FTIR's Role in Recyclable Material Quality Control

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a specialized laboratory technique to an essential tool in various industrial applications. The technology leverages the interaction between infrared radiation and matter to identify molecular structures based on their unique absorption patterns. In the context of recyclable material quality control, FTIR represents a non-destructive analytical method capable of rapidly identifying and quantifying different polymer types and contaminants.

The historical development of FTIR technology has been marked by continuous improvements in instrumentation, data processing capabilities, and application methodologies. Early infrared spectroscopy faced limitations in resolution and speed, but the introduction of Fourier transform mathematics and interferometry in the 1960s revolutionized the field. Modern FTIR systems benefit from miniaturization, increased sensitivity, and advanced computational algorithms, enabling real-time analysis in industrial environments.

Current technological trends in FTIR for recycling applications focus on portability, automation, and integration with artificial intelligence. Handheld FTIR devices now allow for on-site material identification, while inline systems enable continuous monitoring of recycling streams. The integration of machine learning algorithms with spectral databases has significantly enhanced the accuracy of material identification and contaminant detection, even in complex mixed waste streams.

The primary technical objective for FTIR in recyclable material quality control is to achieve rapid, accurate, and cost-effective identification of various polymer types and contaminants in heterogeneous waste streams. This includes distinguishing between different grades of the same polymer family, detecting additives and fillers, and identifying degradation products that might affect recycling processes or end-product quality.

Secondary objectives include developing more robust calibration methods for quantitative analysis, improving spectral libraries to encompass the diversity of commercial plastics and their degradation products, and enhancing data processing algorithms to handle complex mixtures. There is also a growing emphasis on integrating FTIR with other analytical techniques such as Raman spectroscopy and near-infrared spectroscopy to create comprehensive material characterization systems.

The evolution of FTIR technology aligns with broader sustainability goals and circular economy principles, as efficient recycling depends on accurate material identification and sorting. As regulations on recycled content increase globally, the demand for advanced analytical tools like FTIR continues to grow, driving further innovation in this field.

The historical development of FTIR technology has been marked by continuous improvements in instrumentation, data processing capabilities, and application methodologies. Early infrared spectroscopy faced limitations in resolution and speed, but the introduction of Fourier transform mathematics and interferometry in the 1960s revolutionized the field. Modern FTIR systems benefit from miniaturization, increased sensitivity, and advanced computational algorithms, enabling real-time analysis in industrial environments.

Current technological trends in FTIR for recycling applications focus on portability, automation, and integration with artificial intelligence. Handheld FTIR devices now allow for on-site material identification, while inline systems enable continuous monitoring of recycling streams. The integration of machine learning algorithms with spectral databases has significantly enhanced the accuracy of material identification and contaminant detection, even in complex mixed waste streams.

The primary technical objective for FTIR in recyclable material quality control is to achieve rapid, accurate, and cost-effective identification of various polymer types and contaminants in heterogeneous waste streams. This includes distinguishing between different grades of the same polymer family, detecting additives and fillers, and identifying degradation products that might affect recycling processes or end-product quality.

Secondary objectives include developing more robust calibration methods for quantitative analysis, improving spectral libraries to encompass the diversity of commercial plastics and their degradation products, and enhancing data processing algorithms to handle complex mixtures. There is also a growing emphasis on integrating FTIR with other analytical techniques such as Raman spectroscopy and near-infrared spectroscopy to create comprehensive material characterization systems.

The evolution of FTIR technology aligns with broader sustainability goals and circular economy principles, as efficient recycling depends on accurate material identification and sorting. As regulations on recycled content increase globally, the demand for advanced analytical tools like FTIR continues to grow, driving further innovation in this field.

Market Demand for Recycling Quality Control

The global recycling market has witnessed substantial growth in recent years, driven by increasing environmental awareness, regulatory pressures, and corporate sustainability initiatives. The demand for effective quality control in recycling processes has become particularly critical as industries and governments worldwide commit to circular economy principles. Current market estimates value the global waste recycling services market at approximately $55 billion, with projections indicating growth to reach $88 billion by 2030, representing a compound annual growth rate of 5.2%.

