FTIR in Nanotechnology: Characterization Gains

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Nanotechnology Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a basic analytical technique to an indispensable tool in nanotechnology research. The integration of FTIR with nanotechnology represents a convergence of analytical chemistry and materials science that has accelerated dramatically over the past two decades, driven by the increasing demand for precise characterization methods at the nanoscale.

The historical trajectory of FTIR in nanomaterial analysis began with rudimentary applications in the 1990s, primarily focused on bulk property measurements. By the early 2000s, advances in instrumentation, particularly the development of attenuated total reflection (ATR) accessories and microscopy interfaces, enabled researchers to examine nanomaterials with unprecedented spatial resolution and sensitivity. This technological progression has continued with recent innovations in synchrotron-based FTIR and nano-FTIR techniques, pushing the boundaries of spatial resolution below the diffraction limit.

Current technological trends in FTIR nanotechnology applications include the development of tip-enhanced techniques, integration with other spectroscopic methods, and the application of artificial intelligence for spectral interpretation. These advancements are collectively driving toward more comprehensive, high-resolution characterization capabilities that can reveal both structural and functional properties of nanomaterials simultaneously.

The primary objective of employing FTIR in nanotechnology is to achieve detailed molecular-level characterization of nanomaterials, enabling researchers to understand structure-property relationships that govern nanoscale phenomena. Specifically, FTIR offers unique insights into chemical bonding, molecular orientation, and interfacial interactions that are critical for designing nanomaterials with tailored properties.

Technical goals for FTIR in nanotechnology include enhancing spatial resolution to consistently achieve sub-10 nm measurements, improving signal-to-noise ratios for single-molecule detection, developing in-situ and operando capabilities for real-time monitoring of nanoscale processes, and establishing standardized protocols for quantitative analysis of nanomaterial composition and functionality.

The evolution of FTIR techniques has been particularly impactful in several key nanotechnology domains, including nanoelectronics, where it helps characterize semiconductor interfaces; nanomedicine, where it assists in understanding drug delivery systems; environmental nanotechnology, where it monitors pollutant interactions; and energy materials, where it provides insights into battery and photovoltaic nanomaterials.

As nanotechnology continues to advance across multiple industries, FTIR characterization techniques are expected to play an increasingly central role in bridging the gap between molecular design and macroscopic performance, ultimately accelerating the development cycle for next-generation nanomaterials and devices.

The historical trajectory of FTIR in nanomaterial analysis began with rudimentary applications in the 1990s, primarily focused on bulk property measurements. By the early 2000s, advances in instrumentation, particularly the development of attenuated total reflection (ATR) accessories and microscopy interfaces, enabled researchers to examine nanomaterials with unprecedented spatial resolution and sensitivity. This technological progression has continued with recent innovations in synchrotron-based FTIR and nano-FTIR techniques, pushing the boundaries of spatial resolution below the diffraction limit.

Current technological trends in FTIR nanotechnology applications include the development of tip-enhanced techniques, integration with other spectroscopic methods, and the application of artificial intelligence for spectral interpretation. These advancements are collectively driving toward more comprehensive, high-resolution characterization capabilities that can reveal both structural and functional properties of nanomaterials simultaneously.

The primary objective of employing FTIR in nanotechnology is to achieve detailed molecular-level characterization of nanomaterials, enabling researchers to understand structure-property relationships that govern nanoscale phenomena. Specifically, FTIR offers unique insights into chemical bonding, molecular orientation, and interfacial interactions that are critical for designing nanomaterials with tailored properties.

Technical goals for FTIR in nanotechnology include enhancing spatial resolution to consistently achieve sub-10 nm measurements, improving signal-to-noise ratios for single-molecule detection, developing in-situ and operando capabilities for real-time monitoring of nanoscale processes, and establishing standardized protocols for quantitative analysis of nanomaterial composition and functionality.

The evolution of FTIR techniques has been particularly impactful in several key nanotechnology domains, including nanoelectronics, where it helps characterize semiconductor interfaces; nanomedicine, where it assists in understanding drug delivery systems; environmental nanotechnology, where it monitors pollutant interactions; and energy materials, where it provides insights into battery and photovoltaic nanomaterials.

