How to Improve Lithium Nitrate Flowability for Continuous Feed Systems

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Flowability Background and Objectives

Lithium nitrate (LiNO3) has emerged as a critical material in various industrial applications, particularly in energy storage systems, molten salt technologies, and advanced battery formulations. The historical development of lithium nitrate usage can be traced back to the mid-20th century, with significant acceleration in research and application occurring in the past two decades due to the global push for renewable energy solutions and energy storage technologies.

The flowability characteristics of lithium nitrate have become increasingly important as industrial processes shift toward continuous manufacturing systems. Traditional batch processing methods could accommodate materials with suboptimal flow properties, but modern continuous feed systems demand consistent, reliable material flow to maintain production efficiency and product quality. The evolution of lithium nitrate applications has highlighted significant challenges related to its inherent physical properties, including hygroscopicity, particle cohesion, and tendency to agglomerate under various environmental conditions.

Current technological trends indicate a growing demand for improved powder handling systems specifically designed for hygroscopic salts like lithium nitrate. The industry is moving toward more sophisticated process control mechanisms, advanced material characterization techniques, and innovative formulation approaches to address flowability challenges. This evolution is driven by the expanding role of lithium compounds in energy transition technologies and the economic imperative to optimize production processes.

The primary objective of this technical investigation is to comprehensively analyze the factors affecting lithium nitrate flowability in continuous feed systems and develop practical, scalable solutions to enhance its flow characteristics. Specific goals include identifying the critical physical and chemical parameters that influence flowability, evaluating existing modification techniques, and proposing novel approaches to improve flow consistency under varying environmental conditions.

Additionally, this research aims to establish standardized testing methodologies for assessing lithium nitrate flowability that correlate with actual performance in industrial continuous feed systems. This standardization would enable more accurate prediction of material behavior during scale-up and process transfer, reducing costly production disruptions and material waste.

The technological objectives extend to developing cost-effective, environmentally sustainable solutions that do not compromise the chemical integrity or performance characteristics of lithium nitrate in its end applications. This includes exploring surface modification techniques, particle engineering approaches, and formulation strategies that can be implemented within existing manufacturing frameworks without requiring extensive capital investment or process redesign.

The flowability characteristics of lithium nitrate have become increasingly important as industrial processes shift toward continuous manufacturing systems. Traditional batch processing methods could accommodate materials with suboptimal flow properties, but modern continuous feed systems demand consistent, reliable material flow to maintain production efficiency and product quality. The evolution of lithium nitrate applications has highlighted significant challenges related to its inherent physical properties, including hygroscopicity, particle cohesion, and tendency to agglomerate under various environmental conditions.

Current technological trends indicate a growing demand for improved powder handling systems specifically designed for hygroscopic salts like lithium nitrate. The industry is moving toward more sophisticated process control mechanisms, advanced material characterization techniques, and innovative formulation approaches to address flowability challenges. This evolution is driven by the expanding role of lithium compounds in energy transition technologies and the economic imperative to optimize production processes.

The primary objective of this technical investigation is to comprehensively analyze the factors affecting lithium nitrate flowability in continuous feed systems and develop practical, scalable solutions to enhance its flow characteristics. Specific goals include identifying the critical physical and chemical parameters that influence flowability, evaluating existing modification techniques, and proposing novel approaches to improve flow consistency under varying environmental conditions.

Additionally, this research aims to establish standardized testing methodologies for assessing lithium nitrate flowability that correlate with actual performance in industrial continuous feed systems. This standardization would enable more accurate prediction of material behavior during scale-up and process transfer, reducing costly production disruptions and material waste.

The technological objectives extend to developing cost-effective, environmentally sustainable solutions that do not compromise the chemical integrity or performance characteristics of lithium nitrate in its end applications. This includes exploring surface modification techniques, particle engineering approaches, and formulation strategies that can be implemented within existing manufacturing frameworks without requiring extensive capital investment or process redesign.