Quality control challenges in recycling have intensified as contamination issues continue to plague the industry. Since China's National Sword policy implementation in 2018, which banned the import of most plastic waste, recycling facilities worldwide have been forced to improve their sorting and quality control processes to meet stricter purity standards. This regulatory shift has created an urgent market need for advanced analytical technologies like FTIR spectroscopy that can accurately identify and sort materials.

Consumer packaged goods companies are increasingly adopting recycled content commitments, with many major brands pledging to incorporate 25-50% recycled content in their packaging by 2025. These commitments have created substantial demand for high-quality recycled materials that meet virgin material performance standards, further emphasizing the need for precise quality control technologies.

The food and beverage industry represents a particularly demanding segment, requiring recycled materials free from contaminants and hazardous substances. FTIR technology addresses this need by providing detailed chemical composition analysis that ensures recycled materials meet food-contact safety requirements. Similarly, the automotive and electronics industries require recycled materials with specific performance characteristics that can only be guaranteed through advanced analytical methods.

Municipal recycling programs are also driving market demand for better quality control solutions. Contamination rates in curbside recycling programs typically range from 15-25%, significantly reducing the economic value of collected materials. Municipalities and waste management companies are increasingly investing in technologies that can improve sorting efficiency and material purity to enhance the economic viability of their recycling operations.

The market for recycling quality control technologies is further bolstered by extended producer responsibility (EPR) legislation being adopted across Europe, Canada, and increasingly in the United States. These regulations place the financial responsibility for end-of-life product management on manufacturers, creating direct economic incentives for companies to invest in technologies that improve recycling outcomes and material quality.

Quality control challenges in recycling have intensified as contamination issues continue to plague the industry. Since China's National Sword policy implementation in 2018, which banned the import of most plastic waste, recycling facilities worldwide have been forced to improve their sorting and quality control processes to meet stricter purity standards. This regulatory shift has created an urgent market need for advanced analytical technologies like FTIR spectroscopy that can accurately identify and sort materials.

Consumer packaged goods companies are increasingly adopting recycled content commitments, with many major brands pledging to incorporate 25-50% recycled content in their packaging by 2025. These commitments have created substantial demand for high-quality recycled materials that meet virgin material performance standards, further emphasizing the need for precise quality control technologies.

The food and beverage industry represents a particularly demanding segment, requiring recycled materials free from contaminants and hazardous substances. FTIR technology addresses this need by providing detailed chemical composition analysis that ensures recycled materials meet food-contact safety requirements. Similarly, the automotive and electronics industries require recycled materials with specific performance characteristics that can only be guaranteed through advanced analytical methods.

Municipal recycling programs are also driving market demand for better quality control solutions. Contamination rates in curbside recycling programs typically range from 15-25%, significantly reducing the economic value of collected materials. Municipalities and waste management companies are increasingly investing in technologies that can improve sorting efficiency and material purity to enhance the economic viability of their recycling operations.

The market for recycling quality control technologies is further bolstered by extended producer responsibility (EPR) legislation being adopted across Europe, Canada, and increasingly in the United States. These regulations place the financial responsibility for end-of-life product management on manufacturers, creating direct economic incentives for companies to invest in technologies that improve recycling outcomes and material quality.

Current FTIR Applications and Limitations

Fourier Transform Infrared Spectroscopy (FTIR) has emerged as a powerful analytical tool in recyclable material quality control, offering rapid, non-destructive analysis capabilities. Currently, FTIR is widely deployed across recycling facilities to identify and sort various polymer types, particularly in plastic recycling streams where material identification is crucial for effective recycling.

In industrial applications, FTIR systems are integrated into automated sorting lines where they can analyze thousands of items per hour. These systems typically operate by directing infrared radiation onto material samples and measuring the absorbed wavelengths, creating a unique spectral "fingerprint" that identifies specific polymers. Modern recycling facilities utilize this technology to distinguish between PET, HDPE, PVC, PP, PS, and other common plastics with accuracy rates exceeding 95% under optimal conditions.

