Benchmark Lithium Nitrate Process Water Recycling Efficiency

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Process Water Recycling Background and Objectives

Lithium nitrate has emerged as a critical compound in various industrial applications, particularly in the production of lithium-ion batteries, ceramics, and specialty chemicals. The historical development of lithium nitrate processing technology can be traced back to the early 20th century, with significant advancements occurring in the 1970s and 1980s as demand for lithium compounds increased. Over the past decade, the exponential growth in electric vehicle production and energy storage systems has dramatically accelerated the need for efficient lithium processing technologies.

Water plays a crucial role in lithium nitrate production processes, serving as both a reaction medium and a carrier for dissolved lithium compounds. Traditional lithium nitrate production methods typically consume between 50-70 liters of water per kilogram of lithium nitrate produced, creating substantial environmental challenges and operational costs. The industry has recognized that water management represents a critical sustainability bottleneck in scaling production to meet growing global demand.

The evolution of water recycling technologies in lithium processing has progressed through several distinct phases. Early systems employed basic filtration and settling techniques, achieving modest recycling rates of 30-40%. The introduction of reverse osmosis systems in the 2000s improved efficiency to approximately 60-65%. Current state-of-the-art technologies incorporating multi-stage treatment processes, advanced membrane technologies, and electrochemical separation methods have pushed theoretical recycling rates to 80-85%, though practical implementation often achieves lower results.

The primary objective of benchmarking lithium nitrate process water recycling efficiency is to establish standardized performance metrics that enable meaningful comparison across different technological approaches and production facilities. This benchmarking aims to identify best practices, technological limitations, and opportunities for innovation in water recycling systems specific to lithium nitrate production.

Secondary objectives include quantifying the relationship between water recycling efficiency and overall production economics, establishing the correlation between recycling rates and environmental impact metrics, and determining the practical upper limits of recycling efficiency given current technological constraints. The benchmarking process also seeks to evaluate how different water quality parameters affect the purity of final lithium nitrate products.

From a strategic perspective, this technical research aims to support the industry's transition toward more sustainable production methods while maintaining economic viability. As regulatory pressures increase and water scarcity becomes more prevalent in key lithium-producing regions, optimizing water recycling efficiency represents both an environmental imperative and a competitive advantage for forward-thinking producers.

Water plays a crucial role in lithium nitrate production processes, serving as both a reaction medium and a carrier for dissolved lithium compounds. Traditional lithium nitrate production methods typically consume between 50-70 liters of water per kilogram of lithium nitrate produced, creating substantial environmental challenges and operational costs. The industry has recognized that water management represents a critical sustainability bottleneck in scaling production to meet growing global demand.

The evolution of water recycling technologies in lithium processing has progressed through several distinct phases. Early systems employed basic filtration and settling techniques, achieving modest recycling rates of 30-40%. The introduction of reverse osmosis systems in the 2000s improved efficiency to approximately 60-65%. Current state-of-the-art technologies incorporating multi-stage treatment processes, advanced membrane technologies, and electrochemical separation methods have pushed theoretical recycling rates to 80-85%, though practical implementation often achieves lower results.

The primary objective of benchmarking lithium nitrate process water recycling efficiency is to establish standardized performance metrics that enable meaningful comparison across different technological approaches and production facilities. This benchmarking aims to identify best practices, technological limitations, and opportunities for innovation in water recycling systems specific to lithium nitrate production.

Secondary objectives include quantifying the relationship between water recycling efficiency and overall production economics, establishing the correlation between recycling rates and environmental impact metrics, and determining the practical upper limits of recycling efficiency given current technological constraints. The benchmarking process also seeks to evaluate how different water quality parameters affect the purity of final lithium nitrate products.

From a strategic perspective, this technical research aims to support the industry's transition toward more sustainable production methods while maintaining economic viability. As regulatory pressures increase and water scarcity becomes more prevalent in key lithium-producing regions, optimizing water recycling efficiency represents both an environmental imperative and a competitive advantage for forward-thinking producers.

Market Demand Analysis for Water Recycling in Lithium Production

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. This surge has intensified water usage concerns in lithium extraction processes, creating substantial market demand for efficient water recycling technologies. Current estimates indicate that traditional lithium extraction methods consume between 500,000 to 2 million gallons of water per ton of lithium produced, highlighting the critical need for water conservation solutions.

