorithms that have collectively pushed the boundaries of spectral resolution and measurement accuracy.

The current precision goals for FTIR spectrometry are driven by increasingly demanding applications in pharmaceutical quality control, environmental monitoring, materials science, and biomedical diagnostics. These applications require detection of ever-smaller concentrations of analytes, differentiation between closely related molecular structures, and reliable quantification in complex matrices.

Specifically, contemporary precision targets include achieving spectral resolution below 0.1 cm⁻¹, signal-to-noise ratios exceeding 50,000:1, and wavenumber accuracy within ±0.01 cm⁻¹. Additionally, there is growing demand for instruments capable of maintaining this precision across broader spectral ranges, particularly in the far-infrared and terahertz regions that have traditionally been challenging to access with conventional FTIR systems.

The trajectory of FTIR development is now moving toward novel techniques that can overcome fundamental limitations in traditional interferometer designs. These include advanced beam-splitting technologies, quantum-enhanced detection methods, and computational approaches that leverage machine learning for spectral analysis and instrument calibration. The integration of these innovations promises to elevate FTIR precision beyond current limitations, enabling new applications in fields ranging from atmospheric science to pharmaceutical development.

As precision requirements continue to increase, researchers are exploring hybrid systems that combine FTIR with complementary techniques such as Raman spectroscopy, mass spectrometry, and hyperspectral imaging to provide more comprehensive analytical capabilities and overcome the inherent limitations of any single method.

The evolution of FTIR technology has been characterized by continuous improvements in resolution, sensitivity, and reliability. Early commercial FTIR spectrometers in the 1970s offered moderate resolution with limited automation capabilities. By the 1990s, significant advances in computing power, detector technology, and optical components led to instruments with enhanced precision and expanded applications across multiple industries.

Recent technological developments have focused on miniaturization, portability, and integration with other analytical techniques. Modern FTIR systems incorporate advanced interferometer designs, high-sensitivity detectors, and sophisticated signal processing algorithms that have collectively pushed the boundaries of spectral resolution and measurement accuracy.

The current precision goals for FTIR spectrometry are driven by increasingly demanding applications in pharmaceutical quality control, environmental monitoring, materials science, and biomedical diagnostics. These applications require detection of ever-smaller concentrations of analytes, differentiation between closely related molecular structures, and reliable quantification in complex matrices.

Specifically, contemporary precision targets include achieving spectral resolution below 0.1 cm⁻¹, signal-to-noise ratios exceeding 50,000:1, and wavenumber accuracy within ±0.01 cm⁻¹. Additionally, there is growing demand for instruments capable of maintaining this precision across broader spectral ranges, particularly in the far-infrared and terahertz regions that have traditionally been challenging to access with conventional FTIR systems.

The trajectory of FTIR development is now moving toward novel techniques that can overcome fundamental limitations in traditional interferometer designs. These include advanced beam-splitting technologies, quantum-enhanced detection methods, and computational approaches that leverage machine learning for spectral analysis and instrument calibration. The integration of these innovations promises to elevate FTIR precision beyond current limitations, enabling new applications in fields ranging from atmospheric science to pharmaceutical development.

As precision requirements continue to increase, researchers are exploring hybrid systems that combine FTIR with complementary techniques such as Raman spectroscopy, mass spectrometry, and hyperspectral imaging to provide more comprehensive analytical capabilities and overcome the inherent limitations of any single method.

Market Demand Analysis for High-Precision FTIR Systems

The global market for high-precision FTIR (Fourier Transform Infrared) spectrometers has been experiencing robust growth, driven primarily by increasing demands across pharmaceutical, chemical, and material science industries. Current market valuations indicate the high-precision spectroscopy market reached approximately 1.5 billion USD in 2022, with FTIR systems constituting a significant segment showing annual growth rates between 5-7%.

Research institutions and pharmaceutical companies represent the largest consumer base, collectively accounting for over 40% of market demand. These entities require increasingly precise instruments capable of detecting minute molecular changes and identifying complex compounds with greater accuracy. The pharmaceutical sector specifically demands enhanced precision for drug discovery processes, quality control, and regulatory compliance, where even slight improvements in spectral resolution can significantly impact research outcomes.