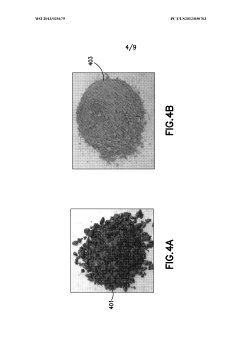

Despite its widespread adoption, FTIR technology faces several significant limitations in recyclable material quality control. Contamination presents a major challenge, as food residues, labels, adhesives, or mixed materials can interfere with spectral readings and reduce identification accuracy. This is particularly problematic in post-consumer waste streams where contamination levels are typically high.

Technical limitations also exist regarding the depth of penetration of infrared radiation, which restricts FTIR analysis primarily to surface characteristics. This creates challenges when analyzing multi-layer materials or items with surface coatings that differ from their core composition. Additionally, black or heavily pigmented materials often absorb too much infrared radiation, resulting in poor spectral quality and reduced identification reliability.

Operational constraints further limit FTIR effectiveness in real-world recycling environments. High-speed conveyor systems may not allow sufficient time for accurate readings, while varying material orientations can affect spectral quality. Environmental factors such as humidity, temperature fluctuations, and dust in recycling facilities can also interfere with measurement accuracy.

Cost considerations remain significant, as high-resolution FTIR systems with advanced data processing capabilities require substantial investment, limiting their adoption in smaller recycling operations. The technology also demands regular calibration and maintenance to maintain accuracy, adding to operational expenses.

Recent advancements have addressed some of these limitations through improved algorithms, machine learning integration, and hybrid sensing approaches that combine FTIR with other technologies like Raman spectroscopy or near-infrared (NIR) systems. These developments have expanded FTIR capabilities to detect additives, contaminants, and degradation markers in recyclable materials, though implementation challenges persist in high-throughput industrial environments.

In industrial applications, FTIR systems are integrated into automated sorting lines where they can analyze thousands of items per hour. These systems typically operate by directing infrared radiation onto material samples and measuring the absorbed wavelengths, creating a unique spectral "fingerprint" that identifies specific polymers. Modern recycling facilities utilize this technology to distinguish between PET, HDPE, PVC, PP, PS, and other common plastics with accuracy rates exceeding 95% under optimal conditions.

Despite its widespread adoption, FTIR technology faces several significant limitations in recyclable material quality control. Contamination presents a major challenge, as food residues, labels, adhesives, or mixed materials can interfere with spectral readings and reduce identification accuracy. This is particularly problematic in post-consumer waste streams where contamination levels are typically high.

Technical limitations also exist regarding the depth of penetration of infrared radiation, which restricts FTIR analysis primarily to surface characteristics. This creates challenges when analyzing multi-layer materials or items with surface coatings that differ from their core composition. Additionally, black or heavily pigmented materials often absorb too much infrared radiation, resulting in poor spectral quality and reduced identification reliability.

Operational constraints further limit FTIR effectiveness in real-world recycling environments. High-speed conveyor systems may not allow sufficient time for accurate readings, while varying material orientations can affect spectral quality. Environmental factors such as humidity, temperature fluctuations, and dust in recycling facilities can also interfere with measurement accuracy.

Cost considerations remain significant, as high-resolution FTIR systems with advanced data processing capabilities require substantial investment, limiting their adoption in smaller recycling operations. The technology also demands regular calibration and maintenance to maintain accuracy, adding to operational expenses.

Recent advancements have addressed some of these limitations through improved algorithms, machine learning integration, and hybrid sensing approaches that combine FTIR with other technologies like Raman spectroscopy or near-infrared (NIR) systems. These developments have expanded FTIR capabilities to detect additives, contaminants, and degradation markers in recyclable materials, though implementation challenges persist in high-throughput industrial environments.

Existing FTIR-based Quality Control Solutions

01 FTIR systems for pharmaceutical quality control

FTIR spectroscopy is widely used in pharmaceutical quality control to analyze and verify the composition, purity, and consistency of drug formulations. These systems can detect impurities, confirm chemical structures, and ensure batch-to-batch consistency. Advanced FTIR systems incorporate automated sampling, data processing algorithms, and compliance with regulatory standards to enhance the efficiency and reliability of pharmaceutical quality control processes.- FTIR systems for pharmaceutical quality control: FTIR spectroscopy is widely used in pharmaceutical quality control to verify the identity, purity, and composition of drug substances and products. These systems can detect impurities, confirm chemical structures, and ensure batch-to-batch consistency. Advanced FTIR systems incorporate automated sampling, data processing algorithms, and compliance with regulatory standards to enhance the efficiency and reliability of pharmaceutical quality control processes.

