Use FTIR to Improve Safety Protocols with Hazardous Agents

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Background and Safety Enhancement Goals

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century. Initially developed as an analytical technique for chemical identification, FTIR has transformed from bulky laboratory equipment to portable, real-time monitoring devices. This evolution has been driven by advancements in computing power, detector sensitivity, and miniaturization technologies, enabling broader applications across various industries including safety management.

The fundamental principle of FTIR involves measuring how infrared radiation is absorbed by materials, creating a unique spectral fingerprint that identifies specific chemical compounds. This capability makes FTIR particularly valuable for hazardous agent detection, as it can identify substances without direct contact, providing a safer approach to chemical analysis compared to traditional methods that might require sample handling.

Current technological trends in FTIR include enhanced spectral resolution, improved signal-to-noise ratios, and integration with artificial intelligence for faster and more accurate substance identification. The development of handheld and wearable FTIR devices represents a significant advancement, allowing for in-field detection and monitoring of hazardous agents in real-time, which is crucial for emergency response scenarios.

The primary goal of implementing FTIR in safety protocols is to enhance hazard identification capabilities while minimizing human exposure to dangerous substances. By enabling remote and rapid detection of chemical, biological, and radiological agents, FTIR technology aims to provide early warning systems that can prevent accidents, reduce exposure risks, and improve emergency response effectiveness.

Another critical objective is to develop comprehensive spectral libraries specifically for hazardous materials commonly found in industrial, laboratory, and emergency response environments. These libraries would enable faster identification of unknown substances, allowing safety personnel to implement appropriate containment and mitigation strategies more efficiently.

Integration goals include incorporating FTIR systems into existing safety infrastructure, such as building ventilation systems for continuous air monitoring, personal protective equipment for individual exposure assessment, and emergency response vehicles for mobile detection capabilities. This integration requires addressing challenges related to system interoperability, data standardization, and real-time information sharing across different safety platforms.

Long-term technological objectives include developing FTIR systems capable of detecting hazardous agents at increasingly lower concentrations, expanding the range of detectable substances, and creating more robust algorithms that can identify mixtures of compounds accurately. Additionally, there is a push toward systems that can function reliably in challenging environments characterized by extreme temperatures, humidity, or the presence of interfering substances.

The fundamental principle of FTIR involves measuring how infrared radiation is absorbed by materials, creating a unique spectral fingerprint that identifies specific chemical compounds. This capability makes FTIR particularly valuable for hazardous agent detection, as it can identify substances without direct contact, providing a safer approach to chemical analysis compared to traditional methods that might require sample handling.

Current technological trends in FTIR include enhanced spectral resolution, improved signal-to-noise ratios, and integration with artificial intelligence for faster and more accurate substance identification. The development of handheld and wearable FTIR devices represents a significant advancement, allowing for in-field detection and monitoring of hazardous agents in real-time, which is crucial for emergency response scenarios.

The primary goal of implementing FTIR in safety protocols is to enhance hazard identification capabilities while minimizing human exposure to dangerous substances. By enabling remote and rapid detection of chemical, biological, and radiological agents, FTIR technology aims to provide early warning systems that can prevent accidents, reduce exposure risks, and improve emergency response effectiveness.

Another critical objective is to develop comprehensive spectral libraries specifically for hazardous materials commonly found in industrial, laboratory, and emergency response environments. These libraries would enable faster identification of unknown substances, allowing safety personnel to implement appropriate containment and mitigation strategies more efficiently.

Integration goals include incorporating FTIR systems into existing safety infrastructure, such as building ventilation systems for continuous air monitoring, personal protective equipment for individual exposure assessment, and emergency response vehicles for mobile detection capabilities. This integration requires addressing challenges related to system interoperability, data standardization, and real-time information sharing across different safety platforms.

Long-term technological objectives include developing FTIR systems capable of detecting hazardous agents at increasingly lower concentrations, expanding the range of detectable substances, and creating more robust algorithms that can identify mixtures of compounds accurately. Additionally, there is a push toward systems that can function reliably in challenging environments characterized by extreme temperatures, humidity, or the presence of interfering substances.

Market Demand for Advanced Hazardous Agent Detection

The global market for hazardous agent detection technologies has experienced significant growth in recent years, driven by increasing concerns about public safety, industrial accidents, and potential terrorist threats. The demand for advanced detection systems utilizing Fourier Transform Infrared Spectroscopy (FTIR) has been particularly robust across multiple sectors including homeland security, industrial safety, environmental monitoring, and healthcare.

In the homeland security sector, government agencies worldwide have substantially increased their budgets for chemical, biological, radiological, nuclear, and explosive (CBRNE) detection equipment. The United States Department of Homeland Security alone allocated over $1.8 billion for CBRNE countermeasures in recent fiscal years, with detection technologies comprising a significant portion of this spending.

Industrial safety represents another major market driver, with chemical manufacturing, oil and gas, and pharmaceutical industries implementing increasingly sophisticated hazardous material monitoring systems. The global industrial safety market is expanding at a compound annual growth rate of 8.2%, with detection technologies being a key component of this growth.

