Quantify Lithium Nitrate’s Lifecycle Carbon Emissions

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Carbon Footprint Background and Objectives

Lithium nitrate has emerged as a critical component in various industrial applications, particularly in energy storage systems and advanced materials. The growing concern over climate change has intensified the focus on understanding and quantifying the carbon footprint associated with chemical compounds used in clean energy technologies. This technical pre-research aims to comprehensively examine the lifecycle carbon emissions of lithium nitrate, establishing a foundation for sustainable production and utilization strategies.

The evolution of lithium nitrate technology has progressed significantly over the past decades, transitioning from limited specialty applications to becoming an essential material in multiple industries. Initially utilized primarily in pyrotechnics and ceramics, lithium nitrate has gained prominence in molten salt thermal energy storage systems and as an electrolyte additive in lithium-ion batteries, highlighting its expanding technological relevance.

Current global environmental policies and corporate sustainability initiatives are driving the need for accurate carbon accounting across supply chains. The Paris Agreement and subsequent climate accords have established frameworks requiring industries to measure, report, and reduce greenhouse gas emissions. Within this context, quantifying the carbon footprint of lithium nitrate represents not merely an academic exercise but a strategic business imperative.

The technical objectives of this research encompass several dimensions. First, we aim to develop a comprehensive lifecycle assessment (LCA) methodology specifically tailored for lithium nitrate production pathways. This includes establishing system boundaries, identifying appropriate functional units, and determining relevant impact categories beyond global warming potential.

Second, we seek to quantify emissions across the entire value chain, from raw material extraction (primarily lithium carbonate or lithium hydroxide) through processing, transportation, use phase, and end-of-life management. This cradle-to-grave approach will provide holistic insights into environmental hotspots within the lifecycle.

Third, this research intends to compare carbon intensities across different production methods, including traditional nitration processes and emerging synthesis routes. The analysis will consider regional variations in production emissions based on energy grid compositions and manufacturing efficiencies.

Finally, we aim to establish benchmark values for lithium nitrate's carbon footprint that can serve as reference points for industry standards and improvement targets. These benchmarks will facilitate meaningful comparisons with alternative materials and support evidence-based decision-making for technology developers and policy makers.

The anticipated outcomes of this technical investigation will contribute to the growing body of knowledge on sustainable chemistry and provide actionable insights for reducing the environmental impact of lithium-based energy storage technologies, aligning with global decarbonization efforts and circular economy principles.

The evolution of lithium nitrate technology has progressed significantly over the past decades, transitioning from limited specialty applications to becoming an essential material in multiple industries. Initially utilized primarily in pyrotechnics and ceramics, lithium nitrate has gained prominence in molten salt thermal energy storage systems and as an electrolyte additive in lithium-ion batteries, highlighting its expanding technological relevance.

Current global environmental policies and corporate sustainability initiatives are driving the need for accurate carbon accounting across supply chains. The Paris Agreement and subsequent climate accords have established frameworks requiring industries to measure, report, and reduce greenhouse gas emissions. Within this context, quantifying the carbon footprint of lithium nitrate represents not merely an academic exercise but a strategic business imperative.

The technical objectives of this research encompass several dimensions. First, we aim to develop a comprehensive lifecycle assessment (LCA) methodology specifically tailored for lithium nitrate production pathways. This includes establishing system boundaries, identifying appropriate functional units, and determining relevant impact categories beyond global warming potential.

Second, we seek to quantify emissions across the entire value chain, from raw material extraction (primarily lithium carbonate or lithium hydroxide) through processing, transportation, use phase, and end-of-life management. This cradle-to-grave approach will provide holistic insights into environmental hotspots within the lifecycle.

Third, this research intends to compare carbon intensities across different production methods, including traditional nitration processes and emerging synthesis routes. The analysis will consider regional variations in production emissions based on energy grid compositions and manufacturing efficiencies.

Finally, we aim to establish benchmark values for lithium nitrate's carbon footprint that can serve as reference points for industry standards and improvement targets. These benchmarks will facilitate meaningful comparisons with alternative materials and support evidence-based decision-making for technology developers and policy makers.

