FTIR vs GC-MS: Which Is More Effective for VOCs?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOCs Analysis Technology Background and Objectives

Volatile Organic Compounds (VOCs) have emerged as significant environmental and health concerns over the past several decades. These compounds, characterized by their high vapor pressure at room temperature, are emitted from various sources including industrial processes, vehicle emissions, consumer products, and natural sources. The detection, identification, and quantification of VOCs have become increasingly important due to their impact on air quality, human health, and climate change.

The evolution of VOC analysis technologies has progressed significantly since the 1970s when environmental regulations first began to address air pollution concerns. Initially, simple colorimetric methods and basic gas chromatography techniques provided limited capabilities for VOC detection. As analytical instrumentation advanced, more sophisticated methods emerged, including Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS), which now represent two of the most widely used techniques for VOC analysis.

FTIR technology utilizes infrared radiation to identify molecular structures based on their vibrational characteristics, offering real-time monitoring capabilities and the ability to simultaneously detect multiple compounds. The development of portable FTIR systems has further expanded its application in field measurements and continuous emissions monitoring.

GC-MS, on the other hand, combines the separation power of gas chromatography with the identification capabilities of mass spectrometry. This technology has evolved from laboratory-bound instruments to more compact, field-deployable systems, with improvements in sensitivity, selectivity, and automation over time.

The primary objective of this technical research report is to conduct a comprehensive comparison between FTIR and GC-MS technologies for VOC analysis. We aim to evaluate their respective strengths, limitations, and optimal application scenarios based on factors including sensitivity, selectivity, speed of analysis, portability, cost-effectiveness, and suitability for different VOC types and concentrations.

Additionally, this report seeks to identify emerging trends in both technologies, including recent advancements such as miniaturization, automation, and integration with other analytical techniques. By understanding the current technological landscape and future development trajectories, we can provide strategic insights for technology investment, method selection, and potential innovation opportunities in VOC analysis.

The findings of this research will serve as a foundation for informed decision-making regarding analytical method selection for specific VOC monitoring applications, from environmental compliance testing to industrial process control, indoor air quality assessment, and emerging fields such as breath analysis for medical diagnostics.

The evolution of VOC analysis technologies has progressed significantly since the 1970s when environmental regulations first began to address air pollution concerns. Initially, simple colorimetric methods and basic gas chromatography techniques provided limited capabilities for VOC detection. As analytical instrumentation advanced, more sophisticated methods emerged, including Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS), which now represent two of the most widely used techniques for VOC analysis.

FTIR technology utilizes infrared radiation to identify molecular structures based on their vibrational characteristics, offering real-time monitoring capabilities and the ability to simultaneously detect multiple compounds. The development of portable FTIR systems has further expanded its application in field measurements and continuous emissions monitoring.

GC-MS, on the other hand, combines the separation power of gas chromatography with the identification capabilities of mass spectrometry. This technology has evolved from laboratory-bound instruments to more compact, field-deployable systems, with improvements in sensitivity, selectivity, and automation over time.

The primary objective of this technical research report is to conduct a comprehensive comparison between FTIR and GC-MS technologies for VOC analysis. We aim to evaluate their respective strengths, limitations, and optimal application scenarios based on factors including sensitivity, selectivity, speed of analysis, portability, cost-effectiveness, and suitability for different VOC types and concentrations.

Additionally, this report seeks to identify emerging trends in both technologies, including recent advancements such as miniaturization, automation, and integration with other analytical techniques. By understanding the current technological landscape and future development trajectories, we can provide strategic insights for technology investment, method selection, and potential innovation opportunities in VOC analysis.

The findings of this research will serve as a foundation for informed decision-making regarding analytical method selection for specific VOC monitoring applications, from environmental compliance testing to industrial process control, indoor air quality assessment, and emerging fields such as breath analysis for medical diagnostics.

Market Demand for VOCs Detection Methods

The global market for Volatile Organic Compounds (VOCs) detection methods has experienced significant growth in recent years, driven by increasing environmental regulations, growing health concerns, and industrial safety requirements. The demand for accurate, reliable, and efficient VOC detection technologies continues to expand across multiple sectors including environmental monitoring, industrial hygiene, indoor air quality assessment, and manufacturing process control.