Environmental monitoring agencies and first responders also constitute a growing market segment. These organizations require portable, rapid, and accurate detection capabilities for hazardous materials during emergency response situations. The market for portable chemical detection devices is projected to reach $2.5 billion by 2025, with FTIR-based systems capturing an increasing share.

Healthcare facilities have emerged as a new growth area, particularly following global health crises that highlighted the need for improved detection of airborne pathogens and hazardous biological agents. Hospitals and research laboratories are investing in advanced detection systems to ensure workplace safety and prevent contamination incidents.

Market research indicates that end-users are increasingly demanding detection systems with specific performance characteristics: higher sensitivity to detect lower concentrations of hazardous agents; improved specificity to reduce false alarms; faster detection speeds for rapid response; multi-agent detection capabilities; and enhanced portability for field operations.

The integration of FTIR technology with artificial intelligence and machine learning represents a particularly high-growth segment, as these combined technologies offer superior pattern recognition capabilities and can continuously improve detection accuracy through data analysis. Market analysts project that AI-enhanced detection systems will see a compound annual growth rate of 12.7% over the next five years.

Regional analysis shows North America currently leading the market for advanced detection technologies, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in developing regions where industrial expansion and security concerns are driving rapid adoption of safety technologies.

In the homeland security sector, government agencies worldwide have substantially increased their budgets for chemical, biological, radiological, nuclear, and explosive (CBRNE) detection equipment. The United States Department of Homeland Security alone allocated over $1.8 billion for CBRNE countermeasures in recent fiscal years, with detection technologies comprising a significant portion of this spending.

Industrial safety represents another major market driver, with chemical manufacturing, oil and gas, and pharmaceutical industries implementing increasingly sophisticated hazardous material monitoring systems. The global industrial safety market is expanding at a compound annual growth rate of 8.2%, with detection technologies being a key component of this growth.

Environmental monitoring agencies and first responders also constitute a growing market segment. These organizations require portable, rapid, and accurate detection capabilities for hazardous materials during emergency response situations. The market for portable chemical detection devices is projected to reach $2.5 billion by 2025, with FTIR-based systems capturing an increasing share.

Healthcare facilities have emerged as a new growth area, particularly following global health crises that highlighted the need for improved detection of airborne pathogens and hazardous biological agents. Hospitals and research laboratories are investing in advanced detection systems to ensure workplace safety and prevent contamination incidents.

Market research indicates that end-users are increasingly demanding detection systems with specific performance characteristics: higher sensitivity to detect lower concentrations of hazardous agents; improved specificity to reduce false alarms; faster detection speeds for rapid response; multi-agent detection capabilities; and enhanced portability for field operations.

The integration of FTIR technology with artificial intelligence and machine learning represents a particularly high-growth segment, as these combined technologies offer superior pattern recognition capabilities and can continuously improve detection accuracy through data analysis. Market analysts project that AI-enhanced detection systems will see a compound annual growth rate of 12.7% over the next five years.

Regional analysis shows North America currently leading the market for advanced detection technologies, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in developing regions where industrial expansion and security concerns are driving rapid adoption of safety technologies.

Current FTIR Implementation Challenges in Safety Protocols

Despite the significant potential of FTIR (Fourier Transform Infrared Spectroscopy) in enhancing safety protocols for hazardous agents, several implementation challenges currently limit its widespread adoption and effectiveness. The integration of FTIR technology into existing safety frameworks faces technical, operational, and resource-related obstacles that must be addressed for optimal utilization.

Technical challenges represent the primary barrier to effective FTIR implementation. Current FTIR systems often struggle with real-time detection capabilities, particularly in dynamic environments where rapid identification of hazardous agents is critical. The spectral resolution of portable FTIR devices remains insufficient for distinguishing between closely related chemical compounds, potentially leading to false positives or negatives in hazard identification. Additionally, environmental interferences such as humidity, temperature fluctuations, and background contaminants can significantly compromise measurement accuracy.

Data interpretation presents another substantial challenge. The complexity of FTIR spectral data requires sophisticated algorithms and reference libraries for accurate compound identification. Many existing systems lack comprehensive spectral databases for emerging hazardous materials, particularly novel chemical compounds and biological agents. Furthermore, the interpretation software often requires specialized expertise, creating a knowledge gap for frontline safety personnel who may not possess advanced analytical training.

Operational integration issues further complicate FTIR implementation. Current safety protocols rarely include standardized procedures for FTIR deployment, leading to inconsistent application across different facilities and scenarios. The lack of industry-wide standards for FTIR use in safety applications creates uncertainty regarding best practices and validation methodologies. Additionally, many organizations struggle with determining appropriate sampling strategies that balance comprehensive coverage with operational efficiency.

Resource constraints significantly impact FTIR adoption in safety protocols. High-quality FTIR systems represent a substantial capital investment, with costs ranging from $20,000 to $100,000 depending on specifications and capabilities. Ongoing maintenance requirements, including regular calibration and component replacement, add to the total cost of ownership. Many organizations, particularly smaller facilities and emergency response teams, lack the financial resources to acquire and maintain advanced FTIR systems.

