Compare FTIR vs Raman for Biomass Conversion Efficacy

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spectroscopic Analysis Background and Objectives

Spectroscopic analysis techniques have evolved significantly over the past decades, becoming indispensable tools for characterizing and monitoring biomass conversion processes. Fourier Transform Infrared (FTIR) spectroscopy and Raman spectroscopy represent two complementary yet distinct approaches that have gained prominence in biomass research. These techniques enable researchers to probe molecular structures and chemical transformations occurring during biomass conversion, providing critical insights into reaction mechanisms and efficiency parameters.

The historical development of these spectroscopic methods traces back to the mid-20th century, with FTIR becoming commercially viable in the 1960s and Raman experiencing a renaissance in the 1980s with the advent of laser technology. Their application to biomass conversion research has intensified over the past two decades, paralleling the growing interest in renewable energy sources and sustainable chemical production pathways.

Current technological trends indicate a shift toward higher resolution instruments, portable devices for field applications, and integrated systems that combine multiple spectroscopic techniques. The integration of artificial intelligence and machine learning algorithms for spectral data interpretation represents another significant advancement, enabling more accurate and rapid analysis of complex biomass samples.

The primary objective of this technical assessment is to conduct a comprehensive comparison between FTIR and Raman spectroscopic techniques specifically for evaluating biomass conversion efficacy. This includes examining their respective capabilities in monitoring structural changes in lignocellulosic materials, tracking reaction kinetics during thermochemical or biochemical conversion processes, and quantifying conversion yields and product distributions.

Additionally, this assessment aims to identify the specific strengths and limitations of each technique across different biomass feedstocks (woody biomass, agricultural residues, energy crops) and conversion pathways (pyrolysis, gasification, enzymatic hydrolysis, fermentation). The evaluation will consider factors such as sample preparation requirements, detection sensitivity, spatial resolution, temporal resolution for real-time monitoring, and compatibility with diverse reaction environments.

Furthermore, this report seeks to establish clear guidelines for selecting the appropriate spectroscopic technique based on specific research questions and industrial applications in the biomass conversion sector. By systematically analyzing the technical capabilities, practical considerations, and emerging innovations in both FTIR and Raman spectroscopy, this assessment will provide valuable insights for researchers, technology developers, and industry stakeholders working toward more efficient and sustainable biomass utilization strategies.

The historical development of these spectroscopic methods traces back to the mid-20th century, with FTIR becoming commercially viable in the 1960s and Raman experiencing a renaissance in the 1980s with the advent of laser technology. Their application to biomass conversion research has intensified over the past two decades, paralleling the growing interest in renewable energy sources and sustainable chemical production pathways.

Current technological trends indicate a shift toward higher resolution instruments, portable devices for field applications, and integrated systems that combine multiple spectroscopic techniques. The integration of artificial intelligence and machine learning algorithms for spectral data interpretation represents another significant advancement, enabling more accurate and rapid analysis of complex biomass samples.

The primary objective of this technical assessment is to conduct a comprehensive comparison between FTIR and Raman spectroscopic techniques specifically for evaluating biomass conversion efficacy. This includes examining their respective capabilities in monitoring structural changes in lignocellulosic materials, tracking reaction kinetics during thermochemical or biochemical conversion processes, and quantifying conversion yields and product distributions.

Additionally, this assessment aims to identify the specific strengths and limitations of each technique across different biomass feedstocks (woody biomass, agricultural residues, energy crops) and conversion pathways (pyrolysis, gasification, enzymatic hydrolysis, fermentation). The evaluation will consider factors such as sample preparation requirements, detection sensitivity, spatial resolution, temporal resolution for real-time monitoring, and compatibility with diverse reaction environments.

Furthermore, this report seeks to establish clear guidelines for selecting the appropriate spectroscopic technique based on specific research questions and industrial applications in the biomass conversion sector. By systematically analyzing the technical capabilities, practical considerations, and emerging innovations in both FTIR and Raman spectroscopy, this assessment will provide valuable insights for researchers, technology developers, and industry stakeholders working toward more efficient and sustainable biomass utilization strategies.

