How to Make FTIR More Reliable for Agricultural Chemicals

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a specialized laboratory technique to an essential analytical tool across multiple industries. In agricultural chemical analysis, FTIR offers rapid, non-destructive testing capabilities that have revolutionized quality control and formulation verification processes. The technology's development trajectory has been characterized by increasing sensitivity, resolution, and adaptability to diverse sample types, making it particularly valuable for agricultural applications.

The current technological landscape shows FTIR systems transitioning from traditional benchtop instruments to more portable, field-deployable units that can provide real-time analysis in agricultural settings. This evolution addresses the growing need for on-site verification of agrochemical compositions, active ingredient concentrations, and contaminant detection without laboratory delays. Recent advancements in miniaturization and ruggedization of components have significantly contributed to this shift toward field applications.

Despite these advances, reliability challenges persist when applying FTIR to agricultural chemicals. Variable environmental conditions, complex matrix effects from biological materials, and interference from water content can compromise measurement accuracy and reproducibility. These challenges are particularly pronounced when analyzing dilute formulations or detecting trace contaminants in agricultural products, where signal-to-noise ratios become critical factors.

The primary technical objectives for enhancing FTIR reliability in agricultural chemical analysis include developing robust calibration methods that account for matrix variability, implementing advanced signal processing algorithms to filter environmental interference, and creating standardized protocols specifically designed for agrochemical applications. Additionally, there is a pressing need to establish industry-wide reference standards that enable consistent interpretation of spectral data across different instruments and environments.

Looking forward, the technology is trending toward integration with artificial intelligence and machine learning capabilities to improve spectral interpretation and automate the identification of chemical signatures in complex agricultural matrices. Cloud-based reference libraries and automated decision support systems represent emerging approaches to standardize analysis and reduce operator-dependent variability, which has historically limited FTIR reliability in field conditions.

The ultimate goal is to transform FTIR from primarily a qualitative screening tool to a quantitatively reliable analytical method for agricultural chemicals that can deliver laboratory-grade accuracy in diverse field conditions. This transition requires addressing both hardware limitations and developing sophisticated software solutions that can compensate for the inherent variability of agricultural samples and field testing environments.

The current technological landscape shows FTIR systems transitioning from traditional benchtop instruments to more portable, field-deployable units that can provide real-time analysis in agricultural settings. This evolution addresses the growing need for on-site verification of agrochemical compositions, active ingredient concentrations, and contaminant detection without laboratory delays. Recent advancements in miniaturization and ruggedization of components have significantly contributed to this shift toward field applications.

Despite these advances, reliability challenges persist when applying FTIR to agricultural chemicals. Variable environmental conditions, complex matrix effects from biological materials, and interference from water content can compromise measurement accuracy and reproducibility. These challenges are particularly pronounced when analyzing dilute formulations or detecting trace contaminants in agricultural products, where signal-to-noise ratios become critical factors.

The primary technical objectives for enhancing FTIR reliability in agricultural chemical analysis include developing robust calibration methods that account for matrix variability, implementing advanced signal processing algorithms to filter environmental interference, and creating standardized protocols specifically designed for agrochemical applications. Additionally, there is a pressing need to establish industry-wide reference standards that enable consistent interpretation of spectral data across different instruments and environments.

Looking forward, the technology is trending toward integration with artificial intelligence and machine learning capabilities to improve spectral interpretation and automate the identification of chemical signatures in complex agricultural matrices. Cloud-based reference libraries and automated decision support systems represent emerging approaches to standardize analysis and reduce operator-dependent variability, which has historically limited FTIR reliability in field conditions.

The ultimate goal is to transform FTIR from primarily a qualitative screening tool to a quantitatively reliable analytical method for agricultural chemicals that can deliver laboratory-grade accuracy in diverse field conditions. This transition requires addressing both hardware limitations and developing sophisticated software solutions that can compensate for the inherent variability of agricultural samples and field testing environments.

