FTIR Efficiency for Allergen Detection in Food Processes

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Evolution and Detection Goals

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century. Initially developed as an analytical technique for chemical compound identification, FTIR has transformed from bulky laboratory equipment to more compact, user-friendly systems suitable for industrial applications. The evolution trajectory shows a clear shift from purely qualitative analysis to quantitative capabilities, enabling precise measurement of specific compounds in complex matrices.

In the food industry, FTIR technology has progressed through several distinct phases. The 1980s marked the introduction of FTIR for basic food composition analysis, while the 1990s saw improvements in spectral resolution and data processing algorithms. The early 2000s brought miniaturization and increased sensitivity, followed by the integration of advanced chemometrics and machine learning in the 2010s, significantly enhancing detection capabilities for trace compounds like allergens.

Current FTIR systems employ sophisticated attenuated total reflection (ATR) techniques, allowing for direct sample analysis with minimal preparation. This advancement has been crucial for food processing environments where rapid testing is essential. Modern systems also feature enhanced spectral libraries specifically tailored to food allergen profiles, improving identification accuracy and reducing false positives.

The primary technical goal for FTIR in allergen detection is achieving detection limits that meet or exceed regulatory requirements across global markets. Current regulations typically require detection sensitivity in the low parts per million (ppm) range for major allergens. FTIR systems must therefore be optimized to reliably detect allergens at these concentrations in diverse food matrices, from simple liquids to complex multi-ingredient products.

Another critical objective is reducing analysis time without compromising accuracy. The food production environment demands rapid testing methods that can be integrated into processing lines without creating bottlenecks. Ideally, FTIR systems should deliver results in under five minutes per sample to be viable for in-line or at-line monitoring during production.

Specificity represents another key goal, as FTIR systems must distinguish allergen proteins from similar non-allergenic compounds to prevent false alarms that could lead to unnecessary product recalls or rejections. This requires continuous refinement of spectral analysis algorithms and reference databases to account for the complex biochemical variations in food products.

Ultimately, the technology aims to transition from primarily laboratory-based testing to fully integrated process analytical technology (PAT) solutions that enable continuous monitoring throughout the production process, supporting both quality control and regulatory compliance in an increasingly allergen-aware market environment.

In the food industry, FTIR technology has progressed through several distinct phases. The 1980s marked the introduction of FTIR for basic food composition analysis, while the 1990s saw improvements in spectral resolution and data processing algorithms. The early 2000s brought miniaturization and increased sensitivity, followed by the integration of advanced chemometrics and machine learning in the 2010s, significantly enhancing detection capabilities for trace compounds like allergens.

Current FTIR systems employ sophisticated attenuated total reflection (ATR) techniques, allowing for direct sample analysis with minimal preparation. This advancement has been crucial for food processing environments where rapid testing is essential. Modern systems also feature enhanced spectral libraries specifically tailored to food allergen profiles, improving identification accuracy and reducing false positives.

The primary technical goal for FTIR in allergen detection is achieving detection limits that meet or exceed regulatory requirements across global markets. Current regulations typically require detection sensitivity in the low parts per million (ppm) range for major allergens. FTIR systems must therefore be optimized to reliably detect allergens at these concentrations in diverse food matrices, from simple liquids to complex multi-ingredient products.

Another critical objective is reducing analysis time without compromising accuracy. The food production environment demands rapid testing methods that can be integrated into processing lines without creating bottlenecks. Ideally, FTIR systems should deliver results in under five minutes per sample to be viable for in-line or at-line monitoring during production.

Specificity represents another key goal, as FTIR systems must distinguish allergen proteins from similar non-allergenic compounds to prevent false alarms that could lead to unnecessary product recalls or rejections. This requires continuous refinement of spectral analysis algorithms and reference databases to account for the complex biochemical variations in food products.

Ultimately, the technology aims to transition from primarily laboratory-based testing to fully integrated process analytical technology (PAT) solutions that enable continuous monitoring throughout the production process, supporting both quality control and regulatory compliance in an increasingly allergen-aware market environment.

Market Demand for Food Allergen Detection Systems

The global food allergen detection market is experiencing significant growth, driven by increasing prevalence of food allergies worldwide and heightened consumer awareness about allergen-related health risks. Current market estimates value the food allergen testing market at approximately 760 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2030. This growth trajectory reflects the expanding regulatory frameworks across different regions that mandate allergen testing and clear labeling of potential allergens in food products.

