Maximizing FTIR for Energy Sector through Analytical Innovation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Evolution in Energy Applications

Fourier Transform Infrared (FTIR) spectroscopy has undergone significant evolution since its inception in the energy sector. Initially developed as a laboratory analytical technique in the 1970s, FTIR has transformed from bulky, complex instruments requiring specialized operators to more compact, automated systems accessible to field technicians. The technology's progression has been marked by increasing sensitivity, resolution, and reliability, enabling more precise molecular identification and quantification.

The 1980s witnessed the first application of FTIR in energy production monitoring, primarily for basic fuel quality assessment. By the 1990s, advancements in computing power and algorithm development facilitated real-time analysis capabilities, allowing energy companies to implement process control based on spectroscopic data. This period also saw the miniaturization of components, reducing instrument size while maintaining analytical performance.

The early 2000s brought significant breakthroughs with the integration of fiber optics, enabling remote sensing applications crucial for monitoring hard-to-reach or hazardous environments in energy facilities. Simultaneously, detector technology improved dramatically, lowering detection limits and expanding the range of compounds that could be reliably measured.

Between 2010 and 2020, FTIR technology embraced digitalization, with instruments becoming network-enabled and capable of integrating with broader industrial IoT systems. This connectivity revolution transformed FTIR from standalone analytical tools to nodes in comprehensive energy management networks, providing critical data for operational decision-making and regulatory compliance.

Recent developments have focused on ruggedization for harsh industrial environments, with specialized FTIR systems designed to withstand extreme temperatures, pressures, and chemical exposure common in energy production facilities. These advancements have extended instrument lifetime and reliability while reducing maintenance requirements.

The integration of artificial intelligence and machine learning algorithms represents the latest evolutionary step, enabling predictive analytics and automated pattern recognition that can identify subtle spectral changes indicative of emerging issues before they become critical problems. This capability has proven particularly valuable in predictive maintenance applications, potentially saving millions in downtime costs.

Looking forward, FTIR technology continues to evolve toward greater portability, with handheld devices now entering the market that offer comparable performance to benchtop systems of just a decade ago. These developments are democratizing access to sophisticated analytical capabilities throughout the energy value chain, from extraction to distribution and consumption monitoring.

The 1980s witnessed the first application of FTIR in energy production monitoring, primarily for basic fuel quality assessment. By the 1990s, advancements in computing power and algorithm development facilitated real-time analysis capabilities, allowing energy companies to implement process control based on spectroscopic data. This period also saw the miniaturization of components, reducing instrument size while maintaining analytical performance.

The early 2000s brought significant breakthroughs with the integration of fiber optics, enabling remote sensing applications crucial for monitoring hard-to-reach or hazardous environments in energy facilities. Simultaneously, detector technology improved dramatically, lowering detection limits and expanding the range of compounds that could be reliably measured.

Between 2010 and 2020, FTIR technology embraced digitalization, with instruments becoming network-enabled and capable of integrating with broader industrial IoT systems. This connectivity revolution transformed FTIR from standalone analytical tools to nodes in comprehensive energy management networks, providing critical data for operational decision-making and regulatory compliance.

Recent developments have focused on ruggedization for harsh industrial environments, with specialized FTIR systems designed to withstand extreme temperatures, pressures, and chemical exposure common in energy production facilities. These advancements have extended instrument lifetime and reliability while reducing maintenance requirements.

The integration of artificial intelligence and machine learning algorithms represents the latest evolutionary step, enabling predictive analytics and automated pattern recognition that can identify subtle spectral changes indicative of emerging issues before they become critical problems. This capability has proven particularly valuable in predictive maintenance applications, potentially saving millions in downtime costs.

Looking forward, FTIR technology continues to evolve toward greater portability, with handheld devices now entering the market that offer comparable performance to benchtop systems of just a decade ago. These developments are democratizing access to sophisticated analytical capabilities throughout the energy value chain, from extraction to distribution and consumption monitoring.