As nanotechnology continues to advance across multiple industries, FTIR characterization techniques are expected to play an increasingly central role in bridging the gap between molecular design and macroscopic performance, ultimately accelerating the development cycle for next-generation nanomaterials and devices.

Market Applications and Demand Analysis

The market for FTIR (Fourier Transform Infrared Spectroscopy) in nanotechnology applications has experienced significant growth over the past decade, driven by increasing demand for advanced characterization techniques in nanomaterial development and quality control. The global market for nanomaterial characterization equipment, including FTIR systems, currently exceeds $5 billion and is projected to grow at a compound annual growth rate of 7-8% through 2028.

Semiconductor and electronics industries represent the largest application segment for FTIR in nanotechnology, accounting for approximately 35% of the total market share. The continuous miniaturization of electronic components and the development of novel nanomaterials for semiconductor applications have created substantial demand for precise molecular characterization capabilities that FTIR provides.

Pharmaceutical and biotechnology sectors follow closely, comprising about 28% of the market. The application of FTIR in analyzing nanoparticle-based drug delivery systems, protein-nanoparticle interactions, and biocompatibility assessments has become increasingly critical for regulatory approval and quality assurance processes. This segment is expected to show the fastest growth rate due to expanding nanomedicine applications.

Environmental monitoring and remediation applications represent an emerging market segment, currently at 15% but growing rapidly. FTIR's ability to identify and characterize nanomaterials in environmental samples provides valuable data for assessing ecological impacts and developing remediation strategies. Regulatory pressures regarding nanomaterial release into the environment are driving demand in this sector.

Academic and research institutions constitute approximately 17% of the market, with demand primarily focused on advanced FTIR systems with specialized capabilities for nanomaterial research. The remaining market share is distributed among various industries including energy, automotive, and aerospace, where nanomaterial development requires sophisticated characterization techniques.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing R&D investments in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more integrated solutions that combine FTIR with complementary techniques such as Raman spectroscopy and electron microscopy. There is also growing demand for portable and miniaturized FTIR systems that can provide on-site characterization capabilities, particularly in field-based environmental applications and manufacturing quality control.

Semiconductor and electronics industries represent the largest application segment for FTIR in nanotechnology, accounting for approximately 35% of the total market share. The continuous miniaturization of electronic components and the development of novel nanomaterials for semiconductor applications have created substantial demand for precise molecular characterization capabilities that FTIR provides.

Pharmaceutical and biotechnology sectors follow closely, comprising about 28% of the market. The application of FTIR in analyzing nanoparticle-based drug delivery systems, protein-nanoparticle interactions, and biocompatibility assessments has become increasingly critical for regulatory approval and quality assurance processes. This segment is expected to show the fastest growth rate due to expanding nanomedicine applications.

Environmental monitoring and remediation applications represent an emerging market segment, currently at 15% but growing rapidly. FTIR's ability to identify and characterize nanomaterials in environmental samples provides valuable data for assessing ecological impacts and developing remediation strategies. Regulatory pressures regarding nanomaterial release into the environment are driving demand in this sector.

Academic and research institutions constitute approximately 17% of the market, with demand primarily focused on advanced FTIR systems with specialized capabilities for nanomaterial research. The remaining market share is distributed among various industries including energy, automotive, and aerospace, where nanomaterial development requires sophisticated characterization techniques.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding manufacturing capabilities and increasing R&D investments in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more integrated solutions that combine FTIR with complementary techniques such as Raman spectroscopy and electron microscopy. There is also growing demand for portable and miniaturized FTIR systems that can provide on-site characterization capabilities, particularly in field-based environmental applications and manufacturing quality control.

Current FTIR Nanoscale Characterization Challenges

Despite significant advancements in FTIR spectroscopy for nanomaterial characterization, several critical challenges persist that limit its full potential in nanotechnology applications. The fundamental diffraction limit represents the most significant barrier, as conventional FTIR systems are constrained by wavelength-dependent spatial resolution limitations. With mid-infrared wavelengths typically ranging from 2.5 to 25 μm, traditional FTIR techniques cannot resolve nanoscale features below approximately 10 μm, creating a substantial gap between the size of nanomaterials (often 1-100 nm) and achievable resolution.