Environmental regulations worldwide have become increasingly stringent regarding VOC emissions, particularly in developed regions such as North America, Europe, and parts of Asia. The implementation of policies like the Clean Air Act in the United States, the Industrial Emissions Directive in Europe, and similar regulations in China and Japan has created substantial demand for advanced VOC detection technologies. These regulatory frameworks require industries to monitor and control their VOC emissions, directly driving market growth for detection methods.

The industrial sector represents a major market segment for VOC detection technologies. Manufacturing facilities, chemical plants, petroleum refineries, and pharmaceutical production sites all require continuous monitoring of VOCs for process control, quality assurance, and worker safety compliance. This segment shows particular interest in technologies offering real-time analysis capabilities, such as FTIR systems that can provide immediate feedback on process conditions.

Healthcare and indoor air quality monitoring constitute rapidly growing application areas. With increasing awareness of sick building syndrome and the health impacts of VOCs in indoor environments, demand has surged for monitoring solutions in hospitals, schools, office buildings, and residential spaces. This market segment typically values portability, ease of use, and cost-effectiveness alongside analytical performance.

The automotive and transportation sectors also represent significant market opportunities, particularly for technologies capable of monitoring vehicle emissions and cabin air quality. As emission standards become more stringent globally, manufacturers require increasingly sensitive detection methods to ensure compliance during development and production.

Market analysis indicates that the global VOC monitoring equipment market was valued at approximately $1.2 billion in 2022, with projections suggesting growth at a CAGR of 6.8% through 2028. North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%, with the latter showing the fastest growth rate due to rapid industrialization and strengthening environmental regulations.

Customer requirements are evolving toward solutions offering greater sensitivity, selectivity, portability, and connectivity features. There is increasing demand for systems that can be integrated into IoT networks, providing remote monitoring capabilities and real-time data analytics. This trend favors technologies that can balance analytical performance with practical deployment considerations.

Environmental regulations worldwide have become increasingly stringent regarding VOC emissions, particularly in developed regions such as North America, Europe, and parts of Asia. The implementation of policies like the Clean Air Act in the United States, the Industrial Emissions Directive in Europe, and similar regulations in China and Japan has created substantial demand for advanced VOC detection technologies. These regulatory frameworks require industries to monitor and control their VOC emissions, directly driving market growth for detection methods.

The industrial sector represents a major market segment for VOC detection technologies. Manufacturing facilities, chemical plants, petroleum refineries, and pharmaceutical production sites all require continuous monitoring of VOCs for process control, quality assurance, and worker safety compliance. This segment shows particular interest in technologies offering real-time analysis capabilities, such as FTIR systems that can provide immediate feedback on process conditions.

Healthcare and indoor air quality monitoring constitute rapidly growing application areas. With increasing awareness of sick building syndrome and the health impacts of VOCs in indoor environments, demand has surged for monitoring solutions in hospitals, schools, office buildings, and residential spaces. This market segment typically values portability, ease of use, and cost-effectiveness alongside analytical performance.

The automotive and transportation sectors also represent significant market opportunities, particularly for technologies capable of monitoring vehicle emissions and cabin air quality. As emission standards become more stringent globally, manufacturers require increasingly sensitive detection methods to ensure compliance during development and production.

Market analysis indicates that the global VOC monitoring equipment market was valued at approximately $1.2 billion in 2022, with projections suggesting growth at a CAGR of 6.8% through 2028. North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%, with the latter showing the fastest growth rate due to rapid industrialization and strengthening environmental regulations.

Customer requirements are evolving toward solutions offering greater sensitivity, selectivity, portability, and connectivity features. There is increasing demand for systems that can be integrated into IoT networks, providing remote monitoring capabilities and real-time data analytics. This trend favors technologies that can balance analytical performance with practical deployment considerations.

FTIR and GC-MS Current Status and Challenges

Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS) represent two distinct analytical approaches for Volatile Organic Compounds (VOCs) detection and quantification. Currently, FTIR technology has evolved significantly with the development of portable and handheld devices, enabling real-time monitoring in field conditions. These advancements have expanded FTIR applications in environmental monitoring, industrial emissions control, and indoor air quality assessment. However, FTIR faces challenges in distinguishing between compounds with similar molecular structures and functional groups, particularly in complex mixtures where spectral overlapping occurs.