Market Demand Analysis for Continuous Feed Systems

The continuous feed systems market for lithium nitrate is experiencing robust growth, driven primarily by the expanding energy storage sector. As renewable energy integration accelerates globally, the demand for efficient thermal energy storage materials has surged, with lithium nitrate being a critical component in molten salt systems for concentrated solar power (CSP) plants. Market research indicates that the global thermal energy storage market is projected to grow at a compound annual growth rate of 12.8% through 2028, with molten salt technologies representing a significant portion of this expansion.

Industrial applications beyond energy storage are also fueling demand for improved lithium nitrate handling systems. Chemical processing industries require precise, uninterrupted material flow for reaction efficiency and product quality consistency. The pharmaceutical sector similarly demands reliable continuous feed systems for lithium compounds used in various medication formulations, particularly those treating mental health conditions.

Battery manufacturing represents another substantial market driver, as lithium nitrate serves as an electrolyte additive that enhances the performance and safety of lithium-ion batteries. With electric vehicle production scaling rapidly worldwide, the need for efficient continuous processing of battery materials has become increasingly critical to manufacturing economics.

The market demand is further characterized by industry-wide pressure to reduce operational costs and improve production efficiency. End users consistently report that material handling issues with lithium nitrate, particularly its tendency to agglomerate and create flow blockages, result in significant maintenance costs and production downtime. Survey data from manufacturing facilities indicates that flow-related disruptions can reduce overall equipment effectiveness by up to 15% in continuous processing operations.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization and renewable energy deployment are creating substantial opportunities for advanced material handling technologies. North American and European markets show steady growth driven primarily by sustainability initiatives and the transition toward green energy infrastructure.

Customer requirements increasingly emphasize systems that can handle variable environmental conditions, as lithium nitrate's hygroscopic nature makes its flowability particularly susceptible to humidity fluctuations. This has created market opportunities for innovative solutions that can maintain consistent material flow regardless of ambient conditions, with potential premium pricing for systems demonstrating superior reliability.

The competitive landscape shows fragmentation, with specialized equipment manufacturers developing proprietary solutions for specific industrial applications. This indicates significant market potential for standardized, versatile continuous feed technologies that can effectively address lithium nitrate's unique handling challenges across multiple industries and processing environments.

Industrial applications beyond energy storage are also fueling demand for improved lithium nitrate handling systems. Chemical processing industries require precise, uninterrupted material flow for reaction efficiency and product quality consistency. The pharmaceutical sector similarly demands reliable continuous feed systems for lithium compounds used in various medication formulations, particularly those treating mental health conditions.

Battery manufacturing represents another substantial market driver, as lithium nitrate serves as an electrolyte additive that enhances the performance and safety of lithium-ion batteries. With electric vehicle production scaling rapidly worldwide, the need for efficient continuous processing of battery materials has become increasingly critical to manufacturing economics.

The market demand is further characterized by industry-wide pressure to reduce operational costs and improve production efficiency. End users consistently report that material handling issues with lithium nitrate, particularly its tendency to agglomerate and create flow blockages, result in significant maintenance costs and production downtime. Survey data from manufacturing facilities indicates that flow-related disruptions can reduce overall equipment effectiveness by up to 15% in continuous processing operations.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization and renewable energy deployment are creating substantial opportunities for advanced material handling technologies. North American and European markets show steady growth driven primarily by sustainability initiatives and the transition toward green energy infrastructure.

Customer requirements increasingly emphasize systems that can handle variable environmental conditions, as lithium nitrate's hygroscopic nature makes its flowability particularly susceptible to humidity fluctuations. This has created market opportunities for innovative solutions that can maintain consistent material flow regardless of ambient conditions, with potential premium pricing for systems demonstrating superior reliability.

The competitive landscape shows fragmentation, with specialized equipment manufacturers developing proprietary solutions for specific industrial applications. This indicates significant market potential for standardized, versatile continuous feed technologies that can effectively address lithium nitrate's unique handling challenges across multiple industries and processing environments.

Current Flowability Challenges and Technical Limitations

Lithium nitrate (LiNO3) presents significant flowability challenges in continuous feed systems, primarily due to its inherent physicochemical properties. The material exhibits strong hygroscopic tendencies, readily absorbing moisture from the ambient environment, which leads to particle agglomeration and subsequent flow impediments. This moisture absorption occurs even at relatively low humidity levels (approximately 30-40% RH), making it particularly problematic in industrial settings where environmental conditions cannot always be tightly controlled.

