Driving Innovation in FTIR for Biodiesel Content Analysis

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Evolution and Biodiesel Analysis Objectives

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century. Initially developed as an analytical technique for chemical identification, FTIR has transformed from bulky laboratory equipment to sophisticated, portable devices capable of real-time analysis. The evolution trajectory shows a clear pattern of increasing sensitivity, resolution, and application specificity, particularly in the last two decades with the integration of advanced computing capabilities and miniaturization technologies.

The biodiesel industry has experienced substantial growth globally, driven by environmental concerns and the push for renewable energy sources. This expansion has created an urgent need for reliable, accurate, and efficient methods to analyze biodiesel content in various fuel blends. Traditional analytical methods often require complex sample preparation, consume significant time, and may involve environmentally harmful chemicals.

FTIR technology presents a compelling solution for biodiesel content analysis due to its non-destructive nature, minimal sample preparation requirements, and potential for rapid results. The technique leverages the unique infrared absorption patterns of fatty acid methyl esters (FAMEs) in biodiesel, allowing for differentiation from conventional petroleum diesel components. This spectroscopic fingerprinting capability makes FTIR particularly valuable for quality control and regulatory compliance in biodiesel production and distribution.

Current objectives in FTIR technology development for biodiesel analysis focus on several key areas. First, enhancing detection sensitivity to accurately measure biodiesel content across a wide range of blend percentages, from B2 (2% biodiesel) to B100 (pure biodiesel). Second, improving specificity to distinguish between different biodiesel feedstocks, which can vary significantly in their chemical composition depending on the source material (soybean, palm, waste cooking oil, etc.).

Additionally, there is a growing emphasis on developing portable and field-deployable FTIR systems that maintain laboratory-grade accuracy while enabling on-site testing at production facilities, distribution centers, and regulatory checkpoints. Such systems would significantly reduce testing time and costs while ensuring compliance with increasingly stringent quality standards.

The integration of artificial intelligence and machine learning algorithms with FTIR spectroscopy represents another frontier, potentially enabling automated pattern recognition, anomaly detection, and predictive analytics for biodiesel quality parameters beyond simple content analysis. These advanced computational approaches could transform raw spectral data into actionable insights regarding fuel stability, cold flow properties, and potential contaminants.

The biodiesel industry has experienced substantial growth globally, driven by environmental concerns and the push for renewable energy sources. This expansion has created an urgent need for reliable, accurate, and efficient methods to analyze biodiesel content in various fuel blends. Traditional analytical methods often require complex sample preparation, consume significant time, and may involve environmentally harmful chemicals.

FTIR technology presents a compelling solution for biodiesel content analysis due to its non-destructive nature, minimal sample preparation requirements, and potential for rapid results. The technique leverages the unique infrared absorption patterns of fatty acid methyl esters (FAMEs) in biodiesel, allowing for differentiation from conventional petroleum diesel components. This spectroscopic fingerprinting capability makes FTIR particularly valuable for quality control and regulatory compliance in biodiesel production and distribution.

Current objectives in FTIR technology development for biodiesel analysis focus on several key areas. First, enhancing detection sensitivity to accurately measure biodiesel content across a wide range of blend percentages, from B2 (2% biodiesel) to B100 (pure biodiesel). Second, improving specificity to distinguish between different biodiesel feedstocks, which can vary significantly in their chemical composition depending on the source material (soybean, palm, waste cooking oil, etc.).

Additionally, there is a growing emphasis on developing portable and field-deployable FTIR systems that maintain laboratory-grade accuracy while enabling on-site testing at production facilities, distribution centers, and regulatory checkpoints. Such systems would significantly reduce testing time and costs while ensuring compliance with increasingly stringent quality standards.

The integration of artificial intelligence and machine learning algorithms with FTIR spectroscopy represents another frontier, potentially enabling automated pattern recognition, anomaly detection, and predictive analytics for biodiesel quality parameters beyond simple content analysis. These advanced computational approaches could transform raw spectral data into actionable insights regarding fuel stability, cold flow properties, and potential contaminants.

Market Demand for Biodiesel Quality Control Solutions

The global biodiesel market has experienced significant growth over the past decade, driven by increasing environmental concerns, government mandates for renewable fuel usage, and the search for sustainable alternatives to fossil fuels. This growth has created a substantial demand for reliable quality control solutions, particularly for biodiesel content analysis in blended fuels.

Regulatory frameworks worldwide have established strict quality standards for biodiesel, including ASTM D6751 in the United States, EN 14214 in Europe, and similar standards in other regions. These standards necessitate accurate measurement of biodiesel content in fuel blends, creating a direct market need for advanced analytical technologies like FTIR spectroscopy.