Training requirements pose additional implementation barriers. Effective FTIR operation demands specialized knowledge in both instrument operation and data interpretation. The current shortage of qualified personnel with FTIR expertise creates bottlenecks in technology deployment. Training programs often fail to adequately prepare safety personnel for the nuanced aspects of FTIR application in hazardous environments, leading to suboptimal utilization of available technology.

Technical challenges represent the primary barrier to effective FTIR implementation. Current FTIR systems often struggle with real-time detection capabilities, particularly in dynamic environments where rapid identification of hazardous agents is critical. The spectral resolution of portable FTIR devices remains insufficient for distinguishing between closely related chemical compounds, potentially leading to false positives or negatives in hazard identification. Additionally, environmental interferences such as humidity, temperature fluctuations, and background contaminants can significantly compromise measurement accuracy.

Data interpretation presents another substantial challenge. The complexity of FTIR spectral data requires sophisticated algorithms and reference libraries for accurate compound identification. Many existing systems lack comprehensive spectral databases for emerging hazardous materials, particularly novel chemical compounds and biological agents. Furthermore, the interpretation software often requires specialized expertise, creating a knowledge gap for frontline safety personnel who may not possess advanced analytical training.

Operational integration issues further complicate FTIR implementation. Current safety protocols rarely include standardized procedures for FTIR deployment, leading to inconsistent application across different facilities and scenarios. The lack of industry-wide standards for FTIR use in safety applications creates uncertainty regarding best practices and validation methodologies. Additionally, many organizations struggle with determining appropriate sampling strategies that balance comprehensive coverage with operational efficiency.

Resource constraints significantly impact FTIR adoption in safety protocols. High-quality FTIR systems represent a substantial capital investment, with costs ranging from $20,000 to $100,000 depending on specifications and capabilities. Ongoing maintenance requirements, including regular calibration and component replacement, add to the total cost of ownership. Many organizations, particularly smaller facilities and emergency response teams, lack the financial resources to acquire and maintain advanced FTIR systems.

Training requirements pose additional implementation barriers. Effective FTIR operation demands specialized knowledge in both instrument operation and data interpretation. The current shortage of qualified personnel with FTIR expertise creates bottlenecks in technology deployment. Training programs often fail to adequately prepare safety personnel for the nuanced aspects of FTIR application in hazardous environments, leading to suboptimal utilization of available technology.

Existing FTIR-Based Hazardous Agent Detection Methods

01 Radiation protection and shielding in FTIR systems

FTIR spectroscopy systems require proper radiation shielding to protect operators from potential IR radiation exposure. Safety protocols include implementing protective barriers, using specialized materials that block infrared radiation, and designing enclosures that contain the radiation within the testing area. These measures ensure that operators can safely conduct analyses without risk of radiation-related health hazards.- FTIR instrument safety design and enclosures: Safety enclosures and protective designs for FTIR spectroscopy equipment help minimize exposure to hazardous radiation and chemicals. These designs include sealed sample chambers, interlocked safety shields, and specialized containment systems that prevent leakage of infrared radiation or sample materials. Advanced enclosures may incorporate automated safety shutoffs and monitoring systems to ensure operator protection during analysis procedures.

- Sample handling and preparation safety protocols: Proper sample handling protocols for FTIR analysis include procedures for safely preparing, mounting, and disposing of potentially hazardous materials. These protocols specify appropriate personal protective equipment, ventilation requirements, and containment measures based on sample characteristics. Guidelines cover handling of volatile, toxic, or biologically active substances, with emphasis on minimizing direct contact and preventing contamination or accidental exposure during the spectroscopic analysis process.

- Radiation protection and monitoring systems: Safety systems for monitoring and controlling radiation exposure during FTIR operation include specialized detectors, shielding materials, and warning indicators. These systems continuously monitor radiation levels and automatically implement protective measures when thresholds are exceeded. Advanced monitoring technologies can detect various forms of radiation associated with FTIR operation and provide real-time feedback to operators about potential exposure risks.

- Automated safety control systems for FTIR: Automated safety control systems integrate multiple safety features into FTIR equipment, including emergency shutdowns, fault detection, and operational monitoring. These systems use sensors and software to continuously evaluate operating conditions and automatically respond to potential hazards. Features may include pressure monitoring, temperature control, gas detection, and automated sample handling to minimize operator interaction with hazardous components during the spectroscopic analysis process.

- Training and operational safety procedures: Comprehensive training protocols and operational safety procedures ensure proper use of FTIR equipment while minimizing risks. These include detailed documentation of startup and shutdown sequences, emergency response procedures, maintenance safety guidelines, and proper use of personal protective equipment. Training materials cover recognition of potential hazards specific to FTIR technology, proper laboratory practices, and documentation requirements to maintain compliance with safety regulations and standards.