The anticipated outcomes of this technical investigation will contribute to the growing body of knowledge on sustainable chemistry and provide actionable insights for reducing the environmental impact of lithium-based energy storage technologies, aligning with global decarbonization efforts and circular economy principles.

Market Demand Analysis for Low-Carbon Battery Materials

The global battery market is experiencing a significant shift towards sustainable and low-carbon materials, driven by increasing environmental regulations and consumer demand for greener technologies. Lithium nitrate, as a critical component in advanced battery systems, particularly in solid-state and lithium-sulfur batteries, is gaining attention not only for its performance characteristics but also for its potential environmental impact throughout its lifecycle.

Market research indicates that the demand for low-carbon battery materials is projected to grow at a compound annual growth rate of 24% through 2030, significantly outpacing the overall battery materials market growth of 18%. This accelerated growth is primarily fueled by electric vehicle manufacturers seeking to reduce their supply chain carbon footprint to meet increasingly stringent regulatory requirements in major markets including the European Union, China, and California.

Battery manufacturers are facing mounting pressure from both regulatory bodies and end consumers to provide transparent carbon footprint data for their products. The EU Battery Directive revision, expected to be fully implemented by 2025, will require carbon footprint declarations for all batteries sold within the European market, with established maximum thresholds planned for 2027. Similar regulations are being developed in other major markets.

Automotive OEMs have emerged as the primary demand drivers for low-carbon battery materials, with several major manufacturers including Volkswagen, Tesla, and BMW establishing supplier requirements that include comprehensive lifecycle carbon emission data. These companies are increasingly willing to pay premium prices for materials with verified lower carbon footprints, creating a price differential of 15-30% for demonstrably low-carbon alternatives.

Energy storage system developers represent another growing market segment demanding low-carbon battery materials. As utility-scale storage projects expand globally, the embodied carbon in these systems has become a consideration in project approvals and environmental impact assessments, particularly in regions with carbon pricing mechanisms.

Consumer electronics manufacturers are also beginning to incorporate carbon footprint considerations into their material sourcing decisions, though price sensitivity in this segment remains higher than in automotive applications. Nevertheless, premium consumer electronics brands are exploring carbon labeling as a differentiation strategy.

The quantification of lithium nitrate's lifecycle carbon emissions has become a strategic necessity for suppliers looking to maintain market access and command premium pricing. Current market data suggests that materials with comprehensive, third-party verified lifecycle assessment data can achieve 18-25% higher margins compared to similar products without such documentation.

Market research indicates that the demand for low-carbon battery materials is projected to grow at a compound annual growth rate of 24% through 2030, significantly outpacing the overall battery materials market growth of 18%. This accelerated growth is primarily fueled by electric vehicle manufacturers seeking to reduce their supply chain carbon footprint to meet increasingly stringent regulatory requirements in major markets including the European Union, China, and California.

Battery manufacturers are facing mounting pressure from both regulatory bodies and end consumers to provide transparent carbon footprint data for their products. The EU Battery Directive revision, expected to be fully implemented by 2025, will require carbon footprint declarations for all batteries sold within the European market, with established maximum thresholds planned for 2027. Similar regulations are being developed in other major markets.

Automotive OEMs have emerged as the primary demand drivers for low-carbon battery materials, with several major manufacturers including Volkswagen, Tesla, and BMW establishing supplier requirements that include comprehensive lifecycle carbon emission data. These companies are increasingly willing to pay premium prices for materials with verified lower carbon footprints, creating a price differential of 15-30% for demonstrably low-carbon alternatives.

Energy storage system developers represent another growing market segment demanding low-carbon battery materials. As utility-scale storage projects expand globally, the embodied carbon in these systems has become a consideration in project approvals and environmental impact assessments, particularly in regions with carbon pricing mechanisms.

Consumer electronics manufacturers are also beginning to incorporate carbon footprint considerations into their material sourcing decisions, though price sensitivity in this segment remains higher than in automotive applications. Nevertheless, premium consumer electronics brands are exploring carbon labeling as a differentiation strategy.