- Real-time monitoring and process control using FTIR: FTIR spectroscopy enables real-time monitoring of manufacturing processes by providing immediate spectral analysis of materials during production. These systems can be integrated into production lines to continuously monitor product quality, detect deviations from specifications, and automatically adjust process parameters. Real-time FTIR monitoring helps maintain consistent product quality, reduce waste, and improve manufacturing efficiency across various industries.

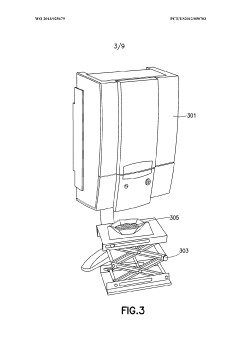

- Portable and handheld FTIR devices for field testing: Portable and handheld FTIR devices allow for quality control testing outside of laboratory settings. These compact instruments enable on-site material verification, counterfeit detection, and quality assurance in field conditions. The devices typically feature simplified interfaces, rugged construction, and battery operation while maintaining sufficient analytical performance for quality control applications. They are particularly valuable for testing in remote locations, incoming material inspection, and rapid decision-making scenarios.

- Automated sampling and data analysis systems for FTIR: Automated FTIR systems incorporate robotic sample handling, advanced data processing algorithms, and machine learning techniques to enhance quality control efficiency. These systems can automatically prepare samples, collect spectra, compare results against reference libraries, and generate compliance reports with minimal human intervention. Automation reduces human error, increases throughput, improves reproducibility, and enables continuous operation for high-volume quality control applications.

- FTIR combined with other analytical techniques for comprehensive QC: Integration of FTIR with complementary analytical techniques such as Raman spectroscopy, near-infrared spectroscopy, or mass spectrometry provides more comprehensive quality control capabilities. These combined systems offer multi-modal analysis that can overcome the limitations of individual techniques, providing more complete characterization of materials. The integrated approach enhances detection sensitivity, specificity, and reliability for complex quality control challenges in industries such as pharmaceuticals, polymers, and food production.

02 Real-time monitoring and process control using FTIR

FTIR spectroscopy enables real-time monitoring of manufacturing processes by providing immediate spectral analysis of materials during production. These systems can be integrated into production lines to continuously monitor product quality, detect deviations from specifications, and automatically adjust process parameters. Real-time FTIR monitoring helps maintain consistent product quality, reduce waste, and optimize manufacturing efficiency across various industries.Expand Specific Solutions03 Portable and handheld FTIR devices for field testing

Portable and handheld FTIR devices allow for quality control testing outside of laboratory settings. These compact instruments enable on-site analysis of materials, reducing the time between sampling and obtaining results. They feature simplified interfaces, rugged designs for field use, and specialized software for rapid identification of substances. These devices are particularly valuable for quality control in remote locations, incoming material inspection, and counterfeit detection.Expand Specific Solutions04 Automated sample preparation and analysis systems

Automated FTIR systems integrate sample preparation, measurement, and data analysis to improve efficiency and reduce human error in quality control processes. These systems include robotic sample handling, automated cleaning procedures, and intelligent software that can identify spectral patterns and anomalies. By standardizing the testing process, these automated systems ensure consistent results, higher throughput, and improved documentation for regulatory compliance.Expand Specific Solutions05 Advanced data processing and chemometric analysis

Advanced data processing techniques enhance the capabilities of FTIR spectroscopy in quality control applications. These include chemometric methods, machine learning algorithms, and multivariate statistical analysis to extract meaningful information from complex spectral data. Such techniques enable more sensitive detection of contaminants, quantitative analysis of components, and pattern recognition for identifying product variations. These advanced analytical approaches improve decision-making in quality control processes across various industries.Expand Specific Solutions