02 Sample handling and preparation safety measures

Safe handling of samples for FTIR analysis involves protocols for managing potentially hazardous materials. This includes proper containment systems, ventilation requirements when working with volatile or toxic samples, use of appropriate personal protective equipment, and specialized sample preparation techniques that minimize exposure risks. Standardized procedures for sample disposal after analysis are also critical components of FTIR safety protocols.Expand Specific Solutions03 Automated safety monitoring and control systems

Modern FTIR systems incorporate automated safety monitoring features that continuously assess operational parameters and environmental conditions. These systems include emergency shutdown capabilities, real-time monitoring of radiation levels, temperature control mechanisms, and fault detection algorithms. Automated alerts notify operators of potential safety issues, while integrated control systems can make adjustments to maintain safe operating conditions.Expand Specific Solutions04 Maintenance and calibration safety procedures

Safety protocols for FTIR maintenance and calibration include power isolation procedures, cooling period requirements before servicing optical components, specialized tools for handling sensitive parts, and verification procedures to ensure system integrity after maintenance. Regular calibration using standard reference materials helps maintain accuracy while following specific safety guidelines for accessing internal components and handling calibration materials.Expand Specific Solutions05 Laboratory environment and operator training requirements

FTIR safety protocols specify requirements for the laboratory environment including proper ventilation, emergency equipment placement, designated safety zones, and appropriate workspace design. Comprehensive operator training programs cover equipment operation, emergency procedures, recognition of potential hazards, and proper documentation practices. Certification requirements ensure that only qualified personnel operate the equipment, with regular refresher training to maintain safety awareness.Expand Specific Solutions

Leading FTIR Manufacturers and Safety Solution Providers

The FTIR technology for hazardous agent safety protocols is in a growth phase, with an expanding market driven by increasing safety regulations and industrial applications. The market demonstrates moderate maturity with established players across academic, commercial, and governmental sectors. Key technology leaders include Focused Photonics (Hangzhou) and its subsidiary Puyu Technology, who are advancing environmental monitoring applications, alongside research powerhouses like Battelle Memorial Institute and academic institutions such as Heriot-Watt University and Harbin Institute of Technology. Industrial players like MKS, Smiths Detection, and QuantaRed Technologies are commercializing specialized FTIR solutions for safety applications, while research institutions like Changchun Institute of Optics and Shanghai Institute of Technical Physics are driving innovation in optical sensing technologies for hazardous agent detection.

