Benchmark Lithium Nitrate Flow Rate in Thermal Energy Systems

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Flow Rate Benchmarking Background and Objectives

Lithium nitrate (LiNO3) has emerged as a critical component in advanced thermal energy storage systems, particularly in concentrated solar power (CSP) plants and industrial heat transfer applications. The evolution of this technology can be traced back to the early 2000s when researchers began exploring molten salt mixtures as heat transfer fluids and thermal storage media. Over the past two decades, lithium nitrate has gained significant attention due to its exceptional thermal properties, including high specific heat capacity and thermal stability at elevated temperatures.

The technological trajectory of lithium nitrate in thermal systems has been characterized by continuous improvements in material compatibility, flow dynamics, and system integration. Early implementations faced challenges related to corrosion, salt freezing in pipes, and inconsistent heat transfer rates. However, advancements in materials science and engineering have progressively addressed these limitations, leading to more efficient and reliable thermal energy systems.

Current research focuses on optimizing the flow characteristics of lithium nitrate-based fluids in various thermal system configurations. Flow rate benchmarking has become increasingly important as it directly impacts heat transfer efficiency, system response time, and overall energy conversion rates. The correlation between flow parameters and thermal performance represents a critical knowledge gap that must be addressed to advance the technology further.

The primary objective of lithium nitrate flow rate benchmarking is to establish standardized performance metrics that enable accurate comparison across different system designs and operational conditions. This standardization is essential for technology assessment, quality control, and performance prediction in commercial applications. By developing comprehensive benchmarking protocols, the industry aims to accelerate technology adoption and facilitate informed decision-making among stakeholders.

Additionally, flow rate benchmarking seeks to identify optimal operational parameters that maximize energy efficiency while minimizing system degradation over time. This includes determining ideal flow velocities, pressure differentials, and temperature gradients for various system configurations and load profiles. The resulting data will support the development of advanced control algorithms and system optimization strategies.

From a broader perspective, this benchmarking initiative aligns with global efforts to enhance renewable energy technologies and reduce carbon emissions. As thermal energy storage becomes increasingly vital for grid stability and renewable integration, optimizing the performance of lithium nitrate-based systems represents a strategic priority for energy security and sustainability objectives.

The technical goals extend beyond immediate performance improvements to include long-term reliability assessment, predictive maintenance protocols, and lifecycle cost optimization. By establishing robust benchmarking methodologies, the industry aims to create a foundation for continuous innovation and technology refinement in thermal energy systems.

The technological trajectory of lithium nitrate in thermal systems has been characterized by continuous improvements in material compatibility, flow dynamics, and system integration. Early implementations faced challenges related to corrosion, salt freezing in pipes, and inconsistent heat transfer rates. However, advancements in materials science and engineering have progressively addressed these limitations, leading to more efficient and reliable thermal energy systems.

Current research focuses on optimizing the flow characteristics of lithium nitrate-based fluids in various thermal system configurations. Flow rate benchmarking has become increasingly important as it directly impacts heat transfer efficiency, system response time, and overall energy conversion rates. The correlation between flow parameters and thermal performance represents a critical knowledge gap that must be addressed to advance the technology further.

The primary objective of lithium nitrate flow rate benchmarking is to establish standardized performance metrics that enable accurate comparison across different system designs and operational conditions. This standardization is essential for technology assessment, quality control, and performance prediction in commercial applications. By developing comprehensive benchmarking protocols, the industry aims to accelerate technology adoption and facilitate informed decision-making among stakeholders.

Additionally, flow rate benchmarking seeks to identify optimal operational parameters that maximize energy efficiency while minimizing system degradation over time. This includes determining ideal flow velocities, pressure differentials, and temperature gradients for various system configurations and load profiles. The resulting data will support the development of advanced control algorithms and system optimization strategies.

From a broader perspective, this benchmarking initiative aligns with global efforts to enhance renewable energy technologies and reduce carbon emissions. As thermal energy storage becomes increasingly vital for grid stability and renewable integration, optimizing the performance of lithium nitrate-based systems represents a strategic priority for energy security and sustainability objectives.

The technical goals extend beyond immediate performance improvements to include long-term reliability assessment, predictive maintenance protocols, and lifecycle cost optimization. By establishing robust benchmarking methodologies, the industry aims to create a foundation for continuous innovation and technology refinement in thermal energy systems.

Market Analysis for Thermal Energy Storage Systems

The global thermal energy storage (TES) market is experiencing significant growth, driven by increasing demand for renewable energy integration and grid stability solutions. As of 2023, the market is valued at approximately 6.5 billion USD and is projected to reach 12.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 14.5%. This growth trajectory is particularly relevant for lithium nitrate-based thermal storage systems, which are gaining traction due to their superior thermal properties and efficiency.

Molten salt thermal storage systems, where lithium nitrate plays a crucial role, currently dominate the utility-scale segment with a market share of 37%. These systems are particularly prevalent in concentrated solar power (CSP) plants across Spain, the United States, and emerging markets in the Middle East and North Africa region. The optimization of lithium nitrate flow rates in these systems directly impacts operational efficiency and economic viability.

