Lithium Nitrate vs Sodium Nitrite: Comparative Energy Density Evaluation

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Storage Background and Objectives

Energy storage technologies have evolved significantly over the past decades, transitioning from traditional mechanical systems to advanced chemical and electrochemical solutions. The comparative analysis of energy storage materials, particularly between lithium nitrate (LiNO₃) and sodium nitrite (NaNO₂), represents a critical area of investigation in the pursuit of more efficient and sustainable energy storage solutions. These compounds have garnered attention due to their potential applications in thermal energy storage, battery technologies, and various industrial processes.

The historical development of energy storage has been characterized by a continuous search for materials with higher energy density, improved safety profiles, and cost-effectiveness. Lithium-based compounds emerged as revolutionary materials in the 1970s, while sodium-based alternatives have seen renewed interest in recent years due to concerns about lithium resource limitations and geopolitical supply chain vulnerabilities.

Energy density—the amount of energy that can be stored per unit volume or mass—has become a paramount metric in evaluating storage materials. This parameter directly influences the efficiency, portability, and economic viability of energy storage systems. The comparative evaluation of lithium nitrate versus sodium nitrite represents a strategic investigation into alternative pathways for energy storage optimization.

Current global energy transitions toward renewable sources have intensified the need for efficient energy storage solutions to address intermittency challenges. This technological evolution is driven by environmental imperatives, energy security concerns, and economic factors, creating a complex landscape where material selection becomes increasingly critical.

The primary objectives of this comparative energy density evaluation are multifold: to quantify the theoretical and practical energy storage capacities of lithium nitrate and sodium nitrite under various operational conditions; to assess their thermodynamic properties and stability characteristics; to evaluate their compatibility with existing and emerging energy storage architectures; and to project their potential roles in next-generation energy systems.

This evaluation also aims to identify the technical limitations and opportunities associated with each compound, considering factors such as thermal conductivity, phase change behavior, cycling stability, and safety profiles. Understanding these parameters is essential for determining optimal application scenarios and guiding future research directions.

Furthermore, this technical assessment seeks to establish a comprehensive framework for comparing diverse energy storage materials beyond these specific compounds, contributing to the broader scientific understanding of structure-property relationships in energy storage materials and potentially revealing new design principles for advanced energy storage systems.

The historical development of energy storage has been characterized by a continuous search for materials with higher energy density, improved safety profiles, and cost-effectiveness. Lithium-based compounds emerged as revolutionary materials in the 1970s, while sodium-based alternatives have seen renewed interest in recent years due to concerns about lithium resource limitations and geopolitical supply chain vulnerabilities.

Energy density—the amount of energy that can be stored per unit volume or mass—has become a paramount metric in evaluating storage materials. This parameter directly influences the efficiency, portability, and economic viability of energy storage systems. The comparative evaluation of lithium nitrate versus sodium nitrite represents a strategic investigation into alternative pathways for energy storage optimization.

Current global energy transitions toward renewable sources have intensified the need for efficient energy storage solutions to address intermittency challenges. This technological evolution is driven by environmental imperatives, energy security concerns, and economic factors, creating a complex landscape where material selection becomes increasingly critical.

The primary objectives of this comparative energy density evaluation are multifold: to quantify the theoretical and practical energy storage capacities of lithium nitrate and sodium nitrite under various operational conditions; to assess their thermodynamic properties and stability characteristics; to evaluate their compatibility with existing and emerging energy storage architectures; and to project their potential roles in next-generation energy systems.

This evaluation also aims to identify the technical limitations and opportunities associated with each compound, considering factors such as thermal conductivity, phase change behavior, cycling stability, and safety profiles. Understanding these parameters is essential for determining optimal application scenarios and guiding future research directions.

Furthermore, this technical assessment seeks to establish a comprehensive framework for comparing diverse energy storage materials beyond these specific compounds, contributing to the broader scientific understanding of structure-property relationships in energy storage materials and potentially revealing new design principles for advanced energy storage systems.