Battelle Memorial Institute

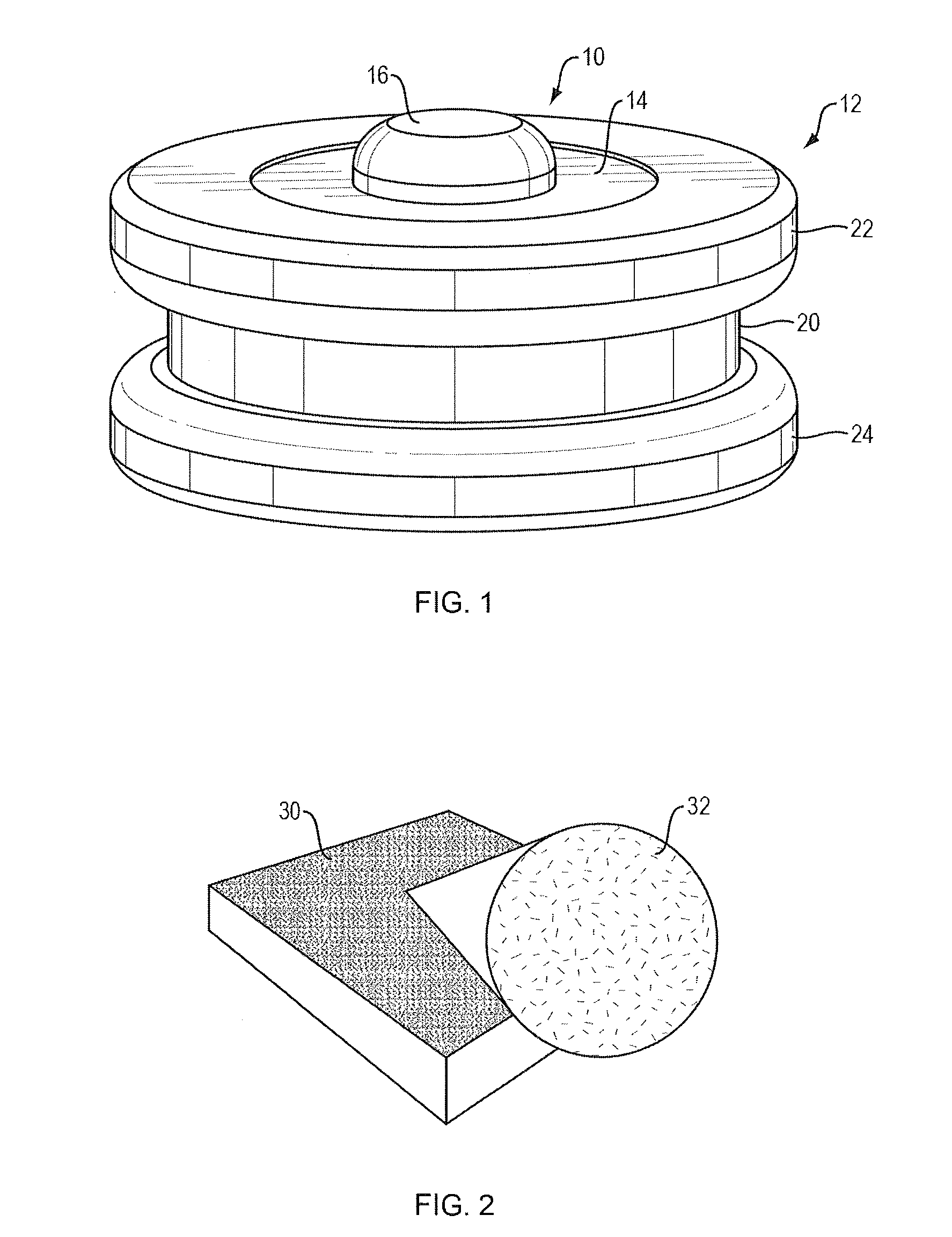

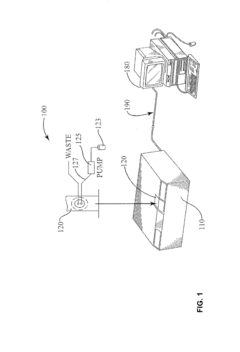

Technical Solution: Battelle has developed comprehensive FTIR-based solutions for hazardous agent detection and safety protocol enhancement across multiple sectors including defense, healthcare, and industrial applications. Their flagship system integrates FTIR spectroscopy with automated sampling handling to minimize human exposure during analysis of unknown substances. The technology employs a sealed-cell design with controlled ventilation systems that prevent accidental release during analysis of volatile toxic compounds[5]. Battelle's approach includes real-time monitoring capabilities that can detect chemical warfare agents and toxic industrial chemicals at concentrations below IDLH (Immediately Dangerous to Life or Health) levels, providing crucial early warning for safety personnel. Their systems incorporate machine learning algorithms that continuously improve detection accuracy through pattern recognition of spectral signatures from new threat compounds[6]. Additionally, Battelle has pioneered the integration of FTIR technology with automated decontamination verification protocols to ensure complete removal of hazardous agents from surfaces, equipment, and personal protective gear before reuse or disposal.

Strengths: Comprehensive end-to-end solutions from detection through decontamination; advanced machine learning capabilities for continuous improvement; extensive experience with military-grade chemical threats. Weaknesses: Systems often require significant infrastructure support; higher implementation costs than simpler detection methods; requires regular updates to threat libraries to maintain effectiveness.

MKS, Inc.

Technical Solution: MKS has developed advanced FTIR gas analysis systems specifically designed for monitoring hazardous gases in semiconductor manufacturing and other high-tech industrial environments. Their MultiGas FTIR analyzers provide real-time monitoring of multiple toxic and corrosive gases simultaneously with detection limits in the low parts-per-billion range[9]. The systems feature specialized gas cells with corrosion-resistant coatings that enable analysis of highly reactive compounds without degradation of the optical components. MKS has integrated their FTIR technology with comprehensive safety protocols that include automated emergency shutdown procedures when dangerous concentration thresholds are detected. Their systems employ specialized chemometric algorithms that can distinguish between similar compounds and accurately quantify components in complex gas mixtures. The company has also developed specialized sampling interfaces that enable monitoring of hazardous gases in high-temperature and high-pressure process environments without compromising safety[10]. Their latest innovations include miniaturized FTIR systems that can be distributed throughout facilities for comprehensive spatial monitoring of potential gas leaks and exposures.

Strengths: Exceptional specificity and sensitivity for gas-phase monitoring; robust design for industrial environments; seamless integration with facility safety systems. Weaknesses: Primarily focused on gas-phase analysis rather than solids or liquids; requires specialized knowledge for maintenance and calibration; higher cost compared to simpler gas detection technologies.

Key FTIR Spectral Analysis Innovations for Agent Identification

Apparatus and method for preconcentrating and transferring analytes from surfaces and measurement thereof using spectroscopy