Market analysis reveals that the water recycling segment within lithium production is projected to grow at a compound annual growth rate of 12.3% through 2030. This growth is particularly pronounced in water-stressed regions such as Chile's Atacama Desert, Argentina's lithium triangle, and parts of Australia where lithium operations compete with agricultural and community water needs. Regulatory pressures are simultaneously intensifying, with countries implementing stricter water usage regulations for mining operations.

The demand for lithium nitrate process water recycling technology stems from multiple market drivers. Primary among these is cost reduction, as water acquisition, treatment, and disposal represent approximately 18-25% of operational expenses in lithium production facilities. Companies implementing advanced water recycling systems report operational cost reductions of 15-22% over a five-year period, creating a compelling economic case beyond environmental considerations.

Environmental compliance represents another significant market driver, with mining companies facing increasing scrutiny from both regulatory bodies and investors regarding their water stewardship practices. The emergence of ESG (Environmental, Social, and Governance) investment criteria has further accelerated this trend, with water efficiency metrics becoming key performance indicators for industry participants.

Market segmentation analysis indicates varying adoption rates across different lithium production methods. Brine operations demonstrate the highest immediate demand for water recycling technologies due to their water-intensive nature, while hard-rock lithium mining operations show growing interest in closed-loop water systems to minimize environmental impact and reduce operational costs.

Geographically, the market demand distribution correlates strongly with water scarcity levels in lithium-producing regions. Latin American operations lead adoption rates, followed by Australian and Chinese producers. North American lithium projects, particularly those in development stages, are increasingly incorporating advanced water recycling systems into their initial design specifications rather than retrofitting existing operations.

Customer surveys indicate that lithium producers prioritize recycling technologies that can handle high concentrations of dissolved solids, operate with minimal energy requirements, and integrate seamlessly with existing production infrastructure. The market increasingly values solutions that can achieve water recovery rates exceeding 85% while maintaining water quality suitable for reuse in processing operations.

Market analysis reveals that the water recycling segment within lithium production is projected to grow at a compound annual growth rate of 12.3% through 2030. This growth is particularly pronounced in water-stressed regions such as Chile's Atacama Desert, Argentina's lithium triangle, and parts of Australia where lithium operations compete with agricultural and community water needs. Regulatory pressures are simultaneously intensifying, with countries implementing stricter water usage regulations for mining operations.

The demand for lithium nitrate process water recycling technology stems from multiple market drivers. Primary among these is cost reduction, as water acquisition, treatment, and disposal represent approximately 18-25% of operational expenses in lithium production facilities. Companies implementing advanced water recycling systems report operational cost reductions of 15-22% over a five-year period, creating a compelling economic case beyond environmental considerations.

Environmental compliance represents another significant market driver, with mining companies facing increasing scrutiny from both regulatory bodies and investors regarding their water stewardship practices. The emergence of ESG (Environmental, Social, and Governance) investment criteria has further accelerated this trend, with water efficiency metrics becoming key performance indicators for industry participants.

Market segmentation analysis indicates varying adoption rates across different lithium production methods. Brine operations demonstrate the highest immediate demand for water recycling technologies due to their water-intensive nature, while hard-rock lithium mining operations show growing interest in closed-loop water systems to minimize environmental impact and reduce operational costs.

Geographically, the market demand distribution correlates strongly with water scarcity levels in lithium-producing regions. Latin American operations lead adoption rates, followed by Australian and Chinese producers. North American lithium projects, particularly those in development stages, are increasingly incorporating advanced water recycling systems into their initial design specifications rather than retrofitting existing operations.

Customer surveys indicate that lithium producers prioritize recycling technologies that can handle high concentrations of dissolved solids, operate with minimal energy requirements, and integrate seamlessly with existing production infrastructure. The market increasingly values solutions that can achieve water recovery rates exceeding 85% while maintaining water quality suitable for reuse in processing operations.