Industrial applications constitute another rapidly expanding market segment, particularly in chemical manufacturing, where real-time monitoring capabilities of high-precision FTIR systems enable improved process control and quality assurance. Environmental monitoring agencies have also emerged as significant stakeholders, requiring portable yet highly accurate FTIR solutions for field analysis of pollutants and atmospheric compounds.

Market research indicates a growing preference for systems offering sub-wavenumber resolution capabilities, with over 65% of potential buyers citing spectral resolution as their primary purchasing consideration. Additionally, there is increasing demand for systems integrating advanced data processing algorithms and machine learning capabilities that can enhance signal-to-noise ratios without hardware modifications.

Regional analysis reveals North America and Europe currently dominate market consumption, collectively representing approximately 60% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and India, demonstrates the fastest growth trajectory with annual increases exceeding 9%, driven by expanding research infrastructure and industrial development.

Customer surveys indicate willingness to invest in premium-priced systems that offer demonstrable improvements in precision, with 72% of respondents stating they would pay 15-20% more for systems providing at least 30% better resolution or sensitivity. This price elasticity suggests significant market opportunity for breakthrough technologies that can deliver measurable performance enhancements.

The competitive landscape shows increasing demand for integrated solutions that combine high-precision FTIR capabilities with complementary analytical techniques, creating opportunities for comprehensive analytical platforms rather than standalone instruments. Additionally, miniaturization trends are gaining momentum, with growing interest in portable high-precision systems that maintain laboratory-grade accuracy while enabling field deployment.

Research institutions and pharmaceutical companies represent the largest consumer base, collectively accounting for over 40% of market demand. These entities require increasingly precise instruments capable of detecting minute molecular changes and identifying complex compounds with greater accuracy. The pharmaceutical sector specifically demands enhanced precision for drug discovery processes, quality control, and regulatory compliance, where even slight improvements in spectral resolution can significantly impact research outcomes.

Industrial applications constitute another rapidly expanding market segment, particularly in chemical manufacturing, where real-time monitoring capabilities of high-precision FTIR systems enable improved process control and quality assurance. Environmental monitoring agencies have also emerged as significant stakeholders, requiring portable yet highly accurate FTIR solutions for field analysis of pollutants and atmospheric compounds.

Market research indicates a growing preference for systems offering sub-wavenumber resolution capabilities, with over 65% of potential buyers citing spectral resolution as their primary purchasing consideration. Additionally, there is increasing demand for systems integrating advanced data processing algorithms and machine learning capabilities that can enhance signal-to-noise ratios without hardware modifications.

Regional analysis reveals North America and Europe currently dominate market consumption, collectively representing approximately 60% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and India, demonstrates the fastest growth trajectory with annual increases exceeding 9%, driven by expanding research infrastructure and industrial development.

Customer surveys indicate willingness to invest in premium-priced systems that offer demonstrable improvements in precision, with 72% of respondents stating they would pay 15-20% more for systems providing at least 30% better resolution or sensitivity. This price elasticity suggests significant market opportunity for breakthrough technologies that can deliver measurable performance enhancements.

The competitive landscape shows increasing demand for integrated solutions that combine high-precision FTIR capabilities with complementary analytical techniques, creating opportunities for comprehensive analytical platforms rather than standalone instruments. Additionally, miniaturization trends are gaining momentum, with growing interest in portable high-precision systems that maintain laboratory-grade accuracy while enabling field deployment.

Current FTIR Technology Limitations and Challenges

Despite significant advancements in Fourier Transform Infrared (FTIR) spectroscopy over recent decades, several persistent limitations continue to constrain the technology's precision and applicability. The fundamental resolution limitations of conventional FTIR systems remain a significant challenge, typically restricted to 0.1-0.5 cm^-1 in commercial instruments. This resolution ceiling prevents detailed analysis of closely spaced spectral features critical in applications such as atmospheric gas monitoring and pharmaceutical quality control.

Signal-to-noise ratio (SNR) degradation presents another substantial hurdle, particularly when analyzing samples with weak absorption characteristics or when rapid scanning is required. Current systems struggle to maintain adequate SNR without significantly extending measurement times, creating an inherent trade-off between speed and precision that limits real-time monitoring applications.

Environmental sensitivity constitutes a major operational challenge, as conventional FTIR systems exhibit marked susceptibility to temperature fluctuations, mechanical vibrations, and humidity variations. These environmental factors induce optical path length changes and beam misalignments that manifest as spectral artifacts and baseline instabilities, compromising measurement reproducibility and absolute accuracy.