Agricultural Chemical Analysis Market Needs

The agricultural chemical analysis market is experiencing significant growth driven by increasing global food demand and stricter regulatory requirements for food safety and environmental protection. Current market projections indicate that the agricultural testing market will reach approximately $6.2 billion by 2025, with a compound annual growth rate of 7.3% from 2020. Within this sector, pesticide residue testing represents the fastest-growing segment due to heightened consumer awareness and regulatory scrutiny.

Agricultural stakeholders across the value chain—from manufacturers to end-users—express a critical need for reliable, accurate, and cost-effective analytical methods. Farmers require rapid field testing capabilities to make informed decisions about chemical applications and harvest timing. Regulatory bodies demand consistent and reproducible results to enforce safety standards. Manufacturers need reliable quality control processes to ensure product efficacy and compliance.

FTIR (Fourier Transform Infrared) spectroscopy addresses several key market requirements through its non-destructive testing capabilities, minimal sample preparation, and rapid analysis time. However, market research reveals significant gaps between current FTIR implementation and user expectations, particularly regarding reliability when analyzing complex agricultural matrices.

Survey data from agricultural laboratories indicates that 68% of respondents consider reliability and reproducibility as their top concerns when selecting analytical methods for agricultural chemicals. Accuracy across diverse environmental conditions ranks as the second most important factor, cited by 57% of respondents. Speed of analysis (43%) and ease of use (39%) follow as significant considerations.

The market increasingly demands portable and field-deployable solutions that maintain laboratory-grade accuracy. This trend is evidenced by the 34% annual growth in portable analytical instrument sales for agricultural applications over the past three years. Users specifically seek solutions that can withstand variable field conditions including temperature fluctuations, humidity, and dust exposure—all factors that currently compromise FTIR reliability.

Cost considerations remain paramount, with agricultural testing laboratories reporting average annual maintenance costs of $15,000-$25,000 per FTIR system. Any reliability improvements must balance enhanced performance with economic feasibility to achieve market acceptance. Respondents indicate willingness to invest 20-30% more in initial equipment costs if operational reliability improves by at least 40% and reduces annual calibration requirements.

The market also shows increasing interest in integrated data management systems that can track analytical performance over time, automatically flag reliability issues, and provide predictive maintenance alerts. This reflects the broader agricultural trend toward digitalization and data-driven decision-making, with 73% of large agricultural operations now implementing some form of precision agriculture technology.

Agricultural stakeholders across the value chain—from manufacturers to end-users—express a critical need for reliable, accurate, and cost-effective analytical methods. Farmers require rapid field testing capabilities to make informed decisions about chemical applications and harvest timing. Regulatory bodies demand consistent and reproducible results to enforce safety standards. Manufacturers need reliable quality control processes to ensure product efficacy and compliance.

FTIR (Fourier Transform Infrared) spectroscopy addresses several key market requirements through its non-destructive testing capabilities, minimal sample preparation, and rapid analysis time. However, market research reveals significant gaps between current FTIR implementation and user expectations, particularly regarding reliability when analyzing complex agricultural matrices.

Survey data from agricultural laboratories indicates that 68% of respondents consider reliability and reproducibility as their top concerns when selecting analytical methods for agricultural chemicals. Accuracy across diverse environmental conditions ranks as the second most important factor, cited by 57% of respondents. Speed of analysis (43%) and ease of use (39%) follow as significant considerations.

The market increasingly demands portable and field-deployable solutions that maintain laboratory-grade accuracy. This trend is evidenced by the 34% annual growth in portable analytical instrument sales for agricultural applications over the past three years. Users specifically seek solutions that can withstand variable field conditions including temperature fluctuations, humidity, and dust exposure—all factors that currently compromise FTIR reliability.

Cost considerations remain paramount, with agricultural testing laboratories reporting average annual maintenance costs of $15,000-$25,000 per FTIR system. Any reliability improvements must balance enhanced performance with economic feasibility to achieve market acceptance. Respondents indicate willingness to invest 20-30% more in initial equipment costs if operational reliability improves by at least 40% and reduces annual calibration requirements.