The sensitivity threshold of commercial FTIR systems typically ranges from parts per million (ppm) to parts per billion (ppb), which may be insufficient for trace VOC analysis in certain environmental and health applications. Additionally, FTIR requires careful calibration and reference spectra libraries, which must be regularly updated to maintain accuracy across diverse VOC profiles.

GC-MS technology, meanwhile, has established itself as the gold standard for VOC analysis in laboratory settings. Modern GC-MS systems offer exceptional sensitivity, often reaching parts per trillion (ppt) levels for many compounds. The separation capability of gas chromatography combined with the identification power of mass spectrometry provides unparalleled compound specificity, allowing for accurate identification of individual VOCs within complex mixtures.

However, GC-MS faces significant challenges in real-time monitoring applications due to its inherently time-consuming analytical process. Sample preparation requirements, including pre-concentration steps, add complexity and delay to the analytical workflow. The equipment remains predominantly laboratory-bound, with limited field-deployable options that often sacrifice performance for portability.

Geographically, advanced FTIR and GC-MS development is concentrated in North America, Europe, and Japan, with emerging contributions from China and South Korea. The technological gap between developed and developing nations remains substantial, affecting global standardization efforts for VOC monitoring protocols.

Recent technological innovations are addressing these limitations through hybrid approaches. Miniaturized GC-MS systems with reduced analysis times are emerging, while FTIR systems with enhanced spectral resolution and advanced chemometric algorithms are improving compound differentiation capabilities. Preconcentration techniques coupled with both technologies are pushing detection limits lower, expanding their application range.

The integration of artificial intelligence and machine learning algorithms represents a significant advancement in both technologies, enabling more accurate compound identification, automated calibration, and predictive maintenance. These developments are gradually reshaping the competitive landscape between FTIR and GC-MS for VOC analysis across various application domains.

The sensitivity threshold of commercial FTIR systems typically ranges from parts per million (ppm) to parts per billion (ppb), which may be insufficient for trace VOC analysis in certain environmental and health applications. Additionally, FTIR requires careful calibration and reference spectra libraries, which must be regularly updated to maintain accuracy across diverse VOC profiles.

GC-MS technology, meanwhile, has established itself as the gold standard for VOC analysis in laboratory settings. Modern GC-MS systems offer exceptional sensitivity, often reaching parts per trillion (ppt) levels for many compounds. The separation capability of gas chromatography combined with the identification power of mass spectrometry provides unparalleled compound specificity, allowing for accurate identification of individual VOCs within complex mixtures.

However, GC-MS faces significant challenges in real-time monitoring applications due to its inherently time-consuming analytical process. Sample preparation requirements, including pre-concentration steps, add complexity and delay to the analytical workflow. The equipment remains predominantly laboratory-bound, with limited field-deployable options that often sacrifice performance for portability.

Geographically, advanced FTIR and GC-MS development is concentrated in North America, Europe, and Japan, with emerging contributions from China and South Korea. The technological gap between developed and developing nations remains substantial, affecting global standardization efforts for VOC monitoring protocols.

Recent technological innovations are addressing these limitations through hybrid approaches. Miniaturized GC-MS systems with reduced analysis times are emerging, while FTIR systems with enhanced spectral resolution and advanced chemometric algorithms are improving compound differentiation capabilities. Preconcentration techniques coupled with both technologies are pushing detection limits lower, expanding their application range.

The integration of artificial intelligence and machine learning algorithms represents a significant advancement in both technologies, enabling more accurate compound identification, automated calibration, and predictive maintenance. These developments are gradually reshaping the competitive landscape between FTIR and GC-MS for VOC analysis across various application domains.

Comparative Analysis of FTIR and GC-MS Solutions

01 FTIR and GC-MS for chemical composition analysis

FTIR (Fourier Transform Infrared Spectroscopy) and GC-MS (Gas Chromatography-Mass Spectrometry) are complementary analytical techniques used for identifying and quantifying chemical compositions in various samples. FTIR provides information about functional groups and molecular structures, while GC-MS separates and identifies individual compounds in complex mixtures. Together, these techniques offer comprehensive characterization of organic and inorganic substances with high sensitivity and specificity.- FTIR and GC-MS for chemical composition analysis: The combination of Fourier Transform Infrared Spectroscopy (FTIR) and Gas Chromatography-Mass Spectrometry (GC-MS) provides comprehensive analysis of chemical compositions in various samples. FTIR identifies functional groups and molecular structures through infrared absorption patterns, while GC-MS separates and identifies individual compounds based on their mass-to-charge ratios. Together, these techniques enable accurate identification and quantification of complex mixtures, making them valuable for quality control and research applications.