Current Status and Challenges in Lithium Process Water Recovery

The global lithium industry currently faces significant challenges in water management, particularly in the recycling and recovery of process water. Current lithium extraction and processing methods, especially in brine operations, consume substantial volumes of water—approximately 500,000 gallons per ton of lithium produced. This high water consumption occurs in regions where water resources are already scarce, creating environmental concerns and operational constraints.

Traditional lithium extraction processes typically recover only 40-60% of process water, with the remainder lost to evaporation, entrainment in waste streams, or discharge. This inefficiency represents both an environmental liability and a missed economic opportunity, as fresh water acquisition costs continue to rise globally.

The benchmark for lithium nitrate process water recycling efficiency currently stands at approximately 65-70% in advanced operations. Leading companies have implemented closed-loop systems that incorporate multi-stage filtration, reverse osmosis, and electrodialysis technologies. However, these systems face persistent challenges with scaling, membrane fouling, and energy intensity.

A significant technical barrier to improved water recovery is the high concentration of contaminants in lithium process water, including magnesium, calcium, boron, and various suspended solids. These impurities complicate recycling efforts and often require energy-intensive treatment processes that diminish the economic viability of higher recovery rates.

Regulatory pressures are increasingly shaping water management practices across the lithium industry. Countries like Chile and Argentina have implemented stricter water usage regulations in lithium-rich regions, while Australia and North America are developing more comprehensive frameworks for water stewardship in mining operations.

Emerging direct lithium extraction (DLE) technologies promise improved water efficiency, with some pilot projects demonstrating potential recovery rates of 80-90%. However, these technologies remain largely unproven at commercial scale and face challenges in selectivity, durability, and operational costs.

The geographical distribution of water recovery technology development shows concentration in water-stressed regions, particularly the Lithium Triangle (Chile, Argentina, Bolivia), where necessity has driven innovation. North American and Australian operations have focused on regulatory compliance and sustainable water management as competitive advantages.

Energy consumption represents another significant challenge, as advanced water recovery systems can account for 15-25% of a lithium operation's total energy budget. This creates a sustainability paradox where water conservation efforts may increase carbon footprints unless powered by renewable energy sources.

Traditional lithium extraction processes typically recover only 40-60% of process water, with the remainder lost to evaporation, entrainment in waste streams, or discharge. This inefficiency represents both an environmental liability and a missed economic opportunity, as fresh water acquisition costs continue to rise globally.

The benchmark for lithium nitrate process water recycling efficiency currently stands at approximately 65-70% in advanced operations. Leading companies have implemented closed-loop systems that incorporate multi-stage filtration, reverse osmosis, and electrodialysis technologies. However, these systems face persistent challenges with scaling, membrane fouling, and energy intensity.

A significant technical barrier to improved water recovery is the high concentration of contaminants in lithium process water, including magnesium, calcium, boron, and various suspended solids. These impurities complicate recycling efforts and often require energy-intensive treatment processes that diminish the economic viability of higher recovery rates.

Regulatory pressures are increasingly shaping water management practices across the lithium industry. Countries like Chile and Argentina have implemented stricter water usage regulations in lithium-rich regions, while Australia and North America are developing more comprehensive frameworks for water stewardship in mining operations.

Emerging direct lithium extraction (DLE) technologies promise improved water efficiency, with some pilot projects demonstrating potential recovery rates of 80-90%. However, these technologies remain largely unproven at commercial scale and face challenges in selectivity, durability, and operational costs.

The geographical distribution of water recovery technology development shows concentration in water-stressed regions, particularly the Lithium Triangle (Chile, Argentina, Bolivia), where necessity has driven innovation. North American and Australian operations have focused on regulatory compliance and sustainable water management as competitive advantages.

Energy consumption represents another significant challenge, as advanced water recovery systems can account for 15-25% of a lithium operation's total energy budget. This creates a sustainability paradox where water conservation efforts may increase carbon footprints unless powered by renewable energy sources.