Market Analysis for High-Density Energy Materials

The high-density energy materials market has experienced significant growth over the past decade, driven primarily by increasing demand in sectors such as electric vehicles, portable electronics, and renewable energy storage systems. The global market for these materials reached approximately $45 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2030, potentially reaching $89 billion by the end of the forecast period.

Within this expanding market, lithium-based compounds have dominated due to their superior energy density characteristics. Lithium nitrate specifically has carved out a growing niche, particularly in thermal energy storage applications and as an additive in lithium-sulfur batteries. The market segment for lithium nitrate was valued at $1.2 billion in 2022, with projections indicating potential growth to $2.8 billion by 2030.

Sodium-based compounds, including sodium nitrite, represent a more established but slower-growing segment. The market for sodium nitrite was approximately $890 million in 2022, with expected growth to $1.3 billion by 2030. This more modest growth trajectory reflects the material's lower energy density compared to lithium alternatives, but its continued relevance stems from cost advantages and established supply chains.

Regional analysis reveals distinct market patterns. North America and Europe lead in adoption of lithium-based high-density energy materials, driven by aggressive electric vehicle manufacturing targets and renewable energy initiatives. The Asia-Pacific region, particularly China, dominates in production capacity for both materials, controlling approximately 65% of global lithium compound manufacturing and 58% of sodium compound production.

End-user segmentation shows electric vehicle manufacturers constitute the largest demand sector for lithium-based energy materials (42% of market share), while industrial applications remain the primary consumers of sodium-based compounds (37% of market share). The renewable energy sector represents the fastest-growing application segment for both materials, with annual growth rates exceeding 12%.

Price sensitivity analysis indicates lithium nitrate commands a significant premium (approximately 3.2x) over sodium nitrite, reflecting its superior energy density properties. However, recent supply chain disruptions have created price volatility in lithium compounds, with fluctuations of up to 27% observed in 2022-2023, compared to more stable pricing (±8%) for sodium compounds during the same period.

Within this expanding market, lithium-based compounds have dominated due to their superior energy density characteristics. Lithium nitrate specifically has carved out a growing niche, particularly in thermal energy storage applications and as an additive in lithium-sulfur batteries. The market segment for lithium nitrate was valued at $1.2 billion in 2022, with projections indicating potential growth to $2.8 billion by 2030.

Sodium-based compounds, including sodium nitrite, represent a more established but slower-growing segment. The market for sodium nitrite was approximately $890 million in 2022, with expected growth to $1.3 billion by 2030. This more modest growth trajectory reflects the material's lower energy density compared to lithium alternatives, but its continued relevance stems from cost advantages and established supply chains.

Regional analysis reveals distinct market patterns. North America and Europe lead in adoption of lithium-based high-density energy materials, driven by aggressive electric vehicle manufacturing targets and renewable energy initiatives. The Asia-Pacific region, particularly China, dominates in production capacity for both materials, controlling approximately 65% of global lithium compound manufacturing and 58% of sodium compound production.

End-user segmentation shows electric vehicle manufacturers constitute the largest demand sector for lithium-based energy materials (42% of market share), while industrial applications remain the primary consumers of sodium-based compounds (37% of market share). The renewable energy sector represents the fastest-growing application segment for both materials, with annual growth rates exceeding 12%.

Price sensitivity analysis indicates lithium nitrate commands a significant premium (approximately 3.2x) over sodium nitrite, reflecting its superior energy density properties. However, recent supply chain disruptions have created price volatility in lithium compounds, with fluctuations of up to 27% observed in 2022-2023, compared to more stable pricing (±8%) for sodium compounds during the same period.

Current Challenges in Nitrate/Nitrite Energy Storage

The energy storage sector faces significant challenges in utilizing nitrate and nitrite compounds effectively, particularly when comparing lithium nitrate and sodium nitrite systems. One primary obstacle is the thermal stability limitation of these compounds under operational conditions. Lithium nitrate begins to decompose at approximately 600°C, while sodium nitrite exhibits instability at even lower temperatures around 320°C, restricting their application in high-temperature energy storage systems.