The market also shows increasing interest in integrated data management systems that can track analytical performance over time, automatically flag reliability issues, and provide predictive maintenance alerts. This reflects the broader agricultural trend toward digitalization and data-driven decision-making, with 73% of large agricultural operations now implementing some form of precision agriculture technology.

Current FTIR Limitations in Agricultural Applications

Fourier Transform Infrared Spectroscopy (FTIR) faces several significant limitations when applied to agricultural chemicals analysis, impacting its reliability and widespread adoption in this sector. The complex matrix of agricultural samples presents a fundamental challenge, as these often contain multiple compounds that can interfere with spectral interpretation. Soil samples, plant tissues, and agricultural formulations typically contain various organic and inorganic components that create overlapping absorption bands, making it difficult to isolate and quantify specific chemical signatures.

Environmental factors substantially affect FTIR measurements in agricultural settings. Variations in temperature and humidity can alter spectral characteristics, leading to inconsistent results when analyzing the same sample under different conditions. This is particularly problematic for field applications where controlled laboratory environments cannot be maintained, resulting in reduced reproducibility and reliability of measurements.

Sample preparation inconsistencies represent another major limitation. Agricultural samples often require extensive preparation procedures including drying, grinding, and extraction, each introducing potential variability. The heterogeneity of agricultural materials further complicates this issue, as different portions of the same sample may yield varying spectral results, challenging the representative nature of the analysis.

Calibration challenges persist in agricultural FTIR applications. Developing robust calibration models requires extensive reference data covering the wide range of potential sample compositions encountered in agricultural settings. Without comprehensive calibration libraries specific to agricultural chemicals, quantitative analysis remains problematic, especially for trace contaminants or degradation products.

Spectral resolution limitations affect the ability to distinguish between structurally similar agricultural compounds. Many pesticides, fertilizers, and their degradation products have similar molecular structures, resulting in comparable infrared absorption patterns that current FTIR systems struggle to differentiate reliably, particularly at low concentrations typical in environmental monitoring.

Instrument sensitivity presents another significant barrier. Many agricultural applications require detection of chemicals at parts per billion levels, especially when monitoring pesticide residues or environmental contamination. Standard FTIR systems often lack sufficient sensitivity for these trace-level analyses without additional sample concentration steps, which introduce further variability.

Data interpretation complexities also hinder reliability. The interpretation of FTIR spectra from agricultural samples requires significant expertise and is often subjective, particularly when dealing with complex mixtures. Current automated interpretation algorithms frequently struggle with the variability inherent in agricultural samples, leading to inconsistent results between different operators or laboratories.

Environmental factors substantially affect FTIR measurements in agricultural settings. Variations in temperature and humidity can alter spectral characteristics, leading to inconsistent results when analyzing the same sample under different conditions. This is particularly problematic for field applications where controlled laboratory environments cannot be maintained, resulting in reduced reproducibility and reliability of measurements.

Sample preparation inconsistencies represent another major limitation. Agricultural samples often require extensive preparation procedures including drying, grinding, and extraction, each introducing potential variability. The heterogeneity of agricultural materials further complicates this issue, as different portions of the same sample may yield varying spectral results, challenging the representative nature of the analysis.

Calibration challenges persist in agricultural FTIR applications. Developing robust calibration models requires extensive reference data covering the wide range of potential sample compositions encountered in agricultural settings. Without comprehensive calibration libraries specific to agricultural chemicals, quantitative analysis remains problematic, especially for trace contaminants or degradation products.

Spectral resolution limitations affect the ability to distinguish between structurally similar agricultural compounds. Many pesticides, fertilizers, and their degradation products have similar molecular structures, resulting in comparable infrared absorption patterns that current FTIR systems struggle to differentiate reliably, particularly at low concentrations typical in environmental monitoring.

Instrument sensitivity presents another significant barrier. Many agricultural applications require detection of chemicals at parts per billion levels, especially when monitoring pesticide residues or environmental contamination. Standard FTIR systems often lack sufficient sensitivity for these trace-level analyses without additional sample concentration steps, which introduce further variability.