Signal-to-noise ratio (SNR) issues present another major challenge when analyzing nanoscale samples. The extremely small sample volumes inherent to nanomaterials produce weak absorption signals that are often overwhelmed by background noise, detector limitations, and environmental interferences. This problem is particularly pronounced when attempting to characterize individual nanoparticles or thin films with thicknesses below 100 nm.

Sample preparation techniques for nanoscale FTIR analysis remain problematic and often introduce artifacts. Current methods frequently require substrate materials that may interfere with spectral data, while sample mounting procedures can alter the native state of nanomaterials. Additionally, the interface between nanomaterials and their surrounding environment significantly influences spectral characteristics, making it difficult to distinguish intrinsic material properties from environmental effects.

Quantitative analysis at the nanoscale presents unique challenges due to the complex relationship between spectral response and nanomaterial morphology. Factors such as particle size distribution, surface roughness, and local structural variations can dramatically alter spectral features, complicating data interpretation. Current calibration methods developed for bulk materials often fail to account for these nanoscale-specific phenomena.

Technical limitations in instrumentation further constrain nanoscale FTIR applications. Most commercial FTIR systems lack the specialized optics, precise sample positioning mechanisms, and advanced detectors necessary for nanoscale analysis. Integration with complementary techniques like AFM (Atomic Force Microscopy) remains technically challenging and expensive, limiting widespread adoption.

Data interpretation challenges are equally significant, as nanoscale FTIR spectra often exhibit features not present in bulk material spectra of the same composition. The scientific community lacks comprehensive spectral libraries and theoretical models specifically developed for nanomaterials, making accurate interpretation difficult. Additionally, the influence of quantum confinement effects and surface phenomena on vibrational modes is not fully understood or accounted for in current analytical frameworks.

Reproducibility issues further complicate nanoscale FTIR characterization, with measurements often showing significant variation between instruments, operators, and even between successive analyses of the same sample. These challenges collectively highlight the need for innovative approaches to overcome the current limitations of FTIR in nanoscale characterization.

Signal-to-noise ratio (SNR) issues present another major challenge when analyzing nanoscale samples. The extremely small sample volumes inherent to nanomaterials produce weak absorption signals that are often overwhelmed by background noise, detector limitations, and environmental interferences. This problem is particularly pronounced when attempting to characterize individual nanoparticles or thin films with thicknesses below 100 nm.

Sample preparation techniques for nanoscale FTIR analysis remain problematic and often introduce artifacts. Current methods frequently require substrate materials that may interfere with spectral data, while sample mounting procedures can alter the native state of nanomaterials. Additionally, the interface between nanomaterials and their surrounding environment significantly influences spectral characteristics, making it difficult to distinguish intrinsic material properties from environmental effects.

Quantitative analysis at the nanoscale presents unique challenges due to the complex relationship between spectral response and nanomaterial morphology. Factors such as particle size distribution, surface roughness, and local structural variations can dramatically alter spectral features, complicating data interpretation. Current calibration methods developed for bulk materials often fail to account for these nanoscale-specific phenomena.

Technical limitations in instrumentation further constrain nanoscale FTIR applications. Most commercial FTIR systems lack the specialized optics, precise sample positioning mechanisms, and advanced detectors necessary for nanoscale analysis. Integration with complementary techniques like AFM (Atomic Force Microscopy) remains technically challenging and expensive, limiting widespread adoption.

Data interpretation challenges are equally significant, as nanoscale FTIR spectra often exhibit features not present in bulk material spectra of the same composition. The scientific community lacks comprehensive spectral libraries and theoretical models specifically developed for nanomaterials, making accurate interpretation difficult. Additionally, the influence of quantum confinement effects and surface phenomena on vibrational modes is not fully understood or accounted for in current analytical frameworks.

Reproducibility issues further complicate nanoscale FTIR characterization, with measurements often showing significant variation between instruments, operators, and even between successive analyses of the same sample. These challenges collectively highlight the need for innovative approaches to overcome the current limitations of FTIR in nanoscale characterization.