Benchmark Methodologies for Process Water Recycling Efficiency

01 Membrane filtration systems for lithium nitrate process water recycling

Advanced membrane filtration technologies are employed to efficiently separate lithium nitrate from process water streams. These systems utilize specialized membranes that selectively filter out impurities while allowing the recovery of valuable lithium compounds. The filtration process significantly improves water recycling efficiency by removing contaminants that would otherwise accumulate in closed-loop systems. This approach reduces freshwater consumption and minimizes waste discharge in lithium processing operations.- Membrane filtration systems for lithium nitrate process water recycling: Advanced membrane filtration technologies are employed to separate lithium nitrate from process water streams, enabling efficient water recycling in lithium production facilities. These systems typically utilize reverse osmosis, nanofiltration, or ultrafiltration membranes to remove impurities while concentrating the valuable lithium compounds. The filtered water can be reused in the process, significantly reducing freshwater consumption and wastewater discharge while maintaining high lithium recovery rates.

- Evaporation and crystallization techniques for lithium recovery: Evaporation and crystallization processes are utilized to recover lithium nitrate from process water while enabling water recycling. These techniques involve controlled evaporation of water to concentrate lithium solutions, followed by crystallization to separate solid lithium compounds. The condensed water vapor can be collected and recycled back into the process. This approach is particularly effective in arid regions where water conservation is critical, and can achieve high lithium recovery rates while minimizing water losses.

- Closed-loop water recycling systems for lithium extraction: Integrated closed-loop systems are designed to maximize water recycling efficiency in lithium nitrate processing. These systems incorporate multiple treatment stages including filtration, ion exchange, and purification to remove contaminants from process water. By implementing closed-loop designs, facilities can achieve water recycling rates exceeding 90%, significantly reducing environmental impact and operational costs. These systems often include real-time monitoring and control mechanisms to maintain optimal water quality for reuse.

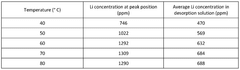

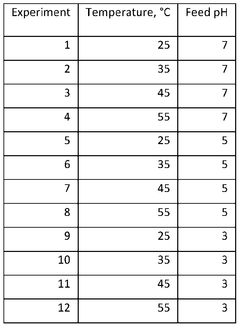

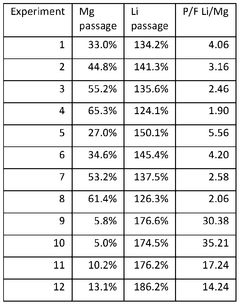

- Ion exchange and adsorption technologies for selective lithium recovery: Selective ion exchange and adsorption technologies are employed to efficiently separate lithium nitrate from process water streams. These methods utilize specialized resins or adsorbents with high selectivity for lithium ions, allowing for effective recovery of lithium compounds while producing purified water suitable for recycling. The regeneration of these materials is designed to minimize water consumption, further enhancing the overall water efficiency of the process. This approach is particularly valuable for treating dilute lithium-containing solutions.

- Energy-efficient thermal treatment processes for water recovery: Energy-efficient thermal treatment processes are implemented to recover water from lithium nitrate solutions while minimizing energy consumption. These include multi-effect evaporation, mechanical vapor recompression, and heat integration systems that reuse thermal energy throughout the process. By optimizing heat transfer and utilizing waste heat recovery, these systems can significantly reduce the energy required for water recycling while maintaining high water recovery rates. Some advanced systems incorporate renewable energy sources to further improve sustainability.

02 Evaporation and crystallization techniques for lithium recovery

Evaporation and crystallization methods are utilized to concentrate and recover lithium nitrate from process water. These techniques involve controlled evaporation of water to increase lithium concentration, followed by crystallization to separate solid lithium compounds. The process allows for high-purity recovery of lithium nitrate while enabling the treated water to be recycled back into the production system. This approach is particularly effective in arid regions where water conservation is critical for sustainable lithium production.Expand Specific Solutions03 Ion exchange and adsorption systems for lithium purification

Ion exchange and adsorption technologies are implemented to selectively remove lithium nitrate from process water streams. These systems utilize specialized resins or adsorbents that have high affinity for lithium ions, enabling efficient separation from other dissolved components. The purified water can then be recycled back into the process, while the captured lithium compounds are recovered through desorption or regeneration steps. This method achieves high water recycling efficiency while maintaining the quality requirements for lithium processing operations.Expand Specific Solutions04 Closed-loop water recycling systems for lithium nitrate processing