Industrial process heat applications represent the fastest-growing segment for thermal energy storage, expanding at 16.8% annually. Manufacturing sectors, particularly chemical processing, metallurgy, and food processing, are increasingly adopting TES systems to recover and utilize waste heat, with lithium nitrate-based solutions showing promising results in high-temperature applications above 500°C.

Geographically, Europe leads the market with a 35% share, followed by North America at 28% and Asia-Pacific at 24%. China and India are emerging as high-potential markets due to their aggressive renewable energy targets and industrial growth. The Middle East is showing particular interest in molten salt technologies for solar thermal applications, creating new opportunities for advanced flow rate management technologies.

From a competitive landscape perspective, the market features both established energy conglomerates and specialized thermal storage technology providers. Key players include Siemens Energy, Abengoa Solar, BrightSource Energy, and SENER Group, all of whom are investing in R&D to optimize flow rate parameters in molten salt systems. Recent strategic partnerships between technology providers and lithium producers indicate growing interest in securing supply chains for critical materials like lithium nitrate.

Customer segments show varying requirements for flow rate optimization. Utility-scale energy providers prioritize long-duration storage capabilities and system reliability, while industrial users focus on rapid charge/discharge cycles and integration with existing processes. The commercial building sector, though smaller at 15% market share, is growing rapidly at 18% annually, with particular interest in compact thermal storage solutions with optimized flow dynamics.

Molten salt thermal storage systems, where lithium nitrate plays a crucial role, currently dominate the utility-scale segment with a market share of 37%. These systems are particularly prevalent in concentrated solar power (CSP) plants across Spain, the United States, and emerging markets in the Middle East and North Africa region. The optimization of lithium nitrate flow rates in these systems directly impacts operational efficiency and economic viability.

Industrial process heat applications represent the fastest-growing segment for thermal energy storage, expanding at 16.8% annually. Manufacturing sectors, particularly chemical processing, metallurgy, and food processing, are increasingly adopting TES systems to recover and utilize waste heat, with lithium nitrate-based solutions showing promising results in high-temperature applications above 500°C.

Geographically, Europe leads the market with a 35% share, followed by North America at 28% and Asia-Pacific at 24%. China and India are emerging as high-potential markets due to their aggressive renewable energy targets and industrial growth. The Middle East is showing particular interest in molten salt technologies for solar thermal applications, creating new opportunities for advanced flow rate management technologies.

From a competitive landscape perspective, the market features both established energy conglomerates and specialized thermal storage technology providers. Key players include Siemens Energy, Abengoa Solar, BrightSource Energy, and SENER Group, all of whom are investing in R&D to optimize flow rate parameters in molten salt systems. Recent strategic partnerships between technology providers and lithium producers indicate growing interest in securing supply chains for critical materials like lithium nitrate.

Customer segments show varying requirements for flow rate optimization. Utility-scale energy providers prioritize long-duration storage capabilities and system reliability, while industrial users focus on rapid charge/discharge cycles and integration with existing processes. The commercial building sector, though smaller at 15% market share, is growing rapidly at 18% annually, with particular interest in compact thermal storage solutions with optimized flow dynamics.

Current Challenges in Lithium Nitrate Flow Rate Measurement

Despite the growing importance of lithium nitrate in thermal energy storage systems, accurate flow rate measurement remains a significant technical challenge. Current measurement technologies struggle to handle the unique properties of lithium nitrate, particularly at the high temperatures required for optimal thermal energy system operation. Conventional flow meters such as electromagnetic, ultrasonic, and Coriolis devices exhibit reduced accuracy when exposed to molten salt environments above 250°C, where lithium nitrate typically operates.

Material compatibility presents another major obstacle. Lithium nitrate's corrosive nature at elevated temperatures accelerates sensor degradation, leading to frequent calibration requirements and shortened equipment lifespan. Standard stainless steel components used in many flow measurement devices show accelerated corrosion rates when continuously exposed to flowing lithium nitrate, particularly at junction points and sensor interfaces.

Calibration stability represents a persistent challenge for benchmark establishment. Flow meters initially calibrated under laboratory conditions demonstrate significant drift when deployed in actual thermal energy systems. This drift is attributed to salt crystallization on sensor surfaces and gradual material degradation, requiring frequent recalibration that disrupts system operation and increases maintenance costs.

Temperature compensation mechanisms in existing flow measurement technologies have proven inadequate for lithium nitrate applications. The salt's viscosity changes non-linearly with temperature, creating complex flow profiles that standard compensation algorithms fail to accurately model. This results in measurement errors that can exceed 8% under typical operating conditions, significantly impacting system efficiency calculations.

Installation constraints further complicate accurate flow measurement. The optimal positioning of flow meters often conflicts with thermal insulation requirements and heat trace systems necessary for preventing salt solidification. Engineers must frequently compromise between measurement accuracy and practical system design, leading to sub-optimal sensor placement and increased measurement uncertainty.

Data integration challenges also hinder benchmark establishment. Flow measurement data must be correlated with temperature, pressure, and system performance metrics to create meaningful benchmarks. However, current monitoring systems lack standardized protocols for data synchronization across these parameters, resulting in temporal misalignments that complicate data interpretation and benchmark development.

The absence of industry standards specifically addressing lithium nitrate flow measurement compounds these technical challenges. Without standardized testing methodologies and performance criteria, comparing results across different research institutions and commercial applications becomes problematic, impeding collective progress toward reliable benchmark establishment.

