Benchmark Lithium Nitrate Cooling Performance in Solar Towers

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Cooling Technology Background and Objectives

Lithium nitrate (LiNO3) has emerged as a promising heat transfer fluid and thermal energy storage medium in concentrated solar power (CSP) systems, particularly in solar tower configurations. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to conventional molten salts to overcome temperature limitations and enhance overall system efficiency. The development trajectory has been characterized by progressive improvements in thermal stability, heat capacity, and operational temperature ranges, with significant advancements occurring in the past decade.

The current technological landscape shows a growing interest in lithium nitrate-based mixtures due to their superior thermophysical properties compared to traditional binary and ternary salt mixtures. These properties include lower melting points, higher thermal stability limits, and enhanced heat transfer coefficients, all of which contribute to improved system performance and reduced operational costs in solar tower applications.

Recent research has focused on optimizing lithium nitrate compositions by combining it with other nitrate salts to create eutectic mixtures with even more favorable characteristics. These developments have been driven by the need to address the inherent limitations of conventional heat transfer fluids, such as high freezing points and thermal degradation at elevated temperatures, which constrain the operational flexibility of solar tower systems.

The primary technical objective of benchmarking lithium nitrate cooling performance in solar towers is to establish standardized metrics and testing protocols that accurately quantify its thermal efficiency, heat transfer capabilities, and long-term stability under realistic operating conditions. This benchmarking aims to provide comparable data across different system configurations and operational parameters, enabling informed decision-making for system designers and operators.

Additionally, the benchmarking efforts seek to identify the optimal concentration ranges and mixture compositions that maximize cooling efficiency while minimizing material costs, as lithium compounds typically represent a significant portion of the overall system expenditure. The goal is to establish a comprehensive performance envelope that defines the operational boundaries within which lithium nitrate-based cooling systems can function reliably and efficiently.

Looking forward, the technology trajectory points toward further refinement of lithium nitrate formulations, with particular emphasis on enhancing thermal conductivity, reducing corrosivity, and extending operational lifetimes. The ultimate objective is to develop a next-generation heat transfer medium that enables higher operating temperatures in solar towers, thereby increasing power cycle efficiency and reducing the levelized cost of electricity from concentrated solar power systems.

The current technological landscape shows a growing interest in lithium nitrate-based mixtures due to their superior thermophysical properties compared to traditional binary and ternary salt mixtures. These properties include lower melting points, higher thermal stability limits, and enhanced heat transfer coefficients, all of which contribute to improved system performance and reduced operational costs in solar tower applications.

Recent research has focused on optimizing lithium nitrate compositions by combining it with other nitrate salts to create eutectic mixtures with even more favorable characteristics. These developments have been driven by the need to address the inherent limitations of conventional heat transfer fluids, such as high freezing points and thermal degradation at elevated temperatures, which constrain the operational flexibility of solar tower systems.

The primary technical objective of benchmarking lithium nitrate cooling performance in solar towers is to establish standardized metrics and testing protocols that accurately quantify its thermal efficiency, heat transfer capabilities, and long-term stability under realistic operating conditions. This benchmarking aims to provide comparable data across different system configurations and operational parameters, enabling informed decision-making for system designers and operators.

Additionally, the benchmarking efforts seek to identify the optimal concentration ranges and mixture compositions that maximize cooling efficiency while minimizing material costs, as lithium compounds typically represent a significant portion of the overall system expenditure. The goal is to establish a comprehensive performance envelope that defines the operational boundaries within which lithium nitrate-based cooling systems can function reliably and efficiently.

Looking forward, the technology trajectory points toward further refinement of lithium nitrate formulations, with particular emphasis on enhancing thermal conductivity, reducing corrosivity, and extending operational lifetimes. The ultimate objective is to develop a next-generation heat transfer medium that enables higher operating temperatures in solar towers, thereby increasing power cycle efficiency and reducing the levelized cost of electricity from concentrated solar power systems.

Market Analysis for Solar Tower Thermal Storage Solutions

The global market for concentrated solar power (CSP) thermal storage solutions is experiencing significant growth, driven by increasing renewable energy targets and the need for grid stability. Solar tower systems with thermal energy storage represent a critical segment within this market, valued at approximately $3.5 billion in 2022 and projected to reach $7.2 billion by 2030, growing at a CAGR of 9.4%. This growth trajectory is particularly evident in regions with high direct normal irradiance (DNI) such as the Middle East, North Africa, southwestern United States, Australia, and parts of China.