Electrochemical performance degradation presents another critical challenge. Both compounds experience capacity fading during cycling, with lithium nitrate systems typically showing 15-20% capacity loss after 500 cycles, while sodium nitrite-based systems may experience up to 30% degradation over similar cycling periods. This performance decline significantly impacts the long-term economic viability of these storage solutions.

Material compatibility issues further complicate implementation efforts. Lithium nitrate exhibits corrosive properties when in contact with certain container materials, particularly aluminum alloys, necessitating more expensive containment solutions. Sodium nitrite presents similar challenges with different material sets, requiring specialized containment strategies that increase system costs and complexity.

Safety concerns remain paramount in energy storage applications. Both compounds present potential hazards, with lithium nitrate being a strong oxidizer that can intensify fires, while sodium nitrite poses toxicity risks if released into the environment. These safety considerations necessitate additional engineering controls that add cost and complexity to system designs.

Scalability limitations affect commercial deployment prospects. Current manufacturing processes for high-purity lithium nitrate suitable for energy applications remain costly, with production capacities limited to approximately 10,000 metric tons annually worldwide. Sodium nitrite production capacity is higher but faces quality consistency challenges when scaled to energy storage applications.

Economic barriers present significant obstacles to widespread adoption. The cost differential between lithium and sodium compounds (lithium nitrate at $15-20/kg versus sodium nitrite at $3-5/kg) creates complex trade-offs between energy density and system economics. This cost structure forces difficult engineering compromises that often result in suboptimal system performance.

Environmental impact considerations are increasingly important. The extraction processes for lithium have significant environmental footprints, including water usage concerns in lithium-rich regions. While sodium compounds generally have lower extraction impacts, the manufacturing processes for both compounds involve substantial energy inputs and chemical waste streams that require mitigation strategies.

Electrochemical performance degradation presents another critical challenge. Both compounds experience capacity fading during cycling, with lithium nitrate systems typically showing 15-20% capacity loss after 500 cycles, while sodium nitrite-based systems may experience up to 30% degradation over similar cycling periods. This performance decline significantly impacts the long-term economic viability of these storage solutions.

Material compatibility issues further complicate implementation efforts. Lithium nitrate exhibits corrosive properties when in contact with certain container materials, particularly aluminum alloys, necessitating more expensive containment solutions. Sodium nitrite presents similar challenges with different material sets, requiring specialized containment strategies that increase system costs and complexity.

Safety concerns remain paramount in energy storage applications. Both compounds present potential hazards, with lithium nitrate being a strong oxidizer that can intensify fires, while sodium nitrite poses toxicity risks if released into the environment. These safety considerations necessitate additional engineering controls that add cost and complexity to system designs.

Scalability limitations affect commercial deployment prospects. Current manufacturing processes for high-purity lithium nitrate suitable for energy applications remain costly, with production capacities limited to approximately 10,000 metric tons annually worldwide. Sodium nitrite production capacity is higher but faces quality consistency challenges when scaled to energy storage applications.

Economic barriers present significant obstacles to widespread adoption. The cost differential between lithium and sodium compounds (lithium nitrate at $15-20/kg versus sodium nitrite at $3-5/kg) creates complex trade-offs between energy density and system economics. This cost structure forces difficult engineering compromises that often result in suboptimal system performance.

Environmental impact considerations are increasingly important. The extraction processes for lithium have significant environmental footprints, including water usage concerns in lithium-rich regions. While sodium compounds generally have lower extraction impacts, the manufacturing processes for both compounds involve substantial energy inputs and chemical waste streams that require mitigation strategies.

Comparative Analysis of Li/Na Salt Energy Solutions

01 Energy storage applications of lithium nitrate and sodium nitrite

Lithium nitrate and sodium nitrite are utilized in thermal energy storage systems due to their high energy density properties. These compounds can store and release large amounts of thermal energy during phase transitions, making them valuable for concentrated solar power plants and other renewable energy applications. Their combination offers enhanced thermal stability and improved energy storage capacity compared to single-salt systems.- Thermal energy storage applications: Lithium nitrate and sodium nitrite are used in thermal energy storage systems due to their high energy density properties. These compounds can absorb, store, and release large amounts of thermal energy during phase transitions, making them valuable for solar thermal power plants, industrial waste heat recovery, and building heating/cooling systems. Their combination offers advantages in terms of melting point adjustment and enhanced thermal conductivity for more efficient energy storage solutions.