PatentActiveUS20160103124A1

Innovation

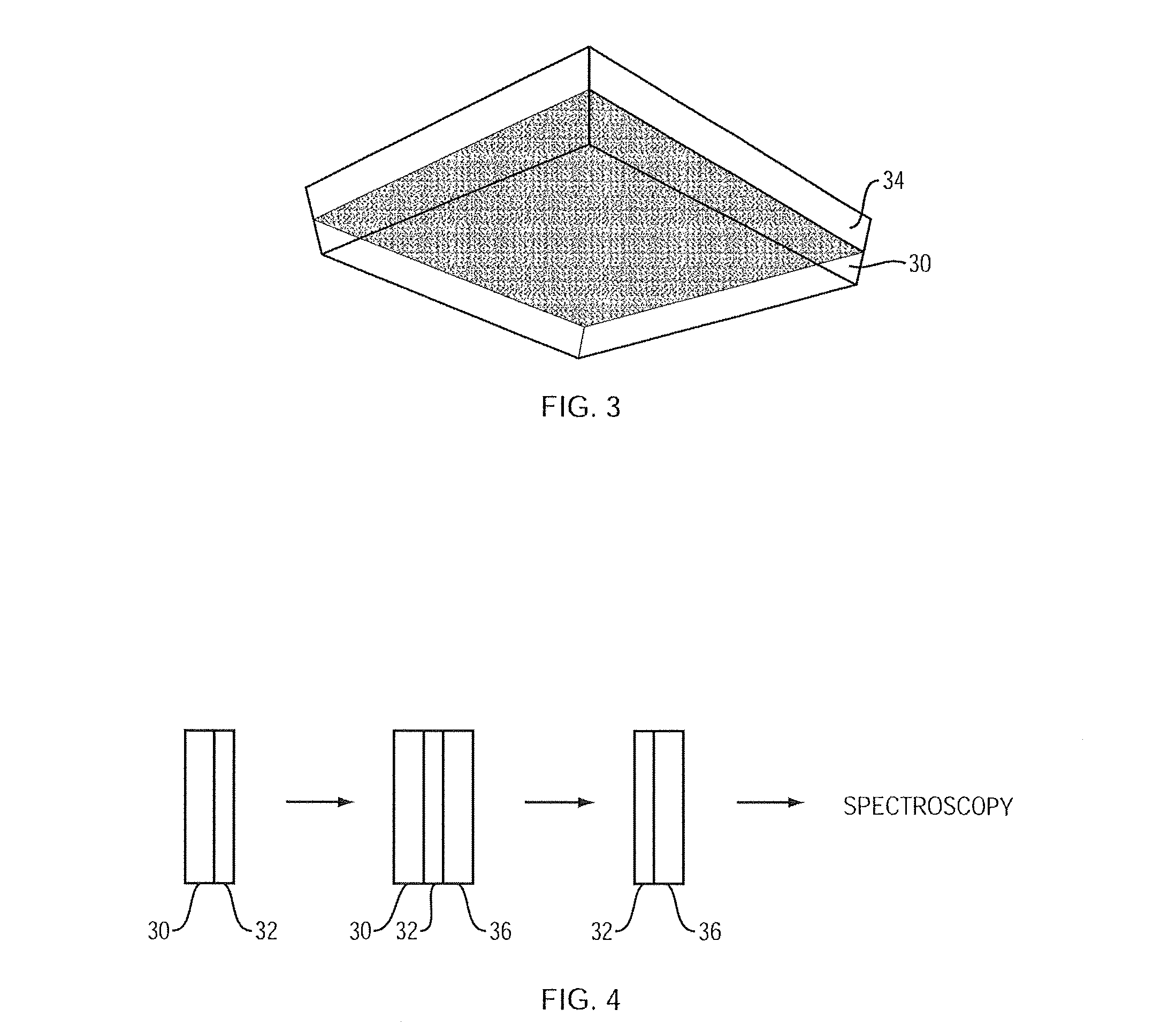

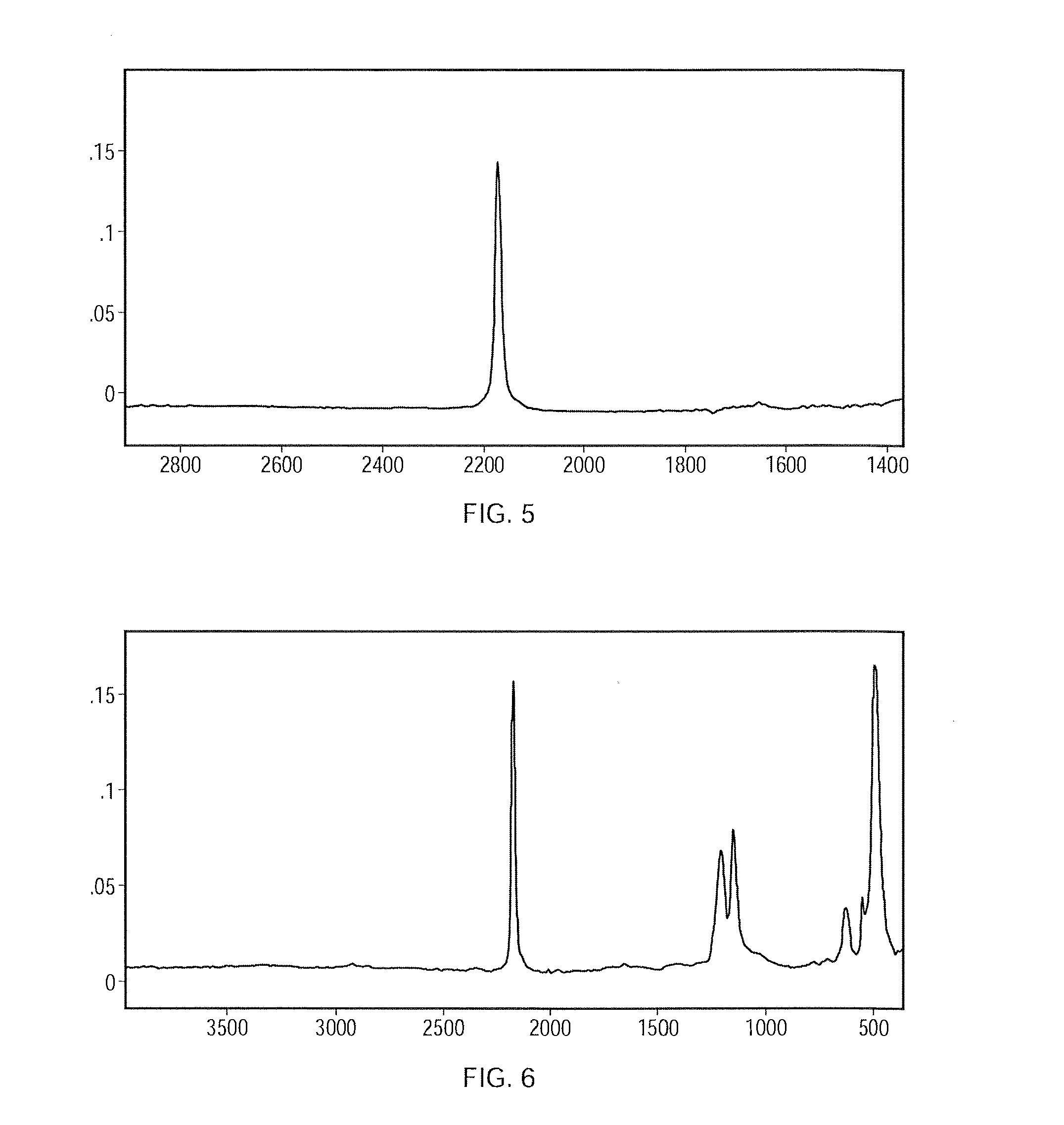

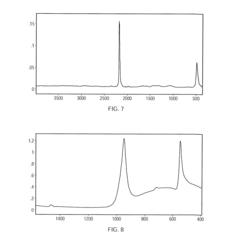

- The development of 'smart wipes' using collection substrates with optimized materials for high affinity, transparency, and immobilization capabilities, allowing for efficient capture, concentration, and transfer of analytes for interference-free analysis using spectroscopy, including optical, ion mobility, and mass spectroscopy.

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

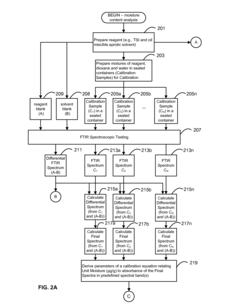

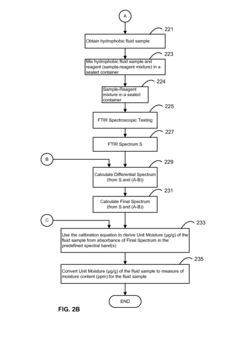

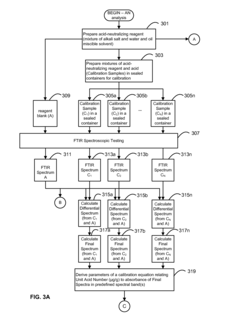

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Risk Assessment Framework for FTIR Safety Implementation

The implementation of FTIR (Fourier Transform Infrared Spectroscopy) technology in hazardous agent safety protocols requires a structured risk assessment framework to ensure comprehensive protection measures. This framework must systematically evaluate potential hazards, establish risk levels, and determine appropriate control measures for each identified risk.

The risk assessment framework for FTIR safety implementation begins with hazard identification, where all potential risks associated with the use of FTIR in analyzing hazardous agents are cataloged. These hazards include chemical exposure during sample preparation, potential for aerosolization during analysis, cross-contamination risks, and equipment-related hazards such as electrical or thermal risks from the FTIR instrumentation itself.

Risk characterization follows, employing a matrix approach that evaluates both the likelihood of occurrence and the severity of consequences for each identified hazard. This quantitative assessment assigns numerical values to create a risk priority score, enabling safety managers to focus resources on the most critical risks first. The framework incorporates specific FTIR-related parameters such as sample volatility, toxicity profiles, and instrument-specific vulnerabilities.