Integrated closed-loop systems are designed to maximize water recycling efficiency in lithium nitrate production facilities. These systems incorporate multiple treatment stages including filtration, chemical treatment, and purification to maintain water quality throughout repeated cycles. By minimizing water discharge and freshwater intake, these closed-loop approaches significantly reduce the environmental footprint of lithium processing operations. The systems often include real-time monitoring and automated control mechanisms to optimize water usage and treatment efficiency.Expand Specific Solutions05 Chemical precipitation methods for lithium recovery and water purification

Chemical precipitation techniques are employed to separate lithium compounds from process water while enabling water recycling. These methods involve the addition of specific reagents that selectively precipitate lithium as recoverable compounds, leaving purified water that can be reused in the process. The precipitation approach allows for efficient removal of impurities that would otherwise accumulate in recycled water streams. This technology is particularly valuable for improving water recycling efficiency in regions with limited water resources.Expand Specific Solutions

Key Industry Players in Lithium Water Treatment Solutions

The lithium nitrate process water recycling efficiency benchmark landscape is currently in a growth phase, with increasing market demand driven by sustainability imperatives in the lithium industry. The market is expanding rapidly as companies seek to minimize water consumption and environmental impact in lithium extraction operations. Technologically, the field shows varying maturity levels across players. Energy Exploration Technologies and Green Li-Ion are pioneering advanced extraction and recycling technologies, while established companies like LG Chem and SK Innovation are integrating water recycling into their battery production processes. Academic institutions including Jiangxi University of Science & Technology and Qinghai Institute of Salt Lakes are contributing fundamental research, while specialized firms like Hydrokemós and Guangdong Bangpu Recycling Technology are developing commercial-scale solutions with improved efficiency metrics.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has developed LiTAS (Lithium Ionic Transmission and Separation), a direct lithium extraction technology that significantly improves water recycling efficiency in lithium nitrate processing. Their system utilizes advanced metal-organic framework (MOF) membranes that selectively extract lithium ions while allowing process water to be recycled with minimal treatment. The technology reduces water consumption by approximately 70% compared to traditional evaporation methods. EnergyX's system operates at ambient temperature and pressure, requiring significantly less energy than thermal processes. Their modular design allows for scalable implementation, from pilot plants to industrial-scale operations. The company has demonstrated water recycling efficiency exceeding 90% in field trials, with minimal chemical additives required for water treatment.

Strengths: Highly selective lithium extraction with minimal water loss; energy-efficient operation that reduces overall process costs; modular design enabling flexible deployment. Weaknesses: Relatively new technology with limited long-term operational data; membrane replacement costs may impact long-term economics.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed an advanced membrane-based recycling system specifically for lithium nitrate process water. Their technology employs a multi-stage reverse osmosis (RO) and nanofiltration (NF) membrane cascade that achieves water recovery rates of up to 85-90%. The system incorporates specialized pre-treatment processes to handle the high salt concentrations typical in lithium extraction operations. Their proprietary anti-scaling technology prevents membrane fouling even with high-concentration lithium-bearing solutions. The institute has also pioneered a thermal crystallization process that works in conjunction with membrane filtration to recover valuable lithium compounds from concentrated reject streams, creating a near-closed loop system that minimizes freshwater consumption in arid regions where many lithium operations are located.

Strengths: Exceptionally high water recovery rates in challenging high-salinity environments; integrated resource recovery system that captures lithium compounds from waste streams. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized technical expertise for operation and maintenance.

Critical Technologies in Lithium Nitrate Water Purification

Lithium extraction method

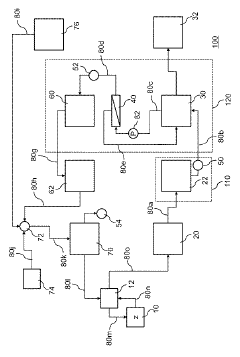

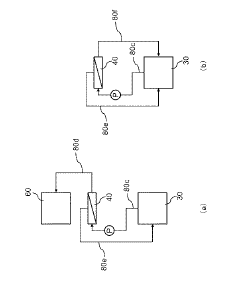

PatentWO2025137291A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

Recycling method of aqueous nitric acid solution, electrolytic processing method using the same, recycling solution of aqueous nitric acid solution, and recycling system

PatentActiveJP2021041369A

Innovation

- A method involving the reduction of hexavalent chromium to trivalent chromium using a reducing agent like elemental iron powder, followed by separation through a reverse osmosis membrane to obtain a permeate containing nitrate ions and water, with controlled chromium concentration below 5.0 ppm, thereby stabilizing the recycling process.