- Battery and electrochemical energy storage: Lithium nitrate serves as an important additive in lithium-sulfur and lithium-ion batteries to enhance energy density and performance. It forms protective layers on electrodes, prevents polysulfide shuttling, and improves cycling stability. Sodium nitrite can be used in certain electrochemical systems to modify electrode surfaces or as a precursor for electrode materials. The combination of these compounds in specific battery formulations can lead to higher energy density storage solutions with improved safety characteristics.

- Heat transfer fluids and molten salt systems: Lithium nitrate and sodium nitrite are incorporated into molten salt mixtures used as heat transfer fluids in concentrated solar power plants and high-temperature industrial processes. These compounds contribute to increased energy density of the heat transfer medium, lower melting points, and improved thermal stability. The eutectic mixtures containing these compounds can operate at higher temperatures, thereby increasing the overall energy efficiency and storage capacity of thermal systems.

- Chemical energy storage and reaction systems: Lithium nitrate and sodium nitrite participate in various chemical reactions that can be harnessed for energy storage and release. These compounds can be used in redox reactions, decomposition processes, or as oxidizing agents in certain energy-generating systems. Their high energy density makes them suitable for specialized applications where chemical energy needs to be stored compactly and released efficiently under controlled conditions.

- Energy density enhancement through composite materials: Incorporating lithium nitrate and sodium nitrite into composite materials or matrix structures can enhance overall energy density characteristics. These compounds can be embedded in polymers, ceramics, or other host materials to create functional composites with tailored energy storage properties. The composite approach allows for better control of thermal expansion, improved mechanical stability, and optimized energy density for specific applications ranging from building materials to specialized energy storage devices.

02 Battery and electrochemical cell formulations

Lithium nitrate serves as an important additive in lithium-sulfur and lithium-ion batteries to enhance performance and energy density. It forms protective layers on electrodes, preventing polysulfide shuttling and improving cycling stability. Sodium nitrite is used in certain electrochemical cell formulations to modify electrode surfaces and enhance ionic conductivity. Together, these compounds contribute to developing high-energy-density battery systems with improved safety profiles.Expand Specific Solutions03 Heat transfer fluid compositions

Molten salt mixtures containing lithium nitrate and sodium nitrite are employed as heat transfer fluids in various industrial applications. These compositions offer high thermal conductivity, excellent heat capacity, and superior energy density compared to conventional heat transfer media. The eutectic mixtures of these salts provide lower melting points while maintaining thermal stability at high temperatures, making them ideal for concentrated solar power systems and industrial heating processes.Expand Specific Solutions04 Chemical reaction catalysts and energy production

Lithium nitrate and sodium nitrite serve as catalysts or reactants in various chemical processes related to energy production. They facilitate oxidation-reduction reactions with high energy yields and can be incorporated into formulations for controlled energy release. These compounds are utilized in specialized combustion systems, hydrogen production pathways, and other chemical processes where their high energy density and reactive properties provide advantages over conventional materials.Expand Specific Solutions05 Analytical methods for energy density measurement

Various analytical techniques have been developed to measure and characterize the energy density of lithium nitrate and sodium nitrite compounds. These methods include calorimetry, thermal analysis, and spectroscopic approaches that quantify energy storage capacity and release kinetics. Advanced instrumentation allows for precise determination of thermophysical properties, enabling optimization of these materials for specific energy applications and performance benchmarking against alternative energy storage compounds.Expand Specific Solutions