Market Applications in Biomass Conversion Industry

The biomass conversion industry has witnessed significant growth in recent years, driven by increasing environmental concerns and the push towards sustainable energy sources. Within this expanding market, analytical techniques such as FTIR and Raman spectroscopy have found diverse applications across multiple sectors, each offering unique advantages for specific market needs.

In the biofuel production sector, both FTIR and Raman spectroscopy serve critical roles in quality control and process optimization. FTIR has established itself as the preferred method for large-scale industrial biofuel producers due to its cost-effectiveness and ability to rapidly analyze large sample batches. The technique enables manufacturers to monitor feedstock quality and conversion efficiency in real-time, resulting in improved production yields and consistent product quality.

Raman spectroscopy, while less widely implemented in large-scale operations, has carved out a niche in premium biofuel production where detailed molecular characterization is essential. Companies producing aviation biofuels and other high-specification products leverage Raman's superior ability to detect subtle structural changes during conversion processes, justifying its higher implementation costs through enhanced product differentiation.

The agricultural waste management sector represents another significant market application. Here, FTIR dominates due to its robustness in field conditions and lower technical expertise requirements. Agricultural cooperatives and waste management facilities utilize portable FTIR systems to assess biomass composition before processing, optimizing resource allocation and increasing operational efficiency.

In the emerging biorefinery market, where multiple value-added products are derived from biomass, the complementary use of both techniques has become standard practice. Biorefineries employ FTIR for high-throughput screening and process monitoring, while Raman spectroscopy is utilized for detailed characterization of high-value components and products. This dual-technique approach has been adopted by leading biorefinery operators to maximize both process efficiency and product quality.

The pharmaceutical and nutraceutical industries have also embraced these spectroscopic methods for biomass-derived compounds. Raman spectroscopy holds a competitive edge in this sector due to its non-destructive nature and superior ability to identify specific bioactive compounds. Pharmaceutical companies developing plant-based medicines particularly value Raman's capacity to verify molecular structures without sample preparation, streamlining quality control processes.

Regional market differences are notable, with North American and European industries favoring integrated systems that combine both techniques, while developing markets in Asia and Africa typically begin with FTIR systems due to lower initial investment requirements and gradually incorporate Raman capabilities as operations scale up and diversify.

In the biofuel production sector, both FTIR and Raman spectroscopy serve critical roles in quality control and process optimization. FTIR has established itself as the preferred method for large-scale industrial biofuel producers due to its cost-effectiveness and ability to rapidly analyze large sample batches. The technique enables manufacturers to monitor feedstock quality and conversion efficiency in real-time, resulting in improved production yields and consistent product quality.

Raman spectroscopy, while less widely implemented in large-scale operations, has carved out a niche in premium biofuel production where detailed molecular characterization is essential. Companies producing aviation biofuels and other high-specification products leverage Raman's superior ability to detect subtle structural changes during conversion processes, justifying its higher implementation costs through enhanced product differentiation.

The agricultural waste management sector represents another significant market application. Here, FTIR dominates due to its robustness in field conditions and lower technical expertise requirements. Agricultural cooperatives and waste management facilities utilize portable FTIR systems to assess biomass composition before processing, optimizing resource allocation and increasing operational efficiency.

In the emerging biorefinery market, where multiple value-added products are derived from biomass, the complementary use of both techniques has become standard practice. Biorefineries employ FTIR for high-throughput screening and process monitoring, while Raman spectroscopy is utilized for detailed characterization of high-value components and products. This dual-technique approach has been adopted by leading biorefinery operators to maximize both process efficiency and product quality.