The biodiesel quality control solutions market is projected to grow steadily as biodiesel production continues to expand globally. Major biodiesel producing regions include the European Union, United States, Brazil, Argentina, and increasingly Southeast Asian countries like Indonesia and Malaysia. Each region represents a significant market for quality control technologies.

Fuel blending terminals, petroleum distributors, and regulatory compliance laboratories constitute the primary customer segments for biodiesel content analysis solutions. These stakeholders require rapid, accurate, and cost-effective methods to verify biodiesel blend percentages and ensure compliance with regulatory standards.

Traditional methods for biodiesel content analysis, such as gas chromatography, are being increasingly challenged by the need for faster, field-deployable solutions. This shift is creating market opportunities for portable FTIR systems that can provide real-time analysis at various points in the supply chain.

The market is also witnessing increased demand for integrated solutions that combine hardware and software components, offering not just measurement capabilities but also data management, trend analysis, and compliance reporting functionalities. This reflects the industry's movement toward digitalization and process automation.

Cost considerations remain significant market factors, as many potential users, particularly smaller fuel distributors and testing facilities, are sensitive to both initial investment and operational costs. Solutions that offer a balance between analytical performance and economic feasibility are likely to capture larger market shares.

As biodiesel formulations evolve and new feedstocks emerge, the market increasingly demands flexible analytical solutions capable of adapting to changing product characteristics. This creates opportunities for FTIR technologies that can be easily calibrated for different biodiesel types and blend ratios.

Regulatory frameworks worldwide have established strict quality standards for biodiesel, including ASTM D6751 in the United States, EN 14214 in Europe, and similar standards in other regions. These standards necessitate accurate measurement of biodiesel content in fuel blends, creating a direct market need for advanced analytical technologies like FTIR spectroscopy.

The biodiesel quality control solutions market is projected to grow steadily as biodiesel production continues to expand globally. Major biodiesel producing regions include the European Union, United States, Brazil, Argentina, and increasingly Southeast Asian countries like Indonesia and Malaysia. Each region represents a significant market for quality control technologies.

Fuel blending terminals, petroleum distributors, and regulatory compliance laboratories constitute the primary customer segments for biodiesel content analysis solutions. These stakeholders require rapid, accurate, and cost-effective methods to verify biodiesel blend percentages and ensure compliance with regulatory standards.

Traditional methods for biodiesel content analysis, such as gas chromatography, are being increasingly challenged by the need for faster, field-deployable solutions. This shift is creating market opportunities for portable FTIR systems that can provide real-time analysis at various points in the supply chain.

The market is also witnessing increased demand for integrated solutions that combine hardware and software components, offering not just measurement capabilities but also data management, trend analysis, and compliance reporting functionalities. This reflects the industry's movement toward digitalization and process automation.

Cost considerations remain significant market factors, as many potential users, particularly smaller fuel distributors and testing facilities, are sensitive to both initial investment and operational costs. Solutions that offer a balance between analytical performance and economic feasibility are likely to capture larger market shares.

As biodiesel formulations evolve and new feedstocks emerge, the market increasingly demands flexible analytical solutions capable of adapting to changing product characteristics. This creates opportunities for FTIR technologies that can be easily calibrated for different biodiesel types and blend ratios.

Current FTIR Spectroscopy Challenges in Biofuel Analysis

Fourier Transform Infrared (FTIR) spectroscopy has become a cornerstone analytical technique for biodiesel content analysis, yet several significant challenges persist that limit its full potential in biofuel applications. The primary challenge lies in spectral interference and overlapping absorption bands. Biodiesel samples contain complex mixtures of fatty acid methyl esters (FAMEs) alongside potential contaminants, resulting in crowded spectra where key diagnostic peaks may be obscured or difficult to isolate. This spectral congestion complicates accurate quantification, particularly at lower biodiesel blend percentages.

Sample preparation inconsistencies represent another substantial hurdle. The heterogeneous nature of biodiesel-petroleum diesel blends can lead to stratification and non-uniform sampling, introducing variability in measurements. Additionally, moisture absorption during sample handling can significantly alter spectral profiles, as water exhibits strong IR absorption bands that may mask important biodiesel markers.

Calibration stability presents ongoing difficulties for FTIR applications in this field. Current systems require frequent recalibration due to instrument drift, environmental fluctuations, and variations in sample composition. The development of robust calibration models that maintain accuracy across diverse biodiesel feedstocks (soybean, palm, waste cooking oil, etc.) remains elusive, as each feedstock produces slightly different FAME profiles with unique spectral signatures.

