Deploying FTIR for Advanced Material Interaction Evaluation

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a specialized analytical technique to an essential tool across multiple industries. The technology leverages the interaction between infrared radiation and matter to provide detailed molecular composition analysis, offering insights into material properties that remain invisible to other analytical methods.

The historical development of FTIR technology traces back to conventional dispersive infrared spectroscopy, which suffered from slow scanning speeds and limited resolution. The breakthrough came with the application of the Fourier transform mathematical technique to infrared spectroscopy in the 1960s, enabling simultaneous measurement of all infrared frequencies and dramatically improving signal-to-noise ratios through the Fellgett advantage.

Recent technological advancements have miniaturized FTIR systems while enhancing their sensitivity and resolution. Modern FTIR spectrometers incorporate sophisticated interferometers, advanced detectors, and powerful computational algorithms that allow for real-time analysis of complex material compositions. The integration of attenuated total reflection (ATR) accessories has further expanded FTIR applications by simplifying sample preparation and enabling analysis of previously challenging materials.

The current technological trajectory points toward increasingly portable, user-friendly, and interconnected FTIR systems. Handheld devices capable of field deployment are gaining traction, while cloud-based spectral libraries and machine learning algorithms are enhancing analytical capabilities and interpretation accuracy.

The primary objective of deploying FTIR for advanced material interaction evaluation is to establish a non-destructive, high-throughput methodology for characterizing material interfaces and interaction dynamics at the molecular level. This includes mapping chemical bonds, identifying functional groups, and quantifying compositional changes during material interactions.

Secondary objectives encompass developing standardized protocols for material compatibility assessment, creating comprehensive spectral databases for various material interactions, and integrating FTIR data with complementary analytical techniques to form holistic material evaluation frameworks.

The technology aims to address critical challenges in materials science, including predicting long-term material stability, understanding degradation mechanisms, and optimizing material combinations for specific applications. By providing molecular-level insights into material behavior, FTIR deployment supports innovation across industries ranging from pharmaceuticals and polymers to electronics and renewable energy technologies.

As materials become increasingly complex and application requirements more stringent, FTIR technology continues to evolve, with emerging capabilities in hyperspectral imaging, nanoscale resolution, and in-situ monitoring of dynamic material processes representing the frontier of current research and development efforts.

The historical development of FTIR technology traces back to conventional dispersive infrared spectroscopy, which suffered from slow scanning speeds and limited resolution. The breakthrough came with the application of the Fourier transform mathematical technique to infrared spectroscopy in the 1960s, enabling simultaneous measurement of all infrared frequencies and dramatically improving signal-to-noise ratios through the Fellgett advantage.

Recent technological advancements have miniaturized FTIR systems while enhancing their sensitivity and resolution. Modern FTIR spectrometers incorporate sophisticated interferometers, advanced detectors, and powerful computational algorithms that allow for real-time analysis of complex material compositions. The integration of attenuated total reflection (ATR) accessories has further expanded FTIR applications by simplifying sample preparation and enabling analysis of previously challenging materials.

The current technological trajectory points toward increasingly portable, user-friendly, and interconnected FTIR systems. Handheld devices capable of field deployment are gaining traction, while cloud-based spectral libraries and machine learning algorithms are enhancing analytical capabilities and interpretation accuracy.

The primary objective of deploying FTIR for advanced material interaction evaluation is to establish a non-destructive, high-throughput methodology for characterizing material interfaces and interaction dynamics at the molecular level. This includes mapping chemical bonds, identifying functional groups, and quantifying compositional changes during material interactions.

Secondary objectives encompass developing standardized protocols for material compatibility assessment, creating comprehensive spectral databases for various material interactions, and integrating FTIR data with complementary analytical techniques to form holistic material evaluation frameworks.