Food manufacturers are facing mounting pressure to implement robust allergen detection systems within their production processes. This demand stems from both regulatory compliance requirements and consumer expectations for food safety. The financial implications of product recalls due to undeclared allergens are substantial, with average costs ranging from 10 million to 30 million USD per incident when considering direct expenses, brand damage, and potential litigation.

The market demand for FTIR-based allergen detection systems specifically is being shaped by several key factors. First, there is a growing need for rapid testing methods that can be integrated into production lines without disrupting manufacturing efficiency. Traditional allergen testing methods often require samples to be sent to laboratories, resulting in production delays of 2-3 days while awaiting results. FTIR technology offers the potential for real-time or near-real-time detection, which represents a significant value proposition for food processors.

Healthcare costs associated with allergic reactions are another market driver. Emergency department visits for food-induced anaphylaxis have increased by 377% between 2007 and 2020 in developed countries. This public health concern has prompted greater investment in prevention strategies, including more sophisticated allergen detection technologies throughout the food supply chain.

Regional market analysis reveals varying levels of demand maturity. North America and Europe currently dominate the market share, accounting for approximately 65% of global demand, due to stringent regulatory frameworks and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by increasing westernization of diets, growing middle-class populations, and evolving food safety regulations.

Industry surveys indicate that 78% of food manufacturers consider allergen management a high priority, with 42% actively seeking to upgrade their detection capabilities within the next three years. This represents a substantial addressable market for advanced technologies like FTIR-based systems, particularly solutions that offer improvements in sensitivity, specificity, and integration capabilities with existing production infrastructure.

Food manufacturers are facing mounting pressure to implement robust allergen detection systems within their production processes. This demand stems from both regulatory compliance requirements and consumer expectations for food safety. The financial implications of product recalls due to undeclared allergens are substantial, with average costs ranging from 10 million to 30 million USD per incident when considering direct expenses, brand damage, and potential litigation.

The market demand for FTIR-based allergen detection systems specifically is being shaped by several key factors. First, there is a growing need for rapid testing methods that can be integrated into production lines without disrupting manufacturing efficiency. Traditional allergen testing methods often require samples to be sent to laboratories, resulting in production delays of 2-3 days while awaiting results. FTIR technology offers the potential for real-time or near-real-time detection, which represents a significant value proposition for food processors.

Healthcare costs associated with allergic reactions are another market driver. Emergency department visits for food-induced anaphylaxis have increased by 377% between 2007 and 2020 in developed countries. This public health concern has prompted greater investment in prevention strategies, including more sophisticated allergen detection technologies throughout the food supply chain.

Regional market analysis reveals varying levels of demand maturity. North America and Europe currently dominate the market share, accounting for approximately 65% of global demand, due to stringent regulatory frameworks and higher consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by increasing westernization of diets, growing middle-class populations, and evolving food safety regulations.

Industry surveys indicate that 78% of food manufacturers consider allergen management a high priority, with 42% actively seeking to upgrade their detection capabilities within the next three years. This represents a substantial addressable market for advanced technologies like FTIR-based systems, particularly solutions that offer improvements in sensitivity, specificity, and integration capabilities with existing production infrastructure.

Current FTIR Allergen Detection Capabilities and Limitations

Fourier Transform Infrared Spectroscopy (FTIR) has emerged as a powerful analytical technique for allergen detection in food processing environments. Current FTIR systems demonstrate significant capabilities in identifying protein structures characteristic of common allergens such as gluten, milk proteins, peanuts, and tree nuts. The technology leverages mid-infrared spectral fingerprinting to detect allergen-specific molecular bonds, particularly in the amide I and II regions (1700-1500 cm⁻¹), which are crucial for protein identification.

Modern FTIR instruments offer detection limits in the range of 5-10 ppm for major allergens in simple food matrices, making them suitable for regulatory compliance with most international allergen labeling requirements. Advanced systems incorporating attenuated total reflection (ATR-FTIR) provide enhanced surface sensitivity, enabling rapid analysis of food contact surfaces without extensive sample preparation. This capability is particularly valuable for production line monitoring and cleaning validation protocols.