Resolution limitations of conventional FTIR instruments impede the differentiation between closely related chemical structures in biodiesel samples. Standard mid-IR FTIR systems typically operate at resolutions of 4-8 cm⁻¹, which may be insufficient to distinguish subtle spectral features critical for precise biodiesel characterization, particularly when analyzing adulterated or degraded samples.

Data interpretation complexity further complicates FTIR analysis of biodiesel. Current software solutions often struggle with automated peak assignment and quantification in complex biofuel matrices. Analysts frequently resort to manual interpretation, introducing subjectivity and reducing throughput. The lack of standardized spectral libraries specifically optimized for biodiesel analysis compounds this challenge.

Field deployment constraints represent a significant barrier to widespread adoption. Most high-performance FTIR systems require controlled laboratory environments, limiting on-site testing capabilities at production facilities or distribution points. Portable FTIR devices exist but typically sacrifice sensitivity and resolution, compromising analytical performance for biodiesel content determination.

Regulatory compliance issues also present challenges, as different regions maintain varying standards for biodiesel analysis methodologies. While FTIR offers advantages in speed and simplicity, some regulatory frameworks still favor traditional wet chemistry methods, creating barriers to FTIR adoption despite its potential benefits for rapid quality control.

Sample preparation inconsistencies represent another substantial hurdle. The heterogeneous nature of biodiesel-petroleum diesel blends can lead to stratification and non-uniform sampling, introducing variability in measurements. Additionally, moisture absorption during sample handling can significantly alter spectral profiles, as water exhibits strong IR absorption bands that may mask important biodiesel markers.

Calibration stability presents ongoing difficulties for FTIR applications in this field. Current systems require frequent recalibration due to instrument drift, environmental fluctuations, and variations in sample composition. The development of robust calibration models that maintain accuracy across diverse biodiesel feedstocks (soybean, palm, waste cooking oil, etc.) remains elusive, as each feedstock produces slightly different FAME profiles with unique spectral signatures.

Resolution limitations of conventional FTIR instruments impede the differentiation between closely related chemical structures in biodiesel samples. Standard mid-IR FTIR systems typically operate at resolutions of 4-8 cm⁻¹, which may be insufficient to distinguish subtle spectral features critical for precise biodiesel characterization, particularly when analyzing adulterated or degraded samples.

Data interpretation complexity further complicates FTIR analysis of biodiesel. Current software solutions often struggle with automated peak assignment and quantification in complex biofuel matrices. Analysts frequently resort to manual interpretation, introducing subjectivity and reducing throughput. The lack of standardized spectral libraries specifically optimized for biodiesel analysis compounds this challenge.

Field deployment constraints represent a significant barrier to widespread adoption. Most high-performance FTIR systems require controlled laboratory environments, limiting on-site testing capabilities at production facilities or distribution points. Portable FTIR devices exist but typically sacrifice sensitivity and resolution, compromising analytical performance for biodiesel content determination.

Regulatory compliance issues also present challenges, as different regions maintain varying standards for biodiesel analysis methodologies. While FTIR offers advantages in speed and simplicity, some regulatory frameworks still favor traditional wet chemistry methods, creating barriers to FTIR adoption despite its potential benefits for rapid quality control.

Existing FTIR Methodologies for Biodiesel Content Determination

01 Improving FTIR spectroscopy accuracy through calibration methods

Various calibration techniques can significantly enhance the accuracy of FTIR spectroscopy analysis. These methods include using reference standards, developing specialized calibration algorithms, and implementing statistical correction models. Proper calibration helps compensate for instrumental drift, environmental variations, and sample-related interferences, resulting in more reliable and reproducible spectral data for quantitative and qualitative analysis.- Calibration methods for improving FTIR accuracy: Various calibration techniques are employed to enhance the accuracy of FTIR spectroscopy analysis. These methods include using reference standards, automated calibration procedures, and mathematical algorithms to correct for instrumental drift and environmental variations. Proper calibration ensures reliable quantitative and qualitative analysis results by minimizing systematic errors and establishing accurate baseline measurements.

- Advanced data processing algorithms for FTIR analysis: Sophisticated data processing algorithms significantly improve FTIR analysis accuracy. These include spectral deconvolution techniques, multivariate statistical methods, machine learning approaches, and noise reduction algorithms. Such computational methods enhance the ability to identify and quantify components in complex mixtures, improve signal-to-noise ratios, and extract meaningful information from overlapping spectral bands.