Environmental Impact Assessment of Lithium Water Recycling

The environmental impact assessment of lithium water recycling reveals significant ecological benefits when comparing conventional extraction methods with advanced recycling technologies. Traditional lithium extraction processes typically consume between 500,000 to 2 million gallons of water per ton of lithium produced, creating substantial water stress in arid regions where lithium deposits are commonly found, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia.

Benchmark studies of lithium nitrate process water recycling efficiency demonstrate potential water conservation rates of 80-95% when closed-loop systems are properly implemented. These systems significantly reduce freshwater withdrawal requirements and minimize discharge of process water containing elevated concentrations of lithium, boron, arsenic, and other potentially harmful elements into surrounding ecosystems.

Field measurements from pilot recycling operations indicate a reduction in land subsidence rates by up to 70% compared to conventional extraction methods. This is particularly crucial in salt flat ecosystems where excessive water extraction has historically led to destabilization of local hydrology and damage to fragile desert habitats.

Carbon footprint analyses reveal that water recycling technologies in lithium processing can reduce overall greenhouse gas emissions by 15-30% per ton of lithium produced. This reduction stems primarily from decreased energy requirements for pumping and treating new water supplies, as well as reduced transportation needs for water delivery in remote extraction locations.

Biodiversity impact studies conducted at sites utilizing advanced water recycling show measurably lower disruption to local flora and fauna. Monitoring of indicator species in adjacent wetland areas demonstrates 40-60% higher population stability compared to areas near conventional extraction operations without water recycling systems.

Economic valuation of ecosystem services preserved through water recycling in lithium operations estimates benefits of $2,000-4,500 per ton of lithium produced when accounting for watershed protection, habitat preservation, and sustainable water availability for local communities and agriculture. These figures become increasingly significant as water scarcity intensifies in lithium-rich regions due to climate change impacts.

Implementation of zero liquid discharge (ZLD) technologies in conjunction with lithium nitrate process water recycling has demonstrated the potential to virtually eliminate harmful discharge to surface waters, though challenges remain in managing concentrated waste streams and energy consumption requirements for these advanced treatment processes.

Benchmark studies of lithium nitrate process water recycling efficiency demonstrate potential water conservation rates of 80-95% when closed-loop systems are properly implemented. These systems significantly reduce freshwater withdrawal requirements and minimize discharge of process water containing elevated concentrations of lithium, boron, arsenic, and other potentially harmful elements into surrounding ecosystems.

Field measurements from pilot recycling operations indicate a reduction in land subsidence rates by up to 70% compared to conventional extraction methods. This is particularly crucial in salt flat ecosystems where excessive water extraction has historically led to destabilization of local hydrology and damage to fragile desert habitats.

Carbon footprint analyses reveal that water recycling technologies in lithium processing can reduce overall greenhouse gas emissions by 15-30% per ton of lithium produced. This reduction stems primarily from decreased energy requirements for pumping and treating new water supplies, as well as reduced transportation needs for water delivery in remote extraction locations.

Biodiversity impact studies conducted at sites utilizing advanced water recycling show measurably lower disruption to local flora and fauna. Monitoring of indicator species in adjacent wetland areas demonstrates 40-60% higher population stability compared to areas near conventional extraction operations without water recycling systems.

Economic valuation of ecosystem services preserved through water recycling in lithium operations estimates benefits of $2,000-4,500 per ton of lithium produced when accounting for watershed protection, habitat preservation, and sustainable water availability for local communities and agriculture. These figures become increasingly significant as water scarcity intensifies in lithium-rich regions due to climate change impacts.

Implementation of zero liquid discharge (ZLD) technologies in conjunction with lithium nitrate process water recycling has demonstrated the potential to virtually eliminate harmful discharge to surface waters, though challenges remain in managing concentrated waste streams and energy consumption requirements for these advanced treatment processes.