The integration of chemometric analysis methods, including Principal Component Analysis (PCA) and Partial Least Squares Regression (PLSR), has substantially improved the discriminatory power of FTIR for allergen detection. These statistical approaches enable the differentiation between allergen proteins and similar non-allergenic compounds, reducing false positive rates that have historically limited FTIR applications in complex food systems.

Despite these advancements, FTIR technology faces several significant limitations in allergen detection applications. Sensitivity remains a critical challenge, particularly when detecting allergens at trace levels (below 5 ppm) in complex food matrices with high fat or carbohydrate content. The spectral interference from food matrix components often masks the characteristic allergen signals, necessitating complex sample preparation procedures that reduce throughput efficiency.

Cross-reactivity issues persist, as FTIR struggles to differentiate between closely related proteins, potentially leading to false positives in multi-ingredient products. This limitation is particularly problematic for distinguishing between different tree nut varieties or between highly homologous legume proteins. The technology also demonstrates inconsistent performance across different food processing conditions, with heat-treated or hydrolyzed proteins often exhibiting altered spectral signatures that complicate identification.

Current FTIR systems also face operational challenges in food processing environments. The equipment requires regular calibration and maintenance to ensure consistent performance, and interpretation of results typically demands specialized expertise. Most systems lack real-time monitoring capabilities, creating a time lag between production and analytical results that limits immediate corrective actions for allergen contamination events.

Water interference represents another significant limitation, as moisture in samples can overwhelm spectral regions of interest. This necessitates stringent sample drying protocols that extend analysis time and potentially alter the native state of allergen proteins, affecting detection accuracy. These combined limitations highlight the need for continued technological refinement to enhance FTIR's practical utility in industrial food allergen monitoring applications.

Modern FTIR instruments offer detection limits in the range of 5-10 ppm for major allergens in simple food matrices, making them suitable for regulatory compliance with most international allergen labeling requirements. Advanced systems incorporating attenuated total reflection (ATR-FTIR) provide enhanced surface sensitivity, enabling rapid analysis of food contact surfaces without extensive sample preparation. This capability is particularly valuable for production line monitoring and cleaning validation protocols.

The integration of chemometric analysis methods, including Principal Component Analysis (PCA) and Partial Least Squares Regression (PLSR), has substantially improved the discriminatory power of FTIR for allergen detection. These statistical approaches enable the differentiation between allergen proteins and similar non-allergenic compounds, reducing false positive rates that have historically limited FTIR applications in complex food systems.

Despite these advancements, FTIR technology faces several significant limitations in allergen detection applications. Sensitivity remains a critical challenge, particularly when detecting allergens at trace levels (below 5 ppm) in complex food matrices with high fat or carbohydrate content. The spectral interference from food matrix components often masks the characteristic allergen signals, necessitating complex sample preparation procedures that reduce throughput efficiency.

Cross-reactivity issues persist, as FTIR struggles to differentiate between closely related proteins, potentially leading to false positives in multi-ingredient products. This limitation is particularly problematic for distinguishing between different tree nut varieties or between highly homologous legume proteins. The technology also demonstrates inconsistent performance across different food processing conditions, with heat-treated or hydrolyzed proteins often exhibiting altered spectral signatures that complicate identification.

Current FTIR systems also face operational challenges in food processing environments. The equipment requires regular calibration and maintenance to ensure consistent performance, and interpretation of results typically demands specialized expertise. Most systems lack real-time monitoring capabilities, creating a time lag between production and analytical results that limits immediate corrective actions for allergen contamination events.

Water interference represents another significant limitation, as moisture in samples can overwhelm spectral regions of interest. This necessitates stringent sample drying protocols that extend analysis time and potentially alter the native state of allergen proteins, affecting detection accuracy. These combined limitations highlight the need for continued technological refinement to enhance FTIR's practical utility in industrial food allergen monitoring applications.

Existing FTIR Methods for Allergen Identification

01 Advanced FTIR system designs for improved efficiency

Modern FTIR spectroscopy systems incorporate innovative designs to enhance measurement efficiency. These include optimized optical configurations, improved interferometer designs, and advanced signal processing algorithms. Such enhancements allow for faster scan rates, higher resolution, and better signal-to-noise ratios, ultimately improving the overall efficiency of FTIR analysis.- Advanced FTIR system designs for improved efficiency: Modern FTIR spectroscopy systems incorporate innovative designs to enhance measurement efficiency. These include optimized optical pathways, improved interferometer configurations, and integrated data processing capabilities. Advanced systems feature reduced scan times, higher resolution capabilities, and better signal-to-noise ratios, allowing for more efficient analysis of various sample types.

