How to Prevent Lithium Nitrate Corrosion in Molten State Equipment

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Corrosion Background and Objectives

Lithium nitrate (LiNO3) has emerged as a critical component in various advanced energy storage and thermal applications, particularly in concentrated solar power (CSP) systems and molten salt batteries. The historical development of lithium nitrate usage can be traced back to the 1970s when researchers began exploring its potential as a heat transfer fluid due to its excellent thermal properties. Over the decades, its application has expanded significantly, driven by the growing demand for efficient energy storage solutions and the global push toward renewable energy technologies.

The corrosion challenges associated with lithium nitrate in its molten state have become increasingly prominent as deployment scales up. When in molten form, typically at temperatures ranging from 250°C to 550°C, lithium nitrate exhibits aggressive corrosive behavior toward containment materials, particularly metal alloys commonly used in industrial equipment. This corrosion phenomenon has been documented to accelerate exponentially with temperature increases, creating significant engineering challenges for long-term system reliability.

Recent technological trends indicate a growing interest in lithium nitrate-based thermal storage systems, with annual research publications on the topic increasing by approximately 35% between 2015 and 2022. This surge reflects both the promising potential of the technology and the urgent need to address its corrosion-related limitations. The evolution of corrosion mitigation strategies has progressed from simple material selection approaches to more sophisticated surface treatment techniques and corrosion inhibitor development.

The primary technical objectives for preventing lithium nitrate corrosion in molten state equipment encompass several dimensions. First, there is a need to develop comprehensive understanding of corrosion mechanisms specific to lithium nitrate at various operating temperatures and in the presence of common contaminants. Second, researchers aim to identify or develop cost-effective materials that can withstand prolonged exposure to molten lithium nitrate without significant degradation.

Additionally, the development of effective corrosion inhibitors compatible with lithium nitrate's chemical properties represents a critical objective. These inhibitors must maintain their effectiveness throughout the operational temperature range without compromising the thermal properties that make lithium nitrate valuable in the first place. Finally, there is a growing focus on establishing standardized testing protocols and accelerated aging methodologies to accurately predict long-term corrosion behavior and validate potential solutions.

The ultimate goal is to enable lithium nitrate-based systems with operational lifespans exceeding 25 years while maintaining thermal efficiency and minimizing maintenance requirements. Achieving these objectives would significantly enhance the economic viability of technologies dependent on molten lithium nitrate, particularly in renewable energy applications where system longevity directly impacts return on investment calculations.

The corrosion challenges associated with lithium nitrate in its molten state have become increasingly prominent as deployment scales up. When in molten form, typically at temperatures ranging from 250°C to 550°C, lithium nitrate exhibits aggressive corrosive behavior toward containment materials, particularly metal alloys commonly used in industrial equipment. This corrosion phenomenon has been documented to accelerate exponentially with temperature increases, creating significant engineering challenges for long-term system reliability.

Recent technological trends indicate a growing interest in lithium nitrate-based thermal storage systems, with annual research publications on the topic increasing by approximately 35% between 2015 and 2022. This surge reflects both the promising potential of the technology and the urgent need to address its corrosion-related limitations. The evolution of corrosion mitigation strategies has progressed from simple material selection approaches to more sophisticated surface treatment techniques and corrosion inhibitor development.

The primary technical objectives for preventing lithium nitrate corrosion in molten state equipment encompass several dimensions. First, there is a need to develop comprehensive understanding of corrosion mechanisms specific to lithium nitrate at various operating temperatures and in the presence of common contaminants. Second, researchers aim to identify or develop cost-effective materials that can withstand prolonged exposure to molten lithium nitrate without significant degradation.

Additionally, the development of effective corrosion inhibitors compatible with lithium nitrate's chemical properties represents a critical objective. These inhibitors must maintain their effectiveness throughout the operational temperature range without compromising the thermal properties that make lithium nitrate valuable in the first place. Finally, there is a growing focus on establishing standardized testing protocols and accelerated aging methodologies to accurately predict long-term corrosion behavior and validate potential solutions.

The ultimate goal is to enable lithium nitrate-based systems with operational lifespans exceeding 25 years while maintaining thermal efficiency and minimizing maintenance requirements. Achieving these objectives would significantly enhance the economic viability of technologies dependent on molten lithium nitrate, particularly in renewable energy applications where system longevity directly impacts return on investment calculations.