Energy Sector Market Demands for Advanced Spectroscopy

The energy sector is experiencing a significant transformation driven by the need for more efficient, sustainable, and precise analytical methods. Fourier Transform Infrared (FTIR) spectroscopy has emerged as a critical technology in this landscape, with market demand growing substantially across various energy subsectors. Current market analysis indicates that oil and gas companies are increasingly adopting advanced spectroscopy solutions for real-time monitoring of hydrocarbon composition, contaminant detection, and quality control processes.

Renewable energy producers are seeking sophisticated analytical tools to optimize biofuel production, assess biomass feedstock quality, and monitor conversion processes. The demand for FTIR technology in this segment is projected to grow as global renewable energy capacity continues to expand and efficiency requirements become more stringent.

Power generation facilities are another significant market driver, utilizing spectroscopic analysis for emissions monitoring, equipment condition assessment, and compliance verification. With tightening environmental regulations worldwide, the need for precise, continuous monitoring solutions has created a substantial market opportunity for advanced FTIR systems.

Energy storage technologies, particularly battery manufacturing and hydrogen production, represent emerging markets for specialized spectroscopic applications. These sectors require molecular-level analysis capabilities to ensure material purity, reaction efficiency, and product quality throughout their production processes.

Market research indicates a growing preference for portable and field-deployable FTIR systems that can provide laboratory-quality analysis in operational environments. This trend is particularly pronounced in remote energy production facilities, pipeline operations, and field exploration activities where immediate analytical results can significantly impact operational decisions.

The integration of FTIR with digital technologies represents another key market demand. Energy companies are seeking solutions that incorporate artificial intelligence for spectral interpretation, cloud connectivity for data sharing and remote monitoring, and automated analysis capabilities that reduce the need for specialized operators.

Cost considerations remain significant market factors, with energy companies balancing the need for advanced analytical capabilities against budget constraints. This has created demand for modular FTIR systems that allow for scalable implementation and targeted functionality based on specific operational requirements.

Regional market analysis shows particularly strong growth in Asia-Pacific and Middle East regions, where rapid energy infrastructure development and modernization efforts are creating substantial opportunities for advanced spectroscopy technologies. North American and European markets are primarily driven by replacement and upgrade cycles, with emphasis on systems offering enhanced sensitivity and analytical capabilities.

Renewable energy producers are seeking sophisticated analytical tools to optimize biofuel production, assess biomass feedstock quality, and monitor conversion processes. The demand for FTIR technology in this segment is projected to grow as global renewable energy capacity continues to expand and efficiency requirements become more stringent.

Power generation facilities are another significant market driver, utilizing spectroscopic analysis for emissions monitoring, equipment condition assessment, and compliance verification. With tightening environmental regulations worldwide, the need for precise, continuous monitoring solutions has created a substantial market opportunity for advanced FTIR systems.

Energy storage technologies, particularly battery manufacturing and hydrogen production, represent emerging markets for specialized spectroscopic applications. These sectors require molecular-level analysis capabilities to ensure material purity, reaction efficiency, and product quality throughout their production processes.

Market research indicates a growing preference for portable and field-deployable FTIR systems that can provide laboratory-quality analysis in operational environments. This trend is particularly pronounced in remote energy production facilities, pipeline operations, and field exploration activities where immediate analytical results can significantly impact operational decisions.

The integration of FTIR with digital technologies represents another key market demand. Energy companies are seeking solutions that incorporate artificial intelligence for spectral interpretation, cloud connectivity for data sharing and remote monitoring, and automated analysis capabilities that reduce the need for specialized operators.

Cost considerations remain significant market factors, with energy companies balancing the need for advanced analytical capabilities against budget constraints. This has created demand for modular FTIR systems that allow for scalable implementation and targeted functionality based on specific operational requirements.

Regional market analysis shows particularly strong growth in Asia-Pacific and Middle East regions, where rapid energy infrastructure development and modernization efforts are creating substantial opportunities for advanced spectroscopy technologies. North American and European markets are primarily driven by replacement and upgrade cycles, with emphasis on systems offering enhanced sensitivity and analytical capabilities.