State-of-the-Art FTIR Nanoscale Characterization Methods

01 FTIR instrumentation and apparatus design

Various designs and configurations of FTIR spectroscopy instruments are described, including specialized components and optical arrangements that enhance measurement capabilities. These innovations focus on improving the precision, sensitivity, and reliability of FTIR systems through advanced hardware configurations, novel interferometer designs, and optimized optical pathways that enable more accurate spectral data collection across different sample types.- FTIR instrumentation and apparatus design: Various designs and configurations of FTIR spectroscopy instruments are described, including specialized components and optical arrangements that enhance measurement capabilities. These designs focus on improving resolution, sensitivity, and reliability of spectroscopic measurements. Innovations include novel interferometer configurations, detector arrangements, and sample handling mechanisms that optimize the performance of FTIR systems for different analytical applications.

- Sample preparation and handling techniques for FTIR analysis: Methods and devices for preparing and handling samples for FTIR spectroscopic analysis are detailed. These include techniques for processing various sample types (solids, liquids, gases) to ensure optimal spectral acquisition. Specialized sample holders, preparation protocols, and handling mechanisms are described that minimize interference and maximize signal quality. These approaches address challenges in analyzing complex matrices and ensure reproducible FTIR characterization results.

- FTIR data processing and analysis methods: Advanced computational methods for processing and analyzing FTIR spectral data are presented. These include algorithms for spectral correction, baseline adjustment, peak identification, and quantitative analysis. Machine learning and artificial intelligence approaches are applied to extract meaningful information from complex spectral datasets. These methods enhance the interpretation of FTIR data and enable automated analysis for various applications including material identification and quality control.

- FTIR applications in material characterization: Applications of FTIR spectroscopy for characterizing various materials are described, including polymers, pharmaceuticals, biological samples, and nanomaterials. The technique is used to identify chemical compositions, determine molecular structures, and analyze functional groups. FTIR characterization provides valuable information about material properties, purity, and structural features that influence performance characteristics. These applications demonstrate the versatility of FTIR as an analytical tool across multiple industries.

- Portable and in-situ FTIR systems: Development of portable, miniaturized, and field-deployable FTIR systems for on-site and in-situ characterization is detailed. These systems enable real-time analysis outside laboratory environments, featuring compact designs, ruggedized components, and simplified interfaces. Innovations include battery operation, wireless connectivity, and environmental protection features that allow FTIR characterization in challenging conditions. These portable systems facilitate immediate decision-making in applications such as environmental monitoring, quality control, and forensic analysis.

02 Sample analysis and characterization techniques

Methods for analyzing and characterizing various materials using FTIR spectroscopy, including techniques for sample preparation, data collection protocols, and spectral interpretation. These approaches enable the identification of chemical compositions, molecular structures, and functional groups in diverse sample types. The techniques include specialized sampling methods for different material states (solid, liquid, gas) and adaptations for challenging sample environments.Expand Specific Solutions03 Integration with other analytical methods

Combining FTIR spectroscopy with complementary analytical techniques to provide comprehensive material characterization. These integrated approaches pair FTIR with methods such as Raman spectroscopy, mass spectrometry, thermal analysis, or microscopy to overcome the limitations of individual techniques and provide multi-dimensional analytical data. Such combinations enable more thorough characterization of complex materials and enhance the reliability of analytical results.Expand Specific Solutions04 Automated and real-time monitoring systems

Development of automated FTIR systems for continuous or real-time monitoring applications in industrial processes, environmental monitoring, and quality control. These systems incorporate automated sampling, data processing algorithms, and feedback mechanisms that enable ongoing analysis without manual intervention. The innovations include remote monitoring capabilities, automated calibration procedures, and integration with control systems for process optimization.Expand Specific Solutions05 Advanced data processing and interpretation methods

Sophisticated algorithms and computational methods for processing and interpreting FTIR spectral data, including chemometric approaches, machine learning techniques, and statistical analysis tools. These methods enhance the extraction of meaningful information from complex spectra, improve the detection of subtle spectral features, and enable automated identification of compounds. The approaches include multivariate analysis, spectral preprocessing techniques, and pattern recognition algorithms that increase the sensitivity and specificity of FTIR analysis.Expand Specific Solutions