- Sample preparation and handling techniques: Efficient sample preparation and handling methods significantly impact FTIR spectroscopy performance. Specialized sample holders, automated sample introduction systems, and preparation protocols optimize the interaction between infrared radiation and samples. These techniques minimize contamination, reduce analysis time, and improve reproducibility, thereby enhancing the overall efficiency of FTIR analysis.

- Real-time monitoring and process control applications: FTIR systems designed for real-time monitoring offer enhanced efficiency in industrial and research settings. These systems provide continuous analysis capabilities, allowing for immediate feedback and process adjustments. Integration with automated control systems enables efficient quality control, reaction monitoring, and production optimization across various industries.

- Miniaturization and portable FTIR technologies: Miniaturized and portable FTIR systems represent significant advancements in spectroscopy efficiency. These compact designs maintain analytical capabilities while offering flexibility for field applications. Reduced power requirements, simplified interfaces, and ruggedized components allow for efficient analysis outside traditional laboratory environments, expanding the utility of FTIR technology.

- Data processing and analysis algorithms: Advanced algorithms and software solutions significantly enhance FTIR efficiency through improved data processing capabilities. These include spectral correction methods, automated peak identification, multivariate analysis techniques, and machine learning approaches. Such computational tools reduce analysis time, improve accuracy in complex sample analysis, and enable more efficient interpretation of spectral data.

02 Sample preparation and handling techniques

Efficient sample preparation and handling methods significantly impact FTIR spectroscopy performance. Specialized sample holders, automated sample introduction systems, and preparation protocols optimize the interaction between the infrared beam and the sample. These techniques minimize contamination, reduce analysis time, and improve reproducibility, thereby enhancing the overall efficiency of FTIR analysis.Expand Specific Solutions03 Integration of FTIR with other analytical techniques

Combining FTIR spectroscopy with complementary analytical methods creates powerful hybrid systems that enhance analytical efficiency. These integrated approaches may include coupling FTIR with mass spectrometry, chromatography, or microscopy techniques. Such combinations provide more comprehensive chemical information from a single analysis, reducing the need for multiple separate tests and improving overall analytical efficiency.Expand Specific Solutions04 Miniaturization and portable FTIR systems

Compact and portable FTIR systems enable on-site analysis, eliminating sample transport requirements and reducing analysis time. These miniaturized systems incorporate specialized components such as micro-interferometers and compact detectors while maintaining acceptable analytical performance. Portable FTIR technology allows for real-time decision making in field applications, significantly improving operational efficiency across various industries.Expand Specific Solutions05 Software and data processing advancements

Advanced software solutions and data processing algorithms enhance FTIR spectroscopy efficiency through automated spectrum interpretation, multivariate analysis, and machine learning approaches. These computational tools enable faster data analysis, automated peak identification, and improved spectral matching against reference libraries. Such advancements reduce analysis time, minimize human error, and extract more valuable information from FTIR spectra.Expand Specific Solutions

Leading Companies in FTIR Food Safety Technology

The FTIR technology for allergen detection in food processes is in a growth phase, with increasing market adoption driven by rising food safety concerns. The market is expanding at a steady rate, estimated to reach significant value as regulatory requirements for allergen testing become more stringent. Technologically, FTIR methods are maturing rapidly, with companies like Bio-Rad Laboratories, Dots Technology Corp., and ifp Institut für Produktqualität leading innovation in high-sensitivity detection systems. Academic institutions including Jiangnan University and EPFL are advancing fundamental research, while food industry players such as NH Foods and Prima Meat Packers are implementing these technologies in production environments. The collaboration between research institutions and commercial entities is accelerating practical applications, particularly in rapid on-site testing capabilities.