Leading FTIR Equipment Manufacturers and Recycling Partners

FTIR technology for recyclable material quality control is in a growth phase, with increasing market adoption driven by sustainability regulations. The market is expanding as industries prioritize circular economy practices, with an estimated global value exceeding $500 million. Technologically, FTIR systems have reached commercial maturity but continue evolving toward greater automation and AI integration. Leading players include Thermo Electron Scientific Instruments, offering specialized industrial spectroscopy solutions; Battelle Memorial Institute, developing advanced material characterization techniques; and Koninklijke Philips, integrating FTIR into comprehensive quality control systems. Other significant contributors include Panasonic Holdings and GLOBALFOUNDRIES, who are applying FTIR technology to semiconductor and electronics recycling applications.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed advanced FTIR spectroscopy solutions specifically designed for recyclable material quality control. Their technology utilizes mid-infrared spectroscopy (4000-400 cm-1) combined with attenuated total reflection (ATR) sampling techniques to provide rapid, non-destructive analysis of various polymer types in recycling streams. Their Nicolet™ FTIR systems incorporate automated material identification algorithms that can detect contaminants down to 1% concentration levels in mixed plastic waste. The company has implemented multivariate statistical analysis methods to differentiate between similar polymer types (e.g., different grades of polyethylene) and identify additives or degradation products that affect recyclability. Their portable FTIR devices allow for on-site testing at recycling facilities, enabling real-time sorting decisions and quality verification before further processing steps.

Strengths: Superior spectral resolution allowing identification of closely related polymer structures; robust databases of reference materials specific to recycling applications; integration capabilities with automated sorting systems. Weaknesses: Higher initial investment cost compared to some alternative technologies; requires some technical expertise for optimal operation and data interpretation; limited penetration depth for analysis of thick or layered materials.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed integrated FTIR solutions for recyclable material quality control as part of their sustainable manufacturing initiatives. Their technology combines compact FTIR spectrometers with automated material handling systems designed for production environments. Their approach utilizes attenuated total reflection (ATR) sampling with specialized crystal materials optimized for different polymer types, allowing for rapid, non-destructive analysis without sample preparation. Panasonic's systems incorporate real-time data processing capabilities that can analyze up to 120 samples per hour, making them suitable for high-volume recycling operations. Their technology features specialized calibration models for common consumer electronics materials, including flame retardants, plasticizers, and fillers that affect recyclability. The company has also developed miniaturized FTIR sensors that can be integrated directly into sorting equipment, enabling inline quality monitoring rather than batch sampling. Their systems include wireless connectivity for integration with facility management systems and quality control databases.

Strengths: Excellent integration capabilities with existing production and sorting equipment; optimized for high-throughput industrial environments; specialized expertise in electronics recycling applications. Weaknesses: Less versatile for non-standard or highly contaminated materials; requires periodic recalibration as waste stream composition changes; moderate spectral resolution compared to research-grade instruments.

Key FTIR Spectral Analysis Innovations

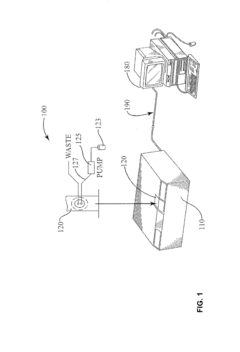

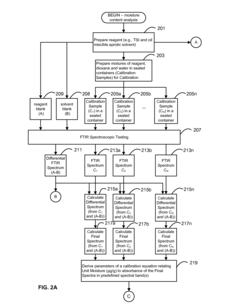

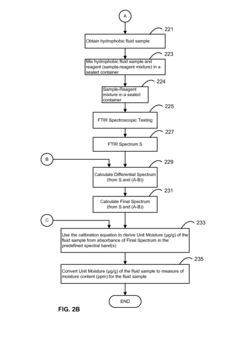

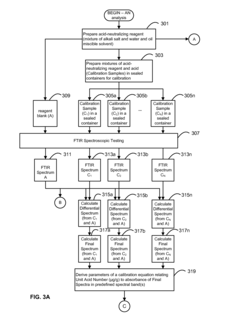

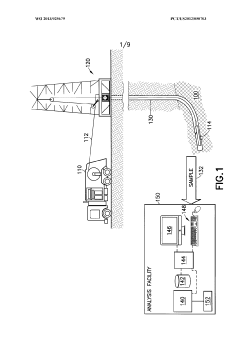

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

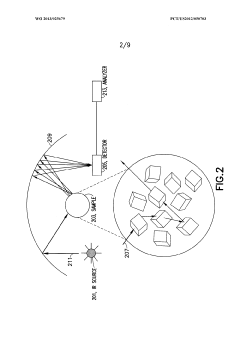

Diffuse reflectance infrared fourier transform spectroscopy for characterization of earth materials