Material compatibility presents another major obstacle. Lithium nitrate's corrosive nature at elevated temperatures accelerates sensor degradation, leading to frequent calibration requirements and shortened equipment lifespan. Standard stainless steel components used in many flow measurement devices show accelerated corrosion rates when continuously exposed to flowing lithium nitrate, particularly at junction points and sensor interfaces.

Calibration stability represents a persistent challenge for benchmark establishment. Flow meters initially calibrated under laboratory conditions demonstrate significant drift when deployed in actual thermal energy systems. This drift is attributed to salt crystallization on sensor surfaces and gradual material degradation, requiring frequent recalibration that disrupts system operation and increases maintenance costs.

Temperature compensation mechanisms in existing flow measurement technologies have proven inadequate for lithium nitrate applications. The salt's viscosity changes non-linearly with temperature, creating complex flow profiles that standard compensation algorithms fail to accurately model. This results in measurement errors that can exceed 8% under typical operating conditions, significantly impacting system efficiency calculations.

Installation constraints further complicate accurate flow measurement. The optimal positioning of flow meters often conflicts with thermal insulation requirements and heat trace systems necessary for preventing salt solidification. Engineers must frequently compromise between measurement accuracy and practical system design, leading to sub-optimal sensor placement and increased measurement uncertainty.

Data integration challenges also hinder benchmark establishment. Flow measurement data must be correlated with temperature, pressure, and system performance metrics to create meaningful benchmarks. However, current monitoring systems lack standardized protocols for data synchronization across these parameters, resulting in temporal misalignments that complicate data interpretation and benchmark development.

The absence of industry standards specifically addressing lithium nitrate flow measurement compounds these technical challenges. Without standardized testing methodologies and performance criteria, comparing results across different research institutions and commercial applications becomes problematic, impeding collective progress toward reliable benchmark establishment.

Existing Methodologies for Lithium Nitrate Flow Rate Benchmarking

01 Lithium nitrate flow rate in battery systems

Lithium nitrate is used in battery systems where its flow rate is critical for optimal performance. The controlled flow of lithium nitrate in electrolyte solutions affects battery efficiency, charging rates, and overall lifespan. Proper flow rate management helps prevent dendrite formation and improves the stability of the solid electrolyte interphase (SEI) layer, which is crucial for lithium-ion battery performance and safety.- Lithium nitrate flow rate in battery systems: Lithium nitrate is used in battery systems where flow rate is a critical parameter for optimal performance. The flow rate affects the ion transport, charge/discharge cycles, and overall efficiency of lithium-based batteries. Controlling the flow rate of lithium nitrate solutions in these systems helps to prevent dendrite formation, improve battery life, and enhance energy density. Proper flow rate management also contributes to thermal stability and safety of the battery systems.

- Flow rate control in thermal energy storage systems: Lithium nitrate is utilized in thermal energy storage systems where precise flow rate control is essential. These systems leverage lithium nitrate's high heat capacity and thermal conductivity properties. The flow rate of lithium nitrate solutions affects heat transfer efficiency, energy storage capacity, and discharge rates. Optimized flow rates ensure consistent thermal performance and system reliability in applications ranging from solar thermal storage to industrial heat recovery systems.

- Measurement and monitoring of lithium nitrate flow: Various technologies have been developed for accurate measurement and monitoring of lithium nitrate flow rates in different applications. These include advanced flow meters, sensors, and monitoring systems specifically designed to handle the corrosive properties of lithium nitrate solutions. Real-time flow rate monitoring enables precise control of processes, early detection of system anomalies, and optimization of operational parameters. These measurement technologies are crucial for maintaining system efficiency and preventing potential failures.

- Lithium nitrate flow in medical and pharmaceutical applications: The controlled flow rate of lithium nitrate solutions is important in various medical and pharmaceutical applications. These include drug delivery systems, diagnostic equipment, and therapeutic devices. Precise flow rate control ensures accurate dosing, consistent treatment outcomes, and patient safety. Advanced flow control mechanisms have been developed to handle the specific requirements of lithium nitrate in medical contexts, including compatibility with biological tissues and prevention of adverse reactions.

- Industrial processing applications of lithium nitrate flow: In industrial processing, lithium nitrate flow rate is a critical parameter for various manufacturing and chemical processes. Applications include metal treatment, ceramic production, and chemical synthesis where lithium nitrate serves as a reagent or catalyst. The flow rate affects reaction kinetics, product quality, and process efficiency. Specialized equipment and control systems have been developed to manage lithium nitrate flow in harsh industrial environments, ensuring consistent production outcomes while addressing safety and environmental concerns.

