How FTIR Supports Novel Material Developments in R&D

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Technology Background and Research Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, transforming from a specialized analytical technique to an essential tool in materials research and development. The technology's foundation lies in the interaction between infrared radiation and matter, allowing scientists to identify molecular structures through their characteristic absorption patterns. This non-destructive analytical method has become increasingly sophisticated with advancements in computing power, detector sensitivity, and data processing algorithms.

The evolution of FTIR technology has been marked by several key milestones, including the transition from dispersive instruments to interferometer-based systems, the development of attenuated total reflection (ATR) accessories, and the integration of microscopy capabilities. These innovations have dramatically expanded the applicability of FTIR across diverse scientific disciplines and industrial sectors, particularly in novel materials development where molecular characterization is paramount.

Current technological trends in FTIR include miniaturization for portable applications, enhanced spectral resolution, faster acquisition times, and integration with artificial intelligence for automated interpretation. The convergence of FTIR with complementary analytical techniques such as Raman spectroscopy and thermal analysis is creating powerful hybrid approaches that provide more comprehensive material characterization than previously possible.

In the context of novel materials development, FTIR serves multiple critical functions throughout the R&D lifecycle. During initial synthesis, it enables rapid verification of reaction products and identification of unexpected byproducts. In the optimization phase, FTIR provides quantitative feedback on composition and purity, guiding iterative improvements. For final characterization, it delivers detailed structural information essential for understanding material properties and performance.

The primary objectives of this technical research report are to comprehensively evaluate how FTIR technology supports and accelerates novel materials development across various industries. Specifically, we aim to assess the current capabilities and limitations of FTIR in characterizing emerging materials such as advanced polymers, nanomaterials, biomaterials, and sustainable alternatives to conventional materials.

Additionally, this report seeks to identify opportunities for technological enhancement that could further strengthen FTIR's role in materials innovation. By examining case studies of successful FTIR applications in breakthrough materials development, we will extract best practices and methodological approaches that can be broadly applied. The ultimate goal is to provide strategic insights that will inform R&D investment decisions and technology adoption strategies in materials-focused organizations.

The evolution of FTIR technology has been marked by several key milestones, including the transition from dispersive instruments to interferometer-based systems, the development of attenuated total reflection (ATR) accessories, and the integration of microscopy capabilities. These innovations have dramatically expanded the applicability of FTIR across diverse scientific disciplines and industrial sectors, particularly in novel materials development where molecular characterization is paramount.

Current technological trends in FTIR include miniaturization for portable applications, enhanced spectral resolution, faster acquisition times, and integration with artificial intelligence for automated interpretation. The convergence of FTIR with complementary analytical techniques such as Raman spectroscopy and thermal analysis is creating powerful hybrid approaches that provide more comprehensive material characterization than previously possible.

In the context of novel materials development, FTIR serves multiple critical functions throughout the R&D lifecycle. During initial synthesis, it enables rapid verification of reaction products and identification of unexpected byproducts. In the optimization phase, FTIR provides quantitative feedback on composition and purity, guiding iterative improvements. For final characterization, it delivers detailed structural information essential for understanding material properties and performance.

The primary objectives of this technical research report are to comprehensively evaluate how FTIR technology supports and accelerates novel materials development across various industries. Specifically, we aim to assess the current capabilities and limitations of FTIR in characterizing emerging materials such as advanced polymers, nanomaterials, biomaterials, and sustainable alternatives to conventional materials.

Additionally, this report seeks to identify opportunities for technological enhancement that could further strengthen FTIR's role in materials innovation. By examining case studies of successful FTIR applications in breakthrough materials development, we will extract best practices and methodological approaches that can be broadly applied. The ultimate goal is to provide strategic insights that will inform R&D investment decisions and technology adoption strategies in materials-focused organizations.

Market Analysis for FTIR in Materials Science

The FTIR (Fourier Transform Infrared Spectroscopy) market within materials science has experienced robust growth over the past decade, driven primarily by increasing demand for advanced material characterization techniques across multiple industries. The global FTIR spectroscopy market was valued at approximately 1.2 billion USD in 2022 and is projected to reach 1.8 billion USD by 2028, representing a compound annual growth rate of 6.5% during the forecast period.