The pharmaceutical and nutraceutical industries have also embraced these spectroscopic methods for biomass-derived compounds. Raman spectroscopy holds a competitive edge in this sector due to its non-destructive nature and superior ability to identify specific bioactive compounds. Pharmaceutical companies developing plant-based medicines particularly value Raman's capacity to verify molecular structures without sample preparation, streamlining quality control processes.

Regional market differences are notable, with North American and European industries favoring integrated systems that combine both techniques, while developing markets in Asia and Africa typically begin with FTIR systems due to lower initial investment requirements and gradually incorporate Raman capabilities as operations scale up and diversify.

Current Capabilities and Limitations of FTIR vs Raman

Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy represent two complementary analytical techniques widely employed in biomass conversion research. FTIR excels in detecting polar bonds and functional groups through infrared absorption, making it particularly effective for identifying oxygen-containing compounds prevalent in biomass. The technique offers high sensitivity for hydroxyl, carbonyl, and carboxylic acid groups, which are crucial markers during biomass degradation processes.

FTIR systems generally provide faster acquisition times compared to Raman, with typical scans completed in seconds to minutes. This rapid data collection capability makes FTIR advantageous for high-throughput screening applications and real-time monitoring of biomass conversion reactions. Additionally, FTIR equipment tends to be more affordable and widely available in research laboratories, with benchtop systems starting at approximately $20,000-30,000, compared to Raman systems that typically begin at $50,000.

However, FTIR faces significant limitations in aqueous environments due to strong water absorption bands that can obscure important spectral features. This presents a considerable challenge for monitoring biomass conversion processes that often occur in aqueous media. Sample preparation for FTIR can also be more complex, frequently requiring drying, grinding, and pellet formation with KBr, which may alter the native state of biomass samples.

Raman spectroscopy, conversely, offers distinct advantages for biomass analysis through its sensitivity to symmetric, non-polar bonds and aromatic structures. This makes it particularly valuable for characterizing lignin components and crystalline cellulose regions in biomass. Unlike FTIR, Raman spectroscopy performs exceptionally well in aqueous environments, as water produces minimal spectral interference, enabling in-situ monitoring of biomass conversion reactions.

Modern Raman systems equipped with surface-enhanced Raman spectroscopy (SERS) capabilities can achieve detection limits in the parts-per-billion range, surpassing conventional FTIR sensitivity. Additionally, Raman microscopy provides spatial resolution down to 1 μm, allowing for detailed mapping of chemical composition across heterogeneous biomass samples.

Nevertheless, Raman spectroscopy suffers from inherent limitations including fluorescence interference from lignin and other biomass components, which can overwhelm the Raman signal. The technique also typically requires longer acquisition times, ranging from minutes to hours for comprehensive spectral mapping, limiting its application in rapid screening scenarios. Furthermore, Raman equipment generally demands higher technical expertise for operation and data interpretation compared to FTIR systems.

Recent technological developments have introduced hybrid systems that combine both techniques, allowing researchers to leverage the complementary information provided by each method. These integrated approaches are increasingly valuable for comprehensive characterization of complex biomass conversion processes, though they remain expensive and are primarily available in specialized research facilities.

FTIR systems generally provide faster acquisition times compared to Raman, with typical scans completed in seconds to minutes. This rapid data collection capability makes FTIR advantageous for high-throughput screening applications and real-time monitoring of biomass conversion reactions. Additionally, FTIR equipment tends to be more affordable and widely available in research laboratories, with benchtop systems starting at approximately $20,000-30,000, compared to Raman systems that typically begin at $50,000.

However, FTIR faces significant limitations in aqueous environments due to strong water absorption bands that can obscure important spectral features. This presents a considerable challenge for monitoring biomass conversion processes that often occur in aqueous media. Sample preparation for FTIR can also be more complex, frequently requiring drying, grinding, and pellet formation with KBr, which may alter the native state of biomass samples.

Raman spectroscopy, conversely, offers distinct advantages for biomass analysis through its sensitivity to symmetric, non-polar bonds and aromatic structures. This makes it particularly valuable for characterizing lignin components and crystalline cellulose regions in biomass. Unlike FTIR, Raman spectroscopy performs exceptionally well in aqueous environments, as water produces minimal spectral interference, enabling in-situ monitoring of biomass conversion reactions.