Exposure assessment constitutes the third component, measuring potential exposure pathways during FTIR operations. This includes evaluation of sample handling procedures, ventilation adequacy in laboratory spaces, and potential for accidental releases. Advanced exposure modeling techniques can be integrated to predict exposure scenarios under various operational conditions.

Control measure determination represents the actionable component of the framework, establishing hierarchical controls following the prevention hierarchy: elimination, substitution, engineering controls, administrative controls, and personal protective equipment. For FTIR applications, this might include automated sample handling systems, enhanced ventilation, specialized training protocols, and appropriate PPE specifications.

Implementation planning provides the operational roadmap, detailing resource requirements, timeline development, and responsibility assignments. This section establishes clear accountability for safety measure implementation and maintenance, ensuring sustained protection over time.

The framework concludes with a monitoring and review mechanism that establishes performance indicators for safety protocol effectiveness, schedules for regular reassessment, and procedures for incorporating new hazard information as it becomes available. This creates a dynamic system capable of evolving with technological advancements and emerging hazard knowledge.

The risk assessment framework for FTIR safety implementation begins with hazard identification, where all potential risks associated with the use of FTIR in analyzing hazardous agents are cataloged. These hazards include chemical exposure during sample preparation, potential for aerosolization during analysis, cross-contamination risks, and equipment-related hazards such as electrical or thermal risks from the FTIR instrumentation itself.