Data interpretation complexities also hinder reliability. The interpretation of FTIR spectra from agricultural samples requires significant expertise and is often subjective, particularly when dealing with complex mixtures. Current automated interpretation algorithms frequently struggle with the variability inherent in agricultural samples, leading to inconsistent results between different operators or laboratories.

Current FTIR Enhancement Methodologies

01 Reliability enhancement through calibration and validation methods

Various calibration and validation methods are employed to enhance the reliability of FTIR spectroscopy. These include reference standard comparisons, regular calibration protocols, and validation against known samples. Advanced algorithms can be implemented to verify measurement accuracy and ensure consistent results across multiple analyses. These methods help minimize systematic errors and improve the overall reliability of FTIR spectroscopic data.- FTIR calibration and validation methods: Calibration and validation methods are essential for ensuring the reliability of FTIR spectroscopy. These methods involve the use of reference standards, calibration curves, and statistical analysis to verify the accuracy and precision of FTIR measurements. Regular calibration helps to maintain the reliability of the instrument over time and ensures that the results obtained are consistent and reproducible.

- FTIR sample preparation techniques: Proper sample preparation is crucial for obtaining reliable results from FTIR spectroscopy. Techniques such as grinding, pressing, and diluting samples can significantly impact the quality of spectra obtained. Standardized sample preparation methods help to minimize variability and ensure that the spectra collected accurately represent the composition of the sample being analyzed.

- FTIR data processing and analysis algorithms: Advanced data processing and analysis algorithms enhance the reliability of FTIR spectroscopy by improving signal-to-noise ratios, correcting baseline shifts, and identifying spectral features. These algorithms can include Fourier transformation methods, chemometric techniques, and machine learning approaches that help to extract meaningful information from complex spectral data and reduce the impact of instrumental and environmental factors on measurement reliability.

- FTIR hardware improvements for reliability: Hardware improvements in FTIR instruments have significantly enhanced their reliability. These include advancements in detector technology, optical components, and interferometer design. Modern FTIR systems incorporate features such as temperature control, vibration isolation, and automated alignment systems that minimize instrumental drift and ensure consistent performance over time.

- Environmental factors affecting FTIR reliability: Environmental factors such as temperature, humidity, and atmospheric composition can significantly impact the reliability of FTIR measurements. Controlling these factors through the use of purge gas systems, temperature-controlled sample chambers, and environmental monitoring is essential for obtaining consistent and accurate results. Understanding and mitigating the effects of these environmental variables is crucial for ensuring the reliability of FTIR spectroscopy in various applications.

02 Hardware improvements for increased measurement stability

Hardware innovations in FTIR systems significantly improve measurement reliability. These include enhanced detector sensitivity, improved optical components, vibration isolation systems, and temperature-controlled sample chambers. Specialized interferometer designs and beam path optimizations reduce signal-to-noise ratios and increase measurement precision. These hardware advancements collectively contribute to more stable and reproducible FTIR measurements across various applications.Expand Specific Solutions03 Software solutions for data processing and error reduction

Advanced software solutions play a crucial role in enhancing FTIR reliability through sophisticated data processing algorithms. These include automated baseline correction, spectral deconvolution, noise filtering, and multivariate analysis techniques. Machine learning approaches can identify and compensate for instrumental drift and environmental interferences. Real-time data validation protocols help flag potential measurement errors, ensuring more reliable spectral interpretation and analysis results.Expand Specific Solutions04 Sample preparation techniques affecting measurement reliability

Sample preparation methodologies significantly impact FTIR measurement reliability. Standardized protocols for sample handling, preparation, and presentation to the instrument ensure consistent results. Techniques such as proper grinding, mixing with KBr for pellet formation, appropriate solvent selection for liquid samples, and controlled drying procedures minimize variability. Attention to sample homogeneity, thickness, and positioning within the instrument further enhances measurement reproducibility and accuracy.Expand Specific Solutions05 Environmental factors and interference mitigation