Materials science applications constitute nearly 40% of the total FTIR market, making it the largest application segment. This dominance stems from the critical role FTIR plays in both academic research and industrial R&D settings for novel material development. Pharmaceutical and biotechnology sectors represent the fastest-growing vertical markets for FTIR in materials analysis, with demand increasing at roughly 8% annually due to stringent regulatory requirements and the push for innovative drug delivery systems.

Geographically, North America holds the largest market share at approximately 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the most rapid growth rate, particularly in China, India, and South Korea, where significant investments in research infrastructure and manufacturing capabilities are driving adoption of advanced analytical technologies.

The competitive landscape features both established analytical instrument manufacturers and specialized spectroscopy companies. Key market players include Thermo Fisher Scientific, Bruker Corporation, Agilent Technologies, PerkinElmer, and Shimadzu Corporation, collectively accounting for over 70% of the global market share. These companies are increasingly focusing on developing more compact, user-friendly, and automated FTIR systems with enhanced data analysis capabilities to meet the evolving needs of materials scientists.

Customer segmentation reveals that academic and research institutions constitute approximately 45% of end-users, while industrial R&D laboratories account for 35%. Government laboratories and testing facilities make up the remaining 20%. This distribution highlights the dual importance of FTIR in both fundamental research and practical applications in materials development.

Market drivers include the growing complexity of composite materials, increasing focus on sustainable and bio-based materials, and the rise of nanomaterials research. Additionally, the integration of FTIR with complementary analytical techniques and artificial intelligence for data interpretation is creating new market opportunities and enhancing the value proposition for end-users.

Challenges facing the market include the high initial investment cost for advanced FTIR systems, technical expertise requirements for data interpretation, and competition from alternative spectroscopic techniques. Nevertheless, the essential role of FTIR in material fingerprinting and quality control ensures its continued relevance in materials science R&D.

Materials science applications constitute nearly 40% of the total FTIR market, making it the largest application segment. This dominance stems from the critical role FTIR plays in both academic research and industrial R&D settings for novel material development. Pharmaceutical and biotechnology sectors represent the fastest-growing vertical markets for FTIR in materials analysis, with demand increasing at roughly 8% annually due to stringent regulatory requirements and the push for innovative drug delivery systems.

Geographically, North America holds the largest market share at approximately 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the most rapid growth rate, particularly in China, India, and South Korea, where significant investments in research infrastructure and manufacturing capabilities are driving adoption of advanced analytical technologies.

The competitive landscape features both established analytical instrument manufacturers and specialized spectroscopy companies. Key market players include Thermo Fisher Scientific, Bruker Corporation, Agilent Technologies, PerkinElmer, and Shimadzu Corporation, collectively accounting for over 70% of the global market share. These companies are increasingly focusing on developing more compact, user-friendly, and automated FTIR systems with enhanced data analysis capabilities to meet the evolving needs of materials scientists.

Customer segmentation reveals that academic and research institutions constitute approximately 45% of end-users, while industrial R&D laboratories account for 35%. Government laboratories and testing facilities make up the remaining 20%. This distribution highlights the dual importance of FTIR in both fundamental research and practical applications in materials development.

Market drivers include the growing complexity of composite materials, increasing focus on sustainable and bio-based materials, and the rise of nanomaterials research. Additionally, the integration of FTIR with complementary analytical techniques and artificial intelligence for data interpretation is creating new market opportunities and enhancing the value proposition for end-users.

Challenges facing the market include the high initial investment cost for advanced FTIR systems, technical expertise requirements for data interpretation, and competition from alternative spectroscopic techniques. Nevertheless, the essential role of FTIR in material fingerprinting and quality control ensures its continued relevance in materials science R&D.

Current FTIR Capabilities and Technical Limitations

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly over the past decades, becoming an indispensable analytical tool in materials research and development. Current FTIR systems offer remarkable capabilities including high spectral resolution (typically 0.1-4 cm⁻¹), wide spectral range coverage (typically 400-4000 cm⁻¹), and rapid data acquisition speeds with some systems capable of collecting complete spectra in milliseconds.