Modern Raman systems equipped with surface-enhanced Raman spectroscopy (SERS) capabilities can achieve detection limits in the parts-per-billion range, surpassing conventional FTIR sensitivity. Additionally, Raman microscopy provides spatial resolution down to 1 μm, allowing for detailed mapping of chemical composition across heterogeneous biomass samples.

Nevertheless, Raman spectroscopy suffers from inherent limitations including fluorescence interference from lignin and other biomass components, which can overwhelm the Raman signal. The technique also typically requires longer acquisition times, ranging from minutes to hours for comprehensive spectral mapping, limiting its application in rapid screening scenarios. Furthermore, Raman equipment generally demands higher technical expertise for operation and data interpretation compared to FTIR systems.

Recent technological developments have introduced hybrid systems that combine both techniques, allowing researchers to leverage the complementary information provided by each method. These integrated approaches are increasingly valuable for comprehensive characterization of complex biomass conversion processes, though they remain expensive and are primarily available in specialized research facilities.

Comparative Analysis of FTIR and Raman Methodologies

01 FTIR and Raman spectroscopy for chemical conversion monitoring

FTIR and Raman spectroscopy techniques can be used to monitor and measure chemical conversion processes in real-time. These spectroscopic methods provide detailed information about molecular structures and chemical bonds, allowing researchers to track reaction progress and conversion efficiency. The techniques can detect subtle changes in chemical composition during conversion processes, making them valuable tools for optimizing reaction conditions and improving conversion efficacy.- FTIR and Raman spectroscopy for conversion efficiency measurement: Both FTIR (Fourier Transform Infrared) and Raman spectroscopy can be used to measure and monitor conversion efficiency in various chemical and physical processes. These spectroscopic techniques provide detailed molecular information about the structural changes occurring during conversion processes, allowing for quantitative assessment of reaction progress and conversion rates. The complementary nature of these techniques enables comprehensive analysis of conversion efficiency across different material types and reaction conditions.

- Real-time monitoring systems using spectroscopic techniques: Advanced systems have been developed that incorporate FTIR and Raman spectroscopy for real-time monitoring of conversion processes. These systems allow for continuous data collection during reactions or transformations, enabling immediate feedback on conversion efficiency. Real-time monitoring facilitates process optimization by identifying reaction endpoints, detecting intermediates, and allowing for adjustments to reaction parameters to maximize conversion efficiency. These systems often include specialized sampling interfaces and data processing algorithms for rapid analysis.

- Multivariate analysis methods for spectroscopic data interpretation: Multivariate analysis techniques are applied to FTIR and Raman spectroscopic data to enhance the accuracy of conversion efficiency measurements. These statistical methods, including principal component analysis, partial least squares regression, and cluster analysis, help extract meaningful information from complex spectral datasets. By correlating spectral features with conversion parameters, these analytical approaches improve the precision of conversion efficiency determinations and enable the identification of subtle changes in molecular structure during conversion processes.

- Combined spectroscopic approaches for enhanced accuracy: Combining multiple spectroscopic techniques, particularly FTIR and Raman, provides complementary information that enhances the accuracy of conversion efficiency measurements. While FTIR is sensitive to polar bond vibrations and functional group changes, Raman spectroscopy excels at detecting symmetric vibrations and non-polar bonds. Using these techniques in tandem allows for more comprehensive characterization of molecular transformations during conversion processes, reducing analytical uncertainties and providing validation through independent measurement methods.