Market Demand for Corrosion-Resistant Molten Salt Equipment

The global market for corrosion-resistant molten salt equipment has been experiencing significant growth, primarily driven by the expanding renewable energy sector, particularly concentrated solar power (CSP) plants that utilize molten salt as thermal energy storage media. The market value for specialized corrosion-resistant equipment in this sector reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 8.7% through 2030.

Energy storage applications represent the largest market segment, accounting for nearly 45% of the total demand. As countries worldwide commit to carbon neutrality goals, investments in renewable energy infrastructure have surged, creating substantial demand for equipment that can withstand the highly corrosive environment of molten salts, especially those containing lithium nitrate.

The nuclear industry constitutes another significant market segment, where molten salt reactors (MSRs) are gaining attention as next-generation nuclear technology. This sector's demand for corrosion-resistant equipment is expected to grow at 12.3% annually as several countries advance their MSR development programs. The chemical processing industry also represents a substantial market, particularly in applications involving high-temperature catalytic processes.

Geographically, China leads the market with approximately 32% share, followed by the European Union (27%) and North America (21%). China's dominance stems from its aggressive expansion of renewable energy capacity and substantial investments in advanced nuclear technologies. The Middle East region is emerging as the fastest-growing market, with Saudi Arabia and UAE making significant investments in concentrated solar power technologies.

Industry surveys indicate that end-users are willing to pay premium prices for equipment with demonstrated corrosion resistance to lithium nitrate in molten state, with 78% of respondents citing equipment longevity as their primary concern. The average lifecycle cost reduction potential for improved corrosion-resistant equipment is estimated at 35-40% compared to conventional alternatives that require frequent replacement.

Material suppliers have identified this market opportunity, with specialized alloy manufacturers reporting 15-20% increased demand specifically for lithium nitrate-resistant materials. The aftermarket service sector for maintenance and repair of molten salt equipment has likewise expanded, currently valued at approximately $870 million annually.

Customer requirements increasingly emphasize not only corrosion resistance but also operational flexibility, as many renewable energy applications require equipment to withstand frequent thermal cycling. This has created a specialized niche market for monitoring systems and predictive maintenance solutions specific to molten salt environments, currently growing at 17.5% annually.

Energy storage applications represent the largest market segment, accounting for nearly 45% of the total demand. As countries worldwide commit to carbon neutrality goals, investments in renewable energy infrastructure have surged, creating substantial demand for equipment that can withstand the highly corrosive environment of molten salts, especially those containing lithium nitrate.

The nuclear industry constitutes another significant market segment, where molten salt reactors (MSRs) are gaining attention as next-generation nuclear technology. This sector's demand for corrosion-resistant equipment is expected to grow at 12.3% annually as several countries advance their MSR development programs. The chemical processing industry also represents a substantial market, particularly in applications involving high-temperature catalytic processes.

Geographically, China leads the market with approximately 32% share, followed by the European Union (27%) and North America (21%). China's dominance stems from its aggressive expansion of renewable energy capacity and substantial investments in advanced nuclear technologies. The Middle East region is emerging as the fastest-growing market, with Saudi Arabia and UAE making significant investments in concentrated solar power technologies.

Industry surveys indicate that end-users are willing to pay premium prices for equipment with demonstrated corrosion resistance to lithium nitrate in molten state, with 78% of respondents citing equipment longevity as their primary concern. The average lifecycle cost reduction potential for improved corrosion-resistant equipment is estimated at 35-40% compared to conventional alternatives that require frequent replacement.

Material suppliers have identified this market opportunity, with specialized alloy manufacturers reporting 15-20% increased demand specifically for lithium nitrate-resistant materials. The aftermarket service sector for maintenance and repair of molten salt equipment has likewise expanded, currently valued at approximately $870 million annually.

Customer requirements increasingly emphasize not only corrosion resistance but also operational flexibility, as many renewable energy applications require equipment to withstand frequent thermal cycling. This has created a specialized niche market for monitoring systems and predictive maintenance solutions specific to molten salt environments, currently growing at 17.5% annually.