Modern FTIR instruments feature advanced sampling techniques that have dramatically expanded their application scope. Attenuated Total Reflection (ATR) accessories allow direct analysis of solid and liquid samples with minimal preparation. Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) enables examination of powdered materials, while microscope-coupled systems permit spatial mapping with resolution approaching 10 μm.

The integration of FTIR with complementary techniques represents a significant advancement. Hyphenated systems like TGA-FTIR (Thermogravimetric Analysis-FTIR) and GC-FTIR (Gas Chromatography-FTIR) provide simultaneous thermal and chemical information critical for material characterization. Additionally, time-resolved FTIR enables monitoring of dynamic processes such as curing reactions, degradation mechanisms, and catalytic transformations in real-time.

Despite these impressive capabilities, FTIR faces several technical limitations that constrain its application in novel materials development. The diffraction limit fundamentally restricts spatial resolution to approximately the wavelength of mid-infrared light (2-25 μm), making nanoscale characterization challenging without specialized techniques like nano-FTIR. This limitation is particularly problematic for analyzing nanomaterials and thin films critical to advanced electronics and photonics.

Sensitivity remains another significant challenge, especially for trace component detection. Conventional FTIR typically requires concentrations of 0.1-1% for reliable detection, which is insufficient for analyzing dopants, contaminants, or minor phases that often critically influence material properties. While techniques like multiple-reflection ATR improve sensitivity, they often require specialized sample preparation that may alter material characteristics.

Water and atmospheric interference present persistent challenges, as strong absorption bands from water vapor and CO₂ can mask important spectral features. Although purge systems and mathematical correction algorithms help mitigate these issues, they add complexity and potential artifacts to the analysis process.

For quantitative analysis, FTIR faces limitations in accuracy and reproducibility, particularly for complex matrices. Beer-Lambert law deviations occur frequently in real-world samples due to scattering effects, concentration-dependent molecular interactions, and instrumental factors. This complicates efforts to develop reliable calibration models for novel materials without extensive reference standards.

Modern FTIR instruments feature advanced sampling techniques that have dramatically expanded their application scope. Attenuated Total Reflection (ATR) accessories allow direct analysis of solid and liquid samples with minimal preparation. Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) enables examination of powdered materials, while microscope-coupled systems permit spatial mapping with resolution approaching 10 μm.

The integration of FTIR with complementary techniques represents a significant advancement. Hyphenated systems like TGA-FTIR (Thermogravimetric Analysis-FTIR) and GC-FTIR (Gas Chromatography-FTIR) provide simultaneous thermal and chemical information critical for material characterization. Additionally, time-resolved FTIR enables monitoring of dynamic processes such as curing reactions, degradation mechanisms, and catalytic transformations in real-time.

Despite these impressive capabilities, FTIR faces several technical limitations that constrain its application in novel materials development. The diffraction limit fundamentally restricts spatial resolution to approximately the wavelength of mid-infrared light (2-25 μm), making nanoscale characterization challenging without specialized techniques like nano-FTIR. This limitation is particularly problematic for analyzing nanomaterials and thin films critical to advanced electronics and photonics.

Sensitivity remains another significant challenge, especially for trace component detection. Conventional FTIR typically requires concentrations of 0.1-1% for reliable detection, which is insufficient for analyzing dopants, contaminants, or minor phases that often critically influence material properties. While techniques like multiple-reflection ATR improve sensitivity, they often require specialized sample preparation that may alter material characteristics.

Water and atmospheric interference present persistent challenges, as strong absorption bands from water vapor and CO₂ can mask important spectral features. Although purge systems and mathematical correction algorithms help mitigate these issues, they add complexity and potential artifacts to the analysis process.

For quantitative analysis, FTIR faces limitations in accuracy and reproducibility, particularly for complex matrices. Beer-Lambert law deviations occur frequently in real-world samples due to scattering effects, concentration-dependent molecular interactions, and instrumental factors. This complicates efforts to develop reliable calibration models for novel materials without extensive reference standards.