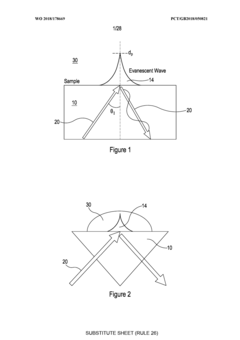

- Specialized sampling techniques for conversion monitoring: Specialized sampling techniques have been developed to optimize the application of FTIR and Raman spectroscopy for conversion efficiency measurements across different material states and reaction environments. These include attenuated total reflectance (ATR) for surface analysis, diffuse reflectance for powdered samples, and fiber-optic probes for remote or in-situ monitoring. Advanced sampling methods enable non-destructive, rapid assessment of conversion processes in challenging environments, including high-temperature reactions, heterogeneous systems, and industrial-scale processes.

02 Quantitative analysis of conversion rates using spectroscopic data

Advanced data analysis methods applied to FTIR and Raman spectroscopic measurements enable quantitative determination of conversion rates and efficacy. By analyzing spectral features and their changes over time, researchers can calculate conversion percentages, reaction kinetics, and process efficiency. These quantitative approaches help in establishing correlations between spectroscopic signals and actual conversion performance, providing reliable metrics for process optimization and quality control.Expand Specific Solutions03 Combined FTIR-Raman systems for enhanced conversion analysis

Integrated systems that combine both FTIR and Raman spectroscopy provide complementary information about conversion processes. While FTIR excels at detecting polar functional groups and certain molecular vibrations, Raman spectroscopy is particularly sensitive to symmetrical bonds and non-polar groups. Using both techniques simultaneously offers a more comprehensive analysis of conversion efficacy, capturing a wider range of chemical changes and providing redundancy in critical measurements.Expand Specific Solutions04 In-situ spectroscopic monitoring for real-time conversion assessment

In-situ implementation of FTIR and Raman spectroscopy allows for real-time monitoring of conversion processes without sampling or process interruption. These techniques can be integrated directly into production lines or reaction vessels to provide continuous feedback on conversion efficacy. Real-time monitoring enables immediate process adjustments to optimize conversion rates, reduce waste, and ensure consistent product quality across production batches.Expand Specific Solutions05 Spectroscopic methods for challenging conversion environments

Specialized FTIR and Raman spectroscopic techniques have been developed for measuring conversion efficacy in challenging environments such as high temperature, high pressure, or highly corrosive conditions. These adapted methods use robust sampling interfaces, remote sensing capabilities, or specialized optical components to maintain measurement accuracy despite harsh conditions. Such innovations extend the applicability of spectroscopic conversion monitoring to industrial processes that were previously difficult to analyze in real-time.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The biomass conversion efficacy analysis using FTIR vs Raman spectroscopy is currently in a growth phase, with the global spectroscopy market expected to reach $20 billion by 2025. While both techniques are mature, their application in biomass conversion is evolving. Leading organizations like Purdue Research Foundation, National Research Council of Canada, and FPInnovations are advancing FTIR applications for cellulose structure analysis, while ChemImage Corp., Boston University, and MIT are developing Raman techniques for real-time monitoring of conversion processes. Academic institutions (Monash, McGill) are combining both technologies to create comprehensive analytical frameworks, indicating a trend toward integrated spectroscopic approaches for optimizing biomass conversion efficiency.

ChemImage Corp.

Technical Solution: ChemImage Corp. has developed advanced Raman imaging systems specifically optimized for biomass conversion analysis. Their technology combines Raman molecular chemical imaging with multivariate analysis to provide detailed spatial and chemical information about biomass samples during conversion processes. Their proprietary systems can simultaneously track multiple components in lignocellulosic biomass (cellulose, hemicellulose, and lignin) during pretreatment and enzymatic hydrolysis stages[1]. ChemImage's technology enables real-time monitoring of structural changes in biomass components, allowing researchers to optimize conversion parameters without destructive sampling. Their systems incorporate chemometric algorithms that can distinguish subtle spectral differences between similar biomass components, providing insights into reaction kinetics and conversion efficiency that would be difficult to obtain with conventional analytical methods[3].