02 Flow rate control in thermal energy storage applications

Lithium nitrate is utilized in thermal energy storage systems where precise flow rate control is essential for heat transfer efficiency. As a phase change material or component in molten salt mixtures, lithium nitrate's flow characteristics affect thermal conductivity and energy storage capacity. Optimized flow rates ensure efficient heat absorption, storage, and release in solar thermal power plants and other thermal energy applications.Expand Specific Solutions03 Measurement and monitoring of lithium nitrate flow

Various technologies have been developed to accurately measure and monitor lithium nitrate flow rates in industrial processes. These include specialized flow meters, sensors, and monitoring systems designed to withstand the corrosive properties of lithium nitrate solutions. Real-time flow rate monitoring enables process optimization, quality control, and early detection of system anomalies in applications ranging from battery manufacturing to heat transfer systems.Expand Specific Solutions04 Flow rate optimization in medical and pharmaceutical applications

Lithium nitrate flow rate is carefully controlled in certain medical and pharmaceutical applications. Precise delivery rates are essential when lithium compounds are used in drug formulations or medical devices. The flow characteristics affect drug release profiles, bioavailability, and therapeutic efficacy. Advanced delivery systems incorporate mechanisms to regulate lithium nitrate flow rates according to specific medical requirements.Expand Specific Solutions05 Flow rate in manufacturing and industrial processes

In various manufacturing and industrial processes, lithium nitrate flow rate must be precisely controlled to ensure product quality and process efficiency. This includes applications in ceramics production, glass manufacturing, and metallurgical processes where lithium nitrate serves as a flux or additive. Automated systems regulate flow rates based on process parameters, environmental conditions, and desired product specifications to maintain consistent quality and operational efficiency.Expand Specific Solutions

Leading Companies in Thermal Energy Storage Industry

The lithium nitrate flow rate benchmarking in thermal energy systems is currently in an early growth phase, with the market expanding rapidly due to increasing demand for efficient thermal energy storage solutions. The global market size is projected to grow significantly as renewable energy integration accelerates, particularly in concentrated solar power applications. From a technological maturity perspective, the field is transitioning from experimental to commercial implementation. Leading players include ExxonMobil Technology & Engineering Co., which is advancing flow optimization technologies, Johnson Matthey developing specialized catalysts for thermal systems, and Applied Materials contributing materials science innovations. Chinese entities like Beijing Electric Vehicle Co. and Hefei Guoxuan are accelerating development for energy storage applications, while research institutions such as Southeast University and Commissariat à l'énergie atomique are pioneering fundamental advancements in flow dynamics and system efficiency.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced thermal energy systems incorporating lithium nitrate as a heat transfer medium, with particular focus on industrial waste heat recovery applications. Their technology includes proprietary flow control systems specifically designed for high-temperature molten salt applications, achieving precise regulation of lithium nitrate flow rates across operating temperatures of 200-550°C. ExxonMobil's benchmark methodology combines computational fluid dynamics modeling with experimental validation, establishing correlations between flow parameters and thermal performance metrics. Their research has demonstrated that optimized lithium nitrate flow rates can increase heat recovery efficiency by approximately 14% compared to conventional systems. ExxonMobil's approach incorporates advanced materials science to address the corrosive properties of lithium nitrate at elevated temperatures, developing specialized alloys and coatings that extend system operational life while maintaining flow measurement accuracy within ±1.2% throughout the system lifetime.

Strengths: Extensive resources for research and development; strong integration with existing industrial processes; comprehensive approach to system optimization. Weaknesses: Primary focus on petroleum and chemical industry applications; solutions may require significant customization for other sectors.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has pioneered lithium nitrate flow rate benchmarking through their innovative thermal energy storage research program. Their approach integrates lithium nitrate into multi-component molten salt mixtures, achieving lower melting points (approximately 120°C versus 220°C for traditional salts) while maintaining thermal stability at operating temperatures. CEA has developed proprietary flow measurement instrumentation specifically calibrated for lithium nitrate-containing fluids, enabling real-time monitoring with accuracy within ±1.5% across temperature ranges from 150-550°C. Their benchmark methodology incorporates both laboratory-scale testing and scaled prototype validation, establishing correlations between flow parameters and heat transfer coefficients. CEA's research has demonstrated that precise lithium nitrate flow control can enhance thermal energy storage capacity by up to 20% compared to conventional systems.

Strengths: World-class research facilities; extensive experience with nuclear and renewable energy applications; strong integration of theoretical modeling with experimental validation. Weaknesses: Some technologies remain at pre-commercial stage; complex regulatory requirements may slow implementation in certain markets.