The moving mirror mechanism in traditional Michelson interferometers introduces inherent mechanical limitations. Wear and tear of moving components leads to alignment drift over time, while velocity inconsistencies during mirror travel generate phase errors that distort spectral information. These mechanical constraints fundamentally limit both long-term stability and absolute precision.

Sample preparation and presentation inconsistencies further compound precision challenges. Variations in sample thickness, concentration, and homogeneity introduce significant measurement uncertainties that current FTIR systems struggle to compensate for automatically. This particularly affects quantitative analysis applications where absolute concentration determinations are required.

Data processing limitations also impact overall system performance. Current algorithms for apodization, phase correction, and baseline adjustment often introduce subtle artifacts or fail to fully compensate for instrumental imperfections. Additionally, the computational demands of advanced correction algorithms can limit real-time processing capabilities in high-throughput applications.

Calibration drift represents a persistent challenge for long-term measurement stability. Current calibration approaches typically require frequent verification against reference standards, and even minor optical component degradation can significantly impact measurement accuracy over time. This necessitates regular maintenance interventions that increase operational costs and downtime.

Signal-to-noise ratio (SNR) degradation presents another substantial hurdle, particularly when analyzing samples with weak absorption characteristics or when rapid scanning is required. Current systems struggle to maintain adequate SNR without significantly extending measurement times, creating an inherent trade-off between speed and precision that limits real-time monitoring applications.

Environmental sensitivity constitutes a major operational challenge, as conventional FTIR systems exhibit marked susceptibility to temperature fluctuations, mechanical vibrations, and humidity variations. These environmental factors induce optical path length changes and beam misalignments that manifest as spectral artifacts and baseline instabilities, compromising measurement reproducibility and absolute accuracy.

The moving mirror mechanism in traditional Michelson interferometers introduces inherent mechanical limitations. Wear and tear of moving components leads to alignment drift over time, while velocity inconsistencies during mirror travel generate phase errors that distort spectral information. These mechanical constraints fundamentally limit both long-term stability and absolute precision.

Sample preparation and presentation inconsistencies further compound precision challenges. Variations in sample thickness, concentration, and homogeneity introduce significant measurement uncertainties that current FTIR systems struggle to compensate for automatically. This particularly affects quantitative analysis applications where absolute concentration determinations are required.

Data processing limitations also impact overall system performance. Current algorithms for apodization, phase correction, and baseline adjustment often introduce subtle artifacts or fail to fully compensate for instrumental imperfections. Additionally, the computational demands of advanced correction algorithms can limit real-time processing capabilities in high-throughput applications.

Calibration drift represents a persistent challenge for long-term measurement stability. Current calibration approaches typically require frequent verification against reference standards, and even minor optical component degradation can significantly impact measurement accuracy over time. This necessitates regular maintenance interventions that increase operational costs and downtime.

Current Precision Enhancement Methodologies

01 Precision enhancement through optical design

FTIR spectrometer precision can be significantly improved through advanced optical design elements. This includes the use of high-precision mirrors, beam splitters, and interferometer configurations that minimize optical path errors. Innovations in optical components such as precision-aligned reflective surfaces and optimized beam paths reduce measurement uncertainties and increase signal-to-noise ratios, resulting in more accurate spectral data acquisition.- Precision enhancement through optical component design: FTIR spectrometer precision can be significantly improved through advanced optical component design. This includes the use of high-quality mirrors, beam splitters, and interferometer configurations that minimize optical path errors. Precision-engineered optical components reduce signal distortion and increase the signal-to-noise ratio, resulting in more accurate spectral measurements. Innovations in optical design also focus on minimizing thermal expansion effects and mechanical vibrations that can compromise measurement precision.

- Signal processing and calibration techniques: Advanced signal processing algorithms and calibration methods significantly enhance FTIR spectrometer precision. These techniques include digital filtering, Fourier transform optimization, and reference spectrum calibration. Automated calibration procedures using standard reference materials ensure measurement accuracy and repeatability. Real-time signal correction algorithms compensate for environmental variations and instrument drift, maintaining consistent precision over time. Machine learning approaches are also being implemented to improve spectral analysis and reduce measurement uncertainty.