The particle morphology of lithium nitrate compounds further exacerbates flowability issues. Commercial-grade lithium nitrate typically features irregular particle shapes with rough surfaces that increase inter-particle friction and mechanical interlocking. These characteristics result in poor flow behavior characterized by bridging in hoppers, ratholing, and inconsistent discharge rates that severely impact the reliability of continuous feed systems.

Cohesive forces between lithium nitrate particles represent another significant technical limitation. The material demonstrates relatively high cohesive strength compared to other industrial salts, with cohesion values typically ranging from 2-4 kPa under standard conditions. This cohesiveness creates substantial resistance to flow initiation and maintenance, particularly problematic at transfer points within processing equipment.

Electrostatic charging during handling operations compounds these challenges. As lithium nitrate particles move through processing equipment, they generate static charges that promote particle adhesion to equipment surfaces and to each other. Measured charge densities can reach 10^-7 to 10^-5 C/m², sufficient to cause significant flow disruptions in industrial-scale operations.

Temperature and humidity fluctuations dramatically affect lithium nitrate's flow properties, creating inconsistent behavior that complicates process control. Studies indicate that relative humidity increases above 45% can reduce flow indices by up to 60%, while temperature variations between 20-40°C can alter flow rates by 15-25% for the same material batch.

Current processing equipment designs often fail to address these specific challenges. Standard hopper angles (typically 55-60°) prove insufficient for reliable lithium nitrate flow, while conventional wall materials with inappropriate surface energies promote adhesion rather than facilitating movement. Industry testing reveals that traditional mass-flow hopper designs achieve only 70-80% efficiency with lithium nitrate compared to their performance with free-flowing materials.

Scale-up from laboratory to industrial production introduces additional complications, as flow behaviors observed in small-scale testing frequently fail to predict performance in full-scale continuous operations. This scaling discrepancy creates significant engineering challenges when designing robust production systems for lithium nitrate processing.

The particle morphology of lithium nitrate compounds further exacerbates flowability issues. Commercial-grade lithium nitrate typically features irregular particle shapes with rough surfaces that increase inter-particle friction and mechanical interlocking. These characteristics result in poor flow behavior characterized by bridging in hoppers, ratholing, and inconsistent discharge rates that severely impact the reliability of continuous feed systems.

Cohesive forces between lithium nitrate particles represent another significant technical limitation. The material demonstrates relatively high cohesive strength compared to other industrial salts, with cohesion values typically ranging from 2-4 kPa under standard conditions. This cohesiveness creates substantial resistance to flow initiation and maintenance, particularly problematic at transfer points within processing equipment.

Electrostatic charging during handling operations compounds these challenges. As lithium nitrate particles move through processing equipment, they generate static charges that promote particle adhesion to equipment surfaces and to each other. Measured charge densities can reach 10^-7 to 10^-5 C/m², sufficient to cause significant flow disruptions in industrial-scale operations.

Temperature and humidity fluctuations dramatically affect lithium nitrate's flow properties, creating inconsistent behavior that complicates process control. Studies indicate that relative humidity increases above 45% can reduce flow indices by up to 60%, while temperature variations between 20-40°C can alter flow rates by 15-25% for the same material batch.

Current processing equipment designs often fail to address these specific challenges. Standard hopper angles (typically 55-60°) prove insufficient for reliable lithium nitrate flow, while conventional wall materials with inappropriate surface energies promote adhesion rather than facilitating movement. Industry testing reveals that traditional mass-flow hopper designs achieve only 70-80% efficiency with lithium nitrate compared to their performance with free-flowing materials.

Scale-up from laboratory to industrial production introduces additional complications, as flow behaviors observed in small-scale testing frequently fail to predict performance in full-scale continuous operations. This scaling discrepancy creates significant engineering challenges when designing robust production systems for lithium nitrate processing.