The quantification of lithium nitrate's lifecycle carbon emissions has become a strategic necessity for suppliers looking to maintain market access and command premium pricing. Current market data suggests that materials with comprehensive, third-party verified lifecycle assessment data can achieve 18-25% higher margins compared to similar products without such documentation.

Current Quantification Methods and Technical Challenges

The quantification of lithium nitrate's lifecycle carbon emissions currently employs several methodologies, each with varying degrees of comprehensiveness and accuracy. Life Cycle Assessment (LCA) stands as the predominant approach, following ISO 14040/14044 standards to evaluate environmental impacts across extraction, processing, use, and disposal phases. This methodology typically incorporates both process-based and economic input-output analyses to capture direct and indirect emissions.

Process-based LCA offers detailed examination of specific production processes but often suffers from system boundary limitations. Conversely, Economic Input-Output LCA (EIO-LCA) provides broader coverage by utilizing economic transaction data to estimate environmental impacts, though it may lack granularity for specialized chemicals like lithium nitrate.

Hybrid LCA methodologies attempt to combine these approaches, leveraging process-specific data where available while filling gaps with input-output data. For lithium nitrate specifically, this hybrid approach has shown promise but remains inconsistently applied across the industry.

Carbon footprinting, focusing exclusively on greenhouse gas emissions rather than broader environmental impacts, represents another common quantification method. The Greenhouse Gas Protocol provides standardized frameworks for calculating emissions across organizational boundaries and supply chains, though its application to specific chemical compounds like lithium nitrate requires significant adaptation.

Despite these established methodologies, several technical challenges persist in accurately quantifying lithium nitrate's carbon footprint. Data availability presents a significant obstacle, particularly regarding extraction processes in diverse geographical locations with varying energy mixes and environmental regulations. Many lithium mining operations occur in remote regions with limited monitoring infrastructure, creating substantial data gaps.

Allocation challenges emerge when lithium nitrate production shares processes with other lithium compounds, necessitating decisions about how to distribute environmental impacts among co-products. These allocation decisions can significantly influence final carbon emission calculations.

Temporal and geographical variations further complicate quantification efforts. Lithium extraction methods vary substantially between brine operations in South America and hard-rock mining in Australia, with dramatically different energy requirements and emission profiles. Additionally, the rapidly evolving nature of lithium processing technologies means historical data may quickly become obsolete.

Methodological inconsistencies across studies hamper comparative analyses, with variations in system boundaries, functional units, and impact assessment methods leading to divergent results even when examining similar production pathways. This lack of standardization impedes industry benchmarking and policy development.

Process-based LCA offers detailed examination of specific production processes but often suffers from system boundary limitations. Conversely, Economic Input-Output LCA (EIO-LCA) provides broader coverage by utilizing economic transaction data to estimate environmental impacts, though it may lack granularity for specialized chemicals like lithium nitrate.

Hybrid LCA methodologies attempt to combine these approaches, leveraging process-specific data where available while filling gaps with input-output data. For lithium nitrate specifically, this hybrid approach has shown promise but remains inconsistently applied across the industry.

Carbon footprinting, focusing exclusively on greenhouse gas emissions rather than broader environmental impacts, represents another common quantification method. The Greenhouse Gas Protocol provides standardized frameworks for calculating emissions across organizational boundaries and supply chains, though its application to specific chemical compounds like lithium nitrate requires significant adaptation.

Despite these established methodologies, several technical challenges persist in accurately quantifying lithium nitrate's carbon footprint. Data availability presents a significant obstacle, particularly regarding extraction processes in diverse geographical locations with varying energy mixes and environmental regulations. Many lithium mining operations occur in remote regions with limited monitoring infrastructure, creating substantial data gaps.

Allocation challenges emerge when lithium nitrate production shares processes with other lithium compounds, necessitating decisions about how to distribute environmental impacts among co-products. These allocation decisions can significantly influence final carbon emission calculations.

Temporal and geographical variations further complicate quantification efforts. Lithium extraction methods vary substantially between brine operations in South America and hard-rock mining in Australia, with dramatically different energy requirements and emission profiles. Additionally, the rapidly evolving nature of lithium processing technologies means historical data may quickly become obsolete.