Contemporary FTIR Applications in Novel Materials

01 FTIR spectroscopy instrumentation and design

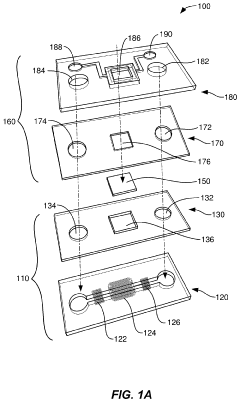

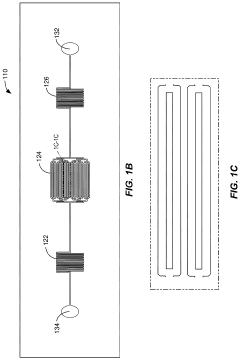

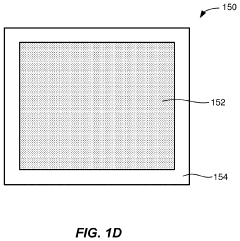

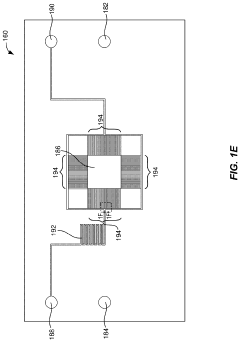

Various designs and configurations of FTIR spectroscopy instruments are described, including portable devices, miniaturized systems, and specialized components that enhance measurement capabilities. These innovations focus on improving the optical path, detector sensitivity, and overall instrument performance for more accurate and efficient spectroscopic analysis.- FTIR instrumentation and apparatus design: Various designs and improvements in FTIR spectroscopy instruments, including specialized components, optical arrangements, and system configurations that enhance measurement accuracy, sensitivity, and reliability. These innovations focus on the physical construction of FTIR devices, including interferometer designs, detector arrangements, and sample handling mechanisms to optimize spectroscopic performance across different applications.

- Sample analysis and characterization techniques: Methods for analyzing and characterizing various materials and substances using FTIR spectroscopy. These techniques involve specific protocols for sample preparation, measurement procedures, and data interpretation to identify chemical compositions, structural properties, and molecular interactions. The approaches enable qualitative and quantitative analysis across diverse sample types including solids, liquids, gases, and biological materials.

- Integration with other analytical technologies: Combination of FTIR spectroscopy with complementary analytical techniques to provide comprehensive material characterization. These integrated systems may combine FTIR with techniques such as Raman spectroscopy, mass spectrometry, thermal analysis, or microscopy to deliver multi-modal analysis capabilities. Such integrations enhance analytical power by providing correlated data from different measurement principles.

- Portable and miniaturized FTIR systems: Development of compact, portable, and field-deployable FTIR spectroscopy systems that enable on-site analysis outside traditional laboratory environments. These innovations focus on miniaturization of components, power efficiency, ruggedization for field use, and simplified operation interfaces. Portable systems allow for real-time analysis in applications such as environmental monitoring, quality control, and security screening.

- Data processing and analysis algorithms: Advanced computational methods for processing and interpreting FTIR spectral data, including algorithms for spectral correction, pattern recognition, chemometrics, and automated analysis. These innovations enhance the extraction of meaningful information from complex spectral data, improve signal-to-noise ratios, and enable automated identification of chemical components. Machine learning approaches may be incorporated to identify patterns and correlations in spectral datasets.

02 Sample analysis and characterization techniques

Methods for analyzing and characterizing samples using FTIR spectroscopy, including techniques for material identification, quantitative analysis, and quality control. These approaches enable the determination of chemical composition, structural properties, and functional group identification in various substances through the interpretation of infrared absorption patterns.Expand Specific Solutions03 Integration with other analytical methods

Combination of FTIR spectroscopy with complementary analytical techniques such as Raman spectroscopy, mass spectrometry, or chromatography to provide comprehensive sample characterization. These integrated approaches offer enhanced analytical capabilities by leveraging the strengths of multiple techniques for more detailed and accurate sample analysis.Expand Specific Solutions04 Industrial and process monitoring applications

Implementation of FTIR spectroscopy for real-time monitoring and control of industrial processes, including manufacturing quality control, environmental monitoring, and production optimization. These applications utilize the rapid, non-destructive nature of FTIR analysis to provide immediate feedback on process conditions and product quality.Expand Specific Solutions05 Advanced data processing and analysis methods