Leading Institutions and Companies in FTIR Nanotechnology

FTIR in nanotechnology characterization is evolving rapidly in a growing market, currently in its expansion phase. The global nanomaterial characterization market is experiencing significant growth, projected to reach several billion dollars by 2025. Technologically, the field shows varying maturity levels across applications. Industry leaders like Bruker Nano have established sophisticated FTIR solutions for nanomaterial analysis, while companies such as Thermo Fisher Scientific and Agilent Technologies offer complementary technologies. Research institutions including Lehigh University, Peking University, and National Research Council of Canada are advancing fundamental applications. Companies like Renesas Electronics and Sony Semiconductor Solutions are integrating FTIR characterization into semiconductor manufacturing processes, while Philips and Saudi Aramco are exploring applications in their respective industries.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced FTIR microscopy systems specifically optimized for nanotechnology applications. Their technology integrates Fourier Transform Infrared Spectroscopy with Atomic Force Microscopy (AFM-IR) to achieve nanoscale spatial resolution beyond the diffraction limit. This approach allows researchers to obtain chemical composition information at the nanoscale with resolution down to 10 nm. Their PeakForce IR system combines IR spectroscopy with mechanical property mapping, enabling simultaneous characterization of both chemical and physical properties of nanomaterials. Bruker's systems incorporate quantum cascade lasers for enhanced sensitivity and signal-to-noise ratio, particularly beneficial when analyzing thin films and nanostructures with minimal sample volumes. Their technology also features automated data processing algorithms that help identify chemical components in complex nanomaterial systems through spectral pattern recognition.

Strengths: Industry-leading spatial resolution (down to 10 nm) for chemical identification at the nanoscale; integration with mechanical property mapping provides comprehensive material characterization. Weaknesses: High equipment cost limits accessibility; requires specialized training for operation and data interpretation; sample preparation can be challenging for certain nanomaterials.

Koninklijke Philips NV

Technical Solution: Philips has developed integrated FTIR systems specifically designed for nanomaterial characterization in semiconductor and electronic device applications. Their technology combines FTIR spectroscopy with automated mapping capabilities to analyze chemical composition across nanoscale electronic components and thin films. Philips' systems feature specialized accessories for grazing angle reflectance measurements, enabling characterization of ultra-thin films and interfaces critical in nanotechnology applications. They have pioneered the use of polarization-modulated FTIR for studying molecular orientation in nanomaterials, providing insights into structure-property relationships. Their technology incorporates machine learning algorithms for automated identification of defects and contaminants in nanomaterial production processes. Philips has also developed specialized FTIR imaging techniques for characterizing organic-inorganic interfaces in hybrid nanomaterials, with applications in flexible electronics and biomedical devices.

Strengths: Excellent integration with semiconductor manufacturing workflows; specialized accessories for thin film analysis provide comprehensive characterization; automated defect detection improves quality control in nanomaterial production. Weaknesses: Systems primarily optimized for electronic applications with less versatility for other nanomaterial types; limited spatial resolution compared to some competing technologies; higher cost compared to general-purpose FTIR systems.

Key Technological Advancements in Nano-FTIR

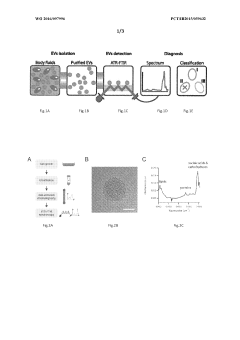

Use of fourier transform infrared spectroscopy analysis of extracellular vesicles isolated from body fluids for diagnosing, prognosing and monitoring pathophysiological states and method therfor

PatentWO2016097996A1

Innovation

- The use of Fourier Transform Infrared Spectroscopy (FTIR) to analyze extracellular vesicles (EVs) isolated from body fluids, combined with multivariate analysis, provides a non-invasive and label-free method for classifying EVs based on their molecular composition, enabling early diagnosis, prognosis, and monitoring of cancer and other proliferative diseases.

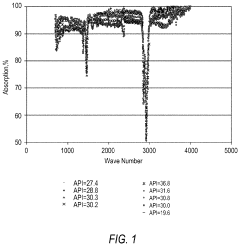

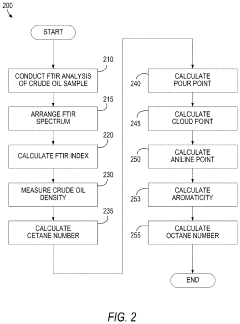

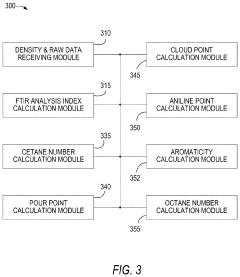

Characterization of crude oil and its fractions by fourier transform infrared (FTIR) spectroscopy analysis

PatentActiveUS10942160B2

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess the indicative properties of crude oil fractions without fractionation, using a system that calculates these properties based on density and FTIR measurements, enabling rapid evaluation of crude oil quality.