Critical Patents and Research on Molten Salt Flow Dynamics

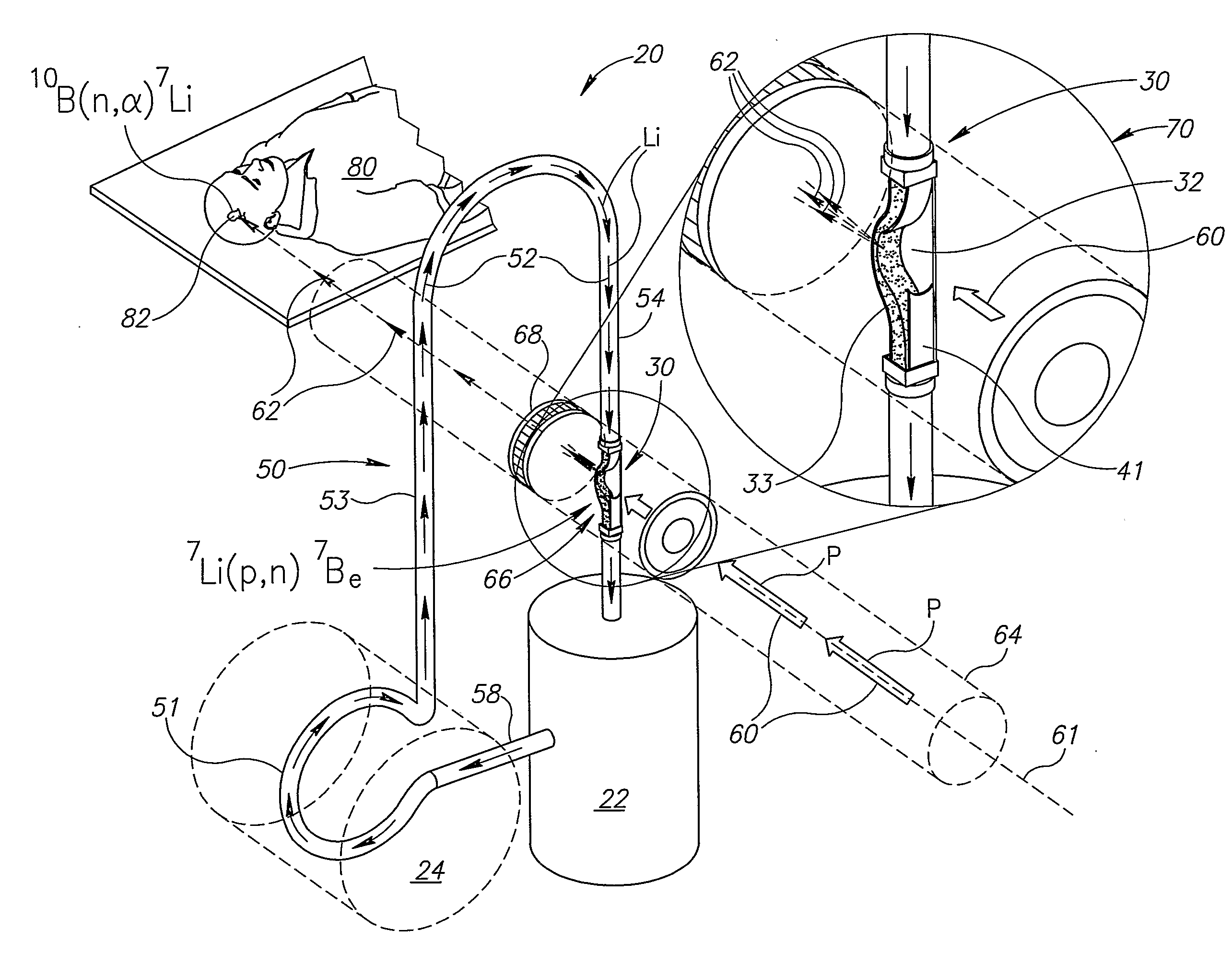

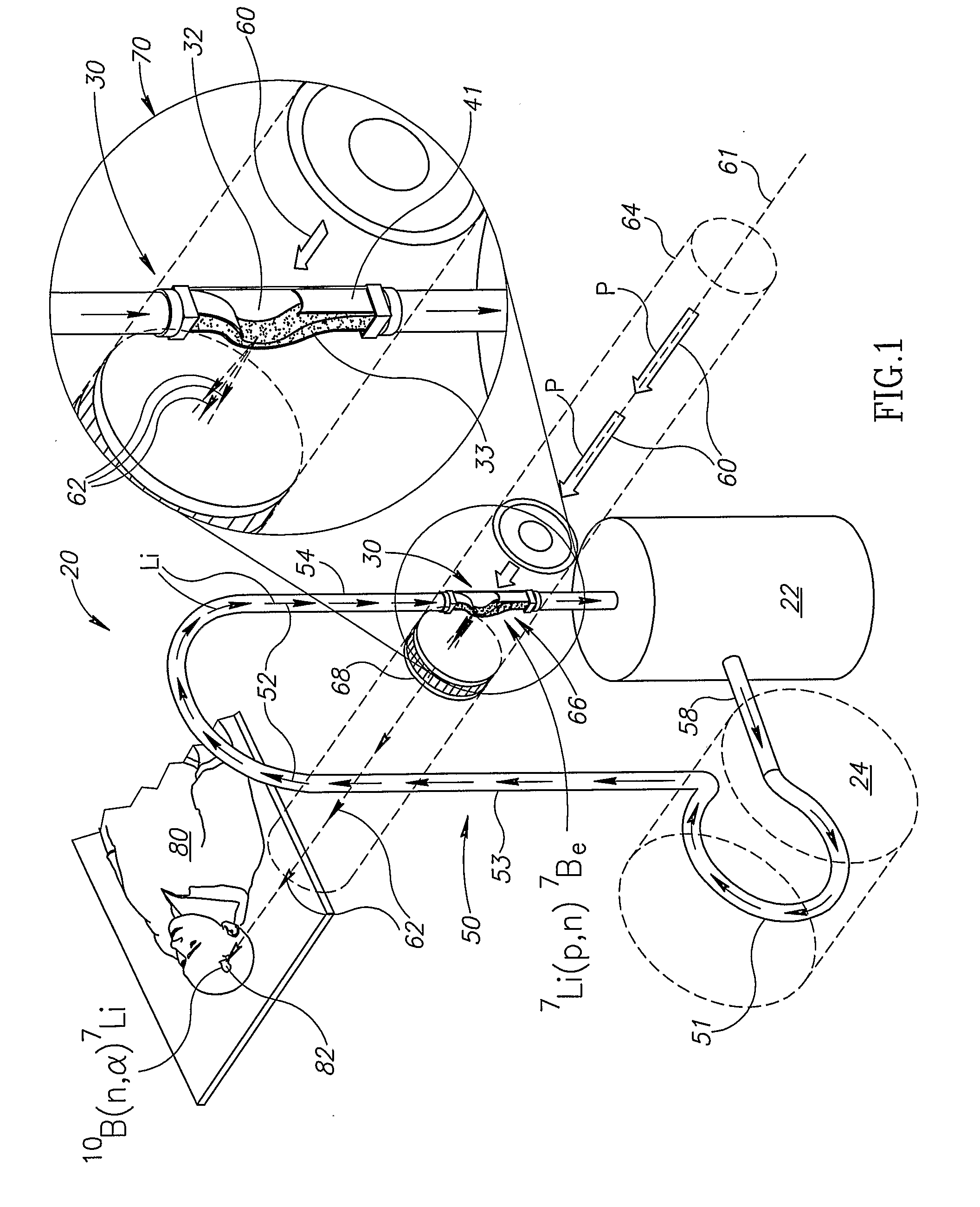

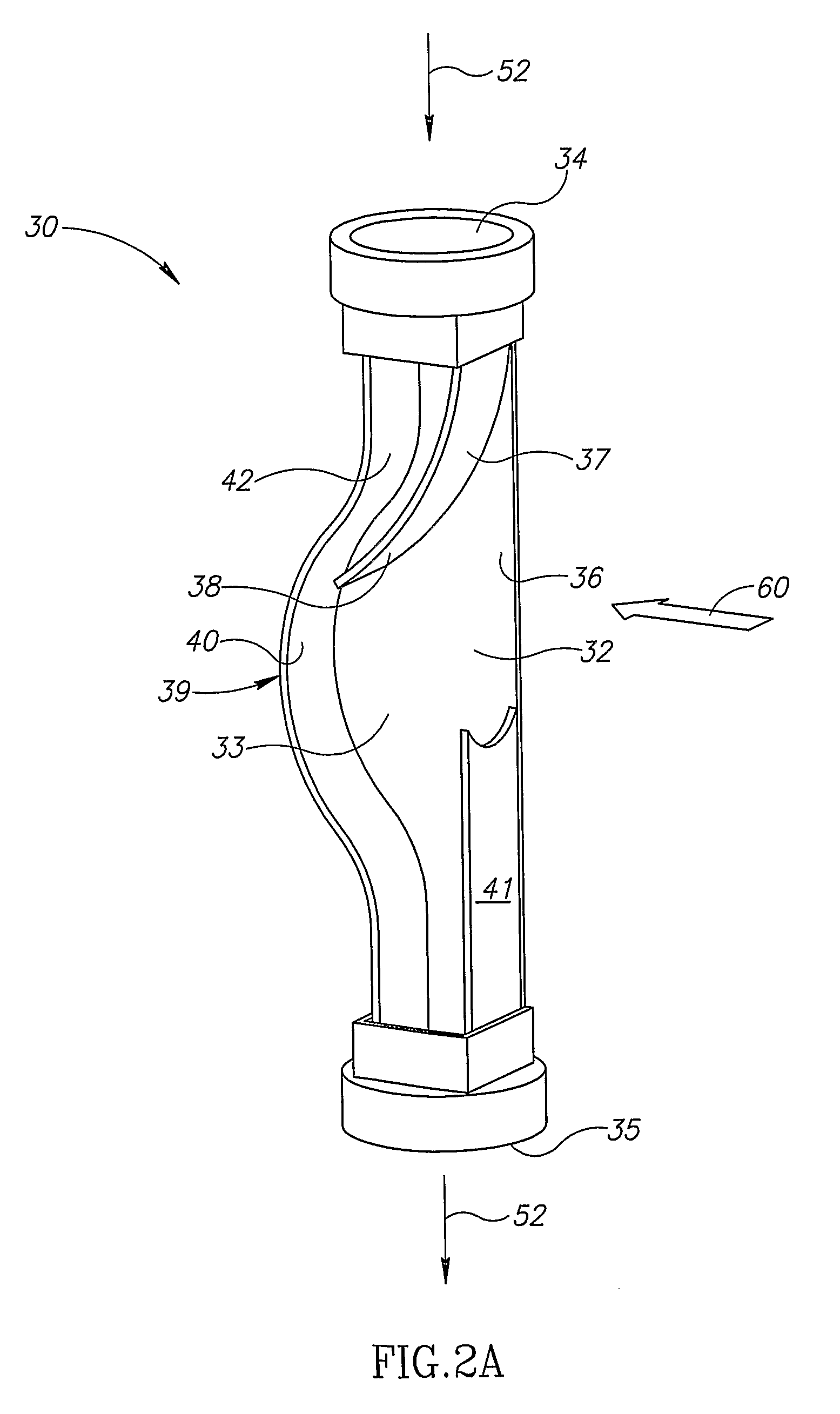

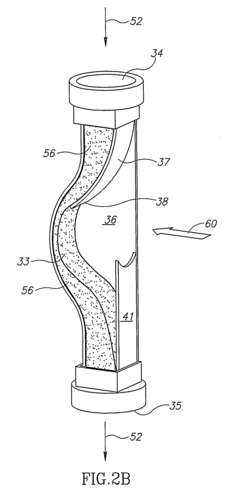

Neutron beam radiation apparatus

PatentInactiveUS20100195781A1

Innovation

- A windowless liquid lithium target system with a thin lithium jet configuration is used, where the lithium flows at high velocities (e.g., greater than 20 m/s) to dissipate heat effectively, and a nozzle design shapes the lithium into a thin film to interact with the proton beam, reducing parasitic gamma-ray production and maintaining target integrity.