The technology aims to address critical challenges in materials science, including predicting long-term material stability, understanding degradation mechanisms, and optimizing material combinations for specific applications. By providing molecular-level insights into material behavior, FTIR deployment supports innovation across industries ranging from pharmaceuticals and polymers to electronics and renewable energy technologies.

As materials become increasingly complex and application requirements more stringent, FTIR technology continues to evolve, with emerging capabilities in hyperspectral imaging, nanoscale resolution, and in-situ monitoring of dynamic material processes representing the frontier of current research and development efforts.

Market Analysis for FTIR in Material Science

The global FTIR (Fourier Transform Infrared) spectroscopy market in material science is experiencing robust growth, valued at approximately $1.2 billion in 2022 and projected to reach $1.8 billion by 2027, representing a compound annual growth rate (CAGR) of 8.4%. This growth is primarily driven by increasing demand for advanced material characterization techniques across multiple industries including pharmaceuticals, polymers, semiconductors, and emerging nanomaterials.

Material science applications currently account for roughly 35% of the total FTIR market, making it the second largest application segment after pharmaceutical and biotechnology uses. The expansion is particularly notable in regions with strong manufacturing bases and research infrastructure, with North America holding approximately 38% market share, followed by Europe (29%) and Asia-Pacific (26%), the latter showing the fastest growth trajectory.

Key market drivers include the rising complexity of material development processes requiring precise molecular interaction analysis, stringent quality control standards in manufacturing, and the growing adoption of FTIR as a non-destructive testing method. The technique's ability to provide detailed chemical composition information while preserving sample integrity represents a significant value proposition for industries working with high-value materials.

Industry-specific demand patterns reveal pharmaceuticals and polymer industries as the largest consumers of FTIR technology for material interaction evaluation, collectively accounting for over 50% of market applications. However, emerging applications in renewable energy materials, particularly for solar cell development and battery technology, represent the fastest-growing segment with an estimated 12.3% CAGR.

Customer segmentation analysis indicates research institutions and academic laboratories constitute approximately 40% of end-users, while industrial applications account for 55%, with the remainder attributed to government and regulatory bodies. This distribution highlights the dual importance of FTIR in both fundamental research and practical industrial applications.

Pricing trends show a gradual decrease in entry-level FTIR systems (approximately 3% annually), while advanced systems with specialized material interaction capabilities maintain premium pricing due to their enhanced analytical capabilities. The total cost of ownership, including maintenance and operator training, remains a significant consideration for potential adopters, particularly small and medium enterprises.

Market challenges include competition from alternative spectroscopic techniques such as Raman spectroscopy and X-ray diffraction, which offer complementary or alternative approaches to material characterization. Additionally, the technical expertise required for effective FTIR data interpretation presents an adoption barrier in some market segments, creating opportunities for integrated software solutions with advanced material databases and interpretation algorithms.

Material science applications currently account for roughly 35% of the total FTIR market, making it the second largest application segment after pharmaceutical and biotechnology uses. The expansion is particularly notable in regions with strong manufacturing bases and research infrastructure, with North America holding approximately 38% market share, followed by Europe (29%) and Asia-Pacific (26%), the latter showing the fastest growth trajectory.

Key market drivers include the rising complexity of material development processes requiring precise molecular interaction analysis, stringent quality control standards in manufacturing, and the growing adoption of FTIR as a non-destructive testing method. The technique's ability to provide detailed chemical composition information while preserving sample integrity represents a significant value proposition for industries working with high-value materials.

Industry-specific demand patterns reveal pharmaceuticals and polymer industries as the largest consumers of FTIR technology for material interaction evaluation, collectively accounting for over 50% of market applications. However, emerging applications in renewable energy materials, particularly for solar cell development and battery technology, represent the fastest-growing segment with an estimated 12.3% CAGR.

Customer segmentation analysis indicates research institutions and academic laboratories constitute approximately 40% of end-users, while industrial applications account for 55%, with the remainder attributed to government and regulatory bodies. This distribution highlights the dual importance of FTIR in both fundamental research and practical industrial applications.

