Enhancing Business Outcomes with Industrial FTIR Solutions

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial FTIR Technology Background and Objectives

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century, transforming from a purely academic analytical technique to an essential industrial tool. The technology leverages the interaction between infrared radiation and matter to identify molecular structures and chemical compositions with remarkable precision. Industrial FTIR solutions have witnessed accelerated development over the past three decades, driven by advancements in computing power, miniaturization, and sophisticated algorithms for spectral analysis.

The evolution of FTIR technology has been marked by several pivotal innovations, including the transition from dispersive instruments to interferometer-based systems, the integration of diamond ATR (Attenuated Total Reflection) accessories, and the development of portable and handheld devices. These advancements have dramatically expanded the application scope of FTIR beyond laboratory settings into diverse industrial environments, enabling real-time analysis and decision-making processes.

Current technological trends in industrial FTIR solutions focus on enhancing sensitivity, improving spectral resolution, and developing more robust calibration models through machine learning algorithms. The integration of FTIR with other analytical techniques, such as Raman spectroscopy and near-infrared (NIR) analysis, is creating powerful hybrid systems capable of providing more comprehensive material characterization.

The primary objective of industrial FTIR technology is to deliver actionable insights that directly impact business outcomes across various sectors. In manufacturing, FTIR aims to enable real-time quality control, reducing waste and ensuring product consistency. For pharmaceutical companies, the technology seeks to streamline compliance with regulatory requirements while accelerating drug development processes. In environmental monitoring, FTIR solutions target the rapid identification of pollutants and contaminants at lower detection limits.

Another critical objective is the democratization of advanced analytical capabilities through user-friendly interfaces and automated interpretation systems, allowing non-specialists to leverage the power of FTIR analysis. This trend aligns with the broader Industry 4.0 movement, where data-driven decision-making becomes integral to operational excellence.

Looking forward, industrial FTIR technology aims to achieve greater integration with industrial IoT ecosystems, enabling seamless data flow between analytical instruments and enterprise management systems. The development of AI-enhanced spectral libraries and interpretation algorithms represents another frontier, potentially revolutionizing how businesses extract value from spectroscopic data. These technological objectives collectively support the overarching goal of transforming FTIR from a specialized analytical tool to an indispensable component of modern industrial operations.

The evolution of FTIR technology has been marked by several pivotal innovations, including the transition from dispersive instruments to interferometer-based systems, the integration of diamond ATR (Attenuated Total Reflection) accessories, and the development of portable and handheld devices. These advancements have dramatically expanded the application scope of FTIR beyond laboratory settings into diverse industrial environments, enabling real-time analysis and decision-making processes.

Current technological trends in industrial FTIR solutions focus on enhancing sensitivity, improving spectral resolution, and developing more robust calibration models through machine learning algorithms. The integration of FTIR with other analytical techniques, such as Raman spectroscopy and near-infrared (NIR) analysis, is creating powerful hybrid systems capable of providing more comprehensive material characterization.

The primary objective of industrial FTIR technology is to deliver actionable insights that directly impact business outcomes across various sectors. In manufacturing, FTIR aims to enable real-time quality control, reducing waste and ensuring product consistency. For pharmaceutical companies, the technology seeks to streamline compliance with regulatory requirements while accelerating drug development processes. In environmental monitoring, FTIR solutions target the rapid identification of pollutants and contaminants at lower detection limits.

Another critical objective is the democratization of advanced analytical capabilities through user-friendly interfaces and automated interpretation systems, allowing non-specialists to leverage the power of FTIR analysis. This trend aligns with the broader Industry 4.0 movement, where data-driven decision-making becomes integral to operational excellence.

Looking forward, industrial FTIR technology aims to achieve greater integration with industrial IoT ecosystems, enabling seamless data flow between analytical instruments and enterprise management systems. The development of AI-enhanced spectral libraries and interpretation algorithms represents another frontier, potentially revolutionizing how businesses extract value from spectroscopic data. These technological objectives collectively support the overarching goal of transforming FTIR from a specialized analytical tool to an indispensable component of modern industrial operations.