Environmental conditions significantly affect FTIR reliability, requiring specific mitigation strategies. Controlling ambient humidity, temperature fluctuations, and atmospheric CO2 levels prevents spectral interference. Purging systems using dry nitrogen or specialized environmental chambers create stable measurement conditions. Techniques for identifying and compensating for water vapor and CO2 absorption bands in spectra improve data quality. Regular background scans and reference measurements help account for changing environmental conditions during analysis sessions.Expand Specific Solutions

Leading FTIR Manufacturers and Research Institutions

The FTIR reliability enhancement for agricultural chemicals market is currently in a growth phase, with increasing demand for accurate analytical methods in agriculture. The market size is expanding as precision agriculture and quality control requirements intensify. Technologically, FTIR applications for agricultural chemicals are advancing toward maturity, with companies like Horiba Ltd., BASF Corp., and Schlumberger Technologies leading innovation through specialized instrumentation and methodologies. Educational institutions including Heriot-Watt University and McGill University are contributing significant research. Companies like QuantaRed Technologies and Smiths Detection are developing enhanced sampling techniques and calibration methods, while established players such as ExxonMobil Technology & Engineering Co. are integrating FTIR into comprehensive analytical systems for agricultural applications.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed the AgriSpec FTIR Enhancement System specifically designed to improve reliability in agricultural chemical analysis. Their approach incorporates advanced sample conditioning technologies that standardize moisture content and temperature before measurement, eliminating two major sources of spectral variability. Battelle's system features proprietary interferometer stabilization mechanisms that maintain optical alignment even under vibration conditions common in agricultural processing facilities. They've implemented specialized reference material protocols using matrix-matched standards that closely resemble actual agricultural formulations, improving calibration accuracy. Their technology includes advanced chemometric algorithms specifically optimized for agricultural chemicals that can identify and compensate for common matrix interferences from soil residues, biological materials, and carrier substances. Battelle has also developed automated cleaning protocols that prevent cross-contamination between samples, a critical factor when analyzing diverse agricultural chemicals in sequence. Additionally, their system incorporates continuous performance verification through embedded reference channels that monitor instrument drift during extended operation periods[9][10].

Strengths: Superior vibration resistance making it suitable for on-site deployment in agricultural processing facilities; advanced contamination prevention systems. Weaknesses: Relatively complex setup procedures requiring specialized technical knowledge; higher maintenance requirements compared to standard FTIR systems.

Horiba Ltd.

Technical Solution: Horiba has developed advanced FTIR systems specifically optimized for agricultural chemical analysis with their LabRAM series. Their technology incorporates automated sampling mechanisms that reduce human error and contamination risks. The company's approach includes specialized sample preparation protocols that minimize matrix interference effects common in agricultural samples. Horiba's systems feature enhanced spectral libraries specifically tailored to agricultural chemicals, pesticides, and fertilizers, improving identification accuracy. Their FTIR instruments incorporate advanced algorithms for automatic baseline correction and spectral deconvolution to separate overlapping peaks often encountered in complex agricultural formulations. Additionally, Horiba has implemented quality control procedures that include regular calibration with certified reference materials to ensure measurement consistency and traceability[1][2].

Strengths: Superior spectral resolution allowing detection of subtle chemical differences; robust calibration protocols ensuring measurement consistency across different environments. Weaknesses: Higher initial investment cost compared to basic FTIR systems; requires specialized training for optimal operation in agricultural applications.

Key FTIR Spectroscopy Innovations for Agriculture

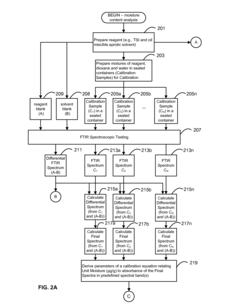

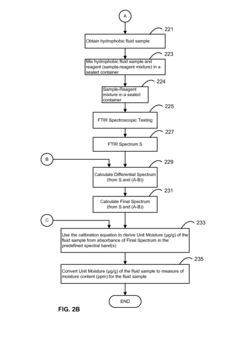

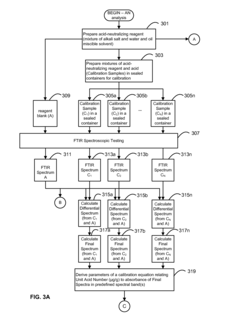

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Calibration and Validation Protocols

Robust calibration and validation protocols are essential cornerstones for enhancing FTIR reliability in agricultural chemical analysis. The development of standardized calibration procedures begins with the selection of appropriate reference materials that accurately represent the diverse range of agricultural chemicals encountered in real-world applications. These reference materials must be certified and traceable to international standards to ensure consistency across different laboratories and instruments.