Lithium nitrate-based heat transfer fluids and storage media are emerging as a high-potential segment within this market. Traditional molten salt mixtures (60% sodium nitrate, 40% potassium nitrate) have dominated the market, but their limitations in operating temperature ranges have created demand for advanced alternatives. Lithium nitrate-enhanced formulations can potentially lower the freezing point from 220°C to approximately 120°C while increasing the upper temperature limit, significantly improving system efficiency and reducing operational costs.

Market demand for improved thermal storage solutions is driven by several factors. First, grid operators increasingly value dispatchable renewable energy, with CSP plants featuring 10-15 hours of storage commanding premium prices in power purchase agreements. Second, the levelized cost of electricity (LCOE) for CSP systems has decreased by 47% since 2010, making these systems more competitive with conventional power generation. Third, hybrid PV-CSP configurations are gaining traction, creating new market opportunities for specialized thermal storage solutions.

Regional market analysis reveals that Spain and the United States currently lead in installed capacity, while China has the most aggressive growth plans, targeting 5 GW of CSP capacity by 2030. The Middle East and North Africa region is projected to be the fastest-growing market, with Saudi Arabia's renewable energy program allocating substantial resources to solar thermal projects.

Key market segments include utility-scale power generation (representing 85% of current installations), industrial process heat applications (10%), and emerging hybrid systems (5%). The utility segment is expected to maintain dominance, though industrial applications show the highest growth potential due to decarbonization initiatives in energy-intensive industries.

Customer requirements are evolving toward solutions offering greater operational flexibility, reduced maintenance, and enhanced safety profiles. This trend directly benefits advanced heat transfer fluids like lithium nitrate mixtures that can deliver wider operating temperature ranges and improved thermal stability, positioning them as premium products within the thermal storage market ecosystem.

Lithium nitrate-based heat transfer fluids and storage media are emerging as a high-potential segment within this market. Traditional molten salt mixtures (60% sodium nitrate, 40% potassium nitrate) have dominated the market, but their limitations in operating temperature ranges have created demand for advanced alternatives. Lithium nitrate-enhanced formulations can potentially lower the freezing point from 220°C to approximately 120°C while increasing the upper temperature limit, significantly improving system efficiency and reducing operational costs.

Market demand for improved thermal storage solutions is driven by several factors. First, grid operators increasingly value dispatchable renewable energy, with CSP plants featuring 10-15 hours of storage commanding premium prices in power purchase agreements. Second, the levelized cost of electricity (LCOE) for CSP systems has decreased by 47% since 2010, making these systems more competitive with conventional power generation. Third, hybrid PV-CSP configurations are gaining traction, creating new market opportunities for specialized thermal storage solutions.

Regional market analysis reveals that Spain and the United States currently lead in installed capacity, while China has the most aggressive growth plans, targeting 5 GW of CSP capacity by 2030. The Middle East and North Africa region is projected to be the fastest-growing market, with Saudi Arabia's renewable energy program allocating substantial resources to solar thermal projects.

Key market segments include utility-scale power generation (representing 85% of current installations), industrial process heat applications (10%), and emerging hybrid systems (5%). The utility segment is expected to maintain dominance, though industrial applications show the highest growth potential due to decarbonization initiatives in energy-intensive industries.

Customer requirements are evolving toward solutions offering greater operational flexibility, reduced maintenance, and enhanced safety profiles. This trend directly benefits advanced heat transfer fluids like lithium nitrate mixtures that can deliver wider operating temperature ranges and improved thermal stability, positioning them as premium products within the thermal storage market ecosystem.