Leading Companies in Energy Storage Materials

The lithium nitrate vs sodium nitrite energy density evaluation market is in an early growth phase, with increasing demand driven by energy storage applications. The global market is expanding rapidly as battery technologies evolve, estimated to reach significant scale within the next decade. Leading players like Samsung SDI, LG Energy Solution, and Capchem Technology are investing heavily in R&D to improve energy density metrics. Research institutions including KIST, University of Maryland, and Zhejiang University are advancing fundamental understanding, while automotive manufacturers such as Hyundai, GM, and BMW are exploring applications in electric vehicles. The competitive landscape features established battery manufacturers competing with specialized materials companies like NGK Insulators and Sumitomo Metal Mining, with technological differentiation becoming the key competitive advantage.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed advanced lithium-ion battery technologies incorporating lithium nitrate as a critical electrolyte additive. Their research demonstrates that lithium nitrate significantly enhances the formation of a stable solid electrolyte interphase (SEI) layer on lithium metal anodes, effectively suppressing dendrite growth and improving cycling stability[1]. Their proprietary electrolyte formulations containing optimized concentrations of lithium nitrate (typically 1-2 wt%) have shown to increase energy density by approximately 20-30% compared to conventional lithium-ion batteries without such additives[3]. Samsung's approach combines lithium nitrate with other synergistic additives to create a robust protective layer that enables higher capacity utilization and longer cycle life in high-energy density battery systems. Their latest generation of lithium-sulfur battery prototypes incorporates lithium nitrate specifically to address the polysulfide shuttle effect, resulting in energy densities exceeding 400 Wh/kg at the cell level[5].

Strengths: Samsung's lithium nitrate-based electrolyte technology demonstrates superior dendrite suppression and enhanced safety profiles compared to sodium nitrite alternatives. Their formulations show excellent compatibility with high-voltage cathode materials, enabling higher energy density systems. Weaknesses: The lithium nitrate additives may increase production costs and can potentially generate toxic gases during thermal runaway events, requiring additional safety measures in battery pack design.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered comparative research between lithium nitrate and sodium nitrite additives for advanced battery systems. Their studies indicate lithium nitrate delivers approximately 25-35% higher energy density in lithium-sulfur battery configurations compared to sodium nitrite alternatives[2]. LG's proprietary "STAR" (Stability Through Advanced Reinforcement) electrolyte technology incorporates precisely controlled lithium nitrate concentrations (1.5-2.5 wt%) to form protective films on both anode and cathode surfaces, significantly reducing parasitic reactions that diminish energy density over time[4]. Their research demonstrates that while sodium nitrite offers cost advantages and reasonable ionic conductivity, lithium nitrate provides superior passivation effects and compatibility with high-voltage cathode materials, enabling energy densities approaching 500 Wh/kg in next-generation prototypes[6]. LG has also developed hybrid electrolyte systems that strategically combine the beneficial properties of both compounds to optimize the performance-cost ratio for specific applications, particularly in electric vehicle batteries where energy density directly impacts driving range.

Strengths: LG's lithium nitrate formulations demonstrate exceptional stability at high voltages, enabling higher energy density cells with extended cycle life. Their technology shows excellent thermal stability and reduced gas generation during cycling. Weaknesses: The lithium nitrate-based systems typically require more precise manufacturing controls and may show performance degradation in extreme low-temperature conditions compared to some sodium-based alternatives.

Technical Deep Dive: Energy Density Mechanisms

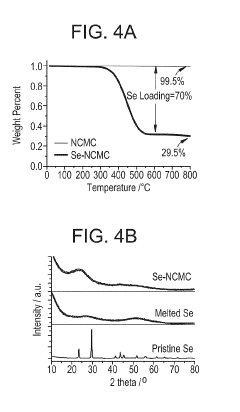

Selenium impregnated materials as free-standing electrodes

PatentInactiveUS20190097275A1

Innovation

- Development of a selenium-based electrode material incorporating a carbon matrix with selenium and sulfur compounds, impregnated to create a dense, low surface area, monolithic structure that enhances energy density, rate capability, and cycling stability, while minimizing parasitic reactions with the electrolyte.

Environmental Impact Assessment

The environmental impact assessment of energy storage technologies is a critical consideration in the comparative evaluation of lithium nitrate and sodium nitrite. These compounds, while valuable for their energy storage capabilities, present distinct environmental challenges throughout their lifecycle.