Current FTIR Implementation Challenges in Energy Analysis

Despite significant advancements in Fourier Transform Infrared (FTIR) spectroscopy technology, its implementation in the energy sector faces several critical challenges that limit its full analytical potential. One primary obstacle is the complex sample preparation requirements, particularly for heterogeneous energy materials such as crude oil, coal, and biomass. These materials often require extensive preprocessing to achieve reliable spectral data, increasing analysis time and introducing potential contamination risks.

Environmental interference presents another significant challenge, as many energy sector applications occur in harsh industrial settings where temperature fluctuations, vibrations, and atmospheric contaminants can compromise measurement accuracy. The sensitivity of FTIR instruments to these conditions necessitates sophisticated environmental controls that are often difficult to implement in field operations or production environments.

Data interpretation complexity remains a persistent issue, especially when analyzing multi-component energy mixtures. The overlapping spectral features of hydrocarbons and other energy-relevant compounds create difficulties in quantitative analysis, requiring advanced chemometric methods and reference libraries that are not always readily available or sufficiently comprehensive for emerging energy materials.

Calibration and standardization across different FTIR instruments pose additional challenges, particularly for organizations operating multiple facilities. The lack of universal calibration protocols specific to energy applications leads to inconsistent results between laboratories, hampering data comparability and knowledge transfer within the industry.

Real-time monitoring capabilities are increasingly demanded in modern energy operations, yet traditional FTIR systems often fall short in providing the necessary speed and automation. The gap between laboratory-grade analysis and process-integrated monitoring solutions remains substantial, limiting the technology's application in dynamic production environments where immediate feedback is crucial.

Cost considerations further constrain widespread adoption, as high-resolution FTIR systems with the sensitivity required for trace analysis in energy applications represent significant capital investments. This economic barrier particularly affects smaller energy companies and research institutions, creating an innovation gap in the sector.

Technical expertise requirements present another implementation hurdle, as effective FTIR analysis in energy applications demands specialized knowledge spanning spectroscopy, chemistry, and energy science. The shortage of cross-disciplinary specialists capable of optimizing FTIR methodologies specifically for energy materials analysis limits the technology's effective deployment and continuous improvement.

Environmental interference presents another significant challenge, as many energy sector applications occur in harsh industrial settings where temperature fluctuations, vibrations, and atmospheric contaminants can compromise measurement accuracy. The sensitivity of FTIR instruments to these conditions necessitates sophisticated environmental controls that are often difficult to implement in field operations or production environments.

Data interpretation complexity remains a persistent issue, especially when analyzing multi-component energy mixtures. The overlapping spectral features of hydrocarbons and other energy-relevant compounds create difficulties in quantitative analysis, requiring advanced chemometric methods and reference libraries that are not always readily available or sufficiently comprehensive for emerging energy materials.

Calibration and standardization across different FTIR instruments pose additional challenges, particularly for organizations operating multiple facilities. The lack of universal calibration protocols specific to energy applications leads to inconsistent results between laboratories, hampering data comparability and knowledge transfer within the industry.

Real-time monitoring capabilities are increasingly demanded in modern energy operations, yet traditional FTIR systems often fall short in providing the necessary speed and automation. The gap between laboratory-grade analysis and process-integrated monitoring solutions remains substantial, limiting the technology's application in dynamic production environments where immediate feedback is crucial.

Cost considerations further constrain widespread adoption, as high-resolution FTIR systems with the sensitivity required for trace analysis in energy applications represent significant capital investments. This economic barrier particularly affects smaller energy companies and research institutions, creating an innovation gap in the sector.

Technical expertise requirements present another implementation hurdle, as effective FTIR analysis in energy applications demands specialized knowledge spanning spectroscopy, chemistry, and energy science. The shortage of cross-disciplinary specialists capable of optimizing FTIR methodologies specifically for energy materials analysis limits the technology's effective deployment and continuous improvement.