Current Technical Solutions for Improving Powder Flowability

01 Additives to improve lithium nitrate flowability

Various additives can be incorporated with lithium nitrate to enhance its flowability characteristics. These additives include flow agents, anti-caking compounds, and surface modifiers that prevent agglomeration and improve powder flow properties. The additives work by reducing inter-particle friction, decreasing moisture absorption, and creating a more uniform particle distribution, resulting in improved handling and processing of lithium nitrate in industrial applications.- Additives to improve lithium nitrate flowability: Various additives can be incorporated with lithium nitrate to enhance its flowability characteristics. These additives can include flow agents, anti-caking compounds, and surface modifiers that reduce particle agglomeration and improve powder flow properties. The additives work by reducing inter-particle friction, preventing moisture absorption, and creating a more uniform particle distribution, which collectively improves the handling and processing of lithium nitrate in industrial applications.

- Particle size control for enhanced flowability: Controlling the particle size distribution of lithium nitrate is crucial for optimizing its flowability. Techniques such as milling, grinding, and classification can be employed to achieve specific particle size ranges that exhibit improved flow characteristics. Smaller, uniform particles with appropriate morphology tend to flow more consistently, while preventing the formation of large agglomerates that can impede flow. Proper particle size control also helps in reducing dusting and improving the bulk density of lithium nitrate powders.

- Moisture control techniques for lithium nitrate: Lithium nitrate is hygroscopic and can absorb moisture from the environment, which significantly impacts its flowability. Various moisture control techniques can be implemented, including proper packaging, storage in controlled humidity environments, and the addition of desiccants or moisture scavengers. Some formulations incorporate hydrophobic coatings or encapsulation methods to create a barrier against moisture absorption, thereby maintaining the free-flowing properties of lithium nitrate during storage and handling.

- Surface modification of lithium nitrate particles: Surface modification techniques can significantly improve the flowability of lithium nitrate. These include coating the particles with hydrophobic materials, silica-based compounds, or polymeric substances that reduce surface energy and inter-particle adhesion. Surface-modified lithium nitrate exhibits reduced tendency to agglomerate, better resistance to environmental conditions, and improved flow characteristics. These modifications are particularly important in applications requiring consistent dosing or continuous processing of lithium nitrate.

- Granulation and agglomeration control: Controlled granulation or agglomeration processes can be used to transform fine lithium nitrate powder into larger, more flowable granules with specific characteristics. These processes involve binding smaller particles together in a controlled manner to create granules with optimized size, shape, and density. The resulting granulated lithium nitrate typically exhibits better flow properties, reduced dusting, and improved handling characteristics compared to the original powder form. Various binding agents and granulation techniques can be employed depending on the specific application requirements.

02 Particle size control for enhanced flowability

Controlling the particle size distribution of lithium nitrate is crucial for optimizing its flowability. Techniques such as milling, grinding, and classification can be employed to achieve specific particle size ranges that exhibit better flow characteristics. Smaller, uniform particles with appropriate morphology tend to flow more freely, while preventing the formation of large agglomerates that can impede flow. Proper particle size control also helps maintain consistent bulk density and reduces bridging in storage containers.Expand Specific Solutions03 Moisture control methods for lithium nitrate

Lithium nitrate's flowability is significantly affected by moisture content due to its hygroscopic nature. Various methods can be employed to control moisture, including proper drying processes, storage in controlled humidity environments, and application of hydrophobic coatings. Maintaining low moisture levels prevents caking and agglomeration, which are major causes of poor flowability. Techniques such as vacuum drying, heated storage, and moisture-resistant packaging help preserve the free-flowing properties of lithium nitrate during storage and handling.Expand Specific Solutions04 Surface modification techniques for lithium nitrate

Surface modification of lithium nitrate particles can significantly improve flowability characteristics. Techniques include coating with hydrophobic materials, surface functionalization, and encapsulation methods that reduce surface energy and inter-particle attraction. These modifications create a physical barrier between particles, preventing them from sticking together and forming agglomerates. Surface-modified lithium nitrate demonstrates improved flow properties, reduced caking tendency, and enhanced stability under various environmental conditions.Expand Specific Solutions05 Lithium nitrate formulations for battery applications