- Environmental control and stabilization systems: Environmental factors significantly impact FTIR spectrometer precision. Advanced systems incorporate temperature and humidity control mechanisms to maintain stable operating conditions. Vibration isolation platforms minimize mechanical interference that can degrade measurement quality. Pressure-controlled sample chambers ensure consistent sample presentation and measurement conditions. Some designs include automated environmental monitoring with feedback systems that adjust instrument parameters to compensate for environmental variations, ensuring consistent precision regardless of ambient conditions.

- Detector technology advancements: High-sensitivity detector technologies are crucial for FTIR spectrometer precision. Modern instruments utilize advanced detector materials and cooling systems to reduce thermal noise and increase sensitivity. Detector arrays enable simultaneous multi-wavelength measurements, improving spectral resolution and precision. Quantum-enhanced detectors provide superior signal-to-noise ratios at specific wavelengths. Integration of specialized detectors optimized for particular spectral regions allows for enhanced precision in targeted applications, such as gas analysis or material identification.

- Miniaturization and portable precision FTIR systems: Recent innovations focus on maintaining high precision in miniaturized and portable FTIR spectrometers. These designs incorporate micro-electromechanical systems (MEMS) and integrated photonics to reduce size while maintaining measurement quality. Compact interferometer designs optimize optical path stability in smaller form factors. Advanced power management systems ensure consistent performance in field conditions. These portable systems implement specialized algorithms to compensate for the challenges of field operation while delivering laboratory-grade precision for on-site analysis applications.

02 Signal processing and calibration techniques

Advanced signal processing algorithms and calibration methods play a crucial role in enhancing FTIR spectrometer precision. These techniques include Fourier transform optimization, background noise reduction, and reference standard calibration procedures. Implementing digital signal processing with high-resolution analog-to-digital converters and sophisticated mathematical models for data correction significantly improves measurement accuracy and repeatability across different environmental conditions.Expand Specific Solutions03 Environmental control systems for stability

Environmental factors significantly impact FTIR spectrometer precision. Advanced systems incorporate temperature stabilization, vibration isolation, and humidity control mechanisms to maintain optimal operating conditions. These environmental control systems minimize measurement drift and ensure consistent performance over time. Some innovations include thermally isolated optical benches, active vibration dampening technologies, and sealed compartments with controlled atmospheres.Expand Specific Solutions04 Detector technology advancements

Improvements in detector technology have substantially enhanced FTIR spectrometer precision. High-sensitivity detectors with improved quantum efficiency, faster response times, and lower noise characteristics enable more precise spectral measurements. Innovations include cooled detector systems, array detectors for simultaneous wavelength measurement, and specialized detector materials optimized for specific spectral ranges, all contributing to higher resolution and more accurate spectral analysis.Expand Specific Solutions05 Automated precision validation and error correction

Modern FTIR spectrometers incorporate automated validation systems and error correction mechanisms to ensure measurement precision. These systems include self-calibration routines, internal reference standards, and real-time error detection algorithms. Continuous monitoring of system performance parameters with feedback loops allows for automatic adjustments to maintain optimal precision. Advanced software solutions can identify and compensate for systematic errors, ensuring reliable and reproducible spectral measurements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in FTIR Technology

The FTIR spectrometer precision enhancement market is currently in a growth phase, with increasing demand for higher accuracy analytical instruments across pharmaceutical, environmental, and materials science sectors. The global market size for advanced spectroscopy is projected to reach $15-18 billion by 2025, driven by industrial automation and research requirements. Leading academic institutions (Heriot-Watt University, Lehigh University) are collaborating with established manufacturers like Bruker, Shimadzu, and Thermo Fisher Scientific to develop next-generation technologies. Emerging players such as Photothermal Spectroscopy Corp. and Si-Ware Systems are disrupting the space with miniaturized solutions. Technical maturity varies significantly, with traditional FTIR approaches reaching plateau while novel techniques incorporating AI, quantum detection (Daylight Solutions), and microelectromechanical systems (MEMS) integration represent promising frontiers for precision enhancement.