Risk characterization follows, employing a matrix approach that evaluates both the likelihood of occurrence and the severity of consequences for each identified hazard. This quantitative assessment assigns numerical values to create a risk priority score, enabling safety managers to focus resources on the most critical risks first. The framework incorporates specific FTIR-related parameters such as sample volatility, toxicity profiles, and instrument-specific vulnerabilities.

Exposure assessment constitutes the third component, measuring potential exposure pathways during FTIR operations. This includes evaluation of sample handling procedures, ventilation adequacy in laboratory spaces, and potential for accidental releases. Advanced exposure modeling techniques can be integrated to predict exposure scenarios under various operational conditions.

Control measure determination represents the actionable component of the framework, establishing hierarchical controls following the prevention hierarchy: elimination, substitution, engineering controls, administrative controls, and personal protective equipment. For FTIR applications, this might include automated sample handling systems, enhanced ventilation, specialized training protocols, and appropriate PPE specifications.

Implementation planning provides the operational roadmap, detailing resource requirements, timeline development, and responsibility assignments. This section establishes clear accountability for safety measure implementation and maintenance, ensuring sustained protection over time.

The framework concludes with a monitoring and review mechanism that establishes performance indicators for safety protocol effectiveness, schedules for regular reassessment, and procedures for incorporating new hazard information as it becomes available. This creates a dynamic system capable of evolving with technological advancements and emerging hazard knowledge.

Regulatory Compliance for Hazardous Material Detection Systems

The implementation of FTIR technology for hazardous agent detection must adhere to a complex framework of international, national, and industry-specific regulations. In the United States, OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandates specific requirements for hazardous material identification and communication, while the EPA's RCRA (Resource Conservation and Recovery Act) governs hazardous waste management practices that FTIR detection systems must support.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive, impose stringent requirements on hazardous substance monitoring and emergency response capabilities. FTIR systems deployed in EU member states must demonstrate compliance with these frameworks, including appropriate sensitivity levels and response times for early warning systems.

ISO standards provide critical technical specifications that FTIR-based detection systems must meet. ISO 11843 establishes detection capability requirements, while ISO/IEC 17025 outlines laboratory testing standards that influence calibration protocols for FTIR instruments. These standards ensure measurement reliability and cross-laboratory consistency in hazardous agent identification.

For pharmaceutical and healthcare applications, FDA 21 CFR Part 11 compliance is essential, particularly regarding electronic records generated by FTIR systems. This regulation requires implementation of audit trails, electronic signatures, and validation procedures to ensure data integrity throughout the detection and monitoring process.

Military and homeland security applications face additional regulatory hurdles, including compliance with CBRN (Chemical, Biological, Radiological, Nuclear) defense standards and NATO standardization agreements. These frameworks specify performance requirements for detection systems under battlefield or terrorist threat scenarios.

Certification processes for FTIR-based hazardous material detection systems typically involve third-party testing against recognized standards such as NFPA 472 (Standard for Competence of Responders to Hazardous Materials) and ANSI Z87.1 for equipment safety. Manufacturers must document compliance through technical files that demonstrate adherence to applicable regulations.

Emerging regulatory trends indicate movement toward real-time compliance monitoring and automated reporting capabilities. Future FTIR systems will likely need to incorporate secure data transmission protocols and integration with regulatory databases to facilitate immediate hazard notification and compliance documentation, particularly in high-risk industrial environments where rapid response to chemical threats is critical.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and the Seveso III Directive, impose stringent requirements on hazardous substance monitoring and emergency response capabilities. FTIR systems deployed in EU member states must demonstrate compliance with these frameworks, including appropriate sensitivity levels and response times for early warning systems.

ISO standards provide critical technical specifications that FTIR-based detection systems must meet. ISO 11843 establishes detection capability requirements, while ISO/IEC 17025 outlines laboratory testing standards that influence calibration protocols for FTIR instruments. These standards ensure measurement reliability and cross-laboratory consistency in hazardous agent identification.

For pharmaceutical and healthcare applications, FDA 21 CFR Part 11 compliance is essential, particularly regarding electronic records generated by FTIR systems. This regulation requires implementation of audit trails, electronic signatures, and validation procedures to ensure data integrity throughout the detection and monitoring process.

Military and homeland security applications face additional regulatory hurdles, including compliance with CBRN (Chemical, Biological, Radiological, Nuclear) defense standards and NATO standardization agreements. These frameworks specify performance requirements for detection systems under battlefield or terrorist threat scenarios.

Certification processes for FTIR-based hazardous material detection systems typically involve third-party testing against recognized standards such as NFPA 472 (Standard for Competence of Responders to Hazardous Materials) and ANSI Z87.1 for equipment safety. Manufacturers must document compliance through technical files that demonstrate adherence to applicable regulations.

Emerging regulatory trends indicate movement toward real-time compliance monitoring and automated reporting capabilities. Future FTIR systems will likely need to incorporate secure data transmission protocols and integration with regulatory databases to facilitate immediate hazard notification and compliance documentation, particularly in high-risk industrial environments where rapid response to chemical threats is critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!