- Hardware innovations for enhanced FTIR precision: Hardware advancements play a crucial role in improving FTIR analysis accuracy. These innovations include high-resolution detectors, improved interferometer designs, temperature-controlled sample chambers, and specialized sampling accessories. Enhanced optical components and mechanical stability features reduce measurement variability and increase the reproducibility of spectral data across different samples and conditions.

- Sample preparation techniques affecting FTIR accuracy: Sample preparation methodologies significantly impact FTIR analysis accuracy. Techniques such as proper grinding, mixing with KBr for pellet formation, thin film preparation, and specialized extraction procedures help ensure homogeneous samples with appropriate thickness and concentration. Standardized preparation protocols minimize variability and interference from contaminants, leading to more accurate spectral interpretation and quantitative analysis.

- Environmental and operational factors affecting FTIR measurement accuracy: Environmental and operational conditions significantly influence FTIR analysis accuracy. Factors such as ambient humidity, temperature fluctuations, CO2 levels, instrument warm-up time, and operator technique can introduce measurement errors. Controlled laboratory environments, purging systems, background correction procedures, and standardized operating protocols help mitigate these variables and ensure consistent, accurate spectral measurements across different analysis sessions.

02 Advanced signal processing techniques for FTIR data analysis

Signal processing algorithms play a crucial role in improving FTIR analysis accuracy. Techniques such as noise reduction, baseline correction, spectral deconvolution, and multivariate statistical analysis help extract meaningful information from complex spectral data. These computational approaches enhance the detection limits, resolution, and overall reliability of FTIR measurements, particularly when analyzing samples with overlapping spectral features or low analyte concentrations.Expand Specific Solutions03 Hardware innovations to enhance FTIR measurement precision

Technological advancements in FTIR instrumentation components significantly improve measurement accuracy. These innovations include high-precision interferometers, enhanced detectors with improved signal-to-noise ratios, temperature-controlled sample chambers, and automated sample positioning systems. Such hardware improvements minimize systematic errors and increase the reproducibility of spectral measurements across different samples and operating conditions.Expand Specific Solutions04 Sample preparation techniques for optimized FTIR analysis

Proper sample preparation methodologies are essential for accurate FTIR analysis. Techniques such as homogenization, particle size control, moisture removal, and appropriate sample mounting can significantly reduce measurement errors. Specialized preparation protocols for different sample types (solids, liquids, gases, biological materials) help minimize artifacts and interferences that could compromise spectral quality and analytical accuracy.Expand Specific Solutions05 Integration of FTIR with complementary analytical techniques

Combining FTIR spectroscopy with other analytical methods creates synergistic approaches that overcome individual technique limitations. Integration with techniques such as Raman spectroscopy, mass spectrometry, chromatography, or thermal analysis provides complementary data that enhances overall analytical accuracy. These hyphenated or correlated techniques enable more comprehensive characterization and validation of results, particularly for complex samples requiring multi-parameter analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions in FTIR Biofuel Analysis

The FTIR biodiesel content analysis market is currently in a growth phase, with increasing demand driven by stricter fuel quality regulations and sustainability initiatives. The market size is expanding at approximately 5-7% annually, reaching an estimated $300-350 million globally. Technologically, the field shows varying maturity levels, with established players like ExxonMobil and Marathon Petroleum focusing on industrial-scale applications, while academic institutions (Heriot-Watt University, Xi'an Jiaotong University) drive fundamental research. Specialized equipment manufacturers such as Stanhope-Seta and Focused Photonics are advancing portable and high-precision instruments. The competitive landscape features collaboration between petroleum companies (Schlumberger, Afton Chemical) and technology providers, with emerging competition from research institutions developing next-generation spectroscopic techniques for faster, more accurate biodiesel content determination.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced FTIR (Fourier Transform Infrared) spectroscopy techniques specifically optimized for biodiesel content analysis in petroleum products. Their approach utilizes mid-infrared spectral regions (1800-1700 cm⁻¹) to detect and quantify fatty acid methyl esters (FAME) with high precision. The company has implemented automated sampling systems with temperature-controlled cells to maintain sample integrity during analysis. Their proprietary chemometric algorithms enable real-time processing of spectral data, allowing for detection limits as low as 0.1% biodiesel content in conventional diesel fuels. ExxonMobil has integrated this technology into their quality control processes across refineries, creating a standardized testing protocol that meets ASTM D7371 requirements while reducing analysis time from hours to minutes compared to traditional wet chemistry methods.

Strengths: Superior detection limits and precision compared to conventional methods; integrated workflow automation reduces human error; robust calibration models account for varying biodiesel feedstocks. Weaknesses: Proprietary nature limits wider industry adoption; requires significant initial investment in specialized equipment and training; potential interference from certain additives in complex fuel matrices.