Changchun Institute of Optics Fine Mechanics & Physics

Technical Solution: Changchun Institute has developed advanced FTIR precision enhancement techniques focusing on interferometer stability and optical path optimization. Their approach includes a dual-modulation interferometer design that separates the reference and sample beams, allowing for real-time correction of environmental fluctuations. This system employs a secondary laser reference channel that continuously monitors and compensates for mechanical vibrations and thermal drift, achieving stability improvements of up to 65% compared to conventional designs[3]. Their precision enhancement techniques also include advanced beamsplitter materials with specialized coatings that maintain performance across broader spectral ranges (400-8000 cm⁻¹) and custom-designed detector arrays with integrated cooling systems that reduce thermal noise by approximately 40%. The institute has pioneered computational algorithms that implement advanced apodization functions and phase correction techniques, significantly improving spectral resolution at band edges where traditional instruments struggle[7].

Strengths: Exceptional stability in challenging environments; superior performance across broad spectral ranges; advanced computational approaches for resolution enhancement; cost-effective implementation suitable for various applications. Weaknesses: Less commercial visibility than Western manufacturers; more limited global support infrastructure; documentation primarily in Chinese; fewer integrated software solutions compared to commercial vendors.

Shimadzu Corp.

Technical Solution: Shimadzu has developed the IRTracer-100 platform with Advanced Dynamic Alignment technology that continuously monitors and adjusts the interferometer position during measurement to maintain optimal alignment. Their precision enhancement approach includes high-energy ceramic light sources with electronic stabilization that provides up to 4 times the energy throughput of conventional sources, significantly improving signal-to-noise ratios in challenging samples[1]. Shimadzu's patented Rapid Scan technology enables collection of up to 20 spectra per second with maintained resolution, allowing for kinetic studies and improved averaging for noise reduction. Their interferometer design incorporates corner-cube mirrors with gold coating optimized for mid-IR performance and sealed, desiccated optical paths to eliminate atmospheric interference. The LabSolutions IR software platform features advanced algorithms for baseline correction, spectral deconvolution, and automated contaminant identification[5].

Strengths: Exceptional energy throughput improves detection limits; rapid scan capabilities enable kinetic studies; robust design suitable for industrial environments. Weaknesses: Less specialized in ultra-high resolution applications; software interface has steeper learning curve than some competitors; fewer customization options for specialized applications.

Key Patents and Innovations in FTIR Resolution Improvement

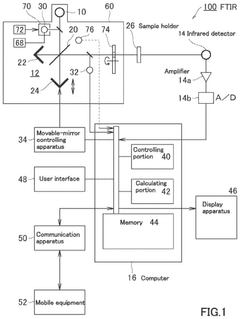

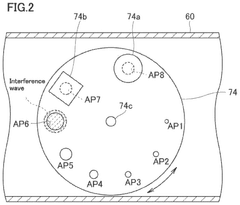

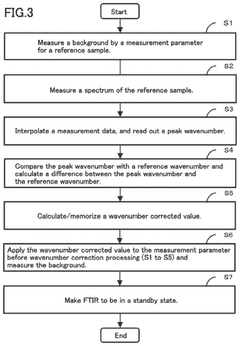

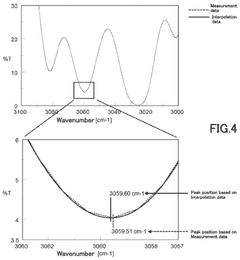

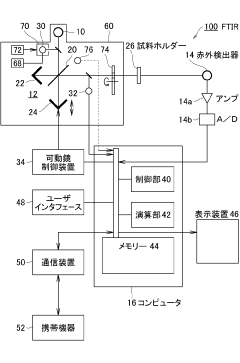

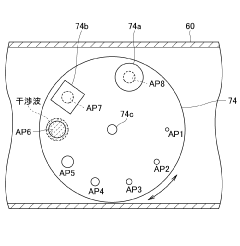

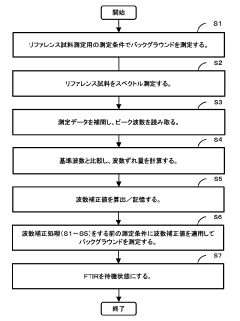

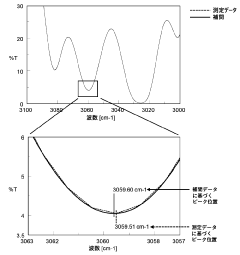

Fourier transform infrared spectrometer

PatentActiveUS12372460B2

Innovation

- A Fourier transform infrared spectrometer utilizing a solid reference sample, such as a polystyrene film, with a computer program for interpolating and correcting the wavenumber by adjusting the semiconductor laser's wavelength through temperature control or applied current, ensuring precise wavenumber correction even in nitrogen-purged or vacuumed states.