Sophisticated algorithms and computational methods for processing and interpreting FTIR spectral data, including chemometric techniques, machine learning approaches, and automated pattern recognition. These methods enhance the extraction of meaningful information from complex spectral data, improving the accuracy and efficiency of sample analysis and classification.Expand Specific Solutions

Leading FTIR Instrument Manufacturers and Research Institutions

FTIR technology in novel material development is currently in a mature growth phase, with an expanding market driven by increasing R&D demands across industries. The competitive landscape features established scientific instrumentation leaders like Thermo Electron Scientific Instruments and Koninklijke Philips alongside specialized players such as Smiths Detection. Academic institutions (Politecnico di Milano, University of Strathclyde, EPFL) and major corporations (Vertex Pharmaceuticals, Saudi Aramco, SINOPEC) are advancing applications through collaborative research. The technology's maturity is evidenced by widespread adoption across pharmaceutical, petrochemical, and materials science sectors, with emerging applications in nanomaterials and composite development being pioneered by companies like TPI Composites and GlobalWafers.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced FTIR technologies integrated into their materials research platforms, particularly focused on semiconductor, polymer, and biomedical materials. Their systems incorporate micro-FTIR capabilities with spatial resolution down to 10 micrometers, enabling detailed mapping of material composition across heterogeneous samples. Philips' technology features specialized accessories for analyzing thin films and interfaces, critical for semiconductor and display material development. Their proprietary software includes multivariate analysis tools that can detect subtle material variations across production batches, supporting quality control in advanced material manufacturing. The company has also pioneered hyphenated techniques that combine FTIR with thermal analysis (TGA-FTIR), allowing researchers to monitor chemical changes during material degradation or curing processes. Their systems support automated sampling handling for high-throughput material screening applications, enabling faster development cycles for novel materials in consumer electronics and healthcare applications.

Strengths: Excellent capabilities for microanalysis and thin film characterization; sophisticated software for multivariate analysis; seamless integration with complementary analytical techniques. Weaknesses: Higher cost compared to standard FTIR systems; requires significant expertise for advanced applications; some specialized accessories have limited flexibility for diverse sample types.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary FTIR-based analytical systems specifically tailored for petroleum and petrochemical material development. Their technology incorporates specialized sampling interfaces for analyzing complex hydrocarbon mixtures and catalytic materials under various temperature and pressure conditions. Sinopec's FTIR systems feature high-temperature cells capable of in-situ monitoring of catalytic reactions up to 800°C, providing real-time data on reaction kinetics and material transformations. The company has also pioneered chemometric algorithms specifically calibrated for petroleum applications that can identify and quantify trace contaminants in complex matrices. Their integrated approach combines FTIR with complementary techniques like Raman spectroscopy to provide comprehensive characterization of novel materials for energy applications, enabling faster development cycles for advanced catalysts and petroleum derivatives.

Strengths: Specialized expertise in petroleum-related materials analysis; robust systems designed for harsh industrial environments; extensive proprietary spectral libraries for hydrocarbon compounds. Weaknesses: Technologies primarily optimized for petroleum applications with less versatility for other material types; limited global service network compared to dedicated instrument manufacturers.

Key FTIR Methodologies for Material Characterization

Devices and methods for spectroscopy of biomaterials and live cells

PatentPendingUS20240042438A1

Innovation

- An open-channel microfluidic membrane device is developed, featuring hydraulic resistors, capillary design for humidity control, and vertical interconnects for real-time detection of spatiotemporal changes in hydrogen bond networks using hyperspectral microscopy, allowing for autonomous analysis without tedious post-treatment sample preparation.