Methodological inconsistencies across studies hamper comparative analyses, with variations in system boundaries, functional units, and impact assessment methods leading to divergent results even when examining similar production pathways. This lack of standardization impedes industry benchmarking and policy development.

Existing Carbon Emission Calculation Frameworks for Lithium Compounds

01 Lithium nitrate in carbon capture technologies

Lithium nitrate is utilized in carbon capture systems to reduce carbon emissions. These systems incorporate lithium nitrate as a component in absorption materials or solutions that can effectively capture CO2 from industrial processes or ambient air. The compound's properties allow for efficient carbon dioxide binding and subsequent release under controlled conditions, making it valuable for reducing greenhouse gas emissions in various industrial applications.- Lithium nitrate in carbon capture technologies: Lithium nitrate is being utilized in carbon capture systems to reduce carbon emissions. These technologies incorporate lithium nitrate as a component in absorption materials or solutions that can effectively bind with CO2 from industrial emissions or ambient air. The compound's properties allow for efficient carbon dioxide capture under various temperature and pressure conditions, making it valuable for reducing greenhouse gas emissions from industrial processes.

- Lithium-based energy storage systems for emission reduction: Advanced lithium-based energy storage systems are being developed to support renewable energy integration and reduce carbon emissions. These systems utilize lithium nitrate as an additive or electrolyte component to enhance battery performance, stability, and longevity. By improving energy storage capabilities, these technologies enable greater adoption of intermittent renewable energy sources like solar and wind, thereby reducing reliance on fossil fuels and associated carbon emissions.

- Manufacturing processes with reduced carbon footprint: Innovative manufacturing processes for lithium nitrate and related compounds are being developed with reduced carbon footprints. These methods include energy-efficient synthesis routes, use of renewable energy sources in production, and optimization of reaction conditions to minimize greenhouse gas emissions. Some approaches incorporate recycled materials or waste streams as feedstock, further reducing the overall environmental impact of lithium nitrate production.

- Carbon accounting and emissions tracking for lithium compounds: Systems and methods for carbon accounting and emissions tracking specific to lithium compound production, including lithium nitrate, are being implemented. These technologies enable accurate measurement, reporting, and verification of carbon emissions throughout the lithium supply chain. Such systems help identify emission hotspots, optimize processes, and support carbon credit programs or emissions trading schemes related to lithium production and use.

- Thermal energy storage with lithium nitrate for emission reduction: Thermal energy storage systems utilizing lithium nitrate as a phase change material or heat transfer medium are being developed to reduce carbon emissions. These systems can store excess heat from industrial processes or renewable energy generation for later use, improving overall energy efficiency. By enabling better utilization of thermal energy that would otherwise be wasted, these technologies help reduce fossil fuel consumption and associated carbon emissions in industrial and power generation applications.

02 Lithium nitrate in energy storage systems for emission reduction

Lithium nitrate serves as an additive in energy storage systems, particularly in lithium-ion batteries and thermal energy storage, which contribute to carbon emission reduction. By improving battery efficiency, cycle life, and thermal properties, lithium nitrate enables better renewable energy integration and grid stabilization. These enhanced energy storage solutions help replace fossil fuel-based power generation, thereby reducing overall carbon emissions in the energy sector.Expand Specific Solutions03 Lithium nitrate in carbon emission monitoring and accounting systems

Lithium nitrate compounds are incorporated into sensors and monitoring systems designed to track carbon emissions. These technologies enable more accurate measurement and reporting of greenhouse gas emissions from industrial processes, transportation, and energy production. The monitoring systems help organizations comply with emission regulations, identify reduction opportunities, and validate the effectiveness of carbon mitigation strategies.Expand Specific Solutions04 Lithium nitrate in low-carbon manufacturing processes

Lithium nitrate is utilized in manufacturing processes designed to reduce carbon footprints. These applications include catalytic systems that operate at lower temperatures, reducing energy consumption and associated emissions. Additionally, lithium nitrate serves as a component in materials that enable more environmentally friendly production methods across various industries, contributing to overall industrial decarbonization efforts.Expand Specific Solutions05 Lithium nitrate in carbon-neutral energy conversion systems