- Applications in environmental monitoring and pollutant detection: FTIR and GC-MS analytical techniques are highly effective for environmental monitoring and pollutant detection. These methods can identify and quantify trace amounts of contaminants in air, water, and soil samples. The high sensitivity of GC-MS allows for detection of volatile organic compounds and persistent organic pollutants, while FTIR provides rapid screening of environmental samples. These complementary techniques enable comprehensive environmental assessment and monitoring of compliance with regulatory standards.

- Pharmaceutical and biomedical analysis applications: In pharmaceutical and biomedical research, FTIR and GC-MS techniques offer powerful analytical capabilities for drug development, quality control, and metabolomic studies. These methods can verify drug purity, identify impurities, and analyze biological samples for biomarkers. FTIR provides structural information about pharmaceutical compounds, while GC-MS offers high sensitivity for detecting trace components. The combination enables comprehensive characterization of pharmaceutical formulations and biological specimens, supporting drug discovery and clinical diagnostics.

- Food safety and quality assessment: FTIR and GC-MS analytical techniques are extensively used for food safety and quality assessment. These methods can detect adulterants, contaminants, and spoilage indicators in food products. FTIR provides rapid screening for authenticity verification, while GC-MS enables detailed analysis of flavor compounds, pesticide residues, and food additives. The combination of these techniques allows for comprehensive evaluation of food composition, ensuring compliance with safety standards and quality specifications in the food industry.

- Advancements in instrumentation and data analysis: Recent advancements in FTIR and GC-MS instrumentation and data analysis have significantly enhanced their effectiveness. Improvements include miniaturization of equipment, automation of sample preparation, integration with other analytical techniques, and development of sophisticated software for data interpretation. Machine learning algorithms now assist in spectral analysis and compound identification, while portable devices enable field analysis. These technological developments have expanded the applications of FTIR and GC-MS across various industries, improving accuracy, sensitivity, and efficiency of analytical processes.

02 Applications in environmental monitoring and pollutant detection

FTIR and GC-MS techniques are highly effective for environmental monitoring and pollutant detection. These analytical methods can identify trace amounts of contaminants in air, water, and soil samples. The combination allows for both screening of broad classes of compounds (FTIR) and precise identification of specific pollutants (GC-MS), making them valuable tools for environmental assessment, regulatory compliance, and remediation efforts.Expand Specific Solutions03 Quality control and authentication in pharmaceutical and food industries

In pharmaceutical and food industries, FTIR and GC-MS techniques are essential for quality control, authentication, and safety assessment. These methods can detect adulterants, contaminants, and verify the composition of raw materials and finished products. The high sensitivity of GC-MS combined with the rapid screening capability of FTIR provides comprehensive quality assurance, helping to ensure product consistency, safety, and regulatory compliance.Expand Specific Solutions04 Advancements in instrumentation and data analysis

Recent advancements in FTIR and GC-MS instrumentation and data analysis have significantly enhanced their effectiveness. Improvements include miniaturization of equipment, automation of sample preparation, increased sensitivity, and development of sophisticated software for spectral interpretation. Machine learning algorithms and spectral libraries have improved the speed and accuracy of compound identification, while portable devices have enabled field analysis without sacrificing analytical performance.Expand Specific Solutions05 Combined analytical approaches for complex sample analysis

Combining FTIR and GC-MS with other analytical techniques creates powerful multi-modal approaches for complex sample analysis. These hyphenated techniques provide complementary information that enhances analytical capabilities. Integration with sample preparation methods, chemometrics, and other spectroscopic techniques allows for more comprehensive characterization of complex matrices, improving detection limits, compound identification accuracy, and quantification in challenging samples across various scientific and industrial applications.Expand Specific Solutions