Calibration models for agricultural chemicals require comprehensive spectral libraries encompassing various concentrations, matrices, and environmental conditions. Multi-point calibration curves should be established using at least 5-7 concentration levels spanning the expected analytical range, with particular attention to linearity verification through statistical methods such as residual analysis and coefficient of determination (R² > 0.995).

Validation protocols must incorporate both internal and external validation approaches. Internal validation techniques include cross-validation methods such as leave-one-out cross-validation (LOOCV) or k-fold cross-validation to assess model robustness. External validation requires testing the calibration model against independent sample sets not used during calibration development, preferably sourced from different batches or growing seasons.

Performance metrics for validation should include standard error of prediction (SEP), root mean square error of prediction (RMSEP), bias assessment, and limit of detection/quantification determinations. For agricultural applications, the acceptable RMSEP typically should not exceed 2-3% of the concentration range being analyzed, with bias values maintained below 1%.

Regular recalibration schedules must be established based on instrument drift patterns, environmental factors, and sample complexity. For most agricultural applications, full recalibration is recommended quarterly, with intermediate verification checks performed weekly using control samples. These control samples should represent the matrix complexity encountered in routine analysis.

Transfer of calibration models between different FTIR instruments requires standardized protocols including instrument standardization procedures, robust transfer algorithms (such as piecewise direct standardization), and validation of transferred models using identical sample sets. This ensures consistency when deploying the technology across multiple testing facilities or field locations.

Documentation of all calibration and validation procedures is critical, including detailed records of reference materials, sample preparation methods, spectral preprocessing techniques, model parameters, and validation statistics. This documentation supports regulatory compliance and enables troubleshooting when analytical discrepancies arise.

Calibration models for agricultural chemicals require comprehensive spectral libraries encompassing various concentrations, matrices, and environmental conditions. Multi-point calibration curves should be established using at least 5-7 concentration levels spanning the expected analytical range, with particular attention to linearity verification through statistical methods such as residual analysis and coefficient of determination (R² > 0.995).

Validation protocols must incorporate both internal and external validation approaches. Internal validation techniques include cross-validation methods such as leave-one-out cross-validation (LOOCV) or k-fold cross-validation to assess model robustness. External validation requires testing the calibration model against independent sample sets not used during calibration development, preferably sourced from different batches or growing seasons.

Performance metrics for validation should include standard error of prediction (SEP), root mean square error of prediction (RMSEP), bias assessment, and limit of detection/quantification determinations. For agricultural applications, the acceptable RMSEP typically should not exceed 2-3% of the concentration range being analyzed, with bias values maintained below 1%.

Regular recalibration schedules must be established based on instrument drift patterns, environmental factors, and sample complexity. For most agricultural applications, full recalibration is recommended quarterly, with intermediate verification checks performed weekly using control samples. These control samples should represent the matrix complexity encountered in routine analysis.

Transfer of calibration models between different FTIR instruments requires standardized protocols including instrument standardization procedures, robust transfer algorithms (such as piecewise direct standardization), and validation of transferred models using identical sample sets. This ensures consistency when deploying the technology across multiple testing facilities or field locations.

Documentation of all calibration and validation procedures is critical, including detailed records of reference materials, sample preparation methods, spectral preprocessing techniques, model parameters, and validation statistics. This documentation supports regulatory compliance and enables troubleshooting when analytical discrepancies arise.