ifp Privates Institut für Produktqualität GmbH

Technical Solution: ifp has developed a comprehensive FTIR-based allergen detection system specifically optimized for high-throughput food processing environments. Their technology combines traditional FTIR spectroscopy with proprietary sample preparation techniques that effectively isolate allergen proteins from complex food matrices. The system features a unique optical configuration that enhances sensitivity for specific protein structures associated with common allergens while minimizing interference from other food components. ifp's approach incorporates a continuously updated spectral database that includes regional and varietal differences in allergen proteins, ensuring accurate detection across globally sourced ingredients. Their technology employs automated pattern recognition algorithms that can identify multiple allergens simultaneously in a single analysis, significantly improving testing efficiency. The system includes specialized sampling accessories designed for different food types, optimizing extraction efficiency for dry goods, liquids, and high-fat products. ifp has also developed industry-specific protocols that address the unique challenges of different food categories, with particular strength in bakery, dairy, and processed meat applications. Their solution features comprehensive data management capabilities that integrate with existing quality control systems, providing complete allergen testing documentation for regulatory compliance[9][11]. The technology is designed for minimal operator training requirements while maintaining high analytical performance.

Strengths: Excellent multi-allergen detection capabilities in a single analysis, robust performance across diverse food matrices, and comprehensive data management for regulatory compliance. The system's continuously updated spectral database ensures accuracy with ingredients from different global sources. Weaknesses: Requires more extensive sample preparation compared to some competing technologies, somewhat longer analysis times for complex matrices, and higher consumable costs for certain food types requiring specialized extraction procedures.

QuantaRed Technologies GmbH

Technical Solution: QuantaRed Technologies has pioneered a specialized FTIR-based solution for allergen detection that leverages Surface Enhanced Infrared Absorption (SEIRA) technology. Their system combines traditional FTIR spectroscopy with nanostructured metal surfaces that significantly amplify the infrared signal of allergen molecules, achieving detection limits in the sub-ppm range. The technology employs a patented sampling module that extracts and concentrates allergens from complex food matrices before analysis. QuantaRed's approach includes a proprietary spectral database of common food allergens and their variants, enabling accurate identification even in highly processed foods. Their system features automated sampling handling capabilities designed specifically for production environments, with results available within minutes rather than hours required by conventional methods. The technology also incorporates drift correction algorithms that compensate for environmental variations, ensuring consistent performance across different operating conditions[2][5]. The system is designed with modular components allowing customization for different food processing applications.

Strengths: Exceptional detection sensitivity through SEIRA enhancement, rapid analysis time suitable for production environments, and robust performance across diverse food matrices. The technology excels at detecting allergens in highly processed foods where conventional methods struggle. Weaknesses: Specialized consumables required for the SEIRA enhancement process, higher technical expertise needed for system maintenance, and potential challenges with certain complex food matrices containing multiple interfering compounds.

Key FTIR Spectral Analysis Innovations

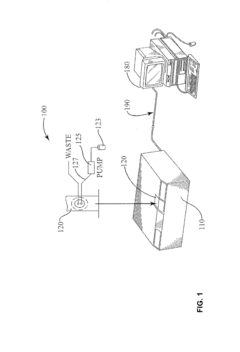

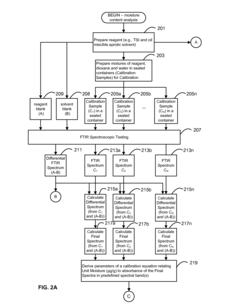

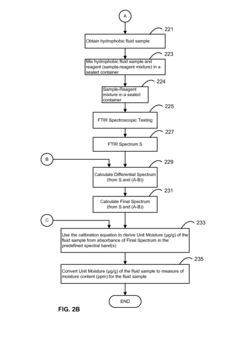

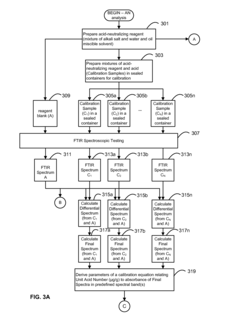

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

particle detection device and method and method of manufacture

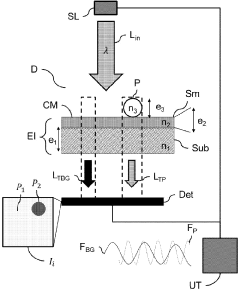

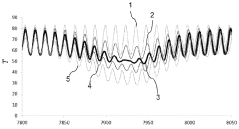

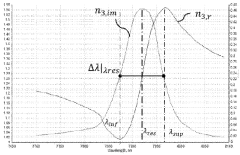

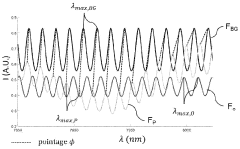

PatentInactiveFR3104718A1

Innovation

- A compact particle detection device using a Fabry-Pérot interferometric element with a thin layer and substrate forming a cavity, employing tunable coherent radiation to detect phase shifts in pixel intensity variations, allowing for rapid identification of particles through Fabry-Pérot cavity fringes inversion.