Pricing trends show a gradual decrease in entry-level FTIR systems (approximately 3% annually), while advanced systems with specialized material interaction capabilities maintain premium pricing due to their enhanced analytical capabilities. The total cost of ownership, including maintenance and operator training, remains a significant consideration for potential adopters, particularly small and medium enterprises.

Market challenges include competition from alternative spectroscopic techniques such as Raman spectroscopy and X-ray diffraction, which offer complementary or alternative approaches to material characterization. Additionally, the technical expertise required for effective FTIR data interpretation presents an adoption barrier in some market segments, creating opportunities for integrated software solutions with advanced material databases and interpretation algorithms.

Current FTIR Implementation Challenges

Despite the significant advancements in Fourier Transform Infrared (FTIR) spectroscopy for material analysis, several critical implementation challenges persist when deploying this technology for advanced material interaction evaluation. The complexity of sample preparation remains a primary obstacle, particularly for heterogeneous materials where achieving representative sampling is difficult. Inconsistent sample thickness and uneven distribution can lead to significant variations in spectral quality, compromising analytical reliability and reproducibility.

Environmental interference poses another substantial challenge, as atmospheric water vapor and carbon dioxide can create spectral artifacts that obscure important material signatures. While purge systems and background subtraction algorithms exist, they add complexity to the instrumentation and may not completely eliminate these interferences, especially in field applications where controlled environments are not feasible.

Resolution limitations continue to constrain FTIR applications, particularly when analyzing complex mixtures with overlapping spectral features. Current commercial systems typically offer resolutions between 0.5-4 cm⁻¹, which may be insufficient for distinguishing subtle molecular interactions in advanced materials. This limitation becomes particularly problematic when evaluating nanomaterials or composite structures where interface interactions occur at molecular scales.

Data interpretation challenges have grown exponentially with the increasing complexity of materials being analyzed. Modern advanced materials often contain multiple components with intricate interaction patterns that generate complex spectral profiles. Current automated interpretation software struggles with novel material combinations, requiring significant human expertise for accurate analysis. This creates bottlenecks in high-throughput screening applications and limits the accessibility of FTIR technology.

Quantitative analysis remains problematic due to non-linear absorption behaviors in certain materials and matrix effects that can distort concentration-absorbance relationships. While calibration methods exist, they often require extensive validation for each specific material system, making standardization difficult across different laboratories and applications.

Miniaturization efforts for portable FTIR systems face significant engineering challenges related to maintaining optical precision while reducing instrument size. Current portable systems typically sacrifice resolution and sensitivity compared to benchtop counterparts, limiting their utility for advanced material characterization in field settings. Additionally, these systems often lack the robustness needed for industrial environments where vibration, temperature fluctuations, and dust can compromise performance.

Integration challenges with other analytical techniques present obstacles to developing comprehensive material characterization workflows. While FTIR provides valuable molecular structure information, correlating these results with other analytical methods (such as XRD, SEM, or thermal analysis) remains largely a manual process requiring specialized expertise to synthesize a complete understanding of material properties and interactions.

Environmental interference poses another substantial challenge, as atmospheric water vapor and carbon dioxide can create spectral artifacts that obscure important material signatures. While purge systems and background subtraction algorithms exist, they add complexity to the instrumentation and may not completely eliminate these interferences, especially in field applications where controlled environments are not feasible.

Resolution limitations continue to constrain FTIR applications, particularly when analyzing complex mixtures with overlapping spectral features. Current commercial systems typically offer resolutions between 0.5-4 cm⁻¹, which may be insufficient for distinguishing subtle molecular interactions in advanced materials. This limitation becomes particularly problematic when evaluating nanomaterials or composite structures where interface interactions occur at molecular scales.