Strengths: Superior spatial resolution allowing visualization of component-specific conversion; non-destructive analysis enabling real-time process monitoring; high chemical specificity for complex biomass matrices. Weaknesses: Higher equipment costs compared to basic FTIR systems; requires more sophisticated data analysis expertise; limited penetration depth in dense biomass samples.

Thermo Scientific Portable Analytical Instruments, Inc.

Technical Solution: Thermo Scientific has pioneered portable FTIR solutions specifically designed for biomass conversion analysis. Their technology features miniaturized FTIR spectrometers with specialized sampling accessories optimized for heterogeneous biomass materials. These systems employ diamond ATR (Attenuated Total Reflectance) technology that allows direct analysis of solid, liquid, and slurry samples without extensive preparation[2]. Their proprietary algorithms can quantify cellulose, hemicellulose, and lignin content in various biomass feedstocks and track conversion efficiency in near real-time. The company has developed specialized calibration models for different biomass types (woody, herbaceous, agricultural residues) that compensate for matrix effects and moisture variations[4]. Their portable systems include automated spectral correction features that minimize interference from water absorption bands, a common challenge in biomass analysis.

Strengths: Excellent for functional group identification in complex biomass matrices; portable solutions enable field and in-process measurements; minimal sample preparation requirements; good sensitivity to hydrogen bonding changes during conversion. Weaknesses: Lower spatial resolution compared to Raman techniques; water interference can still be problematic in high-moisture samples; limited ability to distinguish between similar polysaccharide structures.

Key Technical Innovations in Spectroscopic Biomass Analysis

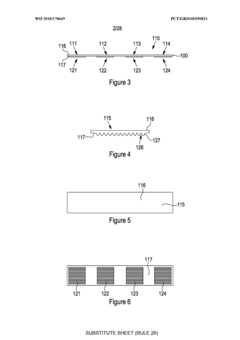

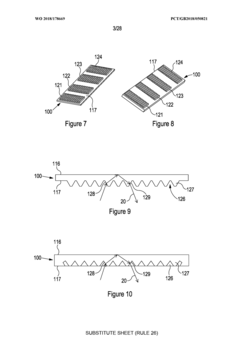

Infra-red spectroscopy system

PatentWO2018178669A2

Innovation

- A sample slide with multiple sample-receiving portions and integrated beam-receiving portions acting as internal reflection elements, allowing for multiple measurements without removing and replacing the slide, and the use of a disposable silicon slide to reduce costs and eliminate cleaning and drying requirements.

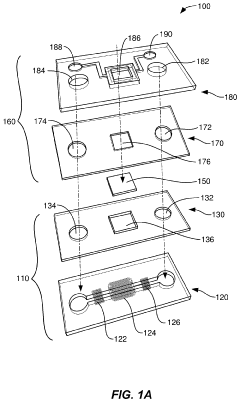

Devices and methods for spectroscopy of biomaterials and live cells

PatentPendingUS20240042438A1

Innovation

- An open-channel microfluidic membrane device is developed, featuring hydraulic resistors, capillary design for humidity control, and vertical interconnects for real-time detection of spatiotemporal changes in hydrogen bond networks using hyperspectral microscopy, allowing for autonomous analysis without tedious post-treatment sample preparation.

Cost-Benefit Analysis of Implementation Strategies

When evaluating the implementation of FTIR versus Raman spectroscopy for biomass conversion efficacy monitoring, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value proposition.

Initial capital expenditure for FTIR systems typically ranges from $30,000 to $100,000, while Raman spectrometers generally command higher prices between $50,000 and $150,000. This price differential reflects the more sophisticated optical components and laser technology required for Raman instrumentation. However, when amortized over the expected 7-10 year lifespan of the equipment, the annual capital cost difference becomes less pronounced.

Operational expenses present another critical dimension for comparison. FTIR systems generally consume less power and require fewer specialized consumables, resulting in approximately 15-20% lower day-to-day running costs compared to Raman systems. Maintenance requirements also favor FTIR, with annual service contracts typically costing 8-12% of the initial investment versus 10-15% for Raman systems.