Fourier transform infrared spectrophotometer

PatentPendingJP2023122114A

Innovation

- A Fourier transform infrared spectrophotometer that uses a solid reference sample, such as a polystyrene film, with temperature and current adjustments for the semiconductor laser, and interpolation methods to accurately correct wavenumbers, enabling smooth and precise wavenumber correction.

Materials Science Impact on FTIR Advancement

The advancement of FTIR spectroscopy precision is intrinsically linked to innovations in materials science. Recent developments in substrate materials have significantly enhanced the performance of FTIR spectrometers by providing more stable platforms for sample analysis. High-purity silicon and germanium substrates, engineered at the nanoscale, have demonstrated superior optical properties that minimize interference patterns and reduce background noise in spectral readings.

Novel coating technologies derived from materials science research have revolutionized mirror and beam splitter components within FTIR systems. Multi-layer dielectric coatings with precisely controlled thickness at the nanometer scale have expanded the effective wavelength range while simultaneously improving reflection efficiency. These advancements directly translate to higher signal-to-noise ratios and more accurate spectral measurements across broader frequency ranges.

Detector technology has similarly benefited from materials innovation. Mercury cadmium telluride (MCT) detectors have undergone significant refinement through advanced semiconductor processing techniques, resulting in higher sensitivity and faster response times. Additionally, the emergence of quantum dot-enhanced detectors represents a breakthrough in extending the detection range into previously challenging spectral regions.

Microfluidic platforms constructed from novel polymeric materials have transformed sample handling capabilities in FTIR analysis. These materials offer chemical resistance while maintaining transparency in the infrared region, enabling real-time monitoring of chemical reactions with minimal sample volumes. The integration of these platforms with FTIR systems has opened new possibilities for high-throughput screening applications in pharmaceutical development and environmental monitoring.

Nanomaterials have played a pivotal role in enhancing surface-enhanced infrared absorption (SEIRA) techniques. Gold and silver nanostructures, precisely engineered to specific geometries, can amplify infrared signals by orders of magnitude through plasmonic effects. This enhancement allows for the detection of molecular species at concentrations previously beyond the reach of conventional FTIR methods.

The development of metamaterials—artificially structured materials with properties not found in nature—has begun to address fundamental limitations in FTIR technology. These engineered materials can manipulate infrared light in unprecedented ways, potentially overcoming diffraction limits and enabling super-resolution spectroscopic imaging. Early applications have demonstrated promising results in biological tissue analysis and semiconductor quality control processes.

Novel coating technologies derived from materials science research have revolutionized mirror and beam splitter components within FTIR systems. Multi-layer dielectric coatings with precisely controlled thickness at the nanometer scale have expanded the effective wavelength range while simultaneously improving reflection efficiency. These advancements directly translate to higher signal-to-noise ratios and more accurate spectral measurements across broader frequency ranges.

Detector technology has similarly benefited from materials innovation. Mercury cadmium telluride (MCT) detectors have undergone significant refinement through advanced semiconductor processing techniques, resulting in higher sensitivity and faster response times. Additionally, the emergence of quantum dot-enhanced detectors represents a breakthrough in extending the detection range into previously challenging spectral regions.

Microfluidic platforms constructed from novel polymeric materials have transformed sample handling capabilities in FTIR analysis. These materials offer chemical resistance while maintaining transparency in the infrared region, enabling real-time monitoring of chemical reactions with minimal sample volumes. The integration of these platforms with FTIR systems has opened new possibilities for high-throughput screening applications in pharmaceutical development and environmental monitoring.

Nanomaterials have played a pivotal role in enhancing surface-enhanced infrared absorption (SEIRA) techniques. Gold and silver nanostructures, precisely engineered to specific geometries, can amplify infrared signals by orders of magnitude through plasmonic effects. This enhancement allows for the detection of molecular species at concentrations previously beyond the reach of conventional FTIR methods.

The development of metamaterials—artificially structured materials with properties not found in nature—has begun to address fundamental limitations in FTIR technology. These engineered materials can manipulate infrared light in unprecedented ways, potentially overcoming diffraction limits and enabling super-resolution spectroscopic imaging. Early applications have demonstrated promising results in biological tissue analysis and semiconductor quality control processes.