Stanhope-Seta Ltd.

Technical Solution: Stanhope-Seta has pioneered portable FTIR technology for on-site biodiesel content analysis through their SETABIODIESEL analyzer system. Their innovation combines miniaturized FTIR spectroscopy with advanced pattern recognition algorithms to identify biodiesel markers in various fuel blends. The system employs a patented sampling interface that requires minimal sample preparation (less than 2ml) and delivers results within 3 minutes. Their technology utilizes specific absorption bands at 1745 cm⁻¹ (C=O stretching) and 1170 cm⁻¹ (C-O stretching) to quantify FAME content with accuracy comparable to laboratory methods. The company has developed field-hardened instruments that maintain calibration stability under varying environmental conditions, making them suitable for both refinery and distribution point testing. Their cloud-based calibration update system ensures measurement consistency across multiple devices deployed globally.

Strengths: Exceptional portability enables field testing at distribution points; rapid analysis time improves operational efficiency; minimal sample volume requirements reduce waste. Weaknesses: Slightly lower precision compared to full laboratory systems; limited ability to differentiate between certain biodiesel feedstock types; requires periodic recalibration to maintain accuracy.

Key Patents and Breakthroughs in FTIR Biodiesel Analysis

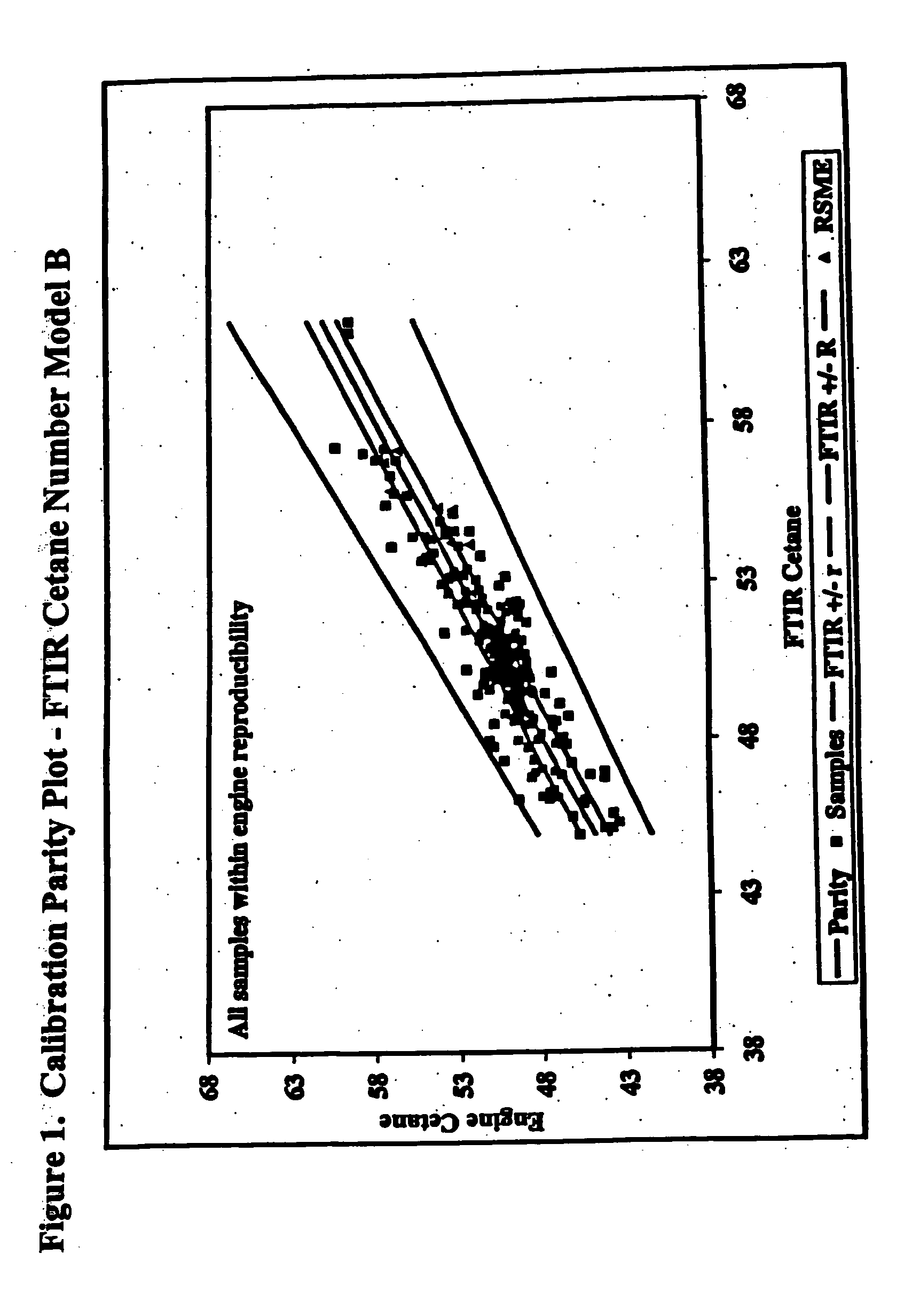

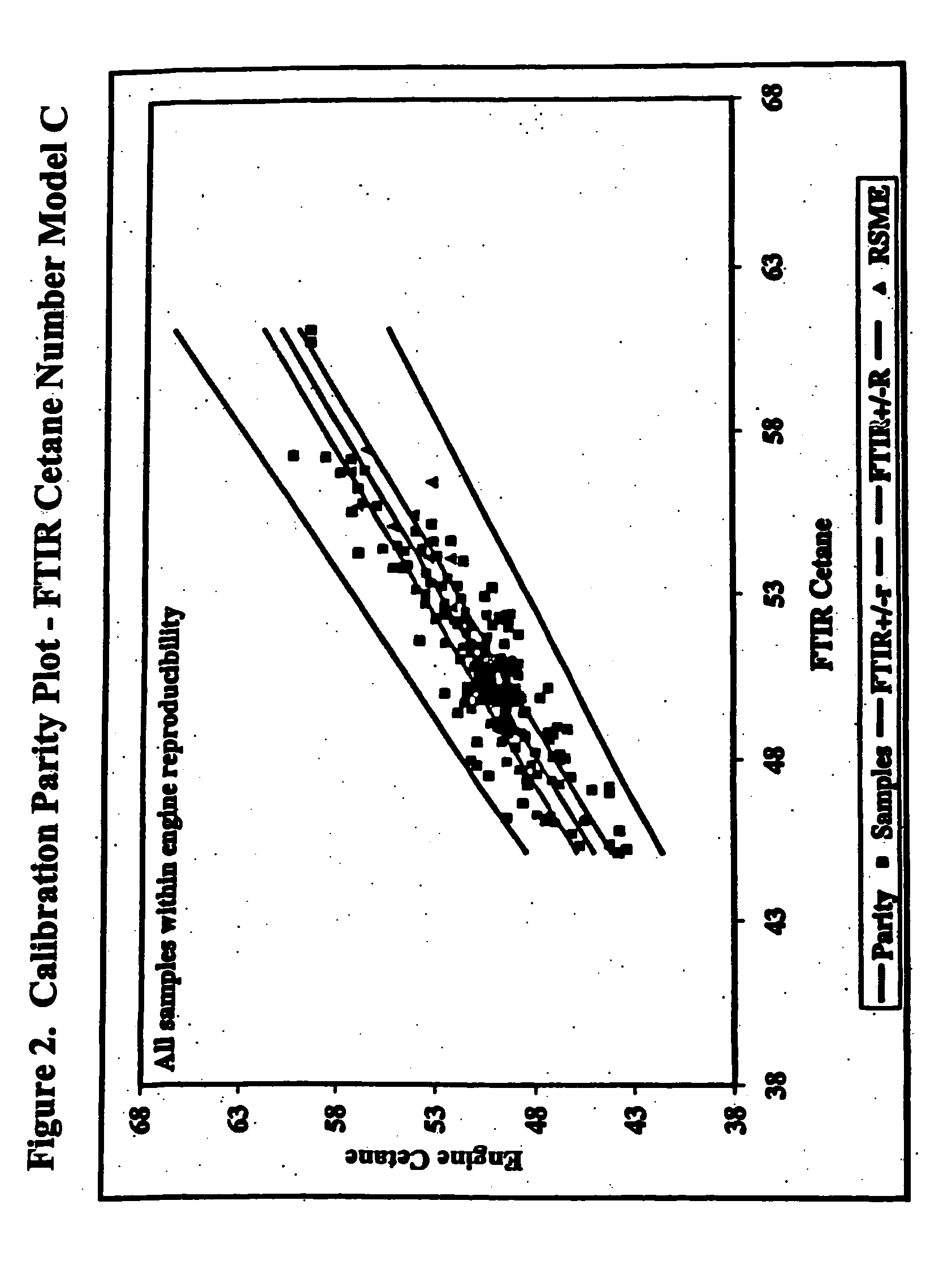

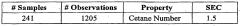

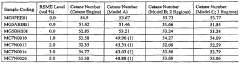

Fourier transform infrared (FTIR) chemometric method to determine cetane number of diesel fuels containing fatty acid alkyl ester additives

PatentActiveUS20070163168A1

Innovation

- Development of an FTIR-based multivariate model using specific infrared spectral regions (4900-3500 cm−1 and 2200-1624 cm−1 or 4900-3500 cm−1, 2200-1800 cm−1, and 1700-1624 cm−1) to correlate infrared spectra with cetane number, enabling recognition and measurement of RSME-containing fuels.