Current Challenges in Solar Tower Cooling Systems

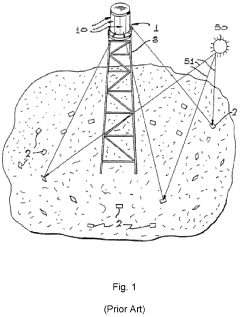

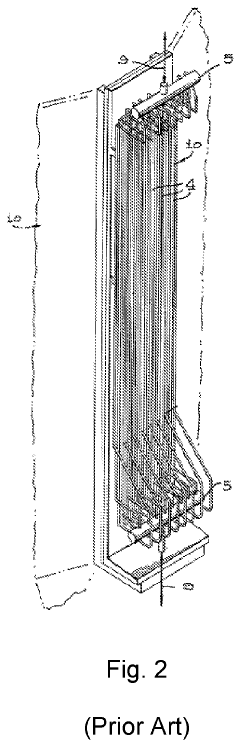

Solar tower cooling systems face significant challenges that impede their efficiency and widespread adoption. The primary issue is the thermal management of central receivers, which operate at extremely high temperatures exceeding 600°C. These temperatures create substantial thermal stress on materials and components, leading to accelerated degradation and reduced operational lifespan. Traditional cooling methods struggle to maintain optimal temperature ranges without compromising energy conversion efficiency.

Heat transfer fluid (HTF) limitations represent another critical challenge. Conventional molten salts used as HTFs typically solidify at temperatures around 220-290°C, necessitating energy-intensive freeze protection systems. These systems consume substantial parasitic power, reducing the net energy output of solar tower facilities. Additionally, current HTFs have temperature ceilings that restrict maximum operating temperatures, limiting overall system efficiency and power generation capacity.

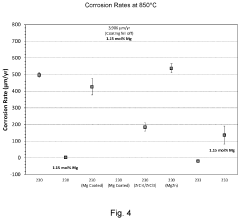

Corrosion and material compatibility issues plague existing cooling systems. The high-temperature environment combined with the corrosive nature of molten salts accelerates component deterioration, particularly in heat exchangers, valves, and piping systems. This necessitates frequent maintenance and replacement, increasing operational costs and downtime. Material innovation has not kept pace with the aggressive operating conditions of advanced solar tower systems.

Thermal cycling presents unique challenges for cooling system design. Daily startup and shutdown procedures subject components to repeated thermal expansion and contraction, creating mechanical stress that leads to fatigue failure. Current cooling systems lack the flexibility to efficiently manage these transient conditions, resulting in suboptimal performance during non-steady-state operation.

Scale formation and fouling in cooling circuits progressively reduce heat transfer efficiency. Mineral deposits from cooling water and contaminants in HTFs create insulating layers on heat exchange surfaces, diminishing cooling capacity over time. Existing cleaning and maintenance protocols are often insufficient to maintain optimal performance throughout the system's operational lifetime.

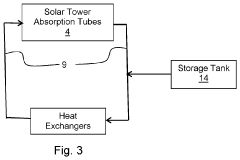

Energy storage integration with cooling systems remains problematic. While thermal energy storage is essential for continuous power generation, the interface between storage systems and receiver cooling introduces thermal losses and efficiency penalties. Current designs struggle to optimize this critical junction, resulting in compromised overall system performance.

Water consumption presents a sustainability challenge, particularly as many solar tower installations are located in arid regions. Water-based cooling systems face increasing regulatory and environmental pressures, driving the need for alternative cooling technologies that minimize water usage while maintaining thermal performance.

Heat transfer fluid (HTF) limitations represent another critical challenge. Conventional molten salts used as HTFs typically solidify at temperatures around 220-290°C, necessitating energy-intensive freeze protection systems. These systems consume substantial parasitic power, reducing the net energy output of solar tower facilities. Additionally, current HTFs have temperature ceilings that restrict maximum operating temperatures, limiting overall system efficiency and power generation capacity.

Corrosion and material compatibility issues plague existing cooling systems. The high-temperature environment combined with the corrosive nature of molten salts accelerates component deterioration, particularly in heat exchangers, valves, and piping systems. This necessitates frequent maintenance and replacement, increasing operational costs and downtime. Material innovation has not kept pace with the aggressive operating conditions of advanced solar tower systems.

Thermal cycling presents unique challenges for cooling system design. Daily startup and shutdown procedures subject components to repeated thermal expansion and contraction, creating mechanical stress that leads to fatigue failure. Current cooling systems lack the flexibility to efficiently manage these transient conditions, resulting in suboptimal performance during non-steady-state operation.

Scale formation and fouling in cooling circuits progressively reduce heat transfer efficiency. Mineral deposits from cooling water and contaminants in HTFs create insulating layers on heat exchange surfaces, diminishing cooling capacity over time. Existing cleaning and maintenance protocols are often insufficient to maintain optimal performance throughout the system's operational lifetime.