Sample preparation considerations significantly impact the total cost of analysis. FTIR often requires more extensive sample preparation for biomass materials, potentially adding 2-3 labor hours per batch of samples. Conversely, Raman spectroscopy's ability to analyze samples with minimal preparation can save approximately $5,000-$10,000 annually in labor and consumable costs for facilities processing multiple samples daily.

Training requirements represent another implementation cost factor. FTIR technology, being more established in biomass applications, typically requires 20-30 hours of operator training. Raman systems, with their more complex data interpretation needs, may necessitate 40-60 hours of specialized training, translating to approximately $2,000-$5,000 in additional upfront personnel development costs.

Return on investment calculations indicate that while FTIR presents lower initial barriers to entry, Raman spectroscopy often delivers superior long-term value for biomass conversion monitoring. Organizations processing high sample volumes typically achieve ROI with Raman systems in 3-4 years, compared to 2-3 years for FTIR. However, this calculation shifts dramatically based on specific application requirements and throughput demands.

Scalability considerations further complicate the analysis. FTIR systems generally offer more straightforward expansion pathways with lower incremental costs, while Raman implementations may require more substantial investments when scaling operations. This difference becomes particularly significant for growing biorefinery operations planning phased capacity increases over 5-10 year horizons.

Initial capital expenditure for FTIR systems typically ranges from $30,000 to $100,000, while Raman spectrometers generally command higher prices between $50,000 and $150,000. This price differential reflects the more sophisticated optical components and laser technology required for Raman instrumentation. However, when amortized over the expected 7-10 year lifespan of the equipment, the annual capital cost difference becomes less pronounced.

Operational expenses present another critical dimension for comparison. FTIR systems generally consume less power and require fewer specialized consumables, resulting in approximately 15-20% lower day-to-day running costs compared to Raman systems. Maintenance requirements also favor FTIR, with annual service contracts typically costing 8-12% of the initial investment versus 10-15% for Raman systems.

Sample preparation considerations significantly impact the total cost of analysis. FTIR often requires more extensive sample preparation for biomass materials, potentially adding 2-3 labor hours per batch of samples. Conversely, Raman spectroscopy's ability to analyze samples with minimal preparation can save approximately $5,000-$10,000 annually in labor and consumable costs for facilities processing multiple samples daily.

Training requirements represent another implementation cost factor. FTIR technology, being more established in biomass applications, typically requires 20-30 hours of operator training. Raman systems, with their more complex data interpretation needs, may necessitate 40-60 hours of specialized training, translating to approximately $2,000-$5,000 in additional upfront personnel development costs.

Return on investment calculations indicate that while FTIR presents lower initial barriers to entry, Raman spectroscopy often delivers superior long-term value for biomass conversion monitoring. Organizations processing high sample volumes typically achieve ROI with Raman systems in 3-4 years, compared to 2-3 years for FTIR. However, this calculation shifts dramatically based on specific application requirements and throughput demands.

Scalability considerations further complicate the analysis. FTIR systems generally offer more straightforward expansion pathways with lower incremental costs, while Raman implementations may require more substantial investments when scaling operations. This difference becomes particularly significant for growing biorefinery operations planning phased capacity increases over 5-10 year horizons.

Environmental Impact and Sustainability Considerations

When comparing FTIR and Raman spectroscopy for biomass conversion efficacy, environmental impact and sustainability considerations play a crucial role in determining the most appropriate analytical technique. Both methods offer distinct environmental footprints throughout their lifecycle, from instrument manufacturing to operational requirements and waste generation.

FTIR spectroscopy typically requires sample preparation involving chemical solvents, particularly when analyzing complex biomass materials. These solvents often include environmentally hazardous compounds such as dichloromethane or chloroform, which pose significant disposal challenges and environmental risks. Additionally, traditional FTIR instruments utilize infrared sources that consume substantial energy during operation, contributing to higher carbon footprints compared to newer spectroscopic technologies.