Fourier transform infrared (FTIR) chemometric method to determine cetane number of diesel fuels containing fatty acid alkyl ester additives

PatentWO2007084406A2

Innovation

- Development of an FTIR-based multivariate chemometric model that correlates the infrared spectrum of biodiesel samples to their cetane number using specific frequency ranges, allowing recognition and measurement of RSME-containing fuels, either with two regions (4900-3500 cm^-1 and 2200-1624 cm^-1) or three regions (4900-3500 cm^-1, 2200-1800 cm^-1, and 1700-1624 cm^-1) depending on the absorbance of the ester functional group.

Standardization and Calibration Protocols for FTIR Biodiesel Analysis

The standardization and calibration of FTIR methods for biodiesel content analysis represent critical components in ensuring reliable, reproducible, and accurate measurements across different laboratories and instruments. Current protocols exhibit significant variations, leading to inconsistencies in results that hamper industry-wide acceptance and regulatory compliance.

Establishing robust calibration protocols begins with the selection of appropriate reference materials. High-purity biodiesel samples with certified compositions, spanning various feedstock types (soybean, palm, rapeseed, etc.), must be utilized to develop comprehensive calibration curves. These reference materials should be traceable to international standards to ensure global consistency in measurements.

Instrument calibration procedures require standardization across multiple parameters. Spectral resolution settings, typically between 2-4 cm^-1, must be optimized to balance signal quality with analysis speed. Sampling techniques, whether using attenuated total reflectance (ATR) or transmission cells, need explicit protocols defining cell path lengths, cleaning procedures, and sample handling methodologies to minimize contamination risks.

Multivariate calibration models represent the cornerstone of modern FTIR biodiesel analysis. Partial Least Squares (PLS) regression has emerged as the preferred mathematical approach, but standardized procedures for model development, validation, and transfer between instruments remain underdeveloped. Cross-validation methodologies and minimum performance metrics (RMSEP, R² values) require industry consensus to establish acceptable thresholds.

Interlaboratory comparison studies have revealed significant variations in results when analyzing identical samples across different facilities. These discrepancies highlight the urgent need for harmonized protocols addressing instrument qualification, regular performance verification, and calibration maintenance schedules. Drift correction procedures and routine system suitability tests must be incorporated into standard operating procedures.

Environmental factors significantly impact FTIR measurements, necessitating standardized controls for temperature (ideally 20-25°C) and humidity (below 60%). Sample temperature control during measurement is particularly critical for biodiesel analysis, as thermal variations can shift characteristic absorption bands and introduce systematic errors.

Regulatory bodies, including ASTM International and the European Committee for Standardization (CEN), have begun developing standardized methods, but significant gaps remain in addressing the full spectrum of biodiesel blends and feedstock variations. Collaborative efforts between instrument manufacturers, petroleum companies, and regulatory agencies are essential to establish universally accepted calibration transfer protocols that enable consistent results across different FTIR platforms.

Establishing robust calibration protocols begins with the selection of appropriate reference materials. High-purity biodiesel samples with certified compositions, spanning various feedstock types (soybean, palm, rapeseed, etc.), must be utilized to develop comprehensive calibration curves. These reference materials should be traceable to international standards to ensure global consistency in measurements.

Instrument calibration procedures require standardization across multiple parameters. Spectral resolution settings, typically between 2-4 cm^-1, must be optimized to balance signal quality with analysis speed. Sampling techniques, whether using attenuated total reflectance (ATR) or transmission cells, need explicit protocols defining cell path lengths, cleaning procedures, and sample handling methodologies to minimize contamination risks.

Multivariate calibration models represent the cornerstone of modern FTIR biodiesel analysis. Partial Least Squares (PLS) regression has emerged as the preferred mathematical approach, but standardized procedures for model development, validation, and transfer between instruments remain underdeveloped. Cross-validation methodologies and minimum performance metrics (RMSEP, R² values) require industry consensus to establish acceptable thresholds.

Interlaboratory comparison studies have revealed significant variations in results when analyzing identical samples across different facilities. These discrepancies highlight the urgent need for harmonized protocols addressing instrument qualification, regular performance verification, and calibration maintenance schedules. Drift correction procedures and routine system suitability tests must be incorporated into standard operating procedures.