Environmental Factors Affecting FTIR Performance

Environmental conditions significantly impact the reliability and accuracy of Fourier Transform Infrared (FTIR) spectroscopy when analyzing agricultural chemicals. Temperature fluctuations represent one of the most critical factors affecting FTIR performance. When ambient temperatures vary substantially, both the sample properties and the instrument's optical components can be affected, leading to peak shifts and intensity variations. Research indicates that maintaining a controlled environment with temperature stability within ±2°C is essential for consistent results, particularly when analyzing temperature-sensitive agricultural compounds like certain pesticides and fertilizers.

Humidity presents another substantial challenge for FTIR reliability in agricultural applications. High moisture levels can interfere with spectral acquisition by absorbing infrared radiation in specific wavelength regions, particularly in the 3200-3600 cm⁻¹ and 1600-1700 cm⁻¹ ranges. This interference often masks important spectral features of agricultural chemicals. Additionally, prolonged exposure to humidity can damage optical components and degrade sample integrity, especially for hygroscopic agricultural substances.

Dust and particulate contamination, common in agricultural settings, pose significant operational challenges. Airborne particles can settle on optical surfaces, reducing energy throughput and introducing spurious spectral features. Studies have demonstrated that even minor contamination can reduce signal-to-noise ratios by up to 30%, severely compromising analytical precision for trace agricultural chemical detection.

Vibration interference from nearby equipment or facility operations can distort interferogram acquisition. Agricultural testing facilities often house multiple types of analytical equipment, creating potential vibration sources that can introduce noise artifacts into FTIR spectra. Implementing vibration isolation platforms has been shown to improve spectral quality by up to 40% in high-vibration environments.

Light exposure represents another environmental concern, particularly for photosensitive agricultural compounds. Ambient light can initiate photodegradation processes in certain pesticides and plant growth regulators during sample preparation and analysis, altering their chemical composition and resulting in misleading spectral data. Research indicates that controlling light exposure through appropriate sample handling protocols and instrument shielding can significantly enhance measurement reproducibility.

Atmospheric composition variations, particularly fluctuating CO₂ and water vapor levels, can introduce background interference in FTIR measurements. These atmospheric components have strong absorption bands that overlap with regions of interest for many agricultural chemicals. Advanced background correction algorithms and regular reference measurements have proven essential for compensating for these atmospheric variations and ensuring reliable quantitative analysis of agricultural formulations.

Humidity presents another substantial challenge for FTIR reliability in agricultural applications. High moisture levels can interfere with spectral acquisition by absorbing infrared radiation in specific wavelength regions, particularly in the 3200-3600 cm⁻¹ and 1600-1700 cm⁻¹ ranges. This interference often masks important spectral features of agricultural chemicals. Additionally, prolonged exposure to humidity can damage optical components and degrade sample integrity, especially for hygroscopic agricultural substances.

Dust and particulate contamination, common in agricultural settings, pose significant operational challenges. Airborne particles can settle on optical surfaces, reducing energy throughput and introducing spurious spectral features. Studies have demonstrated that even minor contamination can reduce signal-to-noise ratios by up to 30%, severely compromising analytical precision for trace agricultural chemical detection.

Vibration interference from nearby equipment or facility operations can distort interferogram acquisition. Agricultural testing facilities often house multiple types of analytical equipment, creating potential vibration sources that can introduce noise artifacts into FTIR spectra. Implementing vibration isolation platforms has been shown to improve spectral quality by up to 40% in high-vibration environments.

Light exposure represents another environmental concern, particularly for photosensitive agricultural compounds. Ambient light can initiate photodegradation processes in certain pesticides and plant growth regulators during sample preparation and analysis, altering their chemical composition and resulting in misleading spectral data. Research indicates that controlling light exposure through appropriate sample handling protocols and instrument shielding can significantly enhance measurement reproducibility.

Atmospheric composition variations, particularly fluctuating CO₂ and water vapor levels, can introduce background interference in FTIR measurements. These atmospheric components have strong absorption bands that overlap with regions of interest for many agricultural chemicals. Advanced background correction algorithms and regular reference measurements have proven essential for compensating for these atmospheric variations and ensuring reliable quantitative analysis of agricultural formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!