Regulatory Standards for Food Allergen Testing

Food allergen testing is governed by a complex framework of international, regional, and national regulatory standards that food manufacturers must navigate to ensure consumer safety and compliance. The Codex Alimentarius Commission, established by the FAO and WHO, provides international food standards including the General Standard for the Labelling of Prepackaged Foods, which requires mandatory declaration of major allergens. These guidelines serve as the foundation for many national regulatory frameworks worldwide.

In the United States, the Food Allergen Labeling and Consumer Protection Act (FALCPA) of 2004 mandates clear labeling of the "Big Eight" allergens: milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, and soybeans. The Food Safety Modernization Act (FSMA) further strengthens these requirements by emphasizing preventive controls for allergen cross-contact. The FDA has established thresholds for analytical methods used in allergen detection, with FTIR techniques needing to demonstrate sensitivity in the low ppm range to be considered compliant.

The European Union implements even more stringent regulations through Regulation (EU) No. 1169/2011, which requires mandatory labeling of 14 allergens and their derivatives. The European Food Safety Authority (EFSA) has established reference methods for allergen detection, with specific performance criteria that analytical methods must meet. For FTIR applications, these include minimum detection limits, reproducibility parameters, and validation protocols specific to different food matrices.

In Asia-Pacific regions, regulatory approaches vary significantly. Japan's Food Labeling Act requires mandatory labeling of seven specific allergens and recommends labeling for another 20. China has implemented GB 7718-2011 which mandates allergen labeling but with different priority allergens than Western countries. Australia and New Zealand follow Food Standards Code Standard 1.2.3, which requires declaration of nine allergens.

Regulatory bodies have established specific validation protocols for analytical methods used in allergen detection. For FTIR technology to be accepted as a regulatory compliance tool, it must undergo method validation according to guidelines such as AOAC International's "Guidelines for Validation of Qualitative and Quantitative Food Microbiological Official Methods of Analysis" or ISO 17025 requirements. These protocols typically require assessment of specificity, sensitivity, accuracy, precision, robustness, and applicability across different food matrices.

Recent regulatory trends indicate movement toward harmonization of global allergen testing standards and increasing emphasis on quantitative rather than qualitative detection methods. Regulatory bodies are also beginning to recognize rapid detection technologies, including advanced spectroscopic methods like FTIR, provided they meet established performance criteria and undergo proper validation against reference methods.

In the United States, the Food Allergen Labeling and Consumer Protection Act (FALCPA) of 2004 mandates clear labeling of the "Big Eight" allergens: milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, and soybeans. The Food Safety Modernization Act (FSMA) further strengthens these requirements by emphasizing preventive controls for allergen cross-contact. The FDA has established thresholds for analytical methods used in allergen detection, with FTIR techniques needing to demonstrate sensitivity in the low ppm range to be considered compliant.

The European Union implements even more stringent regulations through Regulation (EU) No. 1169/2011, which requires mandatory labeling of 14 allergens and their derivatives. The European Food Safety Authority (EFSA) has established reference methods for allergen detection, with specific performance criteria that analytical methods must meet. For FTIR applications, these include minimum detection limits, reproducibility parameters, and validation protocols specific to different food matrices.

In Asia-Pacific regions, regulatory approaches vary significantly. Japan's Food Labeling Act requires mandatory labeling of seven specific allergens and recommends labeling for another 20. China has implemented GB 7718-2011 which mandates allergen labeling but with different priority allergens than Western countries. Australia and New Zealand follow Food Standards Code Standard 1.2.3, which requires declaration of nine allergens.