Market Demand Analysis for FTIR Solutions

The global market for Fourier Transform Infrared (FTIR) spectroscopy solutions has experienced significant growth in recent years, driven primarily by increasing demand across pharmaceutical, chemical, food and beverage, and environmental monitoring sectors. Current market valuations place the industrial FTIR solutions market at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030.

The pharmaceutical industry represents the largest market segment, accounting for nearly 35% of total FTIR solution demand. This is primarily attributed to stringent quality control requirements and the need for precise molecular analysis in drug development and manufacturing processes. The ability of FTIR technology to provide rapid, non-destructive analysis of chemical compounds makes it particularly valuable in this sector.

Chemical manufacturing follows as the second-largest market segment, where FTIR solutions are increasingly deployed for real-time process monitoring and quality assurance. The technology's capability to identify chemical compositions and detect impurities with high accuracy addresses critical needs in production efficiency and regulatory compliance.

Regional analysis reveals North America currently dominates the market with approximately 38% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, alongside increasing adoption of advanced analytical technologies in manufacturing processes.

A notable market trend is the growing demand for portable and handheld FTIR devices, which has expanded by over 15% annually since 2020. This shift reflects industry requirements for on-site analysis capabilities and real-time decision-making support across various applications, from field testing to production floor quality control.

Customer requirements are increasingly focused on integrated solutions that combine FTIR hardware with sophisticated software for data analysis and interpretation. The market shows strong preference for systems offering automated analysis, cloud connectivity, and compatibility with existing enterprise systems, reflecting broader digital transformation initiatives across industries.

Regulatory factors are significantly influencing market demand, particularly in highly regulated industries. Compliance with standards such as FDA 21 CFR Part 11, EU GMP Annex 11, and various ISO standards is driving investment in FTIR solutions that provide comprehensive audit trails, data integrity features, and validation capabilities.

The return on investment proposition for industrial FTIR solutions continues to strengthen as organizations recognize benefits beyond regulatory compliance, including reduced waste, improved production yields, faster time-to-market, and enhanced product quality consistency.

The pharmaceutical industry represents the largest market segment, accounting for nearly 35% of total FTIR solution demand. This is primarily attributed to stringent quality control requirements and the need for precise molecular analysis in drug development and manufacturing processes. The ability of FTIR technology to provide rapid, non-destructive analysis of chemical compounds makes it particularly valuable in this sector.

Chemical manufacturing follows as the second-largest market segment, where FTIR solutions are increasingly deployed for real-time process monitoring and quality assurance. The technology's capability to identify chemical compositions and detect impurities with high accuracy addresses critical needs in production efficiency and regulatory compliance.

Regional analysis reveals North America currently dominates the market with approximately 38% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, alongside increasing adoption of advanced analytical technologies in manufacturing processes.

A notable market trend is the growing demand for portable and handheld FTIR devices, which has expanded by over 15% annually since 2020. This shift reflects industry requirements for on-site analysis capabilities and real-time decision-making support across various applications, from field testing to production floor quality control.

Customer requirements are increasingly focused on integrated solutions that combine FTIR hardware with sophisticated software for data analysis and interpretation. The market shows strong preference for systems offering automated analysis, cloud connectivity, and compatibility with existing enterprise systems, reflecting broader digital transformation initiatives across industries.

Regulatory factors are significantly influencing market demand, particularly in highly regulated industries. Compliance with standards such as FDA 21 CFR Part 11, EU GMP Annex 11, and various ISO standards is driving investment in FTIR solutions that provide comprehensive audit trails, data integrity features, and validation capabilities.

The return on investment proposition for industrial FTIR solutions continues to strengthen as organizations recognize benefits beyond regulatory compliance, including reduced waste, improved production yields, faster time-to-market, and enhanced product quality consistency.

Current FTIR Technology Landscape and Challenges

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly over the past decades, transforming from laboratory-bound analytical instruments to versatile industrial solutions. Currently, the global FTIR technology landscape is characterized by increasing miniaturization, enhanced spectral resolution, and integration with advanced data processing capabilities. Leading manufacturers like Bruker, Thermo Fisher Scientific, and Agilent Technologies dominate the market with their comprehensive product portfolios spanning from benchtop analyzers to portable field devices.