Raman spectroscopy, by contrast, generally requires minimal or no sample preparation for biomass analysis, significantly reducing chemical waste generation. Modern Raman systems employ laser technology that, while energy-intensive during operation, typically consumes less power overall than comparable FTIR setups. The reduced need for consumables in Raman analysis translates to lower material throughput and decreased environmental burden over the instrument's operational lifetime.

From a sustainability perspective, recent advancements in portable and miniaturized versions of both technologies have improved their environmental profiles. Portable Raman devices demonstrate particular promise for field-based biomass conversion monitoring, enabling real-time process optimization that can enhance conversion efficiency and reduce resource waste. These systems require less infrastructure and can operate on renewable energy sources, making them suitable for deployment in remote or developing regions.

Life cycle assessment studies comparing these spectroscopic methods indicate that Raman spectroscopy generally presents a more favorable environmental profile when considering the entire analytical process. The reduced chemical inputs, lower waste generation, and potential for process optimization contribute to smaller ecological footprints. However, the environmental advantage varies depending on specific applications and implementation contexts.

For industrial-scale biomass conversion facilities, the sustainability benefits of selecting the appropriate analytical method extend beyond direct environmental impacts. The precision and reliability of spectroscopic monitoring directly influence process efficiency, potentially reducing energy consumption and improving resource utilization throughout the conversion pathway. In this context, the slightly higher energy demand of Raman instrumentation may be offset by its superior capability to optimize overall process sustainability.

Future developments in both technologies are increasingly focused on improving energy efficiency and reducing environmental impacts. Innovations such as quantum cascade lasers for FTIR and low-power diode lasers for Raman spectroscopy promise to further enhance the sustainability profiles of these analytical approaches for biomass conversion applications.

FTIR spectroscopy typically requires sample preparation involving chemical solvents, particularly when analyzing complex biomass materials. These solvents often include environmentally hazardous compounds such as dichloromethane or chloroform, which pose significant disposal challenges and environmental risks. Additionally, traditional FTIR instruments utilize infrared sources that consume substantial energy during operation, contributing to higher carbon footprints compared to newer spectroscopic technologies.

Raman spectroscopy, by contrast, generally requires minimal or no sample preparation for biomass analysis, significantly reducing chemical waste generation. Modern Raman systems employ laser technology that, while energy-intensive during operation, typically consumes less power overall than comparable FTIR setups. The reduced need for consumables in Raman analysis translates to lower material throughput and decreased environmental burden over the instrument's operational lifetime.

From a sustainability perspective, recent advancements in portable and miniaturized versions of both technologies have improved their environmental profiles. Portable Raman devices demonstrate particular promise for field-based biomass conversion monitoring, enabling real-time process optimization that can enhance conversion efficiency and reduce resource waste. These systems require less infrastructure and can operate on renewable energy sources, making them suitable for deployment in remote or developing regions.

Life cycle assessment studies comparing these spectroscopic methods indicate that Raman spectroscopy generally presents a more favorable environmental profile when considering the entire analytical process. The reduced chemical inputs, lower waste generation, and potential for process optimization contribute to smaller ecological footprints. However, the environmental advantage varies depending on specific applications and implementation contexts.

For industrial-scale biomass conversion facilities, the sustainability benefits of selecting the appropriate analytical method extend beyond direct environmental impacts. The precision and reliability of spectroscopic monitoring directly influence process efficiency, potentially reducing energy consumption and improving resource utilization throughout the conversion pathway. In this context, the slightly higher energy demand of Raman instrumentation may be offset by its superior capability to optimize overall process sustainability.

Future developments in both technologies are increasingly focused on improving energy efficiency and reducing environmental impacts. Innovations such as quantum cascade lasers for FTIR and low-power diode lasers for Raman spectroscopy promise to further enhance the sustainability profiles of these analytical approaches for biomass conversion applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!