Specialized lithium nitrate formulations have been developed specifically for battery applications where flowability is critical for manufacturing processes. These formulations often include specific binders, dispersants, and processing aids that maintain good flow properties while ensuring compatibility with battery components. The flowability of these formulations affects electrode coating uniformity, electrolyte distribution, and ultimately battery performance. Optimized formulations balance flowability requirements with electrochemical performance to achieve high-quality battery production.Expand Specific Solutions

Key Industry Players in Lithium Nitrate Processing

The lithium nitrate flowability improvement market is in a growth phase, with increasing demand driven by the expanding lithium-ion battery sector. Market size is projected to grow significantly as continuous feed systems become more critical in battery manufacturing processes. Technologically, the field is moderately mature but evolving, with key players demonstrating varying levels of expertise. Major battery manufacturers like LG Energy Solution, Panasonic, and BYD are investing heavily in flow optimization technologies. Materials specialists including Sunresin New Materials and Tianqi Lithium are developing innovative solutions for powder handling challenges. Research institutions such as Forschungszentrum Jülich and National Institute for Materials Science are advancing fundamental understanding of flowability mechanisms, while equipment manufacturers like Primix Corp. focus on specialized mixing and feeding equipment to address these challenges.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive approach to improve lithium nitrate flowability for continuous feed systems through their patented particle engineering technology. Their solution involves controlled particle size distribution optimization where lithium nitrate particles are processed to maintain uniform sizes between 100-300 microns, significantly reducing agglomeration tendencies. The company employs surface modification techniques using proprietary silica-based coating agents that create hydrophobic barriers around individual particles, preventing moisture absorption which typically causes caking. Additionally, LG Chem has implemented vibratory feeding systems with specialized anti-bridging mechanisms that maintain consistent material flow rates even under varying humidity conditions. Their process includes real-time monitoring systems that adjust feeder parameters based on detected flow irregularities, ensuring continuous operation in battery production lines.

Strengths: Superior moisture resistance through advanced coating technology; integrated monitoring systems enable adaptive control; proven implementation in high-volume manufacturing environments. Weaknesses: Higher implementation cost compared to basic solutions; requires specialized maintenance protocols; coating agents may introduce trace impurities requiring additional quality control measures.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative approach to lithium nitrate flowability enhancement focused on electrolyte additive applications. Their technology centers on a dual-processing methodology that first subjects lithium nitrate to controlled micronization (reducing particles to 10-50μm range) followed by a proprietary dry coating process using nano-silica and flow-enhancing polymers. This creates composite particles with core-shell structures that maintain free-flowing properties even under pressure and varying humidity conditions. The company has engineered specialized rotary valve feeders with ultrasonic assistance that prevent material bridging and rat-holing during continuous operations. Their system incorporates heated feed lines maintained at precisely controlled temperatures (40-60°C) to prevent any moisture absorption during processing, while nitrogen-purged storage and transfer systems eliminate environmental humidity exposure throughout the production chain.

Strengths: Exceptional flow consistency even at high throughput rates; minimal downtime for cleaning or maintenance; compatible with existing battery manufacturing equipment. Weaknesses: Energy consumption for temperature-controlled systems adds operational costs; requires specialized training for operators; initial capital investment higher than conventional systems.

Critical Patents and Research on Flow Aid Technologies

Method of inhibiting water adsorption of powder by addition of hydrophobic nanaoparticles

PatentActiveUS20120233929A1

Innovation

- Combining larger particles with hydrophobic nanoparticles, such as metal oxide nanoparticles with surface treatments, to reduce water vapor adsorption, thereby improving handling and flow characteristics.

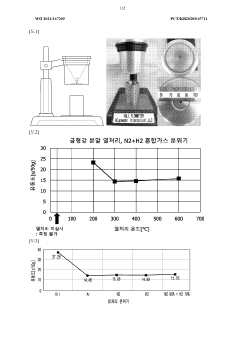

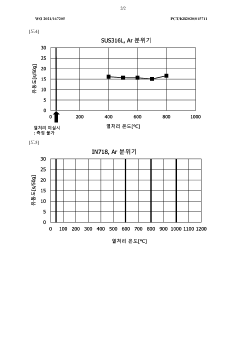

Method for improving flowability of powder, and method for producing powder having improved flowability

PatentWO2021167205A1

Innovation

- Improving the fluidity of metal or alloy powders produced by gas atomization through heat treatment of powders made from metals with a diffusion coefficient greater than nickel, such as copper, magnesium, aluminum, titanium, and iron, within a temperature range of 20% to 70% of the melting point, under controlled atmospheres like argon, nitrogen, or hydrogen.