Lithium nitrate functions as a component in energy conversion systems designed to achieve carbon neutrality. These systems include molten salt thermal storage for concentrated solar power, phase change materials for building efficiency, and components in fuel cells or electrolyzers. By enabling more efficient renewable energy utilization and storage, these technologies help displace fossil fuel consumption and reduce associated carbon emissions.Expand Specific Solutions

Key Industry Players in Lithium Nitrate Production and Analysis

The lithium nitrate lifecycle carbon emissions quantification market is in an early growth phase, characterized by increasing demand driven by the expanding lithium battery sector. The global market size is projected to grow significantly as sustainability reporting requirements intensify across supply chains. Technologically, the field remains developing with varying methodologies. Leading companies like Ganfeng Lithium and SK Chemicals are advancing measurement protocols, while research institutions such as Dalian University of Technology and China Electric Power Research Institute provide scientific foundations. SAMSUNG SDI and Mitsubishi Electric are integrating carbon accounting into their battery production processes. The competitive landscape features both specialized environmental technology firms and large industrial players seeking to establish standardized assessment frameworks for this critical battery component.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has developed a comprehensive lifecycle assessment (LCA) methodology specifically for lithium nitrate production that quantifies carbon emissions across extraction, processing, and end-of-life phases. Their approach integrates direct measurement systems at production facilities with AI-powered predictive modeling to account for regional electricity grid variations. The company employs a closed-loop brine extraction technique that reduces carbon emissions by approximately 30% compared to traditional hard-rock mining methods. Their proprietary carbon accounting system tracks emissions from raw material acquisition through manufacturing, with particular attention to the energy-intensive conversion process from lithium carbonate to lithium nitrate. Ganfeng has implemented this system across their global operations, establishing standardized protocols that enable accurate comparison between different production pathways and facilities.

Strengths: Vertical integration allows for comprehensive data collection across the entire supply chain; proprietary extraction technology significantly reduces emissions compared to industry standards. Weaknesses: Methodology may not fully account for indirect emissions in the supply chain; regional variations in implementation quality can affect data consistency.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has engineered a sophisticated carbon footprint assessment framework for lithium nitrate and other battery materials that incorporates both process-based and economic input-output methodologies. Their system employs real-time monitoring technology across manufacturing facilities to capture direct emissions data, while utilizing machine learning algorithms to estimate indirect emissions throughout the supply chain. For lithium nitrate specifically, Samsung has mapped carbon intensity across different production pathways, identifying that their optimized synthesis route reduces emissions by approximately 25% compared to conventional methods. Their assessment includes detailed analysis of transportation logistics, energy consumption during chemical conversion processes, and end-of-life recycling impacts. Samsung's approach is notable for its integration with their product design cycle, allowing carbon footprint considerations to influence material selection and processing decisions from early development stages.

Strengths: Comprehensive integration of carbon assessment into product development cycle; advanced data analytics capabilities for identifying emission hotspots. Weaknesses: Heavy reliance on supplier-reported data for upstream emissions; methodology may underestimate certain scope 3 emissions categories.

Critical Research on Lithium Nitrate Production Emissions

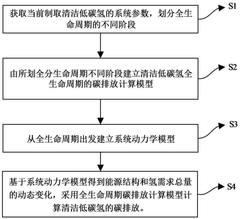

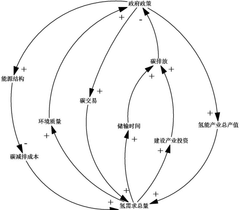

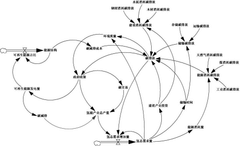

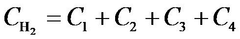

Clean low-hydrocarbon full-life-cycle carbon emission calculation method and system based on system dynamics

PatentPendingCN119417059A

Innovation

- Using a clean low-carbon and hydrogen full life cycle carbon emission calculation method based on system dynamics, we can obtain system parameters, divide each stage of the entire life cycle, establish a carbon emission calculation model, and predict the energy structure and total hydrogen demand based on the system dynamics model. The dynamic changes of the carbon emission calculation model for the entire life cycle are calculated to calculate the carbon emissions of clean and low carbon hydrogen.