Current Challenges in Molten Lithium Nitrate Containment

The containment of molten lithium nitrate presents significant challenges due to its highly corrosive nature at elevated temperatures. When lithium nitrate transitions to its molten state (approximately 255°C), it becomes particularly aggressive toward most conventional containment materials. This corrosivity is primarily attributed to the formation of highly reactive lithium oxide species and the release of nitrogen oxides, which can rapidly degrade metal surfaces through oxidation mechanisms.

Material degradation manifests in several forms, including uniform corrosion, pitting, stress corrosion cracking, and intergranular attack. Stainless steels, commonly used in high-temperature applications, exhibit accelerated corrosion rates when exposed to molten lithium nitrate, with documented penetration rates exceeding 1.5 mm/year in some operating conditions. This rate of degradation significantly compromises equipment integrity and operational safety.

Thermal cycling exacerbates the corrosion challenge by inducing mechanical stresses at material interfaces. The repeated expansion and contraction during heating and cooling cycles create micro-cracks that serve as initiation sites for localized corrosion. These effects are particularly pronounced at welded joints and other stress concentration points within containment vessels and transfer systems.

Impurity management represents another critical challenge. Even trace amounts of moisture or other contaminants can dramatically increase the corrosivity of molten lithium nitrate. Water, in particular, reacts with lithium nitrate to form highly alkaline solutions that accelerate attack on protective oxide layers. Industry data indicates that moisture content above 50 ppm can double corrosion rates in certain alloy systems.

The high operating temperatures required for maintaining lithium nitrate in its molten state (typically 260-350°C for most applications) limit the selection of viable containment materials and sealing technologies. Traditional polymer-based seals degrade rapidly, while metal-to-metal seals must withstand both chemical attack and thermal expansion differentials.

Monitoring and inspection of equipment present additional challenges. The opacity and high temperature of molten lithium nitrate make real-time corrosion monitoring difficult, often resulting in detection only after significant damage has occurred. Non-destructive testing methods are limited by access constraints and the need to maintain operational temperatures.

Economic considerations further complicate solutions, as highly resistant materials such as nickel-based superalloys or ceramic composites significantly increase capital costs. The trade-off between material performance and economic viability remains a central challenge for industries utilizing molten lithium nitrate, particularly in large-scale thermal energy storage applications where containment volumes are substantial.

Material degradation manifests in several forms, including uniform corrosion, pitting, stress corrosion cracking, and intergranular attack. Stainless steels, commonly used in high-temperature applications, exhibit accelerated corrosion rates when exposed to molten lithium nitrate, with documented penetration rates exceeding 1.5 mm/year in some operating conditions. This rate of degradation significantly compromises equipment integrity and operational safety.

Thermal cycling exacerbates the corrosion challenge by inducing mechanical stresses at material interfaces. The repeated expansion and contraction during heating and cooling cycles create micro-cracks that serve as initiation sites for localized corrosion. These effects are particularly pronounced at welded joints and other stress concentration points within containment vessels and transfer systems.

Impurity management represents another critical challenge. Even trace amounts of moisture or other contaminants can dramatically increase the corrosivity of molten lithium nitrate. Water, in particular, reacts with lithium nitrate to form highly alkaline solutions that accelerate attack on protective oxide layers. Industry data indicates that moisture content above 50 ppm can double corrosion rates in certain alloy systems.

The high operating temperatures required for maintaining lithium nitrate in its molten state (typically 260-350°C for most applications) limit the selection of viable containment materials and sealing technologies. Traditional polymer-based seals degrade rapidly, while metal-to-metal seals must withstand both chemical attack and thermal expansion differentials.

Monitoring and inspection of equipment present additional challenges. The opacity and high temperature of molten lithium nitrate make real-time corrosion monitoring difficult, often resulting in detection only after significant damage has occurred. Non-destructive testing methods are limited by access constraints and the need to maintain operational temperatures.

Economic considerations further complicate solutions, as highly resistant materials such as nickel-based superalloys or ceramic composites significantly increase capital costs. The trade-off between material performance and economic viability remains a central challenge for industries utilizing molten lithium nitrate, particularly in large-scale thermal energy storage applications where containment volumes are substantial.