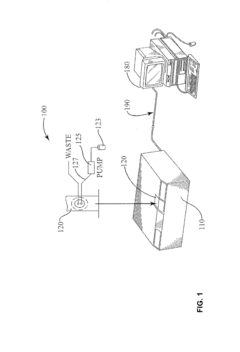

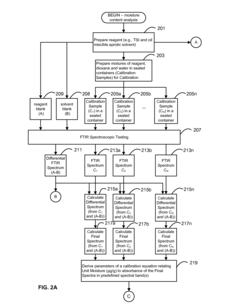

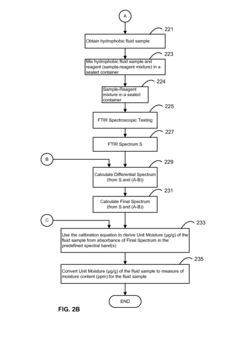

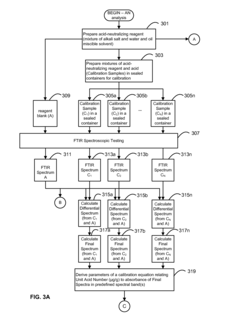

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Integration of FTIR with Complementary Analytical Techniques

The integration of FTIR spectroscopy with complementary analytical techniques represents a powerful approach to comprehensive material characterization in R&D environments. When combined with techniques such as Raman spectroscopy, FTIR provides enhanced molecular fingerprinting capabilities, as Raman detects vibrations that may be IR-inactive and vice versa. This complementarity allows researchers to obtain a more complete structural picture of novel materials, particularly beneficial for complex polymers and composites.

X-ray diffraction (XRD) paired with FTIR creates a synergistic analytical platform that correlates molecular bonding information from FTIR with crystalline structure data from XRD. This integration is particularly valuable in pharmaceutical research, where understanding both molecular interactions and crystal packing arrangements is critical for drug formulation and stability studies.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), when coupled with FTIR, enable researchers to monitor chemical changes during thermal events. FTIR-TGA systems can capture evolved gases during material decomposition, providing insights into degradation mechanisms and thermal stability profiles essential for high-performance materials development.

Advanced microscopy techniques such as Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) complement FTIR by adding spatial resolution and surface topography information. Micro-FTIR and FTIR imaging systems can be correlated with microscopy data to map chemical composition across heterogeneous samples, revealing structure-property relationships at micro and nanoscales.

Mass spectrometry integration with FTIR offers powerful capabilities for identifying unknown compounds in complex mixtures. This hyphenated approach (GC-FTIR-MS or LC-FTIR-MS) provides both structural information and precise molecular identification, accelerating the characterization of novel materials and their degradation products.

Machine learning algorithms are increasingly being applied to integrate and interpret multi-technique analytical data. These computational approaches can identify patterns and correlations across FTIR, Raman, XRD, and other datasets that might not be apparent through conventional analysis, potentially revealing hidden structure-property relationships and accelerating materials discovery.

The future of integrated analytical approaches lies in automated, high-throughput systems that can perform multiple analyses on the same sample with minimal human intervention. Such systems, incorporating FTIR as a central component, promise to dramatically accelerate the materials development cycle from initial synthesis to final application testing.

X-ray diffraction (XRD) paired with FTIR creates a synergistic analytical platform that correlates molecular bonding information from FTIR with crystalline structure data from XRD. This integration is particularly valuable in pharmaceutical research, where understanding both molecular interactions and crystal packing arrangements is critical for drug formulation and stability studies.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), when coupled with FTIR, enable researchers to monitor chemical changes during thermal events. FTIR-TGA systems can capture evolved gases during material decomposition, providing insights into degradation mechanisms and thermal stability profiles essential for high-performance materials development.

Advanced microscopy techniques such as Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) complement FTIR by adding spatial resolution and surface topography information. Micro-FTIR and FTIR imaging systems can be correlated with microscopy data to map chemical composition across heterogeneous samples, revealing structure-property relationships at micro and nanoscales.

Mass spectrometry integration with FTIR offers powerful capabilities for identifying unknown compounds in complex mixtures. This hyphenated approach (GC-FTIR-MS or LC-FTIR-MS) provides both structural information and precise molecular identification, accelerating the characterization of novel materials and their degradation products.

Machine learning algorithms are increasingly being applied to integrate and interpret multi-technique analytical data. These computational approaches can identify patterns and correlations across FTIR, Raman, XRD, and other datasets that might not be apparent through conventional analysis, potentially revealing hidden structure-property relationships and accelerating materials discovery.