Standardization and Metrology Considerations

The standardization of FTIR methodologies in nanotechnology represents a critical frontier for ensuring reliable and comparable characterization results across different laboratories and research institutions. Current FTIR applications in nanomaterial analysis suffer from inconsistencies in sample preparation techniques, measurement parameters, and data interpretation protocols, leading to challenges in reproducing results and establishing universal benchmarks for nanomaterial properties.

International standards organizations including ISO, ASTM, and NIST have begun developing specific guidelines for FTIR applications in nanotechnology, with particular focus on standardizing sample preparation methods for various nanomaterial types. These efforts aim to address the unique challenges posed by nanoscale materials, such as surface effects, quantum confinement phenomena, and increased reactivity that can significantly influence spectral outcomes.

Metrological considerations for FTIR in nanotechnology must account for several critical factors. Signal-to-noise ratio optimization becomes particularly important when analyzing nanoscale samples with limited material quantities. Researchers must carefully balance spectral resolution requirements against acquisition time and signal quality. Additionally, calibration protocols specific to nanomaterial analysis require reference materials that accurately represent the unique properties of materials at the nanoscale.

Quantitative analysis presents particular challenges, as Beer-Lambert law applications may deviate at the nanoscale due to scattering effects and non-linear optical responses. Establishing reliable quantification methodologies requires careful validation against complementary analytical techniques such as electron microscopy or X-ray diffraction to confirm structural and compositional interpretations derived from FTIR data.

Interlaboratory comparison studies have revealed significant variations in FTIR results for identical nanomaterials, highlighting the urgent need for standardized protocols. These studies demonstrate that differences in instrument configurations, atmospheric conditions, and data processing algorithms can substantially impact spectral features critical for nanomaterial characterization. Efforts to develop certified reference nanomaterials with well-characterized FTIR signatures are underway to provide calibration standards for the field.

Data reporting standards represent another crucial aspect of FTIR metrology in nanotechnology. Comprehensive documentation of experimental parameters, including sample preparation details, instrument specifications, measurement conditions, and data processing methodologies, is essential for ensuring reproducibility. The development of standardized data formats and metadata requirements will facilitate more effective comparison of results across different research groups and enable more robust meta-analyses of nanomaterial properties.

International standards organizations including ISO, ASTM, and NIST have begun developing specific guidelines for FTIR applications in nanotechnology, with particular focus on standardizing sample preparation methods for various nanomaterial types. These efforts aim to address the unique challenges posed by nanoscale materials, such as surface effects, quantum confinement phenomena, and increased reactivity that can significantly influence spectral outcomes.

Metrological considerations for FTIR in nanotechnology must account for several critical factors. Signal-to-noise ratio optimization becomes particularly important when analyzing nanoscale samples with limited material quantities. Researchers must carefully balance spectral resolution requirements against acquisition time and signal quality. Additionally, calibration protocols specific to nanomaterial analysis require reference materials that accurately represent the unique properties of materials at the nanoscale.

Quantitative analysis presents particular challenges, as Beer-Lambert law applications may deviate at the nanoscale due to scattering effects and non-linear optical responses. Establishing reliable quantification methodologies requires careful validation against complementary analytical techniques such as electron microscopy or X-ray diffraction to confirm structural and compositional interpretations derived from FTIR data.

Interlaboratory comparison studies have revealed significant variations in FTIR results for identical nanomaterials, highlighting the urgent need for standardized protocols. These studies demonstrate that differences in instrument configurations, atmospheric conditions, and data processing algorithms can substantially impact spectral features critical for nanomaterial characterization. Efforts to develop certified reference nanomaterials with well-characterized FTIR signatures are underway to provide calibration standards for the field.