Key Industry Players in Analytical Instrumentation

The VOC analysis market is in a growth phase, with increasing demand driven by environmental regulations and health concerns. FTIR and GC-MS technologies represent different approaches to VOC detection, each with distinct advantages. GC-MS offers superior compound identification and sensitivity, making it the gold standard for complex mixture analysis, while FTIR provides rapid, real-time monitoring capabilities with lower operational costs. Key players like Spectra Analysis Instruments and Entech Instruments lead in GC-MS technology, while Picarro and LECO Corporation have developed advanced FTIR solutions. Research institutions including Sichuan University and Agency for Science, Technology & Research are advancing both technologies, with recent innovations focusing on miniaturization and field-deployable systems that combine the strengths of both methodologies.

Spectra Analysis Instruments, Inc.

Technical Solution: Spectra Analysis Instruments has developed a hybrid GC-FTIR system called DiscovIR that combines the separation capabilities of gas chromatography with the molecular identification power of FTIR spectroscopy. Their technology employs a unique solid-phase collection interface that deposits GC eluents onto an infrared-transparent substrate for subsequent FTIR analysis. This approach overcomes traditional sensitivity limitations of gas-phase FTIR for VOC analysis by concentrating analytes before measurement. The system provides both chromatographic separation and spectral identification in a single analytical run, allowing for comprehensive characterization of complex VOC mixtures. Their proprietary deposition technology enhances sensitivity by orders of magnitude compared to conventional gas-phase GC-FTIR systems, making it particularly effective for trace VOC analysis in environmental and industrial applications.

Strengths: Combines separation power of GC with structural identification capabilities of FTIR in one system; enhanced sensitivity through solid-phase concentration; provides complementary data to mass spectrometry. Weaknesses: More complex instrumentation requiring specialized expertise; higher initial investment compared to standalone GC-MS; potentially longer analysis times due to the sequential analytical process.

Entech Instruments, Inc.

Technical Solution: Entech Instruments specializes in advanced sample preparation technologies for VOC analysis, with solutions optimized for both GC-MS and FTIR methodologies. Their Bottle-Vac whole air sampling system and SPME Arrow technology enable ultra-trace VOC collection with minimal artifacts. For GC-MS applications, they've developed multi-stage preconcentration systems that can achieve sub-ppt detection limits for a wide range of VOCs. Their proprietary water management technologies effectively handle humidity in air samples, a critical factor in accurate VOC quantification. Entech's automated canister cleaning systems and internal standard addition technologies ensure sample integrity throughout the analytical process. Their integrated approach addresses the entire analytical workflow from sampling to analysis, with particular emphasis on eliminating contamination sources that can compromise VOC measurements at trace levels.

Strengths: Industry-leading sample preparation technologies that enhance both GC-MS and FTIR performance; comprehensive solutions addressing the entire analytical workflow; specialized expertise in ultra-trace VOC analysis. Weaknesses: Primary focus on sample preparation rather than analytical instrumentation; solutions may require integration with third-party analytical systems; higher cost compared to basic sampling approaches.

Technical Deep Dive: FTIR and GC-MS Working Principles

Gas chromatograph, Fourier transform, infrared spectroscopy system

PatentInactiveUS4440013A

Innovation

- A GC/FTIR system design where a narrow bore capillary column is mounted within the GC oven, with its exit end terminating directly inside the light pipe, and a secondary flow of gas is introduced to rapidly carry effluent components through the light pipe, eliminating the need for transfer tubes and minimizing peak broadening.

System for monitoring smoke composition with screen-printed sensors

PatentPendingIN202341066090A

Innovation

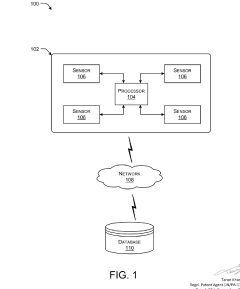

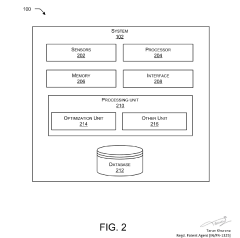

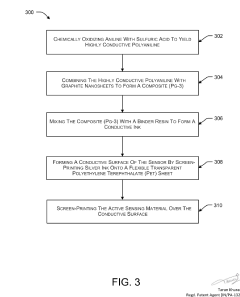

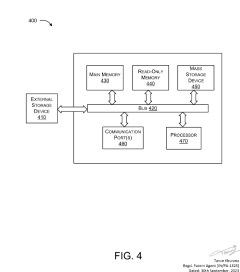

- A real-time monitoring system using flexible chemo-resistive sensors fabricated by screen printing technology, which includes polyaniline and graphite as active sensing materials, deposited on a Polyethylene Terephthalate (PET) substrate, and a processor to determine VOC concentrations and toxic composition.