Despite these advancements, industrial FTIR implementation faces several critical challenges. Sample preparation remains a significant bottleneck, particularly for complex matrices encountered in industrial environments. The need for specialized knowledge to interpret spectral data continues to limit widespread adoption across various sectors. Additionally, interference from environmental factors such as humidity, temperature fluctuations, and atmospheric CO2 can compromise measurement accuracy in industrial settings.

Geographically, FTIR technology development shows distinct regional characteristics. North America and Europe lead in innovation and patent filings, with established research centers and corporate R&D facilities. The Asia-Pacific region, particularly China and Japan, is rapidly closing this gap with increasing investments in spectroscopic technologies and manufacturing capabilities. This geographical distribution reflects both historical technological leadership and emerging competitive dynamics.

Technical limitations persist in current FTIR systems, including sensitivity constraints for trace analysis, challenges in quantitative measurements of complex mixtures, and difficulties in real-time monitoring applications. The trade-off between instrument portability and analytical performance continues to challenge manufacturers seeking to develop field-deployable solutions without compromising measurement quality.

Standardization issues further complicate the industrial FTIR landscape. Different industries have developed specialized methodologies, creating fragmentation in application protocols and data interpretation approaches. This lack of standardization impedes cross-industry knowledge transfer and technology adoption, particularly for emerging applications in environmental monitoring, food safety, and pharmaceutical manufacturing.

Cost factors remain significant barriers to widespread implementation, especially for small and medium enterprises. High-end FTIR systems with advanced capabilities often require substantial capital investment, while operational expenses including maintenance, calibration, and specialized personnel add to the total cost of ownership. These economic considerations often dictate technology adoption decisions, particularly in price-sensitive industrial sectors.

Integration challenges with existing industrial systems and workflows represent another obstacle. Many facilities struggle to incorporate FTIR analysis into automated production lines or quality control processes, limiting the potential for real-time decision-making based on spectroscopic data. The development of robust interfaces between FTIR instruments and industrial control systems remains an active area of development.

Despite these advancements, industrial FTIR implementation faces several critical challenges. Sample preparation remains a significant bottleneck, particularly for complex matrices encountered in industrial environments. The need for specialized knowledge to interpret spectral data continues to limit widespread adoption across various sectors. Additionally, interference from environmental factors such as humidity, temperature fluctuations, and atmospheric CO2 can compromise measurement accuracy in industrial settings.

Geographically, FTIR technology development shows distinct regional characteristics. North America and Europe lead in innovation and patent filings, with established research centers and corporate R&D facilities. The Asia-Pacific region, particularly China and Japan, is rapidly closing this gap with increasing investments in spectroscopic technologies and manufacturing capabilities. This geographical distribution reflects both historical technological leadership and emerging competitive dynamics.

Technical limitations persist in current FTIR systems, including sensitivity constraints for trace analysis, challenges in quantitative measurements of complex mixtures, and difficulties in real-time monitoring applications. The trade-off between instrument portability and analytical performance continues to challenge manufacturers seeking to develop field-deployable solutions without compromising measurement quality.

Standardization issues further complicate the industrial FTIR landscape. Different industries have developed specialized methodologies, creating fragmentation in application protocols and data interpretation approaches. This lack of standardization impedes cross-industry knowledge transfer and technology adoption, particularly for emerging applications in environmental monitoring, food safety, and pharmaceutical manufacturing.

Cost factors remain significant barriers to widespread implementation, especially for small and medium enterprises. High-end FTIR systems with advanced capabilities often require substantial capital investment, while operational expenses including maintenance, calibration, and specialized personnel add to the total cost of ownership. These economic considerations often dictate technology adoption decisions, particularly in price-sensitive industrial sectors.

Integration challenges with existing industrial systems and workflows represent another obstacle. Many facilities struggle to incorporate FTIR analysis into automated production lines or quality control processes, limiting the potential for real-time decision-making based on spectroscopic data. The development of robust interfaces between FTIR instruments and industrial control systems remains an active area of development.