Data interpretation challenges have grown exponentially with the increasing complexity of materials being analyzed. Modern advanced materials often contain multiple components with intricate interaction patterns that generate complex spectral profiles. Current automated interpretation software struggles with novel material combinations, requiring significant human expertise for accurate analysis. This creates bottlenecks in high-throughput screening applications and limits the accessibility of FTIR technology.

Quantitative analysis remains problematic due to non-linear absorption behaviors in certain materials and matrix effects that can distort concentration-absorbance relationships. While calibration methods exist, they often require extensive validation for each specific material system, making standardization difficult across different laboratories and applications.

Miniaturization efforts for portable FTIR systems face significant engineering challenges related to maintaining optical precision while reducing instrument size. Current portable systems typically sacrifice resolution and sensitivity compared to benchtop counterparts, limiting their utility for advanced material characterization in field settings. Additionally, these systems often lack the robustness needed for industrial environments where vibration, temperature fluctuations, and dust can compromise performance.

Integration challenges with other analytical techniques present obstacles to developing comprehensive material characterization workflows. While FTIR provides valuable molecular structure information, correlating these results with other analytical methods (such as XRD, SEM, or thermal analysis) remains largely a manual process requiring specialized expertise to synthesize a complete understanding of material properties and interactions.

Contemporary FTIR Deployment Methodologies

01 FTIR spectroscopy for material identification and analysis

Fourier Transform Infrared Spectroscopy (FTIR) is used for identifying and analyzing materials by measuring how infrared radiation interacts with molecular bonds. The technique provides unique spectral fingerprints of materials based on their absorption patterns, allowing for accurate identification of compounds and their structural characteristics. This method is particularly valuable for analyzing organic and inorganic materials, polymers, and biological samples.- FTIR spectroscopy for material characterization and analysis: Fourier Transform Infrared Spectroscopy (FTIR) is widely used for characterizing and analyzing various materials by measuring how infrared radiation interacts with molecular bonds. This technique helps identify chemical compositions, structural properties, and functional groups in materials. The spectral patterns obtained from FTIR analysis provide unique fingerprints that allow for material identification and quality assessment across different industries.

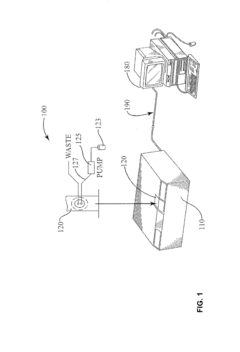

- FTIR systems and apparatus design for material interaction studies: Specialized FTIR systems and apparatus designs enhance the study of material interactions. These systems incorporate advanced components such as optimized detectors, sample holders, and optical arrangements to improve measurement accuracy and sensitivity. Innovations in FTIR equipment design focus on minimizing interference, enhancing signal-to-noise ratios, and enabling analysis of challenging sample types including liquids, solids, and thin films under various environmental conditions.

- Real-time monitoring and process control using FTIR: FTIR spectroscopy enables real-time monitoring of material interactions during industrial processes. By continuously analyzing spectral changes, manufacturers can detect variations in material properties, reaction progress, or contamination levels. This capability allows for automated process control, quality assurance, and early detection of production issues. Integration of FTIR systems with production lines facilitates immediate adjustments to maintain product specifications and optimize manufacturing efficiency.

- Advanced data analysis methods for FTIR material interaction: Sophisticated data analysis methods enhance the interpretation of FTIR spectra for material interaction studies. These include multivariate statistical analysis, machine learning algorithms, and chemometric techniques that extract meaningful patterns from complex spectral data. Advanced computational approaches enable automated identification of subtle spectral changes, quantitative analysis of material compositions, and prediction of material properties based on their infrared absorption characteristics.

- Novel applications of FTIR for specific material interactions: FTIR spectroscopy has been adapted for specialized applications studying unique material interactions. These include analysis of biological samples, pharmaceutical formulations, environmental pollutants, and nanomaterials. Modified FTIR techniques such as attenuated total reflection (ATR), diffuse reflectance, and microscopic FTIR imaging enable the study of material interfaces, surface reactions, and spatial distribution of chemical components within complex material systems.