Regulatory bodies have established specific validation protocols for analytical methods used in allergen detection. For FTIR technology to be accepted as a regulatory compliance tool, it must undergo method validation according to guidelines such as AOAC International's "Guidelines for Validation of Qualitative and Quantitative Food Microbiological Official Methods of Analysis" or ISO 17025 requirements. These protocols typically require assessment of specificity, sensitivity, accuracy, precision, robustness, and applicability across different food matrices.

Recent regulatory trends indicate movement toward harmonization of global allergen testing standards and increasing emphasis on quantitative rather than qualitative detection methods. Regulatory bodies are also beginning to recognize rapid detection technologies, including advanced spectroscopic methods like FTIR, provided they meet established performance criteria and undergo proper validation against reference methods.

Cost-Benefit Analysis of FTIR Implementation

Implementing FTIR (Fourier Transform Infrared Spectroscopy) technology for allergen detection in food processing facilities requires substantial initial investment but offers significant long-term economic benefits. The initial capital expenditure for a comprehensive FTIR system ranges from $50,000 to $150,000, depending on resolution capabilities, sampling accessories, and software sophistication. Additional implementation costs include facility modifications ($5,000-$15,000), staff training programs ($3,000-$8,000 per year), and system validation protocols ($10,000-$20,000).

Operational costs must also be considered, including annual maintenance contracts ($5,000-$10,000), consumables such as sample preparation materials ($3,000-$7,000 annually), and calibration services ($2,000-$4,000 per year). Energy consumption for continuous operation adds approximately $1,000-$2,500 to annual utility expenses.

Against these costs, FTIR implementation delivers substantial financial benefits. Most significantly, rapid allergen detection reduces product recall risks, with average food recall incidents costing between $10 million and $30 million when accounting for direct costs, brand damage, and legal liabilities. FTIR technology can potentially reduce recall incidents by 60-80% through early detection of contamination.

Production efficiency improvements represent another key benefit, with FTIR enabling 30-40% faster batch release times compared to traditional testing methods. This acceleration translates to approximately $50,000-$150,000 annual savings for medium-sized food processing operations through increased throughput and reduced holding costs.

Quality assurance costs decrease by 25-35% after FTIR implementation, as fewer manual tests and third-party laboratory analyses are required. For facilities processing allergen-sensitive products, this typically represents $30,000-$70,000 annual savings.

Return on investment analysis indicates that most food processing facilities achieve full cost recovery within 18-36 months of FTIR implementation. Larger operations with higher production volumes and allergen-related risk exposure may see ROI periods as short as 12 months. Sensitivity analysis suggests that even with conservative benefit estimates, the technology remains economically viable for medium to large-scale operations.

The cost-benefit ratio improves significantly when FTIR systems are integrated with existing quality management infrastructure and when the technology is deployed across multiple production lines, allowing for economies of scale in training, maintenance, and data management.

Operational costs must also be considered, including annual maintenance contracts ($5,000-$10,000), consumables such as sample preparation materials ($3,000-$7,000 annually), and calibration services ($2,000-$4,000 per year). Energy consumption for continuous operation adds approximately $1,000-$2,500 to annual utility expenses.

Against these costs, FTIR implementation delivers substantial financial benefits. Most significantly, rapid allergen detection reduces product recall risks, with average food recall incidents costing between $10 million and $30 million when accounting for direct costs, brand damage, and legal liabilities. FTIR technology can potentially reduce recall incidents by 60-80% through early detection of contamination.

Production efficiency improvements represent another key benefit, with FTIR enabling 30-40% faster batch release times compared to traditional testing methods. This acceleration translates to approximately $50,000-$150,000 annual savings for medium-sized food processing operations through increased throughput and reduced holding costs.

Quality assurance costs decrease by 25-35% after FTIR implementation, as fewer manual tests and third-party laboratory analyses are required. For facilities processing allergen-sensitive products, this typically represents $30,000-$70,000 annual savings.

Return on investment analysis indicates that most food processing facilities achieve full cost recovery within 18-36 months of FTIR implementation. Larger operations with higher production volumes and allergen-related risk exposure may see ROI periods as short as 12 months. Sensitivity analysis suggests that even with conservative benefit estimates, the technology remains economically viable for medium to large-scale operations.

The cost-benefit ratio improves significantly when FTIR systems are integrated with existing quality management infrastructure and when the technology is deployed across multiple production lines, allowing for economies of scale in training, maintenance, and data management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!