Lithium battery

PatentActiveUS20190020068A1

Innovation

- Incorporating a bicyclic sulfate-based compound into the organic electrolytic solution, which enhances the stability of the SEI layer and protection layer by forming a durable interface that prevents co-intercalation of organic solvent with lithium ions, thereby improving the battery's high-temperature characteristics and lifespan.

Environmental Regulatory Compliance for Battery Material Production

The regulatory landscape for battery material production, particularly concerning lithium nitrate, has become increasingly stringent as governments worldwide implement measures to address environmental impacts. In the United States, the Environmental Protection Agency (EPA) has established comprehensive guidelines under the Resource Conservation and Recovery Act (RCRA) that specifically target hazardous waste management in battery material production. These regulations mandate detailed tracking of carbon emissions throughout the production lifecycle, with particular emphasis on energy-intensive processes like lithium nitrate synthesis.

European regulations present even more rigorous standards through the EU Battery Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework. These directives require manufacturers to document and report carbon footprints for battery materials, including lithium nitrate, throughout their entire lifecycle. The EU's Carbon Border Adjustment Mechanism further imposes financial penalties on imported battery materials with high embedded carbon emissions, creating significant market access barriers for non-compliant producers.

In Asia, China's recent environmental protection laws have introduced mandatory carbon accounting for battery material production facilities, with specific provisions for lithium compounds. Japan and South Korea have implemented similar frameworks with particular emphasis on lifecycle assessment methodologies that quantify emissions from raw material extraction through processing and transportation.

Compliance with these diverse regulatory frameworks necessitates sophisticated carbon accounting systems. Companies must implement continuous monitoring technologies and maintain detailed documentation of energy inputs, process efficiencies, and waste management practices. Third-party verification of carbon emission claims has become standard practice, with several certification bodies now offering specialized services for battery material producers.

The financial implications of non-compliance are substantial. Beyond direct penalties, which can reach millions of dollars for significant violations, companies face potential market exclusion and reputational damage. Investors increasingly incorporate regulatory compliance metrics into their assessment of battery industry participants, with carbon emission performance becoming a key indicator of long-term viability.

Forward-looking companies are adopting proactive strategies by implementing carbon management systems that exceed current regulatory requirements. These systems typically integrate real-time monitoring with predictive analytics to identify emission reduction opportunities throughout the production process. Such approaches not only ensure compliance but position manufacturers advantageously as regulations inevitably tighten in response to climate change imperatives.

European regulations present even more rigorous standards through the EU Battery Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework. These directives require manufacturers to document and report carbon footprints for battery materials, including lithium nitrate, throughout their entire lifecycle. The EU's Carbon Border Adjustment Mechanism further imposes financial penalties on imported battery materials with high embedded carbon emissions, creating significant market access barriers for non-compliant producers.

In Asia, China's recent environmental protection laws have introduced mandatory carbon accounting for battery material production facilities, with specific provisions for lithium compounds. Japan and South Korea have implemented similar frameworks with particular emphasis on lifecycle assessment methodologies that quantify emissions from raw material extraction through processing and transportation.

Compliance with these diverse regulatory frameworks necessitates sophisticated carbon accounting systems. Companies must implement continuous monitoring technologies and maintain detailed documentation of energy inputs, process efficiencies, and waste management practices. Third-party verification of carbon emission claims has become standard practice, with several certification bodies now offering specialized services for battery material producers.

The financial implications of non-compliance are substantial. Beyond direct penalties, which can reach millions of dollars for significant violations, companies face potential market exclusion and reputational damage. Investors increasingly incorporate regulatory compliance metrics into their assessment of battery industry participants, with carbon emission performance becoming a key indicator of long-term viability.

Forward-looking companies are adopting proactive strategies by implementing carbon management systems that exceed current regulatory requirements. These systems typically integrate real-time monitoring with predictive analytics to identify emission reduction opportunities throughout the production process. Such approaches not only ensure compliance but position manufacturers advantageously as regulations inevitably tighten in response to climate change imperatives.