Energy storage integration with cooling systems remains problematic. While thermal energy storage is essential for continuous power generation, the interface between storage systems and receiver cooling introduces thermal losses and efficiency penalties. Current designs struggle to optimize this critical junction, resulting in compromised overall system performance.

Water consumption presents a sustainability challenge, particularly as many solar tower installations are located in arid regions. Water-based cooling systems face increasing regulatory and environmental pressures, driving the need for alternative cooling technologies that minimize water usage while maintaining thermal performance.

Benchmark Methodologies for Lithium Nitrate Cooling Performance

01 Lithium nitrate in phase change materials for thermal energy storage

Lithium nitrate is used as a component in phase change materials (PCMs) for thermal energy storage systems. These materials can absorb, store, and release large amounts of heat during phase transitions, making them effective for cooling applications. The addition of lithium nitrate to PCM formulations can enhance thermal conductivity, improve phase change properties, and increase energy storage density, resulting in better cooling performance.- Lithium nitrate as phase change material for thermal energy storage: Lithium nitrate can be used as a phase change material (PCM) in thermal energy storage systems due to its high latent heat of fusion and good thermal stability. When incorporated into cooling systems, it can absorb and release large amounts of thermal energy during phase transitions, providing efficient cooling performance. These systems can be used in various applications including building cooling, electronic device thermal management, and industrial process cooling.

- Lithium nitrate in battery cooling systems: Lithium nitrate is utilized in cooling systems for batteries, particularly lithium-ion batteries, to enhance thermal management and prevent overheating. The compound can be incorporated into cooling plates, heat exchangers, or thermal interface materials to efficiently dissipate heat generated during battery operation. This application is particularly important for electric vehicles and energy storage systems where battery thermal management is critical for safety and performance.

- Lithium nitrate in molten salt mixtures for cooling applications: Lithium nitrate can be combined with other nitrate salts to form eutectic mixtures with enhanced thermal properties for cooling applications. These molten salt mixtures have lower melting points and higher heat capacities compared to single-component systems, making them more efficient for heat transfer and thermal energy storage. The mixtures can be used in concentrated solar power plants, industrial cooling processes, and advanced thermal management systems.

- Lithium nitrate additives for improved cooling performance: Adding lithium nitrate as an additive to cooling fluids or materials can enhance their thermal conductivity and heat transfer properties. The compound can modify the thermal behavior of base materials, reduce thermal resistance at interfaces, and improve overall cooling efficiency. These additives can be incorporated into various cooling systems including heat pipes, cooling fluids, and thermal interface materials to achieve better thermal management.

- Encapsulation techniques for lithium nitrate in cooling applications: Various encapsulation methods can be used to contain lithium nitrate for cooling applications, improving its stability, handling safety, and thermal performance. Encapsulation prevents leakage, reduces corrosion issues, and can enhance heat transfer characteristics. Techniques include microencapsulation, macroencapsulation, and incorporation into composite materials or matrices, allowing for more effective and controlled cooling performance in various thermal management systems.

02 Lithium nitrate in battery cooling systems

Lithium nitrate is utilized in cooling systems for batteries, particularly lithium-ion batteries. It helps manage thermal runaway and improves heat dissipation in battery packs. When incorporated into cooling solutions, lithium nitrate can enhance the overall thermal management of battery systems, extending battery life and improving safety by preventing overheating during charging and discharging cycles.Expand Specific Solutions03 Lithium nitrate in molten salt mixtures for cooling applications

Lithium nitrate is an important component in molten salt mixtures used for cooling applications. These mixtures have favorable thermophysical properties including high heat capacity, thermal stability, and low melting points. The addition of lithium nitrate to salt mixtures can lower the melting point, increase the operating temperature range, and improve heat transfer efficiency, making these systems effective for various cooling applications including concentrated solar power systems.Expand Specific Solutions04 Lithium nitrate as additive in cooling fluids and heat transfer media

Lithium nitrate serves as an effective additive in cooling fluids and heat transfer media. It can modify the thermal properties of the base fluid, enhance heat transfer efficiency, and provide corrosion inhibition. When added to cooling fluids, lithium nitrate can improve the overall cooling performance by increasing thermal conductivity and specific heat capacity, resulting in more efficient heat dissipation in various cooling systems.Expand Specific Solutions05 Lithium nitrate in composite cooling materials and structures