PatentWO2013025679A2

Innovation

- The use of diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) with minimal sample preparation, involving infrared energy irradiation, spectrum collection, and regression analysis against standard libraries to characterize lithology, mineralogy, and organic content, including kerogen types, without the need for potassium bromide or extensive sample processing.

Environmental Impact Assessment of FTIR Implementation

The implementation of Fourier Transform Infrared Spectroscopy (FTIR) in recyclable material quality control offers significant environmental benefits that extend beyond its primary technical function. When properly integrated into recycling operations, FTIR technology contributes to reduced waste, lower energy consumption, and decreased greenhouse gas emissions through more efficient sorting and processing of materials.

FTIR implementation enables more precise identification of contaminants in recycling streams, resulting in higher purity recycled materials. This precision reduces the volume of materials incorrectly sent to landfills or incinerators, directly decreasing methane emissions from landfills and carbon dioxide emissions from incineration processes. Quantitative assessments indicate that advanced sorting technologies like FTIR can reduce misclassification rates by up to 25%, translating to substantial reductions in waste-related emissions.

The technology also contributes to energy conservation throughout the recycling value chain. By ensuring higher quality recycled materials, FTIR reduces the energy required for reprocessing contaminated batches. Studies comparing traditional sorting methods with FTIR-enhanced systems demonstrate energy savings of 15-30% in subsequent manufacturing processes that utilize these recycled materials. This energy reduction translates directly to lower carbon footprints for products made from recycled content.

Water conservation represents another environmental benefit of FTIR implementation. Traditional recycling processes often require water-intensive cleaning stages to remove contaminants. With FTIR's ability to identify materials more accurately at earlier stages, less aggressive cleaning processes can be employed, reducing water consumption by an estimated 10-20% in facilities that have implemented this technology.

The lifecycle assessment of FTIR equipment itself must be considered in a comprehensive environmental impact analysis. While the manufacturing and operation of FTIR systems consume energy and resources, the net environmental benefit typically becomes positive within 1-3 years of implementation, depending on the scale of operations. Modern FTIR systems have increasingly efficient power consumption profiles, with newer models reducing operational energy requirements by up to 40% compared to systems from a decade ago.

Long-term environmental benefits include the preservation of virgin material sources through more effective recycling. By enabling higher recycling rates and better quality recycled materials, FTIR technology indirectly reduces the environmental impacts associated with raw material extraction, including habitat destruction, biodiversity loss, and resource depletion. This upstream impact, while difficult to quantify precisely, represents one of the most significant environmental benefits of improved recycling technology.

FTIR implementation enables more precise identification of contaminants in recycling streams, resulting in higher purity recycled materials. This precision reduces the volume of materials incorrectly sent to landfills or incinerators, directly decreasing methane emissions from landfills and carbon dioxide emissions from incineration processes. Quantitative assessments indicate that advanced sorting technologies like FTIR can reduce misclassification rates by up to 25%, translating to substantial reductions in waste-related emissions.

The technology also contributes to energy conservation throughout the recycling value chain. By ensuring higher quality recycled materials, FTIR reduces the energy required for reprocessing contaminated batches. Studies comparing traditional sorting methods with FTIR-enhanced systems demonstrate energy savings of 15-30% in subsequent manufacturing processes that utilize these recycled materials. This energy reduction translates directly to lower carbon footprints for products made from recycled content.

Water conservation represents another environmental benefit of FTIR implementation. Traditional recycling processes often require water-intensive cleaning stages to remove contaminants. With FTIR's ability to identify materials more accurately at earlier stages, less aggressive cleaning processes can be employed, reducing water consumption by an estimated 10-20% in facilities that have implemented this technology.