Lithium nitrate extraction processes typically involve extensive mining operations that can lead to significant land disturbance, habitat destruction, and soil erosion. The water-intensive nature of lithium extraction, particularly in brine operations, raises concerns about water depletion in often already water-stressed regions. Studies indicate that producing one ton of lithium can require approximately 500,000 gallons of water, creating potential conflicts with agricultural and drinking water needs in mining localities.

Sodium nitrite production, conversely, relies on more abundant raw materials and generally employs less environmentally disruptive extraction methods. The industrial synthesis of sodium nitrite typically generates lower levels of toxic waste compared to lithium extraction processes. However, the energy requirements for sodium nitrite production remain substantial, contributing to indirect carbon emissions when powered by fossil fuel sources.

Both compounds present waste management challenges at the end of their lifecycle. Lithium nitrate disposal requires specialized handling due to its reactivity and potential for groundwater contamination. Improper disposal can lead to soil alkalinization and disruption of local ecosystems. Sodium nitrite, while less problematic in terms of reactivity, can contribute to eutrophication if released into water systems due to its high nitrogen content.

Carbon footprint analysis reveals notable differences between these compounds. The production of lithium nitrate typically generates 5-15 kg CO2 equivalent per kilogram of material, primarily due to energy-intensive extraction and processing. Sodium nitrite manufacturing generally produces lower emissions, averaging 3-8 kg CO2 equivalent per kilogram, representing a potentially significant environmental advantage in large-scale applications.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Union's Battery Directive and similar regulations in North America have established stricter guidelines for lithium-based materials, including requirements for recycling and responsible sourcing. Sodium-based alternatives face fewer regulatory hurdles, potentially accelerating their adoption in environmentally sensitive applications.

Recycling capabilities further differentiate these compounds. Current lithium recycling technologies achieve recovery rates of 50-70%, though implementation remains limited. Sodium-based compounds generally demonstrate higher recovery potential, with some processes achieving over 80% reclamation efficiency, offering superior circular economy performance.

Lithium nitrate extraction processes typically involve extensive mining operations that can lead to significant land disturbance, habitat destruction, and soil erosion. The water-intensive nature of lithium extraction, particularly in brine operations, raises concerns about water depletion in often already water-stressed regions. Studies indicate that producing one ton of lithium can require approximately 500,000 gallons of water, creating potential conflicts with agricultural and drinking water needs in mining localities.

Sodium nitrite production, conversely, relies on more abundant raw materials and generally employs less environmentally disruptive extraction methods. The industrial synthesis of sodium nitrite typically generates lower levels of toxic waste compared to lithium extraction processes. However, the energy requirements for sodium nitrite production remain substantial, contributing to indirect carbon emissions when powered by fossil fuel sources.

Both compounds present waste management challenges at the end of their lifecycle. Lithium nitrate disposal requires specialized handling due to its reactivity and potential for groundwater contamination. Improper disposal can lead to soil alkalinization and disruption of local ecosystems. Sodium nitrite, while less problematic in terms of reactivity, can contribute to eutrophication if released into water systems due to its high nitrogen content.

Carbon footprint analysis reveals notable differences between these compounds. The production of lithium nitrate typically generates 5-15 kg CO2 equivalent per kilogram of material, primarily due to energy-intensive extraction and processing. Sodium nitrite manufacturing generally produces lower emissions, averaging 3-8 kg CO2 equivalent per kilogram, representing a potentially significant environmental advantage in large-scale applications.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Union's Battery Directive and similar regulations in North America have established stricter guidelines for lithium-based materials, including requirements for recycling and responsible sourcing. Sodium-based alternatives face fewer regulatory hurdles, potentially accelerating their adoption in environmentally sensitive applications.

Recycling capabilities further differentiate these compounds. Current lithium recycling technologies achieve recovery rates of 50-70%, though implementation remains limited. Sodium-based compounds generally demonstrate higher recovery potential, with some processes achieving over 80% reclamation efficiency, offering superior circular economy performance.