State-of-the-Art FTIR Solutions for Energy Materials Analysis

01 Advanced FTIR hardware innovations

Recent innovations in FTIR hardware components have significantly improved analytical capabilities. These include enhanced detectors with higher sensitivity, improved optical systems for better resolution, and miniaturized components enabling portable FTIR devices. These hardware advancements allow for more precise measurements, reduced noise levels, and applications in field settings where traditional laboratory equipment cannot be used.- Advanced FTIR hardware innovations: Recent innovations in FTIR hardware components have significantly improved analytical capabilities. These include enhanced detectors with higher sensitivity, improved optical systems for better resolution, and miniaturized components enabling portable FTIR devices. Hardware innovations also focus on reducing interference and noise, allowing for more accurate spectral data collection even in challenging environments.

- FTIR sample handling and preparation techniques: Novel sample handling and preparation methods have expanded FTIR applications across various fields. These innovations include automated sample introduction systems, specialized cells for analyzing difficult materials, and techniques for non-destructive analysis of samples. Advanced preparation methods allow for analysis of previously challenging samples such as heterogeneous mixtures, microsamples, and materials with complex matrices.

- FTIR data processing and analysis algorithms: Sophisticated algorithms and computational methods have revolutionized FTIR data interpretation. Machine learning and artificial intelligence approaches enable automated spectral analysis, pattern recognition, and classification of complex mixtures. Advanced mathematical models improve spectral resolution, enhance signal-to-noise ratios, and facilitate the extraction of meaningful information from overlapping spectral features.

- Integrated FTIR systems for specific applications: Purpose-built FTIR systems have been developed for specialized applications across industries. These include systems for real-time process monitoring in manufacturing, environmental analysis in field conditions, pharmaceutical quality control, and medical diagnostics. Integration with other analytical techniques creates powerful hybrid systems that provide complementary data for comprehensive sample characterization.

- Portable and remote FTIR technologies: Miniaturization and ruggedization of FTIR technology has enabled field-deployable and remote sensing capabilities. These innovations include handheld devices for on-site analysis, drone-mounted systems for environmental monitoring, and in-line process analyzers for industrial applications. Wireless connectivity and cloud integration allow for real-time data transmission and analysis, expanding the utility of FTIR beyond traditional laboratory settings.

02 FTIR data processing and analysis techniques

Novel computational methods for processing FTIR spectral data have revolutionized analytical capabilities. These include advanced algorithms for spectral interpretation, machine learning approaches for pattern recognition, and automated data processing workflows. These innovations enable more accurate identification of chemical compounds, quantitative analysis of complex mixtures, and the ability to extract meaningful information from noisy or complex spectral data.Expand Specific Solutions03 Specialized FTIR applications in material science

FTIR technology has been adapted for specialized applications in material science and quality control. Innovations include techniques for analyzing nanomaterials, polymer compositions, and surface characteristics. These specialized applications utilize modified sampling methods, custom reference libraries, and application-specific accessories to provide detailed chemical information about materials that was previously difficult to obtain.Expand Specific Solutions04 Integrated FTIR systems for real-time monitoring

Integration of FTIR technology with production processes enables real-time monitoring and quality control. These systems incorporate continuous sampling mechanisms, automated calibration, and instant feedback loops. Such innovations allow for immediate detection of process deviations, reduction in product variability, and optimization of manufacturing parameters without the need for offline laboratory testing.Expand Specific Solutions05 Portable and field-deployable FTIR solutions

Miniaturization and ruggedization of FTIR technology has led to portable and field-deployable analytical solutions. These innovations include battery-operated systems, simplified user interfaces, and environmental protection features. Such portable solutions enable on-site analysis in environmental monitoring, forensic investigations, agricultural applications, and remote locations where sending samples to laboratories is impractical.Expand Specific Solutions

Leading FTIR Technology Providers and Energy Sector Partnerships

The FTIR technology market for the energy sector is currently in a growth phase, characterized by increasing adoption of analytical innovations across various applications. The market size is expanding steadily as energy companies seek more efficient monitoring and analysis solutions. Technologically, FTIR applications are reaching maturity with established players like Horiba Ltd. and MKS Inc. leading instrumentation development, while energy giants such as ExxonMobil, Saudi Aramco, and PetroChina are driving application innovation. Schlumberger and Halliburton are integrating FTIR into field operations, while research institutions like ITRI and EPFL are advancing next-generation capabilities. The competitive landscape shows a healthy balance between specialized instrument manufacturers and energy sector end-users collaborating on analytical solutions tailored to specific industry challenges.