Environmental factors significantly impact FTIR measurements, necessitating standardized controls for temperature (ideally 20-25°C) and humidity (below 60%). Sample temperature control during measurement is particularly critical for biodiesel analysis, as thermal variations can shift characteristic absorption bands and introduce systematic errors.

Regulatory bodies, including ASTM International and the European Committee for Standardization (CEN), have begun developing standardized methods, but significant gaps remain in addressing the full spectrum of biodiesel blends and feedstock variations. Collaborative efforts between instrument manufacturers, petroleum companies, and regulatory agencies are essential to establish universally accepted calibration transfer protocols that enable consistent results across different FTIR platforms.

Environmental Impact and Sustainability Considerations of FTIR Methods

The adoption of FTIR spectroscopy for biodiesel content analysis represents a significant advancement in analytical methodology with substantial environmental implications. Traditional wet chemical methods for biodiesel analysis often involve hazardous chemicals and generate considerable waste, contributing to environmental pollution. In contrast, FTIR techniques require minimal sample preparation and virtually eliminate chemical waste, substantially reducing the environmental footprint of analytical procedures in the biofuel industry.

Energy efficiency constitutes another critical environmental advantage of FTIR methods. Modern FTIR instruments consume significantly less power compared to chromatographic techniques like gas chromatography, which require high temperatures and carrier gases. This reduced energy consumption translates directly to lower carbon emissions associated with analytical processes, aligning with global sustainability goals and carbon reduction initiatives in laboratory settings.

The non-destructive nature of FTIR analysis further enhances its sustainability profile. Samples analyzed via FTIR remain intact and can be repurposed for additional testing or returned to production streams, minimizing material waste. This characteristic proves particularly valuable in quality control applications where multiple analytical parameters must be assessed from limited sample volumes.

From a lifecycle perspective, FTIR methods contribute to sustainability throughout the biodiesel production chain. By enabling rapid, accurate monitoring of conversion processes, FTIR technology helps optimize reaction conditions, potentially reducing energy requirements during manufacturing. Additionally, precise content analysis ensures the final biodiesel product meets quality standards, improving combustion efficiency and reducing harmful emissions during end use.

The portability of modern FTIR systems introduces further environmental benefits through decentralized testing capabilities. Field-deployable units eliminate the need to transport samples to centralized laboratories, reducing transportation-related carbon emissions. This aspect proves especially valuable in remote biodiesel production facilities or quality verification at distribution points.

Looking forward, the integration of FTIR analysis with renewable energy sources represents a promising direction for further enhancing environmental sustainability. Solar-powered portable FTIR units are being developed for deployment in off-grid locations, potentially expanding access to advanced analytical capabilities while maintaining minimal environmental impact. Such innovations demonstrate how analytical technologies like FTIR can evolve in harmony with broader sustainability objectives in the renewable energy sector.

Energy efficiency constitutes another critical environmental advantage of FTIR methods. Modern FTIR instruments consume significantly less power compared to chromatographic techniques like gas chromatography, which require high temperatures and carrier gases. This reduced energy consumption translates directly to lower carbon emissions associated with analytical processes, aligning with global sustainability goals and carbon reduction initiatives in laboratory settings.

The non-destructive nature of FTIR analysis further enhances its sustainability profile. Samples analyzed via FTIR remain intact and can be repurposed for additional testing or returned to production streams, minimizing material waste. This characteristic proves particularly valuable in quality control applications where multiple analytical parameters must be assessed from limited sample volumes.

From a lifecycle perspective, FTIR methods contribute to sustainability throughout the biodiesel production chain. By enabling rapid, accurate monitoring of conversion processes, FTIR technology helps optimize reaction conditions, potentially reducing energy requirements during manufacturing. Additionally, precise content analysis ensures the final biodiesel product meets quality standards, improving combustion efficiency and reducing harmful emissions during end use.

The portability of modern FTIR systems introduces further environmental benefits through decentralized testing capabilities. Field-deployable units eliminate the need to transport samples to centralized laboratories, reducing transportation-related carbon emissions. This aspect proves especially valuable in remote biodiesel production facilities or quality verification at distribution points.

Looking forward, the integration of FTIR analysis with renewable energy sources represents a promising direction for further enhancing environmental sustainability. Solar-powered portable FTIR units are being developed for deployment in off-grid locations, potentially expanding access to advanced analytical capabilities while maintaining minimal environmental impact. Such innovations demonstrate how analytical technologies like FTIR can evolve in harmony with broader sustainability objectives in the renewable energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!