Regulatory Compliance for Lithium Processing Wastewater Management

Regulatory compliance for lithium processing wastewater management has become increasingly stringent worldwide as the lithium industry expands to meet growing demand for battery technologies. Current benchmarking data indicates that lithium nitrate process water recycling efficiency varies significantly across operations, with leading facilities achieving 75-85% water recovery rates while maintaining compliance with discharge regulations.

The United States Environmental Protection Agency (EPA) has established specific guidelines under the Clean Water Act that regulate the discharge of lithium processing wastewater, with particular focus on total dissolved solids (TDS), heavy metals, and pH levels. Similarly, the European Union's Water Framework Directive imposes strict limitations on industrial wastewater discharge, requiring extensive treatment before release into natural water bodies. In lithium-rich regions like Chile and Argentina, regulatory frameworks have evolved to address water scarcity concerns, mandating minimum recycling rates of 70% for lithium brine operations.

Compliance challenges are particularly acute for lithium nitrate processing facilities due to the complex chemical composition of wastewater streams. Regulatory thresholds for nitrate concentrations typically range from 10-50 mg/L depending on jurisdiction, while lithium discharge limits generally fall between 2.5-10 mg/L. Meeting these requirements while maximizing water recycling efficiency requires sophisticated treatment trains and continuous monitoring systems.

Recent regulatory trends indicate a move toward zero liquid discharge (ZLD) requirements in water-stressed regions, which will necessitate recycling efficiencies approaching 95%. Companies failing to meet compliance standards face substantial penalties, with fines ranging from $10,000 to $50,000 per day of violation in the United States and similar proportional penalties in other jurisdictions.

Best practice compliance strategies include implementing real-time monitoring systems for key parameters, maintaining detailed water quality documentation, and establishing regular third-party verification of recycling efficiency metrics. Leading operations have found that investing in advanced treatment technologies not only ensures regulatory compliance but also delivers operational cost benefits through reduced freshwater procurement and wastewater disposal expenses.

The regulatory landscape continues to evolve, with several jurisdictions currently developing specific lithium industry standards that will likely impose more stringent recycling requirements. Companies benchmarking their lithium nitrate process water recycling efficiency must therefore adopt forward-looking compliance strategies that anticipate regulatory changes rather than merely meeting current standards.

The United States Environmental Protection Agency (EPA) has established specific guidelines under the Clean Water Act that regulate the discharge of lithium processing wastewater, with particular focus on total dissolved solids (TDS), heavy metals, and pH levels. Similarly, the European Union's Water Framework Directive imposes strict limitations on industrial wastewater discharge, requiring extensive treatment before release into natural water bodies. In lithium-rich regions like Chile and Argentina, regulatory frameworks have evolved to address water scarcity concerns, mandating minimum recycling rates of 70% for lithium brine operations.

Compliance challenges are particularly acute for lithium nitrate processing facilities due to the complex chemical composition of wastewater streams. Regulatory thresholds for nitrate concentrations typically range from 10-50 mg/L depending on jurisdiction, while lithium discharge limits generally fall between 2.5-10 mg/L. Meeting these requirements while maximizing water recycling efficiency requires sophisticated treatment trains and continuous monitoring systems.

Recent regulatory trends indicate a move toward zero liquid discharge (ZLD) requirements in water-stressed regions, which will necessitate recycling efficiencies approaching 95%. Companies failing to meet compliance standards face substantial penalties, with fines ranging from $10,000 to $50,000 per day of violation in the United States and similar proportional penalties in other jurisdictions.

Best practice compliance strategies include implementing real-time monitoring systems for key parameters, maintaining detailed water quality documentation, and establishing regular third-party verification of recycling efficiency metrics. Leading operations have found that investing in advanced treatment technologies not only ensures regulatory compliance but also delivers operational cost benefits through reduced freshwater procurement and wastewater disposal expenses.

The regulatory landscape continues to evolve, with several jurisdictions currently developing specific lithium industry standards that will likely impose more stringent recycling requirements. Companies benchmarking their lithium nitrate process water recycling efficiency must therefore adopt forward-looking compliance strategies that anticipate regulatory changes rather than merely meeting current standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!