Current Anti-Corrosion Solutions for Molten Lithium Nitrate

01 Lithium nitrate as corrosion inhibitor in heat transfer fluids

Lithium nitrate can be used as a corrosion inhibitor in heat transfer fluids, particularly in solar thermal systems and other high-temperature applications. When added to heat transfer fluids, lithium nitrate forms a protective layer on metal surfaces, preventing oxidation and corrosion. This is especially effective in systems containing aluminum, copper, and steel components. The corrosion inhibition properties of lithium nitrate are enhanced when used in combination with other additives such as molten salts.- Lithium nitrate as corrosion inhibitor in cooling systems: Lithium nitrate is used as a corrosion inhibitor in cooling systems, particularly in heat transfer fluids. It provides protection for various metals including aluminum, copper, and steel components in cooling circuits. When formulated with other compounds, it creates effective anti-corrosion packages that prevent oxidation and extend the lifespan of cooling system components while maintaining thermal efficiency.

- Lithium nitrate in battery electrolyte compositions: Lithium nitrate is incorporated into battery electrolyte compositions to form protective films on electrode surfaces, particularly in lithium-ion and lithium-sulfur batteries. It functions as an electrolyte additive that suppresses unwanted side reactions, prevents polysulfide shuttling, and mitigates corrosion of metal current collectors. This improves battery cycle life, stability, and overall electrochemical performance.

- Lithium nitrate in thermal energy storage materials: Lithium nitrate is used in molten salt mixtures for thermal energy storage applications. It helps lower the melting point of salt mixtures while improving thermal stability and reducing corrosive effects on containment materials. These formulations are particularly valuable in concentrated solar power systems and other high-temperature heat storage applications where material compatibility and longevity are critical concerns.

- Lithium nitrate in anti-corrosion coatings: Lithium nitrate is incorporated into protective coating formulations to provide corrosion resistance for metal substrates. These coatings form passive layers that prevent oxidation and degradation of the underlying metal. The compound can be integrated into various coating matrices including polymers, ceramics, and conversion coatings to provide long-term protection against environmental corrosion factors.

- Lithium nitrate in corrosion-resistant alloy development: Lithium nitrate is utilized in processes for developing corrosion-resistant metal alloys and surface treatments. It can be incorporated into metal processing methods to enhance the formation of protective oxide layers or as part of electrochemical treatments that improve corrosion resistance. These techniques are particularly valuable for metals exposed to harsh environments or high-temperature applications where conventional protection methods may be insufficient.

02 Lithium nitrate in battery electrolyte formulations

Lithium nitrate is incorporated into battery electrolyte formulations to prevent corrosion of battery components, particularly in lithium-ion and lithium-sulfur batteries. It forms a stable solid electrolyte interphase (SEI) on electrode surfaces, which protects against parasitic reactions and improves battery cycle life. The addition of lithium nitrate to electrolytes helps suppress the shuttle effect in lithium-sulfur batteries and reduces lithium dendrite formation, which can cause internal short circuits and battery failure.Expand Specific Solutions03 Anti-corrosion coatings containing lithium nitrate

Lithium nitrate is used as a key component in anti-corrosion coating formulations for metal protection. These coatings can be applied to various metal substrates to provide long-term corrosion resistance in aggressive environments. The lithium nitrate in these coatings reacts with the metal surface to form a protective conversion layer that prevents moisture and oxygen from reaching the metal. These coatings are particularly effective for protecting aluminum alloys, steel structures, and aerospace components from environmental degradation.Expand Specific Solutions04 Lithium nitrate in thermal energy storage systems

Lithium nitrate is used in thermal energy storage systems, particularly in molten salt mixtures, where corrosion control is critical for system longevity. The addition of lithium nitrate to these salt mixtures helps reduce their corrosivity toward containment materials such as stainless steel and nickel alloys. These systems operate at high temperatures, and the corrosion inhibition properties of lithium nitrate help extend the service life of heat exchangers and storage tanks. The thermal stability of lithium nitrate makes it suitable for applications requiring repeated heating and cooling cycles.Expand Specific Solutions05 Lithium nitrate in concrete and cement applications

Lithium nitrate is utilized in concrete and cement formulations to prevent corrosion of steel reinforcement and enhance durability. It acts as a corrosion inhibitor by raising the pH of the concrete pore solution and forming a protective film on steel surfaces. Additionally, lithium nitrate can mitigate alkali-silica reaction (ASR) in concrete, which is a form of chemical degradation that can lead to cracking and structural failure. The incorporation of lithium nitrate in concrete mixtures is particularly beneficial in marine environments and infrastructure exposed to deicing salts.Expand Specific Solutions