The lifecycle assessment of FTIR equipment itself must be considered in a comprehensive environmental impact analysis. While the manufacturing and operation of FTIR systems consume energy and resources, the net environmental benefit typically becomes positive within 1-3 years of implementation, depending on the scale of operations. Modern FTIR systems have increasingly efficient power consumption profiles, with newer models reducing operational energy requirements by up to 40% compared to systems from a decade ago.

Long-term environmental benefits include the preservation of virgin material sources through more effective recycling. By enabling higher recycling rates and better quality recycled materials, FTIR technology indirectly reduces the environmental impacts associated with raw material extraction, including habitat destruction, biodiversity loss, and resource depletion. This upstream impact, while difficult to quantify precisely, represents one of the most significant environmental benefits of improved recycling technology.

Cost-Benefit Analysis of FTIR in Recycling Operations

Implementing FTIR technology in recycling operations requires careful financial consideration to ensure the investment delivers appropriate returns. Initial capital expenditure for FTIR systems ranges from $50,000 to $150,000 depending on specifications, resolution capabilities, and additional features such as automated sampling systems. Maintenance costs typically add 5-10% of the initial investment annually, covering calibration, software updates, and potential component replacements.

Labor costs must also be factored in, as specialized technicians commanding salaries of $60,000-$80,000 annually may be required for system operation and data interpretation. Training existing staff represents an additional investment of approximately $3,000-$5,000 per employee, though this decreases over time as institutional knowledge develops.

Against these expenses, FTIR implementation offers substantial financial benefits. Material sorting accuracy improvements of 15-25% directly translate to higher-value recycled materials, with premium recycled plastics commanding 30-40% higher market prices than mixed or contaminated streams. For a medium-sized recycling facility processing 50,000 tons annually, this can represent additional revenue of $500,000-$750,000 per year.

Rejection rate reduction presents another significant benefit, as FTIR systems can decrease material rejection by 10-15%. For facilities experiencing 20% rejection rates, this improvement can reclaim 1,000-1,500 tons of previously discarded material annually, valued at $200,000-$300,000 depending on material types.

Operational efficiency gains typically manifest within 3-6 months of implementation, with most facilities reporting 15-20% increases in throughput without additional labor costs. This efficiency translates to processing more material with existing resources, effectively reducing per-ton handling costs.

Return on investment calculations indicate most recycling operations achieve payback within 12-24 months, with larger facilities experiencing faster returns due to economies of scale. The ROI improves significantly when factoring in regulatory compliance benefits and potential penalties avoided through more accurate material identification and processing.

Long-term financial modeling suggests FTIR systems deliver 5-year net positive returns of 300-500% on initial investment when all direct and indirect benefits are considered, making them increasingly essential components in modern recycling infrastructure despite the substantial upfront costs.

Labor costs must also be factored in, as specialized technicians commanding salaries of $60,000-$80,000 annually may be required for system operation and data interpretation. Training existing staff represents an additional investment of approximately $3,000-$5,000 per employee, though this decreases over time as institutional knowledge develops.

Against these expenses, FTIR implementation offers substantial financial benefits. Material sorting accuracy improvements of 15-25% directly translate to higher-value recycled materials, with premium recycled plastics commanding 30-40% higher market prices than mixed or contaminated streams. For a medium-sized recycling facility processing 50,000 tons annually, this can represent additional revenue of $500,000-$750,000 per year.

Rejection rate reduction presents another significant benefit, as FTIR systems can decrease material rejection by 10-15%. For facilities experiencing 20% rejection rates, this improvement can reclaim 1,000-1,500 tons of previously discarded material annually, valued at $200,000-$300,000 depending on material types.

Operational efficiency gains typically manifest within 3-6 months of implementation, with most facilities reporting 15-20% increases in throughput without additional labor costs. This efficiency translates to processing more material with existing resources, effectively reducing per-ton handling costs.

Return on investment calculations indicate most recycling operations achieve payback within 12-24 months, with larger facilities experiencing faster returns due to economies of scale. The ROI improves significantly when factoring in regulatory compliance benefits and potential penalties avoided through more accurate material identification and processing.

Long-term financial modeling suggests FTIR systems deliver 5-year net positive returns of 300-500% on initial investment when all direct and indirect benefits are considered, making them increasingly essential components in modern recycling infrastructure despite the substantial upfront costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!