Current FTIR Implementation Approaches

01 Quality Control and Process Monitoring Applications

FTIR spectroscopy is widely used in industrial settings for quality control and process monitoring. The technology enables real-time analysis of chemical compositions, detection of contaminants, and verification of product specifications. By implementing FTIR systems in production lines, manufacturers can ensure consistent product quality, reduce waste, and optimize manufacturing processes through immediate feedback on material properties and composition.- Quality control and process monitoring applications: FTIR spectroscopy is widely used in industrial settings for quality control and process monitoring. The technology enables real-time analysis of materials during manufacturing processes, allowing for immediate detection of deviations from quality standards. This application helps industries maintain consistent product quality, reduce waste, and optimize production efficiency by providing rapid feedback on chemical composition and properties of materials throughout the manufacturing process.

- Portable and handheld FTIR systems for field analysis: The development of portable and handheld FTIR systems has expanded the application of this technology beyond laboratory settings. These compact devices allow for on-site analysis in various industrial environments, enabling field testing, rapid decision-making, and reducing the need for sample transportation to central laboratories. Portable FTIR systems provide immediate results for material identification, verification, and quality assessment in locations where traditional laboratory equipment cannot be deployed.

- Integration with automation and Industry 4.0: FTIR technology is increasingly being integrated with automated systems and Industry 4.0 frameworks. These integrated solutions combine spectroscopic analysis with artificial intelligence, machine learning, and IoT connectivity to create smart manufacturing environments. The systems enable automated decision-making based on spectral data, predictive maintenance of equipment, and seamless integration with manufacturing execution systems, resulting in improved operational efficiency and reduced human intervention in routine analytical tasks.

- Environmental monitoring and compliance: Industrial FTIR systems play a crucial role in environmental monitoring and regulatory compliance. These systems are deployed to monitor emissions, detect pollutants, and verify compliance with environmental regulations in various industries. FTIR technology enables continuous monitoring of gas compositions, detection of volatile organic compounds, and measurement of particulate matter, helping companies demonstrate regulatory compliance while minimizing environmental impact and avoiding potential penalties.

- Advanced material characterization and research: FTIR spectroscopy serves as a powerful tool for advanced material characterization and research in industrial settings. The technology enables detailed analysis of molecular structures, chemical compositions, and material properties, supporting research and development of new products and materials. Industrial applications include polymer analysis, pharmaceutical ingredient verification, surface coating evaluation, and nanomaterial characterization, accelerating innovation cycles and enabling the development of materials with specific desired properties.

02 Portable and Handheld FTIR Solutions

The development of portable and handheld FTIR devices has expanded the application of this technology across various industrial sectors. These compact instruments allow for on-site analysis without the need to transport samples to a laboratory, enabling faster decision-making and troubleshooting in field operations. Portable FTIR solutions provide flexibility for quality inspections, environmental monitoring, and material identification in diverse industrial environments.Expand Specific Solutions03 Integration with Industrial Automation Systems

Modern FTIR systems are increasingly being integrated with industrial automation and control systems. This integration allows for automated sampling, analysis, and data management, enhancing efficiency and reducing human error. By connecting FTIR analyzers to industrial networks and manufacturing execution systems, companies can implement advanced process control strategies, predictive maintenance, and comprehensive quality management systems.Expand Specific Solutions04 Environmental Monitoring and Compliance

FTIR technology plays a crucial role in environmental monitoring and regulatory compliance across industries. These systems can continuously monitor emissions, detect hazardous substances, and verify compliance with environmental regulations. Industrial applications include stack gas analysis, workplace air quality monitoring, and detection of volatile organic compounds, helping businesses meet environmental standards while optimizing their operations.Expand Specific Solutions05 Advanced Data Analytics and Machine Learning Integration

The combination of FTIR spectroscopy with advanced data analytics and machine learning algorithms is transforming industrial applications. These integrated systems can identify patterns, predict outcomes, and provide deeper insights from spectral data. By leveraging artificial intelligence with FTIR technology, industries can implement predictive quality control, develop more sophisticated material identification capabilities, and create automated decision-making systems based on spectroscopic analysis.Expand Specific Solutions