Leading Companies in Molten Salt Equipment Manufacturing

The lithium nitrate corrosion prevention market is currently in a growth phase, with increasing applications in molten salt energy storage systems and nuclear technologies. The global market is expanding as renewable energy adoption rises, creating demand for thermal storage solutions. From a technological maturity perspective, established players like Korea Atomic Energy Research Institute and KAERI are leading research efforts, while companies such as Kobe Steel and Hitachi are developing specialized corrosion-resistant materials and equipment. Newer entrants like TAE Technologies and Sichuan Compliance Lithium Material are focusing on innovative approaches to address corrosion challenges. Academic institutions including Texas A&M University and Fudan University are contributing fundamental research, creating a competitive landscape balanced between established industrial players and emerging technology providers.

Sichuan Compliance Lithium Material Technology Co., Ltd.

Technical Solution: Sichuan Compliance Lithium Material Technology has developed specialized corrosion prevention systems for their lithium processing equipment that handles molten lithium nitrate. Their approach combines material innovation with process optimization to address the unique challenges of lithium salt corrosion. The company employs a multi-layer protection strategy starting with base materials selection - using high-molybdenum stainless steel alloys specifically formulated to resist lithium salt attack. These materials are then treated with their proprietary surface nitriding process that creates a dense, nitrogen-rich layer that significantly enhances corrosion resistance. For critical components, they apply a composite ceramic coating containing silicon nitride and aluminum oxide that provides exceptional chemical stability in molten lithium environments. Their process engineering team has also developed operational protocols that minimize temperature fluctuations and control oxygen content in the system, as these factors significantly accelerate lithium nitrate corrosion. The company's monitoring system uses electrochemical impedance spectroscopy to detect early signs of corrosion before equipment failure occurs.

Strengths: Specialized expertise in lithium processing environments; integrated approach combining materials, coatings, and process controls developed specifically for lithium salt handling. Weaknesses: Solutions primarily optimized for lithium processing industry; may require adaptation for other applications; limited published data on long-term performance.

Korea Atomic Energy Research Institute

Technical Solution: Korea Atomic Energy Research Institute (KAERI) has developed advanced corrosion mitigation strategies for molten salt reactors where lithium nitrate corrosion is a significant concern. Their approach involves the use of specialized nickel-based alloys with chromium and molybdenum additions that form protective oxide layers resistant to lithium nitrate attack. KAERI has implemented a multi-layered protection system that includes pre-treatment of metal surfaces with specialized coatings containing rare earth elements that enhance corrosion resistance. They've also pioneered the use of sacrificial anodes and redox potential control systems that maintain the molten salt chemistry within optimal parameters to minimize corrosion. Their research has demonstrated that controlling oxygen impurity levels below 50 ppm significantly reduces corrosion rates in lithium nitrate environments.

Strengths: Comprehensive approach combining material selection, surface treatments, and active chemistry control; extensive testing in nuclear applications provides robust validation data. Weaknesses: Solutions may be cost-prohibitive for non-nuclear applications; requires sophisticated monitoring systems and regular maintenance.

Key Innovations in High-Temperature Corrosion Resistance

Method for preventing corrosion and component obtained by means of such

PatentActiveIN7507CHENP2014A

Innovation

- A multi-layer coating method involving electroplating and electroless plating of nickel alloys on metal substrates, followed by thermal treatment, to create a resistant and structurally homogeneous nickel-based coating with specific hardness and ductility values, allowing the use of less expensive materials like carbon or low-alloy steel.

Corrosion prevention method and corrosion prevention system

PatentWO2024252532A1

Innovation

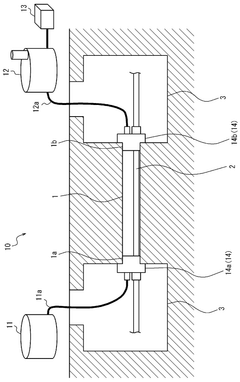

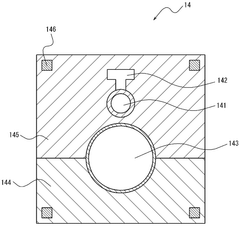

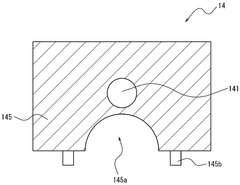

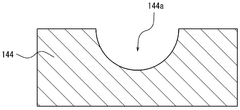

- A corrosion prevention system that involves sealing both ends of a metal conduit with closure caps and filling the conduit with inert gas, using an air supply hose and an exhaust hose, allowing the inner pipe to maintain its original diameter while preventing corrosion through the replacement of air with inert gas.