Data reporting standards represent another crucial aspect of FTIR metrology in nanotechnology. Comprehensive documentation of experimental parameters, including sample preparation details, instrument specifications, measurement conditions, and data processing methodologies, is essential for ensuring reproducibility. The development of standardized data formats and metadata requirements will facilitate more effective comparison of results across different research groups and enable more robust meta-analyses of nanomaterial properties.

Environmental and Safety Implications of Nanomaterial Characterization

The characterization of nanomaterials using Fourier Transform Infrared Spectroscopy (FTIR) has significant environmental and safety implications that must be carefully considered. As nanomaterials continue to proliferate across industries, their potential impact on ecosystems and human health becomes increasingly important to understand and monitor.

FTIR analysis provides crucial data on the surface chemistry and functional groups of nanomaterials, which directly correlates with their environmental behavior and toxicity profiles. This spectroscopic technique enables researchers to identify specific chemical modifications that may occur when nanomaterials interact with environmental matrices, including water, soil, and biological systems.

The environmental fate of nanomaterials can be tracked more effectively through FTIR characterization by monitoring changes in their surface properties over time. For instance, the degradation patterns of polymer-based nanocomposites in various environmental conditions can be assessed, providing insights into their persistence and transformation products. This information is vital for developing accurate environmental risk assessments and regulatory frameworks.

From a safety perspective, FTIR characterization helps identify potential hazardous interactions between nanomaterials and biological systems. The technique can detect protein adsorption patterns on nanoparticle surfaces, which often serve as indicators of biocompatibility and potential cytotoxicity. These insights are essential for designing safer nanomaterials and establishing appropriate handling protocols.

Regulatory bodies worldwide are increasingly requiring comprehensive characterization data for nanomaterial registration and approval. FTIR serves as a valuable tool in this regulatory landscape, providing standardized, reproducible data on chemical composition and surface functionality that can be used to classify nanomaterials according to their potential environmental and health risks.

The non-destructive nature of FTIR analysis also supports sustainable practices in nanomaterial research and development. Samples analyzed by FTIR remain intact and can be used for further testing, reducing waste generation and resource consumption in laboratory settings. This aspect aligns with green chemistry principles that are becoming increasingly important in nanotechnology development.

Recent advancements in FTIR technology, including enhanced sensitivity and spatial resolution, have improved our ability to detect trace amounts of nanomaterials in complex environmental matrices. This capability is particularly valuable for monitoring potential environmental releases and exposure scenarios, supporting more accurate risk management strategies for emerging nanomaterials.

FTIR analysis provides crucial data on the surface chemistry and functional groups of nanomaterials, which directly correlates with their environmental behavior and toxicity profiles. This spectroscopic technique enables researchers to identify specific chemical modifications that may occur when nanomaterials interact with environmental matrices, including water, soil, and biological systems.

The environmental fate of nanomaterials can be tracked more effectively through FTIR characterization by monitoring changes in their surface properties over time. For instance, the degradation patterns of polymer-based nanocomposites in various environmental conditions can be assessed, providing insights into their persistence and transformation products. This information is vital for developing accurate environmental risk assessments and regulatory frameworks.

From a safety perspective, FTIR characterization helps identify potential hazardous interactions between nanomaterials and biological systems. The technique can detect protein adsorption patterns on nanoparticle surfaces, which often serve as indicators of biocompatibility and potential cytotoxicity. These insights are essential for designing safer nanomaterials and establishing appropriate handling protocols.

Regulatory bodies worldwide are increasingly requiring comprehensive characterization data for nanomaterial registration and approval. FTIR serves as a valuable tool in this regulatory landscape, providing standardized, reproducible data on chemical composition and surface functionality that can be used to classify nanomaterials according to their potential environmental and health risks.

The non-destructive nature of FTIR analysis also supports sustainable practices in nanomaterial research and development. Samples analyzed by FTIR remain intact and can be used for further testing, reducing waste generation and resource consumption in laboratory settings. This aspect aligns with green chemistry principles that are becoming increasingly important in nanotechnology development.

Recent advancements in FTIR technology, including enhanced sensitivity and spatial resolution, have improved our ability to detect trace amounts of nanomaterials in complex environmental matrices. This capability is particularly valuable for monitoring potential environmental releases and exposure scenarios, supporting more accurate risk management strategies for emerging nanomaterials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!