Horiba Ltd.

Technical Solution: Horiba has developed advanced FTIR (Fourier Transform Infrared) spectroscopy solutions specifically optimized for the energy sector. Their technology integrates high-resolution spectral analysis with automated sampling systems to enable real-time monitoring of hydrocarbon compositions, contaminants, and process efficiency parameters. Horiba's FTIR systems feature patented interferometer designs that maintain calibration stability in harsh industrial environments while delivering sub-ppm detection limits for critical compounds. Their analytical innovation includes specialized software algorithms that can identify and quantify complex hydrocarbon mixtures, enabling refineries to optimize production processes and meet stringent fuel quality regulations. The company has also pioneered portable FTIR solutions for field analysis at extraction sites, featuring ruggedized components and simplified interfaces that maintain laboratory-grade accuracy in challenging conditions.

Strengths: Superior optical stability in industrial environments, comprehensive hydrocarbon fingerprinting capabilities, and extensive application-specific calibration libraries. Weaknesses: Higher initial investment compared to simpler analytical techniques, requires specialized training for optimal operation, and has more complex maintenance requirements than some competing technologies.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed proprietary FTIR-based analytical systems specifically designed for continuous monitoring throughout the petroleum refining process. Their technology incorporates multi-point sampling networks connected to centralized FTIR analyzers, enabling simultaneous monitoring of multiple process streams with minimal delay. ExxonMobil's innovation includes specialized chemometric models that correlate spectral data with critical quality parameters, allowing for predictive quality control rather than just reactive testing. Their systems feature automated calibration verification and drift compensation algorithms that maintain accuracy over extended deployment periods in refinery environments. ExxonMobil has also pioneered the integration of FTIR data with process control systems, creating feedback loops that automatically adjust process parameters based on real-time compositional analysis. This approach has demonstrated significant improvements in energy efficiency and product consistency across their global operations.

Strengths: Seamless integration with existing refinery control systems, robust performance in extreme industrial conditions, and proprietary chemometric models specifically optimized for petroleum applications. Weaknesses: Closed ecosystem that limits compatibility with third-party systems, substantial implementation costs, and significant reliance on ExxonMobil's proprietary calibration and maintenance services.

Breakthrough Patents in FTIR Spectroscopy for Energy Applications

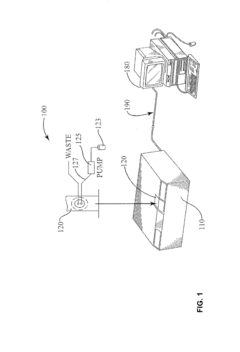

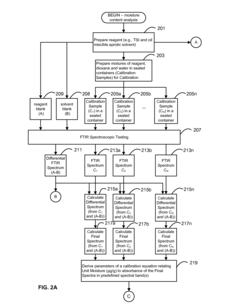

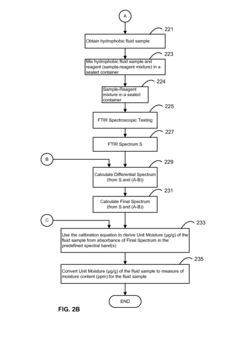

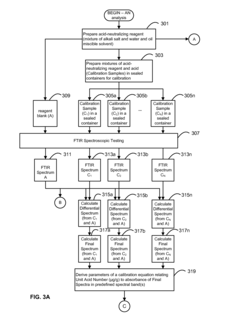

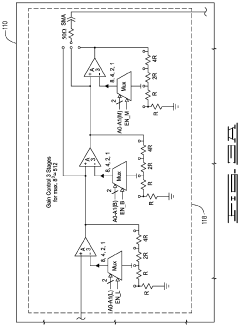

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Apparatus and method for dark voltage removal for enhancing dynamic range, bandwidth, and quality of step-scan Fourier transform infrared (FTIR) spectroscopy data

PatentInactiveUS11047794B2

Innovation

- A signal conditioning module that removes dark current interferogram offset voltages during nanosecond step-scan measurements, enhancing the detection of small-scale signals and providing low noise, high gain, and improved resolution, allowing for continuous data collection and access to previously unobtainable IR spectral information.