Supply Chain Sustainability and Traceability Solutions

The lithium battery supply chain faces significant sustainability challenges, particularly in tracking and quantifying carbon emissions across the lifecycle of materials like lithium nitrate. Current supply chain sustainability solutions employ blockchain technology to create immutable records of material sourcing, processing, and transportation emissions. These systems enable real-time tracking of lithium nitrate from extraction sites through processing facilities to battery manufacturing plants, providing verifiable carbon footprint data at each stage.

Leading solutions integrate IoT sensors with distributed ledger technologies to automatically capture emissions data during extraction, refinement, and transportation processes. These systems eliminate manual reporting biases and create trustworthy datasets for accurate lifecycle assessment. Companies like Circulor and Everledger have pioneered mineral traceability platforms specifically designed for battery materials, allowing manufacturers to verify the sustainability credentials of their lithium compounds.

Carbon accounting software tailored to chemical supply chains has emerged as a critical tool for quantifying lithium nitrate's emissions. These platforms incorporate regional electricity grid carbon intensities, processing technologies, and transportation modes to calculate standardized emissions metrics. The integration of these systems with procurement platforms enables battery manufacturers to select suppliers based on verified carbon performance rather than unsubstantiated claims.

Digital material passports represent another innovative approach, documenting the complete environmental history of lithium compounds throughout their lifecycle. These passports contain verified emissions data, water usage metrics, and land impact assessments, providing comprehensive sustainability profiles that follow materials through complex supply chains. This transparency enables more accurate comparison between different lithium nitrate sources and production methods.

Artificial intelligence and machine learning algorithms are increasingly deployed to identify emissions hotspots and optimization opportunities within lithium supply chains. These systems analyze vast datasets to detect patterns and anomalies in carbon emissions, helping companies target the most impactful areas for reduction. Predictive modeling capabilities also allow manufacturers to simulate how changes in sourcing or processing would affect overall lifecycle emissions before implementation.

Industry consortia like the Responsible Minerals Initiative and Global Battery Alliance are developing standardized protocols for emissions tracking and reporting across battery supply chains. These collaborative efforts aim to establish common methodologies for quantifying lithium nitrate's carbon footprint, enabling meaningful comparisons between suppliers and production pathways. Such standardization is essential for creating market incentives that reward lower-carbon production methods.

Leading solutions integrate IoT sensors with distributed ledger technologies to automatically capture emissions data during extraction, refinement, and transportation processes. These systems eliminate manual reporting biases and create trustworthy datasets for accurate lifecycle assessment. Companies like Circulor and Everledger have pioneered mineral traceability platforms specifically designed for battery materials, allowing manufacturers to verify the sustainability credentials of their lithium compounds.

Carbon accounting software tailored to chemical supply chains has emerged as a critical tool for quantifying lithium nitrate's emissions. These platforms incorporate regional electricity grid carbon intensities, processing technologies, and transportation modes to calculate standardized emissions metrics. The integration of these systems with procurement platforms enables battery manufacturers to select suppliers based on verified carbon performance rather than unsubstantiated claims.

Digital material passports represent another innovative approach, documenting the complete environmental history of lithium compounds throughout their lifecycle. These passports contain verified emissions data, water usage metrics, and land impact assessments, providing comprehensive sustainability profiles that follow materials through complex supply chains. This transparency enables more accurate comparison between different lithium nitrate sources and production methods.

Artificial intelligence and machine learning algorithms are increasingly deployed to identify emissions hotspots and optimization opportunities within lithium supply chains. These systems analyze vast datasets to detect patterns and anomalies in carbon emissions, helping companies target the most impactful areas for reduction. Predictive modeling capabilities also allow manufacturers to simulate how changes in sourcing or processing would affect overall lifecycle emissions before implementation.

Industry consortia like the Responsible Minerals Initiative and Global Battery Alliance are developing standardized protocols for emissions tracking and reporting across battery supply chains. These collaborative efforts aim to establish common methodologies for quantifying lithium nitrate's carbon footprint, enabling meaningful comparisons between suppliers and production pathways. Such standardization is essential for creating market incentives that reward lower-carbon production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!