02 FTIR systems and instrumentation design

Advanced FTIR instrumentation designs incorporate specialized components such as interferometers, detectors, and sample handling systems to enhance measurement accuracy and efficiency. These systems may include portable or miniaturized configurations for field applications, automated sample processing mechanisms, and integrated data analysis software. Innovations in instrumentation focus on improving resolution, sensitivity, and the ability to analyze diverse material types under various environmental conditions.Expand Specific Solutions03 FTIR for real-time monitoring and process control

FTIR spectroscopy enables real-time monitoring of material interactions and chemical processes, making it valuable for quality control and process optimization. The technology allows for continuous analysis of reaction kinetics, detection of contaminants, and verification of material composition during manufacturing. By providing immediate feedback on material properties and changes, FTIR systems help maintain product consistency and detect deviations from desired specifications.Expand Specific Solutions04 Advanced data processing and analysis methods for FTIR

Sophisticated data processing techniques enhance the interpretation of FTIR spectral data, including machine learning algorithms, multivariate analysis, and chemometric methods. These approaches improve the extraction of meaningful information from complex spectra, enable automated pattern recognition, and facilitate the identification of subtle material differences. Advanced computational methods also help in removing noise, correcting baseline issues, and resolving overlapping spectral features for more accurate material characterization.Expand Specific Solutions05 Novel applications of FTIR for material interaction studies

FTIR spectroscopy is being applied in innovative ways to study material interactions across various fields, including biomedical research, environmental monitoring, and advanced materials development. The technique enables the investigation of molecular-level interactions between different materials, surface modifications, degradation mechanisms, and compatibility assessments. These applications extend to analyzing biological tissue-material interactions, environmental contaminant behavior, and the performance of composite materials under different conditions.Expand Specific Solutions

Leading FTIR Equipment Manufacturers and Research Institutions

The FTIR (Fourier Transform Infrared Spectroscopy) market for advanced material interaction evaluation is currently in a growth phase, with increasing adoption across research institutions and industrial applications. The global market size is estimated to be expanding at a CAGR of 6-8%, driven by demands in materials science, pharmaceuticals, and environmental monitoring. Technologically, the field shows varying maturity levels, with established players like Thermo Electron Scientific Instruments and Koninklijke Philips leading commercial applications, while research institutions such as Battelle Memorial Institute, Heriot-Watt University, and École Polytechnique Fédérale de Lausanne push boundaries in specialized applications. Companies like BASF Corp. and Boeing are integrating FTIR into industrial quality control processes, while emerging players like FlatFrog Laboratories are developing novel interface applications, indicating a dynamic competitive landscape with opportunities for both specialized and broad-market solutions.

Battelle Memorial Institute

Technical Solution: Battelle has developed sophisticated FTIR deployment strategies for material interaction evaluation across multiple industries including defense, healthcare, and environmental monitoring. Their approach combines portable FTIR instrumentation with advanced sampling accessories designed for field deployment and in-situ analysis. Battelle's technology features miniaturized FTIR systems with specialized optical configurations that maintain analytical performance while reducing size and power requirements. Their solutions incorporate ruggedized sampling interfaces that can withstand harsh environmental conditions while maintaining spectral quality, enabling material evaluation in challenging field settings. Battelle has pioneered the integration of FTIR with wireless data transmission and cloud-based analytics platforms, allowing for remote monitoring and real-time decision support based on material interaction data. Their systems also include specialized sample preparation protocols that enhance the detection of trace contaminants and subtle material changes, particularly valuable for environmental monitoring and forensic applications. Battelle's FTIR deployment approach emphasizes user-friendly interfaces and automated interpretation algorithms that make advanced material analysis accessible to non-specialist users.