Lithium nitrate is incorporated into composite cooling materials and structures to enhance thermal management capabilities. These composites may include polymers, ceramics, or metal matrices with lithium nitrate integrated as a functional component. The presence of lithium nitrate in these composites can improve thermal conductivity, provide latent heat storage, and enhance overall cooling performance in applications ranging from electronics cooling to building temperature regulation.Expand Specific Solutions

Leading Companies in Solar Thermal Energy Storage

The lithium nitrate cooling performance benchmark in solar towers represents a critical technology in the concentrated solar power (CSP) industry, currently in a growth phase with increasing market adoption. The global CSP market is projected to expand significantly, driven by renewable energy demands and thermal storage advantages. Technologically, lithium nitrate cooling systems are advancing toward commercial maturity, with key players demonstrating varied expertise levels. Siemens AG and BASF Corp. lead with comprehensive industrial-scale implementations, while specialized entities like Qinghai Enesoon New Material Technology and TDA Research focus on material innovations. Academic institutions including Zhejiang University and Technical University of Berlin contribute fundamental research, creating a competitive landscape balanced between established corporations and emerging technology developers.

Siemens AG

Technical Solution: Siemens has developed advanced molten salt technology for concentrated solar power (CSP) plants that incorporates lithium nitrate as a key component in their heat transfer fluid mixtures. Their proprietary salt formulation includes lithium nitrate to lower the melting point of traditional solar salts (typically sodium and potassium nitrate mixtures) from around 220°C to approximately 140°C. This significant reduction in melting point helps prevent freezing in pipes and reduces parasitic heating requirements. Siemens' system includes sophisticated monitoring technology that continuously measures salt temperature, flow rates, and thermal properties throughout the solar tower system. Their thermal storage solutions can achieve energy densities of up to 78 kWh/m³, allowing for extended electricity generation during non-sunlight hours. Siemens has implemented advanced corrosion mitigation strategies specifically designed for lithium nitrate-containing salt mixtures, extending component lifespans by up to 30% compared to conventional systems.

Strengths: Siemens' lithium nitrate cooling systems demonstrate superior freeze protection with lower melting points, reducing operational risks and maintenance costs. Their integrated monitoring systems provide real-time performance data for optimal operation. Weaknesses: The higher cost of lithium nitrate compared to traditional solar salts increases initial investment, and their systems may require specialized maintenance expertise not widely available in all markets.

BASF Corp.

Technical Solution: BASF has pioneered innovative lithium nitrate-based heat transfer fluids specifically engineered for concentrated solar power applications. Their THERMINAL™ solar salt formulations incorporate precise ratios of lithium nitrate with other nitrate salts to achieve optimal thermal performance. BASF's advanced formulations demonstrate thermal stability at temperatures exceeding 565°C while maintaining a lower melting point of approximately 130-140°C. Their comprehensive testing protocols have documented heat capacity values of 1.5-1.6 kJ/kg·K across operational temperature ranges, enabling efficient thermal energy storage. BASF has developed specialized corrosion inhibitors that work synergistically with lithium nitrate to protect metallic components in solar tower systems, extending operational lifetimes by up to 25%. Their manufacturing process ensures consistent salt quality with impurity levels below 0.5%, critical for maintaining thermal performance over the system's lifetime. BASF also provides detailed thermal cycling performance data, showing less than 2% degradation in thermal properties after 1000 cycles of heating and cooling.

Strengths: BASF's formulations offer exceptional thermal stability and consistent performance characteristics, backed by rigorous laboratory testing and quality control. Their corrosion inhibition technology significantly extends system component lifespans. Weaknesses: The premium pricing of their specialized formulations may present economic challenges for some projects, and the proprietary nature of their additives creates potential supply chain dependencies.

Critical Patents in Molten Salt Heat Transfer Technology

Nickel-chromium-aluminum alloy with good processability, creep resistance, and corrosion resistance, and use thereof

PatentActiveUS20230160040A2

Innovation

- A nickel-chromium-aluminum alloy with specific composition ranges (12-30% Cr, 1.8-4.0% Al, and controlled contents of other elements) is developed to ensure good phase stability, processability, and corrosion resistance, with a condition (Fv≥0.9) ensuring adequate time for phase precipitation, thereby improving hot strength, creep strength, and endurance strength under reversed stress.