Environmental Regulations Impacting VOCs Analysis

The regulatory landscape governing Volatile Organic Compounds (VOCs) analysis has evolved significantly over the past decades, directly influencing the selection of analytical methodologies such as FTIR and GC-MS. The Clean Air Act in the United States, particularly its 1990 amendments, established comprehensive frameworks for VOC monitoring and control, setting National Ambient Air Quality Standards (NAAQS) that necessitate precise analytical techniques for compliance verification.

The European Union's regulatory approach through directives such as 2004/42/EC (Paints Directive) and 2010/75/EU (Industrial Emissions Directive) has imposed stringent VOC emission limits across various industrial sectors. These regulations specifically outline acceptable measurement methodologies, with GC-MS often cited as a reference method for certain applications due to its compound-specific quantification capabilities.

In Asia, particularly China and Japan, rapidly evolving environmental protection laws have increasingly incorporated specific technical requirements for VOC analysis. China's Volatile Organic Compounds Pollution Prevention and Control Technology Policy (2013) and subsequent standards have progressively tightened monitoring requirements, influencing analytical method selection based on sensitivity and specificity parameters.

Method-specific regulatory considerations significantly impact the FTIR versus GC-MS decision. The U.S. EPA Method TO-15 for ambient air analysis explicitly utilizes GC-MS for VOC quantification, while Method 320 incorporates FTIR for stationary source emissions. These method-specific endorsements often drive technology adoption in regulated industries, regardless of other technical considerations.

Regulatory detection limit requirements present another critical factor. Many environmental standards now specify Minimum Detection Limits (MDLs) in the parts-per-billion range for certain hazardous VOCs, potentially favoring GC-MS in applications where trace analysis of specific compounds is mandated by law.

Emerging regulations addressing previously unregulated VOCs, particularly those with lower odor thresholds or newly recognized health impacts, are expanding the scope of required analysis. This regulatory evolution demands analytical techniques with adaptability to new target compounds, potentially favoring the compound-specific capabilities of GC-MS for compliance purposes.

Certification and accreditation requirements for environmental testing laboratories further influence methodology selection, with many regulatory bodies requiring specific validation protocols and quality assurance measures that may be more established for one technology over the other.

The European Union's regulatory approach through directives such as 2004/42/EC (Paints Directive) and 2010/75/EU (Industrial Emissions Directive) has imposed stringent VOC emission limits across various industrial sectors. These regulations specifically outline acceptable measurement methodologies, with GC-MS often cited as a reference method for certain applications due to its compound-specific quantification capabilities.

In Asia, particularly China and Japan, rapidly evolving environmental protection laws have increasingly incorporated specific technical requirements for VOC analysis. China's Volatile Organic Compounds Pollution Prevention and Control Technology Policy (2013) and subsequent standards have progressively tightened monitoring requirements, influencing analytical method selection based on sensitivity and specificity parameters.

Method-specific regulatory considerations significantly impact the FTIR versus GC-MS decision. The U.S. EPA Method TO-15 for ambient air analysis explicitly utilizes GC-MS for VOC quantification, while Method 320 incorporates FTIR for stationary source emissions. These method-specific endorsements often drive technology adoption in regulated industries, regardless of other technical considerations.

Regulatory detection limit requirements present another critical factor. Many environmental standards now specify Minimum Detection Limits (MDLs) in the parts-per-billion range for certain hazardous VOCs, potentially favoring GC-MS in applications where trace analysis of specific compounds is mandated by law.

Emerging regulations addressing previously unregulated VOCs, particularly those with lower odor thresholds or newly recognized health impacts, are expanding the scope of required analysis. This regulatory evolution demands analytical techniques with adaptability to new target compounds, potentially favoring the compound-specific capabilities of GC-MS for compliance purposes.