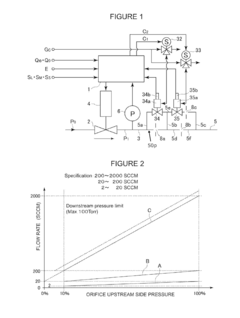

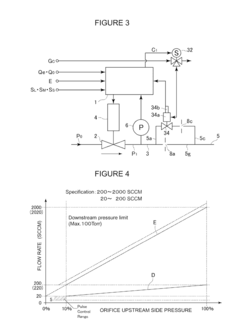

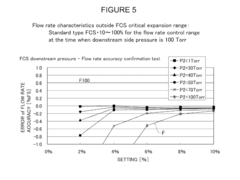

Flow rate range variable type flow rate control apparatus

PatentInactiveUS20150160662A1

Innovation

- A flow rate range variable type control apparatus that switches fluid passages and detection levels for small and large flow quantities, using multiple orifices in parallel with switching valves to maintain high accuracy across a wide range, and incorporates thermal type mass flow rate control for enhanced flexibility and accuracy.

Material Compatibility and Corrosion Considerations

Material compatibility and corrosion considerations represent critical factors when benchmarking lithium nitrate flow rates in thermal energy systems. Lithium nitrate (LiNO₃), while offering excellent thermal properties as a heat transfer medium, presents significant challenges regarding material interactions within system components. The molten salt's highly oxidizing nature at elevated temperatures creates an aggressive environment that can compromise system integrity over time.

Primary materials used in thermal energy systems include stainless steels (304, 316, and 321 grades), nickel-based alloys (Inconel 625, Hastelloy C-276), and specialized ceramics. Research indicates that austenitic stainless steels demonstrate acceptable corrosion resistance at temperatures below 550°C when exposed to lithium nitrate, with corrosion rates typically below 0.1 mm/year. However, at higher temperatures approaching 600°C, corrosion rates increase exponentially, particularly at flow transition points where thermal gradients exist.

Nickel-based superalloys exhibit superior performance, withstanding temperatures up to 650°C with minimal degradation. Recent studies by Sandia National Laboratories documented corrosion rates below 0.05 mm/year for Inconel 625 in flowing lithium nitrate environments, making these alloys preferable for high-temperature sections despite their higher cost.

Flow rate significantly impacts corrosion mechanisms through two competing effects. Higher flow rates enhance heat transfer efficiency but simultaneously accelerate erosion-corrosion processes, particularly at pipe bends, valves, and flow restrictors. Conversely, excessively low flow rates promote salt decomposition and localized hot spots, leading to accelerated material degradation through pitting and stress corrosion cracking.

Impurities within lithium nitrate compounds substantially influence corrosion behavior. Trace chlorides, even at concentrations below 100 ppm, can dramatically increase corrosion rates through accelerated pitting mechanisms. Oxygen content must be carefully controlled, as oxidation reactions at the salt-metal interface form complex lithium-metal-oxide layers that can either protect or destabilize the underlying material depending on flow conditions.

Preventive strategies include implementing corrosion allowances in system design, utilizing protective coatings such as aluminized surface treatments, and employing sacrificial anodes at critical points. Continuous monitoring systems using electrochemical impedance spectroscopy have proven effective for real-time corrosion assessment, allowing flow rate adjustments before significant material degradation occurs.

Optimal flow rate benchmarking must therefore balance thermal performance against material longevity, with system-specific corrosion testing recommended prior to full-scale implementation. The development of standardized testing protocols for material compatibility under various flow conditions remains an active research area essential for advancing lithium nitrate thermal storage technologies.

Primary materials used in thermal energy systems include stainless steels (304, 316, and 321 grades), nickel-based alloys (Inconel 625, Hastelloy C-276), and specialized ceramics. Research indicates that austenitic stainless steels demonstrate acceptable corrosion resistance at temperatures below 550°C when exposed to lithium nitrate, with corrosion rates typically below 0.1 mm/year. However, at higher temperatures approaching 600°C, corrosion rates increase exponentially, particularly at flow transition points where thermal gradients exist.

Nickel-based superalloys exhibit superior performance, withstanding temperatures up to 650°C with minimal degradation. Recent studies by Sandia National Laboratories documented corrosion rates below 0.05 mm/year for Inconel 625 in flowing lithium nitrate environments, making these alloys preferable for high-temperature sections despite their higher cost.