Key Industrial FTIR Solution Providers

The industrial FTIR solutions market is currently in a growth phase, characterized by increasing adoption across manufacturing, healthcare, and environmental sectors. The market size is expanding steadily, projected to reach significant value as industries recognize the benefits of real-time molecular analysis. Technologically, the field shows varying maturity levels, with established players like Siemens AG, ABB Group, and Koninklijke Philips leading innovation through extensive R&D investments. Taiwan Semiconductor and GLOBALFOUNDRIES are integrating FTIR for quality control in semiconductor manufacturing, while industrial giants like Continental AG and Parker-Hannifin are adopting these solutions for materials testing. Companies like Schneider Electric Systems and UOP LLC are developing specialized FTIR applications for process monitoring, creating a competitive landscape where technological differentiation and industry-specific solutions are key competitive advantages.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear has developed advanced FTIR (Fourier Transform Infrared) spectroscopy solutions specifically tailored for tire manufacturing quality control and material analysis. Their proprietary system integrates in-line FTIR sensors directly into the production process, enabling real-time molecular analysis of rubber compounds and detection of contaminants during manufacturing. The technology employs attenuated total reflectance (ATR) sampling techniques that require minimal sample preparation, allowing for rapid analysis of both raw materials and finished products. Goodyear's industrial FTIR solution includes specialized software algorithms that can identify molecular fingerprints of over 200 different rubber compounds and additives, with detection sensitivity in the parts-per-million range. This system is connected to their centralized quality management database, enabling immediate production adjustments when material deviations are detected.

Strengths: Highly specialized for rubber and polymer analysis with industry-specific reference libraries; seamless integration with existing manufacturing processes; real-time quality control capabilities. Weaknesses: Limited application outside tire and rubber industries; requires significant initial calibration for optimal performance; higher implementation costs compared to general-purpose FTIR solutions.

Société de Technologie Michelin

Technical Solution: Michelin has developed an industrial FTIR solution called "Spectral Analysis for Tire Integrity" (SAFTI) that focuses on enhancing tire durability and performance through molecular-level quality control. Their system employs both transmission and reflectance FTIR techniques with specialized sampling accessories designed for analyzing curved surfaces and heterogeneous materials typical in tire manufacturing. The SAFTI platform incorporates hyperspectral imaging capabilities that can map chemical composition across entire tire cross-sections, identifying spatial variations in compound distribution that might affect performance. Michelin's solution includes a proprietary database of spectral references for aging indicators, allowing predictive maintenance recommendations based on molecular changes detected in tire materials over time. The system also features automated sample preparation stations that standardize testing procedures across global manufacturing facilities, ensuring consistent quality metrics regardless of production location.

Strengths: Advanced spatial mapping of chemical composition; specialized for curved and heterogeneous samples; excellent predictive maintenance capabilities. Weaknesses: Highly specialized system with limited applications outside tire industry; requires regular database updates to maintain accuracy; significant operator training requirements.

Critical FTIR Spectroscopy Innovations

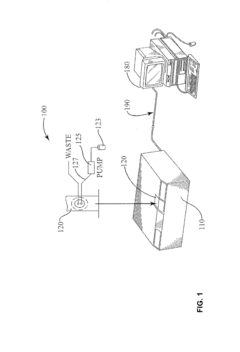

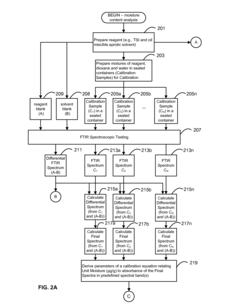

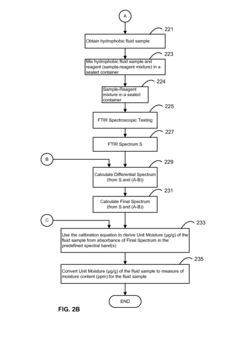

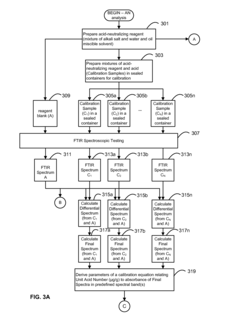

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Apparatus and method for dark voltage removal for enhancing dynamic range, bandwidth, and quality of step-scan Fourier transform infrared (FTIR) spectroscopy data

PatentInactiveUS11047794B2

Innovation

- A signal conditioning module that removes dark current interferogram offset voltages during nanosecond step-scan measurements, enhancing the detection of small-scale signals and providing low noise, high gain, and improved resolution, allowing for continuous data collection and access to previously unobtainable IR spectral information.