Environmental and Safety Considerations

The handling of lithium nitrate in continuous feed systems presents significant environmental and safety challenges that must be carefully addressed. Lithium nitrate, while valuable for energy storage applications, poses potential risks to both human health and the environment if not properly managed. When improving flowability, it is essential to consider that many flow aids and processing methods may introduce additional environmental or safety concerns.

Dust generation during lithium nitrate handling represents a primary safety hazard. Fine lithium nitrate particles can become airborne, creating respiratory risks for workers and potential explosion hazards in confined spaces. Engineering controls such as proper ventilation systems, dust collection equipment, and enclosed transfer systems are critical for minimizing these risks. Personal protective equipment including respiratory protection, chemical-resistant gloves, and safety goggles should be mandatory for personnel working with this material.

Water reactivity presents another significant consideration. While lithium nitrate is less reactive than other lithium compounds, it remains hygroscopic and can absorb moisture from the air, potentially leading to caking issues and chemical reactions. This property necessitates careful environmental control in processing areas, including humidity monitoring and management. Storage and handling facilities must be designed to prevent water ingress and maintain appropriate atmospheric conditions.

From an environmental perspective, lithium nitrate can act as a soil and water contaminant if released. Its high solubility means it can readily migrate through soil into groundwater systems. Containment measures, including proper flooring designs with spill containment features and regular inspection protocols, are essential for preventing environmental contamination. Waste management procedures must address the proper disposal of lithium nitrate-containing materials in compliance with hazardous waste regulations.

The energy requirements for improving flowability must also be evaluated from an environmental standpoint. Heating systems used to reduce moisture content or mechanical systems for breaking agglomerates consume energy and contribute to the overall carbon footprint of the process. Optimization of these systems to minimize energy consumption while maintaining effective flowability represents an important environmental consideration.

Regulatory compliance forms another critical aspect of environmental and safety management. Operations involving lithium nitrate must adhere to various regulations including those governing air quality, water discharge, waste management, and worker safety. Documentation systems for tracking material handling, exposure monitoring, and incident reporting are necessary components of a comprehensive safety management program. Regular audits and continuous improvement processes help ensure ongoing compliance and safety performance.

Dust generation during lithium nitrate handling represents a primary safety hazard. Fine lithium nitrate particles can become airborne, creating respiratory risks for workers and potential explosion hazards in confined spaces. Engineering controls such as proper ventilation systems, dust collection equipment, and enclosed transfer systems are critical for minimizing these risks. Personal protective equipment including respiratory protection, chemical-resistant gloves, and safety goggles should be mandatory for personnel working with this material.

Water reactivity presents another significant consideration. While lithium nitrate is less reactive than other lithium compounds, it remains hygroscopic and can absorb moisture from the air, potentially leading to caking issues and chemical reactions. This property necessitates careful environmental control in processing areas, including humidity monitoring and management. Storage and handling facilities must be designed to prevent water ingress and maintain appropriate atmospheric conditions.

From an environmental perspective, lithium nitrate can act as a soil and water contaminant if released. Its high solubility means it can readily migrate through soil into groundwater systems. Containment measures, including proper flooring designs with spill containment features and regular inspection protocols, are essential for preventing environmental contamination. Waste management procedures must address the proper disposal of lithium nitrate-containing materials in compliance with hazardous waste regulations.

The energy requirements for improving flowability must also be evaluated from an environmental standpoint. Heating systems used to reduce moisture content or mechanical systems for breaking agglomerates consume energy and contribute to the overall carbon footprint of the process. Optimization of these systems to minimize energy consumption while maintaining effective flowability represents an important environmental consideration.