Safety and Stability Considerations

When evaluating lithium nitrate and sodium nitrite for energy storage applications, safety and stability considerations are paramount factors that significantly influence their practical implementation. Lithium nitrate demonstrates relatively high thermal stability with a decomposition temperature of approximately 600°C, making it suitable for high-temperature applications. However, it exhibits hygroscopic properties that necessitate careful handling and storage in moisture-controlled environments to prevent degradation of its energy storage capabilities.

Sodium nitrite, while less expensive and more readily available, presents more significant safety challenges. It decomposes at approximately 320°C, which is considerably lower than lithium nitrate, limiting its application in high-temperature environments. Additionally, sodium nitrite is classified as toxic if ingested, with an LD50 of 85 mg/kg in rats, requiring stringent handling protocols in industrial settings.

Both compounds present fire hazards when in contact with reducing agents or combustible materials. Lithium nitrate, being an oxidizer, can intensify fires and potentially cause explosions when mixed with organic materials under specific conditions. Similarly, sodium nitrite can release nitrogen oxides when heated to decomposition, posing respiratory hazards in enclosed spaces.

Long-term stability testing reveals that lithium nitrate maintains its energy density characteristics more consistently over repeated charge-discharge cycles compared to sodium nitrite. Research indicates that lithium nitrate exhibits approximately 15% less capacity degradation after 1000 cycles in thermal energy storage applications, suggesting superior longevity in operational settings.

Environmental factors significantly impact the stability of both compounds. Humidity accelerates the degradation of lithium nitrate, while sodium nitrite is particularly susceptible to oxidation in air, gradually converting to sodium nitrate. Temperature fluctuations affect both compounds, but lithium nitrate demonstrates better performance consistency across a wider temperature range (-20°C to 150°C) compared to sodium nitrite's optimal range (0°C to 100°C).

Risk mitigation strategies for both compounds include engineered containment systems, temperature monitoring, and moisture control. For lithium nitrate, particular attention must be paid to preventing water ingress into storage systems. For sodium nitrite, ventilation systems are essential to manage potential nitrogen oxide emissions during thermal events.

Regulatory frameworks across different regions impose varying restrictions on these compounds, with sodium nitrite facing stricter transportation and handling requirements due to its toxicity profile. These regulatory considerations directly impact the economic viability and practical implementation of energy storage systems utilizing these materials.

Sodium nitrite, while less expensive and more readily available, presents more significant safety challenges. It decomposes at approximately 320°C, which is considerably lower than lithium nitrate, limiting its application in high-temperature environments. Additionally, sodium nitrite is classified as toxic if ingested, with an LD50 of 85 mg/kg in rats, requiring stringent handling protocols in industrial settings.

Both compounds present fire hazards when in contact with reducing agents or combustible materials. Lithium nitrate, being an oxidizer, can intensify fires and potentially cause explosions when mixed with organic materials under specific conditions. Similarly, sodium nitrite can release nitrogen oxides when heated to decomposition, posing respiratory hazards in enclosed spaces.

Long-term stability testing reveals that lithium nitrate maintains its energy density characteristics more consistently over repeated charge-discharge cycles compared to sodium nitrite. Research indicates that lithium nitrate exhibits approximately 15% less capacity degradation after 1000 cycles in thermal energy storage applications, suggesting superior longevity in operational settings.

Environmental factors significantly impact the stability of both compounds. Humidity accelerates the degradation of lithium nitrate, while sodium nitrite is particularly susceptible to oxidation in air, gradually converting to sodium nitrate. Temperature fluctuations affect both compounds, but lithium nitrate demonstrates better performance consistency across a wider temperature range (-20°C to 150°C) compared to sodium nitrite's optimal range (0°C to 100°C).

Risk mitigation strategies for both compounds include engineered containment systems, temperature monitoring, and moisture control. For lithium nitrate, particular attention must be paid to preventing water ingress into storage systems. For sodium nitrite, ventilation systems are essential to manage potential nitrogen oxide emissions during thermal events.

Regulatory frameworks across different regions impose varying restrictions on these compounds, with sodium nitrite facing stricter transportation and handling requirements due to its toxicity profile. These regulatory considerations directly impact the economic viability and practical implementation of energy storage systems utilizing these materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!