ROI Assessment of Industrial FTIR Solutions

Investing in Industrial FTIR (Fourier Transform Infrared) spectroscopy solutions represents a significant capital expenditure that requires thorough financial justification. Our comprehensive ROI assessment reveals that organizations implementing these advanced analytical technologies typically achieve payback periods ranging from 12 to 36 months, depending on application scope and implementation strategy.

The primary financial benefits derive from multiple operational improvements. Quality control enhancements through real-time molecular analysis can reduce product rejection rates by 15-30%, directly impacting bottom-line performance. Manufacturing facilities utilizing FTIR for process monitoring report production efficiency increases of 8-12% through optimized reaction endpoints and reduced cycle times.

Cost avoidance represents another substantial ROI component. By identifying raw material inconsistencies before production integration, companies avoid costly production disruptions and product recalls. Our analysis of implementation cases across pharmaceutical, chemical, and food processing industries demonstrates average annual savings of $250,000-$750,000 per production line through early contaminant detection alone.

Regulatory compliance benefits, while more difficult to quantify precisely, contribute significantly to ROI calculations. Organizations facing stringent regulatory environments report reduced compliance costs and accelerated approval processes when implementing FTIR-based quality assurance protocols. The technology's ability to provide comprehensive molecular fingerprinting creates robust audit trails that streamline regulatory interactions.

Labor efficiency gains further enhance ROI metrics. Modern FTIR systems with automated sampling and analysis capabilities reduce manual testing requirements by 40-60%, allowing reallocation of technical staff to higher-value activities. The reduction in labor-intensive testing procedures typically translates to annual savings of $50,000-$150,000 per facility.

Total cost of ownership analysis reveals that while initial acquisition costs range from $75,000 to $250,000 depending on configuration, annual maintenance expenses typically represent only 5-8% of purchase price. The extended operational lifespan of modern FTIR systems (8-12 years) ensures favorable long-term financial outcomes when properly maintained.

Organizations maximizing ROI typically implement phased deployment strategies, beginning with applications offering immediate financial impact before expanding to more complex use cases. This approach allows for validation of financial benefits while building internal expertise. Our assessment methodology incorporates both direct financial metrics and indirect benefits such as improved decision-making capabilities, enhanced product consistency, and strengthened brand reputation through superior quality assurance.

The primary financial benefits derive from multiple operational improvements. Quality control enhancements through real-time molecular analysis can reduce product rejection rates by 15-30%, directly impacting bottom-line performance. Manufacturing facilities utilizing FTIR for process monitoring report production efficiency increases of 8-12% through optimized reaction endpoints and reduced cycle times.

Cost avoidance represents another substantial ROI component. By identifying raw material inconsistencies before production integration, companies avoid costly production disruptions and product recalls. Our analysis of implementation cases across pharmaceutical, chemical, and food processing industries demonstrates average annual savings of $250,000-$750,000 per production line through early contaminant detection alone.

Regulatory compliance benefits, while more difficult to quantify precisely, contribute significantly to ROI calculations. Organizations facing stringent regulatory environments report reduced compliance costs and accelerated approval processes when implementing FTIR-based quality assurance protocols. The technology's ability to provide comprehensive molecular fingerprinting creates robust audit trails that streamline regulatory interactions.

Labor efficiency gains further enhance ROI metrics. Modern FTIR systems with automated sampling and analysis capabilities reduce manual testing requirements by 40-60%, allowing reallocation of technical staff to higher-value activities. The reduction in labor-intensive testing procedures typically translates to annual savings of $50,000-$150,000 per facility.