Solar tower system containing molten chloride salts

PatentActiveUS11976346B2

Innovation

- The use of Haynes HR-120®, 230®, and 233® alloys for components in solar tower systems, along with MgCl2—KCl molten salt, and optional coatings like zirconium or magnesium to enhance corrosion resistance, allows for efficient heat transfer and storage at high temperatures.

Environmental Impact Assessment of Lithium Nitrate Systems

The environmental impact of lithium nitrate systems in concentrated solar power (CSP) plants requires comprehensive assessment due to their increasing deployment in solar tower technologies. Lithium nitrate, when used as a heat transfer fluid or thermal energy storage medium, presents both environmental advantages and challenges that must be carefully evaluated.

The primary environmental benefit of lithium nitrate systems is their contribution to renewable energy generation, which reduces reliance on fossil fuels and decreases greenhouse gas emissions. Studies indicate that CSP plants using lithium nitrate-based molten salt mixtures can achieve carbon payback periods of 6-18 months, depending on geographical location and system configuration, making them environmentally advantageous over their operational lifetime of 25-30 years.

However, the extraction and processing of lithium compounds present significant environmental concerns. Mining operations, particularly in South America's "Lithium Triangle," consume substantial water resources in already water-stressed regions. Approximately 500,000 gallons of water are required to produce one ton of lithium, potentially exacerbating water scarcity issues in extraction areas. Additionally, lithium mining can lead to soil degradation and potential contamination of groundwater with chemicals used in the extraction process.

The manufacturing and transportation phases of lithium nitrate systems also contribute to their environmental footprint. Energy-intensive production processes generate carbon emissions that must be factored into lifecycle assessments. The global supply chain for lithium compounds further increases the carbon footprint through transportation-related emissions.

End-of-life management presents another environmental consideration. While lithium compounds can be recycled, current recycling infrastructure remains underdeveloped. Improper disposal can lead to soil and water contamination, as lithium compounds may leach into surrounding ecosystems. Research indicates that establishing effective recycling protocols could reduce the environmental impact by 25-40% compared to systems without recycling provisions.

Operational risks include potential leakage of molten salt mixtures containing lithium nitrate, which could contaminate soil and water resources. Though such incidents are rare in properly maintained facilities, contingency measures and containment systems are essential to mitigate environmental risks. Thermal pollution from cooling systems represents another operational concern that requires careful management through appropriate design and monitoring protocols.

Comparative analyses with alternative heat transfer fluids suggest that lithium nitrate systems generally present lower environmental impacts than synthetic oil-based systems but higher impacts than water-steam systems in certain impact categories. This underscores the importance of context-specific environmental assessments when evaluating technology options for solar tower applications.

The primary environmental benefit of lithium nitrate systems is their contribution to renewable energy generation, which reduces reliance on fossil fuels and decreases greenhouse gas emissions. Studies indicate that CSP plants using lithium nitrate-based molten salt mixtures can achieve carbon payback periods of 6-18 months, depending on geographical location and system configuration, making them environmentally advantageous over their operational lifetime of 25-30 years.

However, the extraction and processing of lithium compounds present significant environmental concerns. Mining operations, particularly in South America's "Lithium Triangle," consume substantial water resources in already water-stressed regions. Approximately 500,000 gallons of water are required to produce one ton of lithium, potentially exacerbating water scarcity issues in extraction areas. Additionally, lithium mining can lead to soil degradation and potential contamination of groundwater with chemicals used in the extraction process.

The manufacturing and transportation phases of lithium nitrate systems also contribute to their environmental footprint. Energy-intensive production processes generate carbon emissions that must be factored into lifecycle assessments. The global supply chain for lithium compounds further increases the carbon footprint through transportation-related emissions.

End-of-life management presents another environmental consideration. While lithium compounds can be recycled, current recycling infrastructure remains underdeveloped. Improper disposal can lead to soil and water contamination, as lithium compounds may leach into surrounding ecosystems. Research indicates that establishing effective recycling protocols could reduce the environmental impact by 25-40% compared to systems without recycling provisions.

Operational risks include potential leakage of molten salt mixtures containing lithium nitrate, which could contaminate soil and water resources. Though such incidents are rare in properly maintained facilities, contingency measures and containment systems are essential to mitigate environmental risks. Thermal pollution from cooling systems represents another operational concern that requires careful management through appropriate design and monitoring protocols.