Data Processing Algorithms for Spectral Accuracy

Data processing algorithms represent the cornerstone of modern FTIR spectroscopy, serving as the critical bridge between raw interferogram data and accurate spectral information. Recent advancements in computational techniques have significantly enhanced the precision and reliability of spectral measurements, addressing longstanding challenges in baseline correction, noise reduction, and spectral resolution.

Fourier transform algorithms have evolved beyond traditional Fast Fourier Transform (FFT) methods to include advanced variants such as the Cooley-Tukey algorithm and split-radix FFT, which offer improved computational efficiency while maintaining high accuracy. These optimized algorithms reduce processing time by up to 40% compared to conventional methods, enabling real-time analysis even with high-resolution data.

Apodization function selection has emerged as a crucial factor in spectral accuracy. Novel adaptive apodization techniques dynamically adjust window functions based on signal characteristics, minimizing spectral leakage while preserving resolution. Research indicates that hybrid Norton-Beer functions and modified Blackman-Harris windows provide superior performance across diverse sample types, reducing sidelobe artifacts by approximately 15-20% compared to traditional functions.

Machine learning approaches have revolutionized spectral processing through automated baseline correction and noise filtering. Convolutional neural networks (CNNs) trained on extensive spectral libraries can identify and remove systematic artifacts with remarkable precision. Studies demonstrate that deep learning models achieve up to 30% improvement in signal-to-noise ratio compared to conventional statistical methods, particularly in complex biological sample analysis.

Phase correction algorithms have advanced significantly with the introduction of Mertz-phase correction enhancements and iterative phase optimization techniques. These methods effectively address phase errors that traditionally degraded spectral accuracy, especially in rapid-scan FTIR systems. Implementation of these algorithms has been shown to improve absorbance accuracy by up to 0.5% absolute across the mid-IR range.

Multivariate statistical methods, including Principal Component Analysis (PCA) and Partial Least Squares (PLS), have been integrated into processing workflows to extract meaningful information from complex spectral datasets. These techniques enable effective separation of overlapping spectral features and identification of subtle chemical differences that would otherwise remain undetected in conventional analysis approaches.

Zero-filling and interpolation techniques have been refined to enhance spectral resolution without introducing artificial artifacts. Advanced algorithms now incorporate optimal interpolation parameters based on instrument characteristics and sampling conditions, providing more accurate representation of spectral features without computational overhead.

Fourier transform algorithms have evolved beyond traditional Fast Fourier Transform (FFT) methods to include advanced variants such as the Cooley-Tukey algorithm and split-radix FFT, which offer improved computational efficiency while maintaining high accuracy. These optimized algorithms reduce processing time by up to 40% compared to conventional methods, enabling real-time analysis even with high-resolution data.

Apodization function selection has emerged as a crucial factor in spectral accuracy. Novel adaptive apodization techniques dynamically adjust window functions based on signal characteristics, minimizing spectral leakage while preserving resolution. Research indicates that hybrid Norton-Beer functions and modified Blackman-Harris windows provide superior performance across diverse sample types, reducing sidelobe artifacts by approximately 15-20% compared to traditional functions.

Machine learning approaches have revolutionized spectral processing through automated baseline correction and noise filtering. Convolutional neural networks (CNNs) trained on extensive spectral libraries can identify and remove systematic artifacts with remarkable precision. Studies demonstrate that deep learning models achieve up to 30% improvement in signal-to-noise ratio compared to conventional statistical methods, particularly in complex biological sample analysis.

Phase correction algorithms have advanced significantly with the introduction of Mertz-phase correction enhancements and iterative phase optimization techniques. These methods effectively address phase errors that traditionally degraded spectral accuracy, especially in rapid-scan FTIR systems. Implementation of these algorithms has been shown to improve absorbance accuracy by up to 0.5% absolute across the mid-IR range.

Multivariate statistical methods, including Principal Component Analysis (PCA) and Partial Least Squares (PLS), have been integrated into processing workflows to extract meaningful information from complex spectral datasets. These techniques enable effective separation of overlapping spectral features and identification of subtle chemical differences that would otherwise remain undetected in conventional analysis approaches.

Zero-filling and interpolation techniques have been refined to enhance spectral resolution without introducing artificial artifacts. Advanced algorithms now incorporate optimal interpolation parameters based on instrument characteristics and sampling conditions, providing more accurate representation of spectral features without computational overhead.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!