Material Selection Criteria for Molten Salt Applications

Material selection for molten salt applications, particularly those involving lithium nitrate, requires careful consideration of several critical factors to ensure equipment longevity and operational safety. The primary selection criteria must address corrosion resistance, as lithium nitrate in its molten state is highly corrosive to many conventional materials.

Temperature resistance stands as a fundamental requirement, with materials needing to maintain structural integrity and performance characteristics at operating temperatures typically ranging from 250°C to 550°C for lithium nitrate applications. Materials must exhibit minimal thermal expansion and excellent thermal shock resistance to withstand rapid temperature fluctuations without developing cracks or deformation.

Corrosion mechanisms in molten lithium nitrate environments include oxidation, dissolution, and intergranular attack. High-nickel alloys such as Hastelloy N and Inconel 625 have demonstrated superior resistance to these mechanisms compared to standard stainless steels. Nickel content above 60% generally correlates with improved corrosion resistance in these environments.

Mechanical properties at elevated temperatures represent another crucial selection criterion. Materials must maintain adequate strength, creep resistance, and fatigue performance throughout the intended service life. Precipitation-hardened nickel-based superalloys often provide the optimal balance of high-temperature strength and corrosion resistance.

Surface treatment options can significantly enhance corrosion resistance. Techniques such as aluminizing, chromizing, or the application of ceramic coatings have shown promise in extending equipment life. Pre-oxidation treatments that form protective oxide layers before exposure to molten salts can also reduce initial corrosion rates.

Compatibility with other system components must be evaluated to prevent galvanic corrosion or unwanted chemical reactions. This includes consideration of welding compatibility, as join points often represent vulnerable areas for corrosion initiation.

Economic factors cannot be overlooked, as high-performance alloys typically command premium prices. Life-cycle cost analysis should balance initial material costs against expected service life, maintenance requirements, and potential downtime costs associated with material failure.

Testing protocols for material selection should include both static immersion tests and dynamic flow testing that more accurately simulates actual operating conditions. Accelerated aging tests can help predict long-term performance, though results should be interpreted with appropriate caution regarding their correlation to real-world service conditions.

Temperature resistance stands as a fundamental requirement, with materials needing to maintain structural integrity and performance characteristics at operating temperatures typically ranging from 250°C to 550°C for lithium nitrate applications. Materials must exhibit minimal thermal expansion and excellent thermal shock resistance to withstand rapid temperature fluctuations without developing cracks or deformation.

Corrosion mechanisms in molten lithium nitrate environments include oxidation, dissolution, and intergranular attack. High-nickel alloys such as Hastelloy N and Inconel 625 have demonstrated superior resistance to these mechanisms compared to standard stainless steels. Nickel content above 60% generally correlates with improved corrosion resistance in these environments.

Mechanical properties at elevated temperatures represent another crucial selection criterion. Materials must maintain adequate strength, creep resistance, and fatigue performance throughout the intended service life. Precipitation-hardened nickel-based superalloys often provide the optimal balance of high-temperature strength and corrosion resistance.

Surface treatment options can significantly enhance corrosion resistance. Techniques such as aluminizing, chromizing, or the application of ceramic coatings have shown promise in extending equipment life. Pre-oxidation treatments that form protective oxide layers before exposure to molten salts can also reduce initial corrosion rates.

Compatibility with other system components must be evaluated to prevent galvanic corrosion or unwanted chemical reactions. This includes consideration of welding compatibility, as join points often represent vulnerable areas for corrosion initiation.

Economic factors cannot be overlooked, as high-performance alloys typically command premium prices. Life-cycle cost analysis should balance initial material costs against expected service life, maintenance requirements, and potential downtime costs associated with material failure.

Testing protocols for material selection should include both static immersion tests and dynamic flow testing that more accurately simulates actual operating conditions. Accelerated aging tests can help predict long-term performance, though results should be interpreted with appropriate caution regarding their correlation to real-world service conditions.