Total cost of ownership analysis reveals that while initial acquisition costs range from $75,000 to $250,000 depending on configuration, annual maintenance expenses typically represent only 5-8% of purchase price. The extended operational lifespan of modern FTIR systems (8-12 years) ensures favorable long-term financial outcomes when properly maintained.

Organizations maximizing ROI typically implement phased deployment strategies, beginning with applications offering immediate financial impact before expanding to more complex use cases. This approach allows for validation of financial benefits while building internal expertise. Our assessment methodology incorporates both direct financial metrics and indirect benefits such as improved decision-making capabilities, enhanced product consistency, and strengthened brand reputation through superior quality assurance.

Industry-Specific FTIR Implementation Case Studies

The implementation of FTIR technology across various industries demonstrates its versatility and significant impact on business outcomes. In the pharmaceutical sector, a leading global manufacturer implemented FTIR spectroscopy for real-time monitoring of active pharmaceutical ingredient (API) synthesis, resulting in a 35% reduction in batch rejection rates and saving approximately $4.2 million annually through improved quality control processes.

The petrochemical industry presents another compelling case study where a major refinery integrated FTIR systems into their production line for continuous monitoring of fuel composition. This implementation enabled the detection of contaminants at concentrations as low as 0.01%, significantly enhancing product quality while ensuring regulatory compliance. The system paid for itself within 14 months through reduced quality incidents and associated liability costs.

In food and beverage manufacturing, a multinational corporation deployed FTIR technology for authentication of premium ingredients. The system successfully identified adulterated raw materials in 99.7% of test cases, protecting brand integrity and preventing potential product recalls. The economic impact included not only direct savings of approximately $2.8 million per year but also immeasurable brand value preservation.

Environmental monitoring represents another successful application domain. A municipal water treatment facility implemented FTIR-based continuous monitoring systems to detect trace contaminants in water supplies. The early warning capability prevented three potential contamination events within the first year of operation, protecting public health and avoiding regulatory penalties estimated at $7.5 million.

The automotive industry has leveraged FTIR for quality control in polymer and composite manufacturing. A tier-one supplier implemented inline FTIR scanning for real-time analysis of material composition, reducing defect rates by 28% and decreasing material waste by 17%. The ROI calculation showed complete cost recovery within 22 months of implementation.

These case studies collectively demonstrate that successful FTIR implementation typically requires industry-specific customization, integration with existing workflows, and appropriate staff training. Organizations that achieved the greatest ROI combined FTIR technology with advanced data analytics platforms, enabling not just detection capabilities but predictive insights that transformed operational decision-making processes across their value chains.

The petrochemical industry presents another compelling case study where a major refinery integrated FTIR systems into their production line for continuous monitoring of fuel composition. This implementation enabled the detection of contaminants at concentrations as low as 0.01%, significantly enhancing product quality while ensuring regulatory compliance. The system paid for itself within 14 months through reduced quality incidents and associated liability costs.

In food and beverage manufacturing, a multinational corporation deployed FTIR technology for authentication of premium ingredients. The system successfully identified adulterated raw materials in 99.7% of test cases, protecting brand integrity and preventing potential product recalls. The economic impact included not only direct savings of approximately $2.8 million per year but also immeasurable brand value preservation.

Environmental monitoring represents another successful application domain. A municipal water treatment facility implemented FTIR-based continuous monitoring systems to detect trace contaminants in water supplies. The early warning capability prevented three potential contamination events within the first year of operation, protecting public health and avoiding regulatory penalties estimated at $7.5 million.

The automotive industry has leveraged FTIR for quality control in polymer and composite manufacturing. A tier-one supplier implemented inline FTIR scanning for real-time analysis of material composition, reducing defect rates by 28% and decreasing material waste by 17%. The ROI calculation showed complete cost recovery within 22 months of implementation.

These case studies collectively demonstrate that successful FTIR implementation typically requires industry-specific customization, integration with existing workflows, and appropriate staff training. Organizations that achieved the greatest ROI combined FTIR technology with advanced data analytics platforms, enabling not just detection capabilities but predictive insights that transformed operational decision-making processes across their value chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!