The future of integrated analytical approaches lies in automated, high-throughput systems that can perform multiple analyses on the same sample with minimal human intervention. Such systems, incorporating FTIR as a central component, promise to dramatically accelerate the materials development cycle from initial synthesis to final application testing.

Sustainability Impact of FTIR-Guided Material Development

The integration of FTIR spectroscopy into material development processes represents a significant advancement in sustainable manufacturing and product design. By enabling precise molecular characterization without destructive testing, FTIR technology substantially reduces waste generation during R&D phases, as samples can be analyzed repeatedly without degradation. This conservation of research materials directly translates to reduced environmental impact in laboratory settings.

FTIR-guided material development has demonstrated remarkable contributions to green chemistry initiatives by facilitating the replacement of hazardous substances with environmentally benign alternatives. The technology's ability to identify molecular structures allows researchers to design materials with reduced toxicity profiles while maintaining or enhancing performance characteristics. This capability has proven particularly valuable in industries transitioning away from legacy chemicals of concern.

In the realm of biodegradable materials research, FTIR serves as a critical analytical tool for monitoring degradation pathways and verifying complete decomposition. By tracking molecular changes over time, researchers can optimize formulations to ensure materials break down into environmentally safe components rather than persistent microplastics or harmful byproducts.

Energy efficiency improvements represent another sustainability benefit of FTIR-guided development. The technology enables the creation of materials with enhanced thermal properties, resulting in better insulation products and energy-conserving building materials. These innovations contribute directly to reduced energy consumption in residential and commercial applications, supporting global carbon reduction goals.

The circular economy benefits significantly from FTIR applications in recycling technology development. By providing detailed compositional analysis of mixed waste streams, FTIR helps in designing more efficient separation processes and developing novel recycling methodologies for previously non-recyclable materials. This capability extends product lifecycles and reduces landfill dependency.

Water conservation efforts have also advanced through FTIR-guided material innovations, particularly in the development of improved filtration membranes and water treatment materials. The precise molecular design enabled by FTIR analysis has led to more efficient purification systems that require less energy and fewer chemical inputs to achieve clean water standards.

As sustainability metrics become increasingly important in corporate governance and reporting, FTIR technology provides valuable data points for lifecycle assessments and environmental impact evaluations of new materials, helping organizations quantify and communicate their sustainability achievements to stakeholders and regulatory bodies.

FTIR-guided material development has demonstrated remarkable contributions to green chemistry initiatives by facilitating the replacement of hazardous substances with environmentally benign alternatives. The technology's ability to identify molecular structures allows researchers to design materials with reduced toxicity profiles while maintaining or enhancing performance characteristics. This capability has proven particularly valuable in industries transitioning away from legacy chemicals of concern.

In the realm of biodegradable materials research, FTIR serves as a critical analytical tool for monitoring degradation pathways and verifying complete decomposition. By tracking molecular changes over time, researchers can optimize formulations to ensure materials break down into environmentally safe components rather than persistent microplastics or harmful byproducts.

Energy efficiency improvements represent another sustainability benefit of FTIR-guided development. The technology enables the creation of materials with enhanced thermal properties, resulting in better insulation products and energy-conserving building materials. These innovations contribute directly to reduced energy consumption in residential and commercial applications, supporting global carbon reduction goals.

The circular economy benefits significantly from FTIR applications in recycling technology development. By providing detailed compositional analysis of mixed waste streams, FTIR helps in designing more efficient separation processes and developing novel recycling methodologies for previously non-recyclable materials. This capability extends product lifecycles and reduces landfill dependency.

Water conservation efforts have also advanced through FTIR-guided material innovations, particularly in the development of improved filtration membranes and water treatment materials. The precise molecular design enabled by FTIR analysis has led to more efficient purification systems that require less energy and fewer chemical inputs to achieve clean water standards.

As sustainability metrics become increasingly important in corporate governance and reporting, FTIR technology provides valuable data points for lifecycle assessments and environmental impact evaluations of new materials, helping organizations quantify and communicate their sustainability achievements to stakeholders and regulatory bodies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!