Certification and accreditation requirements for environmental testing laboratories further influence methodology selection, with many regulatory bodies requiring specific validation protocols and quality assurance measures that may be more established for one technology over the other.

Cost-Benefit Analysis of Analytical Methods

When evaluating analytical methods for volatile organic compounds (VOCs) detection, cost-benefit analysis becomes a critical factor in decision-making processes. FTIR (Fourier Transform Infrared Spectroscopy) and GC-MS (Gas Chromatography-Mass Spectrometry) represent two distinct approaches with significantly different economic profiles.

Initial investment costs vary substantially between these technologies. GC-MS systems typically require capital expenditures ranging from $50,000 to $250,000 for laboratory-grade equipment, while FTIR systems generally fall between $20,000 and $100,000. This substantial difference in acquisition costs can be a determining factor for organizations with limited budgets or those requiring multiple analytical stations.

Operational expenses also differ markedly. GC-MS demands specialized carrier gases (helium or hydrogen), chromatographic columns requiring periodic replacement, and mass spectrometer components with finite lifespans. These consumables can amount to $5,000-15,000 annually per instrument. Conversely, FTIR systems have fewer consumable requirements, typically necessitating only occasional detector replacements and minimal maintenance, resulting in annual operational costs of approximately $2,000-7,000.

Personnel requirements represent another significant cost differential. GC-MS operation demands highly trained specialists with analytical chemistry backgrounds, commanding higher salaries. FTIR systems, while still requiring trained personnel, generally have more straightforward operational protocols that can be mastered with less extensive training, potentially reducing labor costs by 15-30%.

Time efficiency translates directly to economic value. GC-MS analysis typically requires 20-60 minutes per sample, including preparation time. FTIR can deliver results in 1-5 minutes for many applications. This throughput differential can dramatically impact productivity, especially in high-volume testing environments.

The benefit side of the equation must consider analytical performance relative to cost. GC-MS offers superior compound identification capabilities and lower detection limits (often in the ppb range), making it indispensable for certain applications despite higher costs. FTIR provides rapid screening capabilities and multi-component analysis but with higher detection limits (typically ppm range).

Return on investment timelines differ significantly. Organizations with high-volume testing needs may recoup FTIR investments within 1-2 years through operational savings, while GC-MS systems typically require 3-5 years to achieve ROI, primarily justified through their superior analytical capabilities rather than economic efficiency.

Initial investment costs vary substantially between these technologies. GC-MS systems typically require capital expenditures ranging from $50,000 to $250,000 for laboratory-grade equipment, while FTIR systems generally fall between $20,000 and $100,000. This substantial difference in acquisition costs can be a determining factor for organizations with limited budgets or those requiring multiple analytical stations.

Operational expenses also differ markedly. GC-MS demands specialized carrier gases (helium or hydrogen), chromatographic columns requiring periodic replacement, and mass spectrometer components with finite lifespans. These consumables can amount to $5,000-15,000 annually per instrument. Conversely, FTIR systems have fewer consumable requirements, typically necessitating only occasional detector replacements and minimal maintenance, resulting in annual operational costs of approximately $2,000-7,000.

Personnel requirements represent another significant cost differential. GC-MS operation demands highly trained specialists with analytical chemistry backgrounds, commanding higher salaries. FTIR systems, while still requiring trained personnel, generally have more straightforward operational protocols that can be mastered with less extensive training, potentially reducing labor costs by 15-30%.

Time efficiency translates directly to economic value. GC-MS analysis typically requires 20-60 minutes per sample, including preparation time. FTIR can deliver results in 1-5 minutes for many applications. This throughput differential can dramatically impact productivity, especially in high-volume testing environments.

The benefit side of the equation must consider analytical performance relative to cost. GC-MS offers superior compound identification capabilities and lower detection limits (often in the ppb range), making it indispensable for certain applications despite higher costs. FTIR provides rapid screening capabilities and multi-component analysis but with higher detection limits (typically ppm range).

Return on investment timelines differ significantly. Organizations with high-volume testing needs may recoup FTIR investments within 1-2 years through operational savings, while GC-MS systems typically require 3-5 years to achieve ROI, primarily justified through their superior analytical capabilities rather than economic efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!