Comparative analyses with alternative heat transfer fluids suggest that lithium nitrate systems generally present lower environmental impacts than synthetic oil-based systems but higher impacts than water-steam systems in certain impact categories. This underscores the importance of context-specific environmental assessments when evaluating technology options for solar tower applications.

Cost-Benefit Analysis of Advanced Cooling Technologies

The implementation of advanced cooling technologies in concentrated solar power (CSP) systems, particularly those utilizing lithium nitrate in solar towers, requires thorough cost-benefit analysis to determine economic viability. Initial capital expenditure for lithium nitrate cooling systems ranges from $250-350 per kW of installed capacity, significantly higher than conventional water-based cooling systems at $150-200 per kW. However, this premium is offset by operational advantages over the system's lifetime.

Operational expenditure analysis reveals that lithium nitrate cooling systems reduce water consumption by approximately 85-90% compared to traditional wet cooling methods, translating to savings of $1.2-1.8 million annually for a typical 100 MW solar tower facility in arid regions where water costs are premium. Maintenance costs are approximately 15% lower due to reduced scaling and corrosion issues, extending heat exchanger lifespans by an estimated 3-5 years.

Energy efficiency improvements constitute a major economic benefit, with lithium nitrate systems demonstrating 7-12% higher thermal efficiency during peak summer conditions compared to conventional cooling technologies. This efficiency gain translates to approximately $1.5-2.3 million in additional annual revenue for a 100 MW plant, depending on electricity market prices and regional demand patterns.

Lifecycle cost analysis indicates that despite higher upfront investment, lithium nitrate cooling systems reach cost parity with conventional systems within 4-6 years of operation in most deployment scenarios. The total cost of ownership over a 25-year plant lifetime shows a 12-18% advantage for lithium nitrate systems when factoring in all operational benefits, efficiency gains, and reduced water procurement costs.

Environmental compliance benefits provide additional economic value through reduced regulatory compliance costs and potential carbon credit opportunities. Facilities implementing lithium nitrate cooling technology can expect to reduce their environmental compliance expenditure by approximately $300,000-500,000 annually, depending on local regulatory frameworks and carbon pricing mechanisms.

Risk assessment indicates that while lithium nitrate prices have shown volatility (±25% fluctuation over the past decade), the total cooling system cost remains relatively stable as the salt mixture represents only 15-20% of the total cooling infrastructure cost. Supply chain security has improved with diversification of lithium production globally, reducing procurement risks that previously affected economic calculations.

Operational expenditure analysis reveals that lithium nitrate cooling systems reduce water consumption by approximately 85-90% compared to traditional wet cooling methods, translating to savings of $1.2-1.8 million annually for a typical 100 MW solar tower facility in arid regions where water costs are premium. Maintenance costs are approximately 15% lower due to reduced scaling and corrosion issues, extending heat exchanger lifespans by an estimated 3-5 years.

Energy efficiency improvements constitute a major economic benefit, with lithium nitrate systems demonstrating 7-12% higher thermal efficiency during peak summer conditions compared to conventional cooling technologies. This efficiency gain translates to approximately $1.5-2.3 million in additional annual revenue for a 100 MW plant, depending on electricity market prices and regional demand patterns.

Lifecycle cost analysis indicates that despite higher upfront investment, lithium nitrate cooling systems reach cost parity with conventional systems within 4-6 years of operation in most deployment scenarios. The total cost of ownership over a 25-year plant lifetime shows a 12-18% advantage for lithium nitrate systems when factoring in all operational benefits, efficiency gains, and reduced water procurement costs.

Environmental compliance benefits provide additional economic value through reduced regulatory compliance costs and potential carbon credit opportunities. Facilities implementing lithium nitrate cooling technology can expect to reduce their environmental compliance expenditure by approximately $300,000-500,000 annually, depending on local regulatory frameworks and carbon pricing mechanisms.

Risk assessment indicates that while lithium nitrate prices have shown volatility (±25% fluctuation over the past decade), the total cooling system cost remains relatively stable as the salt mixture represents only 15-20% of the total cooling infrastructure cost. Supply chain security has improved with diversification of lithium production globally, reducing procurement risks that previously affected economic calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!