Thermal Energy Storage System Integration Considerations

The integration of lithium nitrate-based thermal energy storage systems requires careful consideration of material compatibility and corrosion prevention strategies. When designing such systems, engineers must account for the highly corrosive nature of molten lithium nitrate, particularly at elevated temperatures where thermal energy storage typically operates. Material selection becomes paramount, with specialized high-temperature alloys such as Inconel, Hastelloy, and certain stainless steel grades demonstrating superior resistance to lithium nitrate corrosion compared to conventional metals.

System architecture must incorporate appropriate isolation mechanisms between the thermal storage medium and vulnerable components. This may include protective barrier coatings, such as ceramic or specialized metal oxide layers, which can significantly extend equipment lifespan by preventing direct contact between molten lithium nitrate and metal surfaces. Additionally, implementing redundant containment systems with corrosion monitoring capabilities enables early detection of potential failures before catastrophic damage occurs.

Temperature management strategies play a crucial role in mitigating corrosion risks. Operating within optimal temperature ranges can reduce corrosion rates, while avoiding thermal cycling whenever possible minimizes stress on protective layers and containment materials. Implementing precise temperature control systems with appropriate safety margins ensures that thermal storage media remain within design parameters during all operational phases.

Maintenance protocols must be specifically tailored for lithium nitrate systems. Regular inspection schedules, utilizing techniques such as ultrasonic thickness measurement and infrared thermography, can identify early signs of corrosion before system integrity is compromised. Establishing clear procedures for safe system drainage, cleaning, and component replacement minimizes exposure risks during maintenance operations.

Integration with existing energy infrastructure requires careful interface design. Heat exchangers, pumps, and valves must incorporate corrosion-resistant materials at all points of contact with the thermal storage medium. Isolation valves and secondary containment systems should be strategically positioned to prevent contamination of connected systems in case of leakage. Furthermore, sensor placement must account for the corrosive environment, with appropriate protection or regular replacement schedules for monitoring equipment.

Economic considerations must balance initial investment in corrosion-resistant materials against long-term maintenance costs and system reliability. While premium corrosion-resistant alloys and protective coatings increase upfront expenses, they can significantly reduce lifetime costs by extending equipment service life and minimizing downtime for repairs. A comprehensive lifecycle cost analysis should guide material selection decisions, particularly for large-scale thermal energy storage implementations.

System architecture must incorporate appropriate isolation mechanisms between the thermal storage medium and vulnerable components. This may include protective barrier coatings, such as ceramic or specialized metal oxide layers, which can significantly extend equipment lifespan by preventing direct contact between molten lithium nitrate and metal surfaces. Additionally, implementing redundant containment systems with corrosion monitoring capabilities enables early detection of potential failures before catastrophic damage occurs.

Temperature management strategies play a crucial role in mitigating corrosion risks. Operating within optimal temperature ranges can reduce corrosion rates, while avoiding thermal cycling whenever possible minimizes stress on protective layers and containment materials. Implementing precise temperature control systems with appropriate safety margins ensures that thermal storage media remain within design parameters during all operational phases.

Maintenance protocols must be specifically tailored for lithium nitrate systems. Regular inspection schedules, utilizing techniques such as ultrasonic thickness measurement and infrared thermography, can identify early signs of corrosion before system integrity is compromised. Establishing clear procedures for safe system drainage, cleaning, and component replacement minimizes exposure risks during maintenance operations.

Integration with existing energy infrastructure requires careful interface design. Heat exchangers, pumps, and valves must incorporate corrosion-resistant materials at all points of contact with the thermal storage medium. Isolation valves and secondary containment systems should be strategically positioned to prevent contamination of connected systems in case of leakage. Furthermore, sensor placement must account for the corrosive environment, with appropriate protection or regular replacement schedules for monitoring equipment.

Economic considerations must balance initial investment in corrosion-resistant materials against long-term maintenance costs and system reliability. While premium corrosion-resistant alloys and protective coatings increase upfront expenses, they can significantly reduce lifetime costs by extending equipment service life and minimizing downtime for repairs. A comprehensive lifecycle cost analysis should guide material selection decisions, particularly for large-scale thermal energy storage implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!