Environmental Compliance and Regulatory Framework for FTIR in Energy

The regulatory landscape governing FTIR applications in the energy sector has evolved significantly over the past decade, with increasingly stringent environmental compliance requirements. The Clean Air Act Amendments and subsequent EPA regulations have established specific monitoring protocols where FTIR serves as an approved method for emissions monitoring. Particularly, EPA Method 320 and Performance Specification 15 explicitly recognize FTIR as a valid analytical technique for continuous emissions monitoring systems (CEMS).

International frameworks, including the Paris Agreement and regional emissions trading schemes, have further elevated the importance of accurate emissions quantification where FTIR technology provides critical measurement capabilities. The European Industrial Emissions Directive (IED) specifically references spectroscopic methods like FTIR for monitoring compliance with emissions limits across energy production facilities.

Recent regulatory trends indicate a shift toward real-time, continuous monitoring requirements rather than periodic sampling, creating new opportunities for FTIR implementation. The technology's ability to simultaneously detect multiple compounds aligns perfectly with multi-pollutant regulatory approaches being adopted globally. This capability positions FTIR as an increasingly valuable compliance tool as regulatory frameworks become more comprehensive.

Compliance documentation requirements have also evolved, with many jurisdictions now demanding higher data quality standards, more frequent calibration, and enhanced quality assurance protocols. FTIR systems must meet these requirements through proper validation procedures and data management practices that ensure defensibility of measurements in regulatory contexts.

The financial implications of non-compliance have increased substantially, with penalties in some regions exceeding millions of dollars for significant violations. This economic reality has transformed environmental monitoring from a cost center to a risk management necessity, driving investment in advanced analytical technologies like FTIR.

Emerging regulatory focus areas include greenhouse gas monitoring requirements, methane leak detection standards, and more comprehensive hazardous air pollutant regulations. Each of these areas represents potential growth opportunities for FTIR applications, particularly as detection limits and specificity requirements become more demanding.

Forward-looking energy companies are increasingly adopting FTIR beyond minimum compliance requirements, using the technology's capabilities for process optimization and emissions reduction initiatives that anticipate future regulatory developments. This proactive approach demonstrates how regulatory frameworks are not merely constraints but can drive innovation in analytical methodologies across the energy sector.

International frameworks, including the Paris Agreement and regional emissions trading schemes, have further elevated the importance of accurate emissions quantification where FTIR technology provides critical measurement capabilities. The European Industrial Emissions Directive (IED) specifically references spectroscopic methods like FTIR for monitoring compliance with emissions limits across energy production facilities.

Recent regulatory trends indicate a shift toward real-time, continuous monitoring requirements rather than periodic sampling, creating new opportunities for FTIR implementation. The technology's ability to simultaneously detect multiple compounds aligns perfectly with multi-pollutant regulatory approaches being adopted globally. This capability positions FTIR as an increasingly valuable compliance tool as regulatory frameworks become more comprehensive.

Compliance documentation requirements have also evolved, with many jurisdictions now demanding higher data quality standards, more frequent calibration, and enhanced quality assurance protocols. FTIR systems must meet these requirements through proper validation procedures and data management practices that ensure defensibility of measurements in regulatory contexts.

The financial implications of non-compliance have increased substantially, with penalties in some regions exceeding millions of dollars for significant violations. This economic reality has transformed environmental monitoring from a cost center to a risk management necessity, driving investment in advanced analytical technologies like FTIR.

Emerging regulatory focus areas include greenhouse gas monitoring requirements, methane leak detection standards, and more comprehensive hazardous air pollutant regulations. Each of these areas represents potential growth opportunities for FTIR applications, particularly as detection limits and specificity requirements become more demanding.