Strengths: Exceptional field deployment capabilities; robust design for operation in challenging environments; simplified user interfaces making technology accessible to broader user base. Weaknesses: Some sacrifice in spectral resolution compared to laboratory systems; higher maintenance requirements for field-deployed units; more limited spectral libraries compared to dedicated laboratory systems.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed advanced FTIR spectroscopy systems specifically designed for material interaction evaluation. Their technology incorporates high-resolution spectrometers with customizable sampling interfaces that enable real-time monitoring of material surface interactions at the molecular level. The company's FTIR solutions feature patented ATR (Attenuated Total Reflectance) accessories that allow for direct measurement of solid-liquid interfaces without sample preparation. Their systems integrate machine learning algorithms for automated spectral analysis, enabling rapid identification of chemical changes during material interactions. Thermo's FTIR platforms also include environmental control chambers that can simulate various temperature, pressure, and humidity conditions to evaluate material performance under different environmental stresses, providing comprehensive data on material degradation mechanisms and interaction kinetics.

Strengths: Industry-leading spectral resolution and sensitivity allowing detection of subtle molecular changes; extensive library of reference spectra for material identification; robust software integration for data analysis. Weaknesses: Higher cost compared to competitors; complex systems require specialized training; limited portability for field applications.

Critical FTIR Spectral Analysis Techniques

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

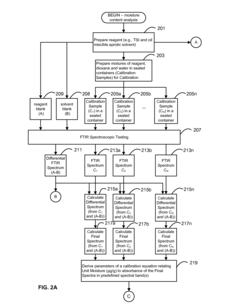

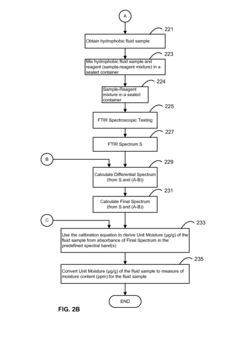

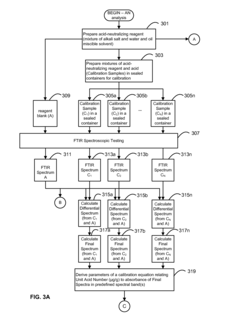

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

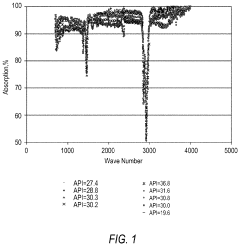

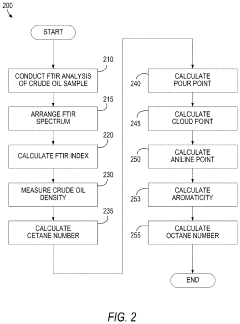

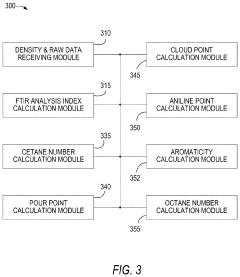

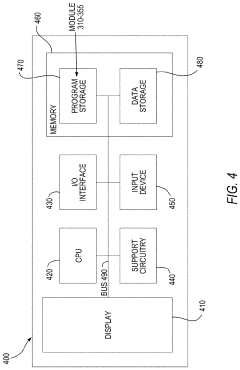

Characterization of crude oil and its fractions by fourier transform infrared (FTIR) spectroscopy analysis

PatentActiveUS10942160B2

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess the indicative properties of crude oil fractions without fractionation, using a system that calculates these properties based on density and FTIR measurements, enabling rapid evaluation of crude oil quality.

Standardization and Calibration Protocols

Standardization and calibration protocols are essential for ensuring the reliability, reproducibility, and accuracy of FTIR measurements in advanced material interaction evaluation. The establishment of robust protocols begins with the selection of appropriate reference materials that exhibit well-characterized spectral features across the relevant infrared regions. These reference materials typically include polystyrene films, water vapor, and carbon dioxide, which provide consistent absorption peaks for wavelength calibration.