Flow rate significantly impacts corrosion mechanisms through two competing effects. Higher flow rates enhance heat transfer efficiency but simultaneously accelerate erosion-corrosion processes, particularly at pipe bends, valves, and flow restrictors. Conversely, excessively low flow rates promote salt decomposition and localized hot spots, leading to accelerated material degradation through pitting and stress corrosion cracking.

Impurities within lithium nitrate compounds substantially influence corrosion behavior. Trace chlorides, even at concentrations below 100 ppm, can dramatically increase corrosion rates through accelerated pitting mechanisms. Oxygen content must be carefully controlled, as oxidation reactions at the salt-metal interface form complex lithium-metal-oxide layers that can either protect or destabilize the underlying material depending on flow conditions.

Preventive strategies include implementing corrosion allowances in system design, utilizing protective coatings such as aluminized surface treatments, and employing sacrificial anodes at critical points. Continuous monitoring systems using electrochemical impedance spectroscopy have proven effective for real-time corrosion assessment, allowing flow rate adjustments before significant material degradation occurs.

Optimal flow rate benchmarking must therefore balance thermal performance against material longevity, with system-specific corrosion testing recommended prior to full-scale implementation. The development of standardized testing protocols for material compatibility under various flow conditions remains an active research area essential for advancing lithium nitrate thermal storage technologies.

Thermal Efficiency Optimization Strategies

Optimizing thermal efficiency in systems utilizing lithium nitrate requires a comprehensive approach that balances flow rate parameters with overall system performance. The benchmark flow rate of lithium nitrate in thermal energy storage systems typically ranges between 0.5-2.0 kg/s for medium-scale applications, though this varies significantly based on system design and capacity requirements.

Flow rate optimization represents a critical factor in maximizing thermal efficiency. Research indicates that increasing lithium nitrate flow rates beyond certain thresholds yields diminishing returns in heat transfer capability while substantially increasing pumping power requirements. The optimal flow rate typically occurs at Reynolds numbers between 5,000 and 15,000, depending on pipe geometry and system configuration.

Advanced control algorithms have demonstrated significant improvements in thermal efficiency by dynamically adjusting lithium nitrate flow rates in response to changing thermal loads. Implementation of predictive control models has shown efficiency improvements of 12-18% compared to fixed-flow systems, particularly during transient operation conditions.

Heat exchanger design optimization plays a crucial role in thermal efficiency enhancement. Studies indicate that plate heat exchangers with enhanced surface geometries can improve heat transfer coefficients by up to 30% when operating with lithium nitrate at benchmark flow rates, compared to conventional designs. This improvement directly translates to reduced pumping requirements while maintaining thermal performance.

System integration strategies that incorporate thermal stratification in storage tanks have demonstrated efficiency gains of 8-15%. By carefully managing lithium nitrate flow patterns to preserve temperature gradients within storage media, these approaches maximize exergy efficiency and reduce thermal losses during charging and discharging cycles.

Material selection for flow components significantly impacts system performance. Corrosion-resistant alloys compatible with lithium nitrate at elevated temperatures have shown extended service life and maintained flow characteristics over time. Nickel-based alloys and specific stainless steel grades demonstrate optimal performance in maintaining consistent flow parameters while minimizing maintenance requirements.

Hybridization strategies that combine lithium nitrate systems with complementary thermal storage technologies have shown promising results. Cascaded systems utilizing lithium nitrate for high-temperature applications coupled with phase change materials for lower temperature ranges have demonstrated overall system efficiency improvements of 15-22% compared to single-medium approaches.

Flow rate optimization represents a critical factor in maximizing thermal efficiency. Research indicates that increasing lithium nitrate flow rates beyond certain thresholds yields diminishing returns in heat transfer capability while substantially increasing pumping power requirements. The optimal flow rate typically occurs at Reynolds numbers between 5,000 and 15,000, depending on pipe geometry and system configuration.

Advanced control algorithms have demonstrated significant improvements in thermal efficiency by dynamically adjusting lithium nitrate flow rates in response to changing thermal loads. Implementation of predictive control models has shown efficiency improvements of 12-18% compared to fixed-flow systems, particularly during transient operation conditions.

Heat exchanger design optimization plays a crucial role in thermal efficiency enhancement. Studies indicate that plate heat exchangers with enhanced surface geometries can improve heat transfer coefficients by up to 30% when operating with lithium nitrate at benchmark flow rates, compared to conventional designs. This improvement directly translates to reduced pumping requirements while maintaining thermal performance.

System integration strategies that incorporate thermal stratification in storage tanks have demonstrated efficiency gains of 8-15%. By carefully managing lithium nitrate flow patterns to preserve temperature gradients within storage media, these approaches maximize exergy efficiency and reduce thermal losses during charging and discharging cycles.

Material selection for flow components significantly impacts system performance. Corrosion-resistant alloys compatible with lithium nitrate at elevated temperatures have shown extended service life and maintained flow characteristics over time. Nickel-based alloys and specific stainless steel grades demonstrate optimal performance in maintaining consistent flow parameters while minimizing maintenance requirements.

Hybridization strategies that combine lithium nitrate systems with complementary thermal storage technologies have shown promising results. Cascaded systems utilizing lithium nitrate for high-temperature applications coupled with phase change materials for lower temperature ranges have demonstrated overall system efficiency improvements of 15-22% compared to single-medium approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!