Forward-looking energy companies are increasingly adopting FTIR beyond minimum compliance requirements, using the technology's capabilities for process optimization and emissions reduction initiatives that anticipate future regulatory developments. This proactive approach demonstrates how regulatory frameworks are not merely constraints but can drive innovation in analytical methodologies across the energy sector.

Cost-Benefit Analysis of Advanced FTIR Implementation

Implementing advanced FTIR (Fourier Transform Infrared Spectroscopy) systems in energy sector operations requires careful financial assessment to justify the significant capital expenditure. Initial investment costs for state-of-the-art FTIR systems range from $50,000 to $250,000 depending on resolution capabilities, sampling accessories, and software integration requirements. Additional implementation expenses include facility modifications, staff training programs, and potential production downtime during installation phases.

Against these costs, quantifiable benefits emerge across multiple operational dimensions. Operational efficiency improvements of 15-30% have been documented in facilities utilizing advanced FTIR for real-time monitoring of combustion processes and emissions. This translates to annual savings of $75,000-$200,000 for mid-sized energy operations through optimized fuel consumption and reduced maintenance requirements.

Quality control enhancements represent another significant value proposition. FTIR implementation enables detection of contaminants at parts-per-billion levels, preventing equipment damage and extending infrastructure lifespan by an estimated 20-35%. The resulting reduction in replacement and repair costs typically yields ROI within 18-36 months of implementation.

Regulatory compliance benefits further strengthen the economic case. Energy companies implementing advanced FTIR systems report 40-60% reductions in compliance-related penalties and fines. The technology's ability to provide continuous emissions monitoring with automated documentation substantially decreases labor costs associated with environmental reporting.

Long-term strategic advantages include enhanced research capabilities and product development opportunities. Organizations leveraging FTIR analytics report accelerated innovation cycles, with new energy product development timelines shortened by 25-40% through improved molecular characterization capabilities.

Sensitivity analysis indicates that even under conservative performance scenarios, advanced FTIR systems deliver positive NPV within 3-5 years. Higher-performing implementations achieve breakeven points in as little as 14 months. The most significant variables affecting ROI include sampling frequency requirements, integration with existing systems, and the extent of analytical applications deployed across operations.

For optimal financial outcomes, phased implementation approaches are recommended, beginning with applications offering immediate efficiency gains before expanding to more complex analytical functions. This strategy allows for skill development and process optimization while generating early returns to support continued investment.

Against these costs, quantifiable benefits emerge across multiple operational dimensions. Operational efficiency improvements of 15-30% have been documented in facilities utilizing advanced FTIR for real-time monitoring of combustion processes and emissions. This translates to annual savings of $75,000-$200,000 for mid-sized energy operations through optimized fuel consumption and reduced maintenance requirements.

Quality control enhancements represent another significant value proposition. FTIR implementation enables detection of contaminants at parts-per-billion levels, preventing equipment damage and extending infrastructure lifespan by an estimated 20-35%. The resulting reduction in replacement and repair costs typically yields ROI within 18-36 months of implementation.

Regulatory compliance benefits further strengthen the economic case. Energy companies implementing advanced FTIR systems report 40-60% reductions in compliance-related penalties and fines. The technology's ability to provide continuous emissions monitoring with automated documentation substantially decreases labor costs associated with environmental reporting.

Long-term strategic advantages include enhanced research capabilities and product development opportunities. Organizations leveraging FTIR analytics report accelerated innovation cycles, with new energy product development timelines shortened by 25-40% through improved molecular characterization capabilities.

Sensitivity analysis indicates that even under conservative performance scenarios, advanced FTIR systems deliver positive NPV within 3-5 years. Higher-performing implementations achieve breakeven points in as little as 14 months. The most significant variables affecting ROI include sampling frequency requirements, integration with existing systems, and the extent of analytical applications deployed across operations.

For optimal financial outcomes, phased implementation approaches are recommended, beginning with applications offering immediate efficiency gains before expanding to more complex analytical functions. This strategy allows for skill development and process optimization while generating early returns to support continued investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!