Instrument performance verification must be conducted regularly through standardized procedures that assess spectral resolution, wavenumber accuracy, photometric precision, and signal-to-noise ratio. These parameters should be evaluated against internationally recognized standards such as those established by ASTM International (E1421) and the National Institute of Standards and Technology (NIST).

Sample preparation standardization represents another critical aspect of FTIR protocols. For solid materials, consistent grinding techniques, KBr pellet preparation methods, and defined pressure parameters must be established. Liquid samples require standardized cell path lengths, window materials, and cleaning procedures to minimize contamination and ensure measurement consistency.

Background correction methodologies need explicit documentation, including atmospheric compensation techniques and baseline correction algorithms. The frequency of background scans should be determined based on environmental stability and measurement sensitivity requirements, with more frequent scans necessary in fluctuating conditions.

Quantitative analysis demands rigorous calibration curves using certified reference materials at multiple concentration levels. These calibration procedures must account for matrix effects and potential spectral interferences, with validation through independent methods such as chromatography or elemental analysis when applicable.

Data processing standardization is equally important, encompassing spectral preprocessing techniques like smoothing, normalization, and derivative calculations. Specific parameters for these operations should be documented to ensure consistency across different operators and instruments. Statistical methods for multivariate analysis and chemometric modeling require validation protocols that assess model robustness and predictive performance.

Interlaboratory comparison studies serve as the ultimate validation of standardization efforts, allowing for the identification of systematic errors and the establishment of measurement uncertainty budgets. Participation in proficiency testing programs provides external verification of laboratory competence and helps refine calibration protocols over time.

Documentation of all calibration and standardization procedures in a comprehensive quality management system ensures traceability and facilitates continuous improvement of measurement protocols. This documentation should include detailed records of reference materials, calibration certificates, maintenance logs, and operator training requirements.

Instrument performance verification must be conducted regularly through standardized procedures that assess spectral resolution, wavenumber accuracy, photometric precision, and signal-to-noise ratio. These parameters should be evaluated against internationally recognized standards such as those established by ASTM International (E1421) and the National Institute of Standards and Technology (NIST).

Sample preparation standardization represents another critical aspect of FTIR protocols. For solid materials, consistent grinding techniques, KBr pellet preparation methods, and defined pressure parameters must be established. Liquid samples require standardized cell path lengths, window materials, and cleaning procedures to minimize contamination and ensure measurement consistency.

Background correction methodologies need explicit documentation, including atmospheric compensation techniques and baseline correction algorithms. The frequency of background scans should be determined based on environmental stability and measurement sensitivity requirements, with more frequent scans necessary in fluctuating conditions.

Quantitative analysis demands rigorous calibration curves using certified reference materials at multiple concentration levels. These calibration procedures must account for matrix effects and potential spectral interferences, with validation through independent methods such as chromatography or elemental analysis when applicable.

Data processing standardization is equally important, encompassing spectral preprocessing techniques like smoothing, normalization, and derivative calculations. Specific parameters for these operations should be documented to ensure consistency across different operators and instruments. Statistical methods for multivariate analysis and chemometric modeling require validation protocols that assess model robustness and predictive performance.

Interlaboratory comparison studies serve as the ultimate validation of standardization efforts, allowing for the identification of systematic errors and the establishment of measurement uncertainty budgets. Participation in proficiency testing programs provides external verification of laboratory competence and helps refine calibration protocols over time.

Documentation of all calibration and standardization procedures in a comprehensive quality management system ensures traceability and facilitates continuous improvement of measurement protocols. This documentation should include detailed records of reference materials, calibration certificates, maintenance logs, and operator training requirements.

Environmental Impact of FTIR Testing Procedures

The environmental implications of Fourier Transform Infrared Spectroscopy (FTIR) testing procedures warrant careful consideration as this analytical technique becomes increasingly prevalent in material science applications. While FTIR itself is generally considered a relatively clean analytical method compared to many chemical testing procedures, its environmental footprint extends beyond the immediate testing environment.