Regulatory compliance forms another critical aspect of environmental and safety management. Operations involving lithium nitrate must adhere to various regulations including those governing air quality, water discharge, waste management, and worker safety. Documentation systems for tracking material handling, exposure monitoring, and incident reporting are necessary components of a comprehensive safety management program. Regular audits and continuous improvement processes help ensure ongoing compliance and safety performance.

Scale-up Strategies and Process Integration

Scaling up lithium nitrate processing from laboratory to industrial scale requires careful consideration of both technical and operational factors. The transition demands systematic approaches that maintain or enhance flowability characteristics while adapting to larger production volumes. A phased scale-up strategy is recommended, beginning with pilot-scale testing that bridges laboratory findings with industrial implementation. This intermediate step allows for identification of potential issues related to material handling, equipment selection, and process parameters before full-scale deployment.

Equipment selection becomes increasingly critical during scale-up, with specialized continuous feeders designed specifically for cohesive powders offering significant advantages. Vibrating feeders with optimized trough designs, loss-in-weight feeders with specialized agitation mechanisms, and screw feeders with modified flight geometries have demonstrated success in handling lithium nitrate at larger scales. The integration of real-time monitoring systems becomes essential to maintain process control as volumes increase.

Process integration considerations must address the interface between lithium nitrate handling systems and downstream operations. Establishing buffer zones or intermediate storage solutions with controlled environmental conditions helps maintain flowability properties between process stages. Implementing feedback control loops that connect downstream operations with the feeding system enables dynamic adjustments to feed rates based on process demands, ensuring consistent material delivery despite variations in material properties.

Heat management strategies become more complex at industrial scale, requiring careful thermal mapping of the entire process line to identify potential condensation points or temperature gradients that could affect flowability. Implementing localized heating or cooling zones at critical transition points helps maintain optimal temperature conditions throughout the process chain, preventing moisture absorption that could compromise flowability.

Automation and digital integration represent key enablers for successful scale-up. Implementing Industry 4.0 principles through integrated sensor networks, predictive maintenance systems, and machine learning algorithms for process optimization creates a responsive manufacturing environment. These technologies enable real-time adjustments to process parameters based on material property variations, environmental changes, and production demands, maintaining optimal flowability across varying production conditions.

Validation protocols must evolve with scale-up, incorporating continuous verification methods rather than batch-based testing. Implementing Process Analytical Technology (PAT) tools at strategic points throughout the production line enables real-time quality assurance while minimizing process interruptions. This approach supports regulatory compliance while maintaining production efficiency in continuous processing environments.

Equipment selection becomes increasingly critical during scale-up, with specialized continuous feeders designed specifically for cohesive powders offering significant advantages. Vibrating feeders with optimized trough designs, loss-in-weight feeders with specialized agitation mechanisms, and screw feeders with modified flight geometries have demonstrated success in handling lithium nitrate at larger scales. The integration of real-time monitoring systems becomes essential to maintain process control as volumes increase.

Process integration considerations must address the interface between lithium nitrate handling systems and downstream operations. Establishing buffer zones or intermediate storage solutions with controlled environmental conditions helps maintain flowability properties between process stages. Implementing feedback control loops that connect downstream operations with the feeding system enables dynamic adjustments to feed rates based on process demands, ensuring consistent material delivery despite variations in material properties.

Heat management strategies become more complex at industrial scale, requiring careful thermal mapping of the entire process line to identify potential condensation points or temperature gradients that could affect flowability. Implementing localized heating or cooling zones at critical transition points helps maintain optimal temperature conditions throughout the process chain, preventing moisture absorption that could compromise flowability.

Automation and digital integration represent key enablers for successful scale-up. Implementing Industry 4.0 principles through integrated sensor networks, predictive maintenance systems, and machine learning algorithms for process optimization creates a responsive manufacturing environment. These technologies enable real-time adjustments to process parameters based on material property variations, environmental changes, and production demands, maintaining optimal flowability across varying production conditions.

Validation protocols must evolve with scale-up, incorporating continuous verification methods rather than batch-based testing. Implementing Process Analytical Technology (PAT) tools at strategic points throughout the production line enables real-time quality assurance while minimizing process interruptions. This approach supports regulatory compliance while maintaining production efficiency in continuous processing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!