The primary environmental concerns associated with FTIR testing relate to sample preparation methods and waste disposal. Many FTIR applications require the use of solvents for sample extraction or preparation, including potentially hazardous substances such as chloroform, acetone, and methanol. These chemicals, if improperly handled or disposed of, can contribute to air pollution, water contamination, and soil degradation. Organizations implementing FTIR testing must establish robust waste management protocols that comply with local environmental regulations.

Energy consumption represents another significant environmental consideration. Modern FTIR spectrometers require continuous power supply for operation, temperature control systems, and data processing capabilities. The carbon footprint associated with this energy usage varies considerably depending on regional energy sources and instrument efficiency. Newer FTIR models have made substantial improvements in energy efficiency, with some manufacturers reporting reductions of 30-40% in power consumption compared to previous generations.

Sample destruction during testing also presents environmental challenges. While FTIR is often described as non-destructive, certain applications require permanent sample alteration or consumption. This necessitates careful consideration of sample quantities to minimize material waste, particularly when analyzing rare or environmentally sensitive materials.

The manufacturing of FTIR equipment itself carries environmental implications. Production processes for optical components, electronic systems, and precision mechanics involve resource extraction, energy-intensive manufacturing, and potential use of rare earth elements. Leading manufacturers have begun implementing sustainability initiatives, including recycling programs for outdated equipment and reduction of hazardous materials in new instrument designs.

Encouragingly, technological advancements are continuously improving the environmental profile of FTIR testing. Miniaturization trends have led to portable FTIR devices that consume significantly less power than traditional benchtop instruments. Additionally, developments in sampling techniques have reduced or eliminated the need for environmentally problematic solvents in many applications, with solvent-free approaches gaining prominence in recent years.

Organizations deploying FTIR for advanced material interaction evaluation should incorporate environmental impact assessments into their testing protocols, considering the full lifecycle environmental costs alongside analytical benefits when establishing testing procedures.

The primary environmental concerns associated with FTIR testing relate to sample preparation methods and waste disposal. Many FTIR applications require the use of solvents for sample extraction or preparation, including potentially hazardous substances such as chloroform, acetone, and methanol. These chemicals, if improperly handled or disposed of, can contribute to air pollution, water contamination, and soil degradation. Organizations implementing FTIR testing must establish robust waste management protocols that comply with local environmental regulations.

Energy consumption represents another significant environmental consideration. Modern FTIR spectrometers require continuous power supply for operation, temperature control systems, and data processing capabilities. The carbon footprint associated with this energy usage varies considerably depending on regional energy sources and instrument efficiency. Newer FTIR models have made substantial improvements in energy efficiency, with some manufacturers reporting reductions of 30-40% in power consumption compared to previous generations.

Sample destruction during testing also presents environmental challenges. While FTIR is often described as non-destructive, certain applications require permanent sample alteration or consumption. This necessitates careful consideration of sample quantities to minimize material waste, particularly when analyzing rare or environmentally sensitive materials.

The manufacturing of FTIR equipment itself carries environmental implications. Production processes for optical components, electronic systems, and precision mechanics involve resource extraction, energy-intensive manufacturing, and potential use of rare earth elements. Leading manufacturers have begun implementing sustainability initiatives, including recycling programs for outdated equipment and reduction of hazardous materials in new instrument designs.

Encouragingly, technological advancements are continuously improving the environmental profile of FTIR testing. Miniaturization trends have led to portable FTIR devices that consume significantly less power than traditional benchtop instruments. Additionally, developments in sampling techniques have reduced or eliminated the need for environmentally problematic solvents in many applications, with solvent-free approaches gaining prominence in recent years.

Organizations deploying FTIR for advanced material interaction evaluation should incorporate environmental impact assessments into their testing protocols, considering the full lifecycle environmental costs alongside analytical benefits when establishing testing procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!